Cutting off machine

A cutting machine and frame technology, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of easy flying of cutting blade fragments, low service life of the cutting blade, and uneven cutting surface, etc. To achieve the effect of good appearance, high consistency and smooth incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

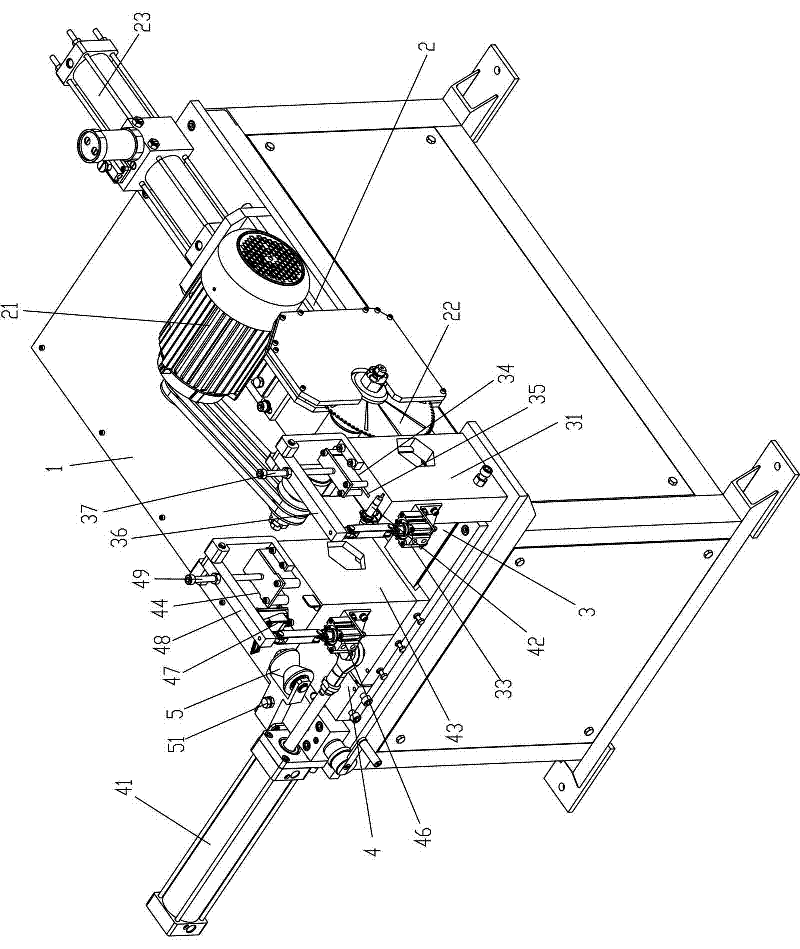

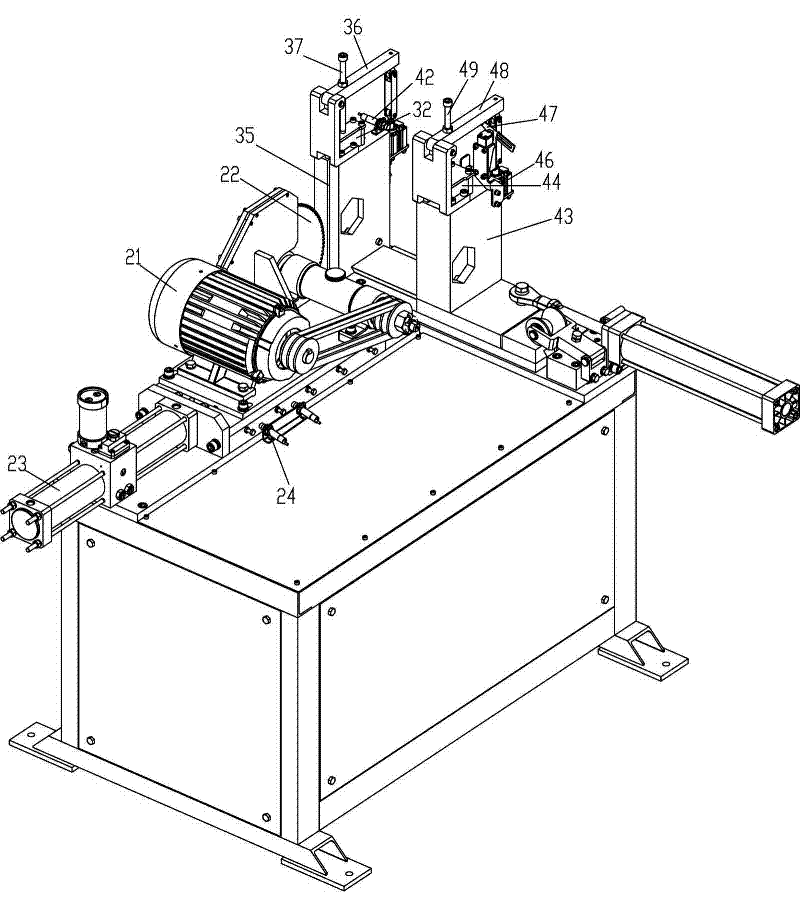

[0021] refer to Figure 1 to Figure 4 As shown, a cutting machine includes a frame 1. The frame 1 is provided with a feeding and clamping mechanism and a cutting power assembly 2. The feeding and clamping mechanism includes a clamping device 3 and a feeding device 4 propelled along a track. The feeding device 4 Clamp the blank and send it to the clamping device 3 in translation; the cutting power assembly 2 includes a motor 21 and a cutting piece 22 driven by the motor 21 to rotate at a high speed; in the horizontal direction, the feeding and clamping mechanism and the cutting power assembly 2 The relative movement between them is constrained by the track, and the cutting piece 22 of the cutting power assembly 2 translates along the track direction and cuts into the blank clamped on the clamping device 3 .

[0022] When cutting, the blank is translated along the track and pushed into the clamping device under the clamping of the feeding device. After being clamped by the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com