Improved filament welding machine

A welding machine and filament technology, applied in the field of machinery, can solve problems such as low work efficiency, high labor costs, and low degree of automation, and achieve the effect of not being easy to misuse, not easy to loosen, and firmly clamped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

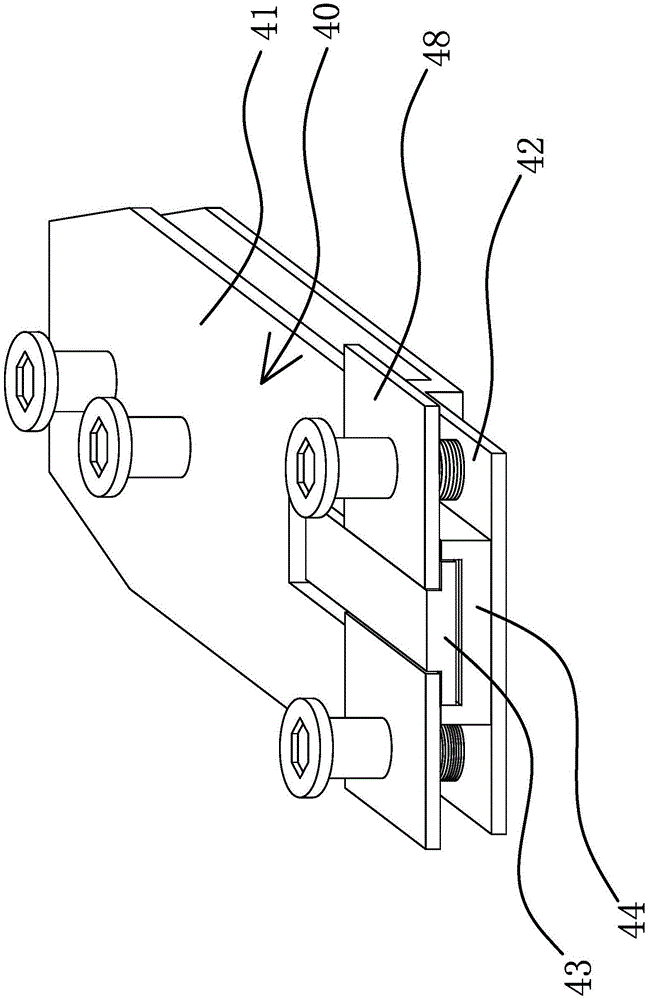

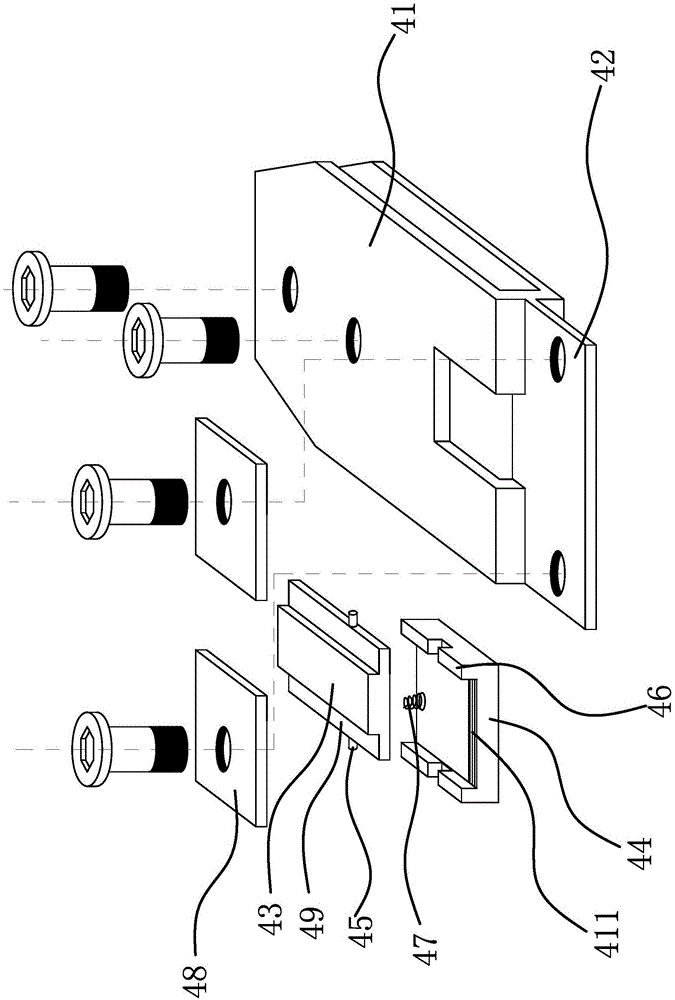

[0039] Such as figure 1 and Figure 4 As shown, the improved filament welding machine includes a base 1, a turntable 2 is arranged on the base 1, a stepping motor 3 is arranged between the turntable 2 and the base 1 to drive the turntable 2 to rotate, and the periphery of the turntable 2 is uniformly distributed with Several clamping structures, the base 1 is provided with a molybdenum belt feeding device, a first soldering device, a tantalum tape welding device, a second soldering device, a tungsten wire welding device and a filament blanking device, and a molybdenum belt feeding device, a second A soldering device, a tantalum strip soldering device, a second soldering device, a tungsten wire soldering device and a filament feeding device are distributed on the periphery of the turntable 2 in sequence. The molybdenum strip is tightly pressed in the clamping structure, and the preparation of the filament is completed through the processes of fluxing, tantalum strip welding, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com