A fixation method for underground gas storage well bore

A fixing method and technology for gas storage wells, which are applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve the problems of difficult construction, inability to fix, and accidents in the wellbore, and improve safety. performance and mission, the fixing process is simple, and the effect of coagulation is firm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

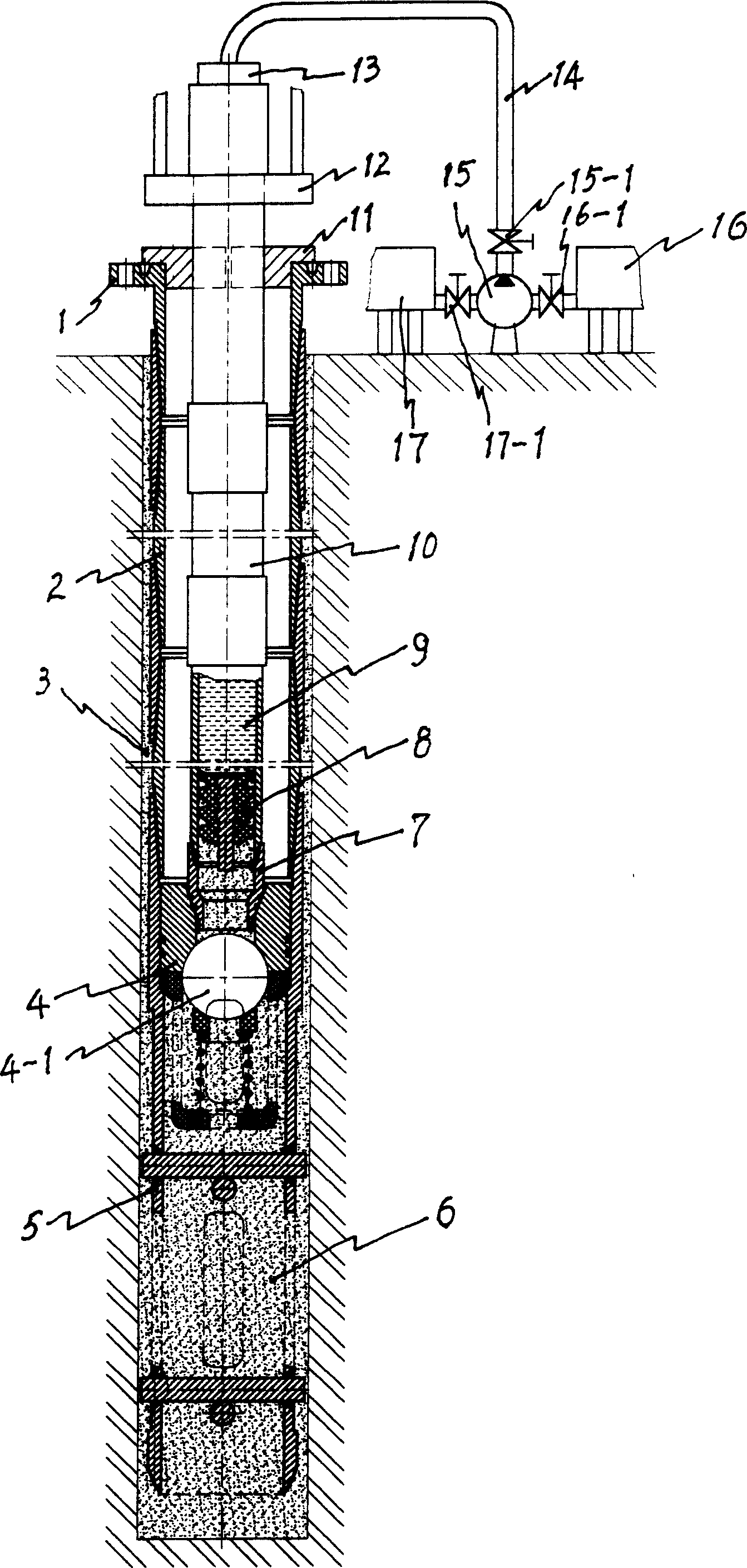

[0012] Take the fixing of a wellbore with an effective gas storage length of 125m when the outer diameter of the wellbore is 7 as an example:

[0013] A. Down the wellbore: first use the 7-hour conduit back pressure valve for drilling in oil and gas fields as a one-way valve 4, fasten it with the bottom of the wellbore 2 through the pipe taper thread, and weld the fixing frame 5 at the lower end of the valve body; then install the wellbore 2 It is placed in the foundation well 3 with a diameter of φ215.9mm (8 h) and a depth of 128m drilled according to the petroleum and geological drilling procedures and requirements, and a flange 1 is installed on the upper mouth of the wellbore; the fixed frame 5 adopts a 1.5m long At 7 o'clock, four holes of 1000×50mm are symmetrically opened and cross-welded to the bottom of the valve through two φ30mm steel bars;

[0014] B. Install the grouting device: the intubation pipe 10 adopts a 3-hour drill pipe. First, the 3-hour connecting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com