Extrusion cutting type multi-particle size adjustable granulating machine

A granulator and multi-particle size technology, applied in the direction of raw material extrusion granulation, press, material forming press, etc., can solve the high requirements for lubrication and cooling of parts, high cooling requirements of lubricating oil, and cannot be adjusted and other problems to achieve the effect of speeding up the dissolution rate, increasing the surface area, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

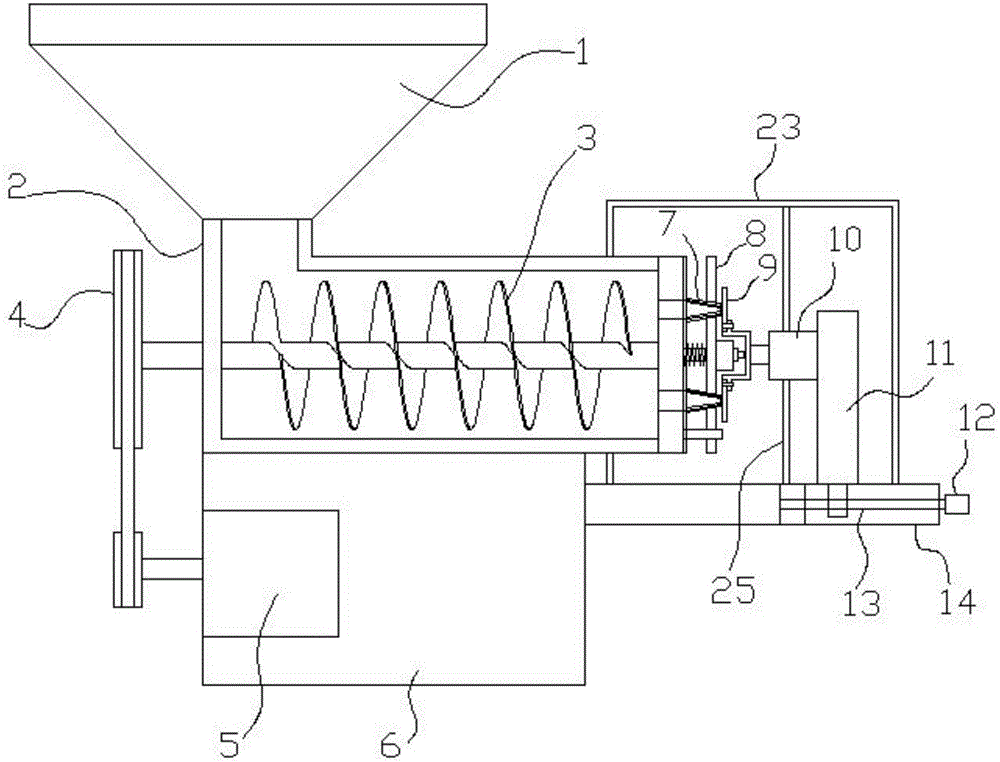

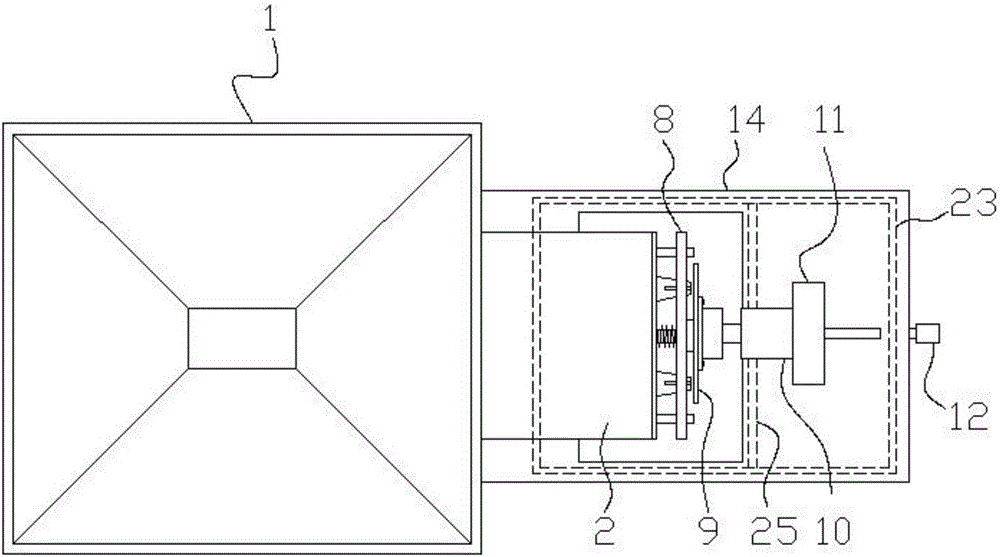

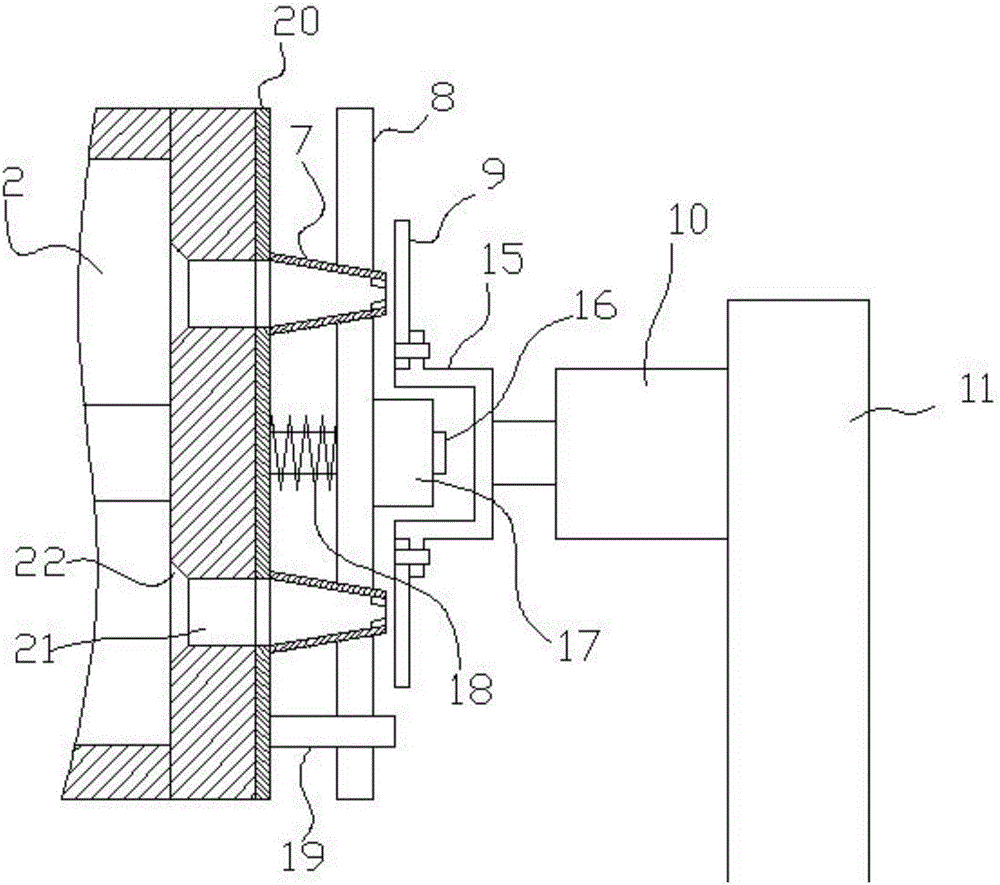

[0033] like Figure 1-Figure 10 As shown, the specific structure of the present invention is: an extruding and cutting type multi-particle diameter adjustable granulator, which includes a base 6, and the base 6 is provided with a mixing drum 2, and a screw propeller 3 is provided therein; The upper end of the mixing drum 2 is provided with a feed hopper 1; the screw propeller 3 is connected to the propulsion motor 5; the front end of the mixing drum 2 is provided with a granulation disc 20; The granulation sleeve 7; the conical granulation sleeve 7 is sleeved on the adjustment disc 8; the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com