Auxiliary fixture for precision grinding machine

A precision grinding machine and jig technology, applied in the field of metal surface treatment, can solve problems affecting processing capacity and economic benefits, insufficient clamping reliability and consistency, easy to damage the surface of the workpiece, etc., to improve process flexibility and good cooperation , improving reliability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art, and the drawings in the following description are only the application For some embodiments described in , those skilled in the art can also obtain other drawings based on these drawings without creative work.

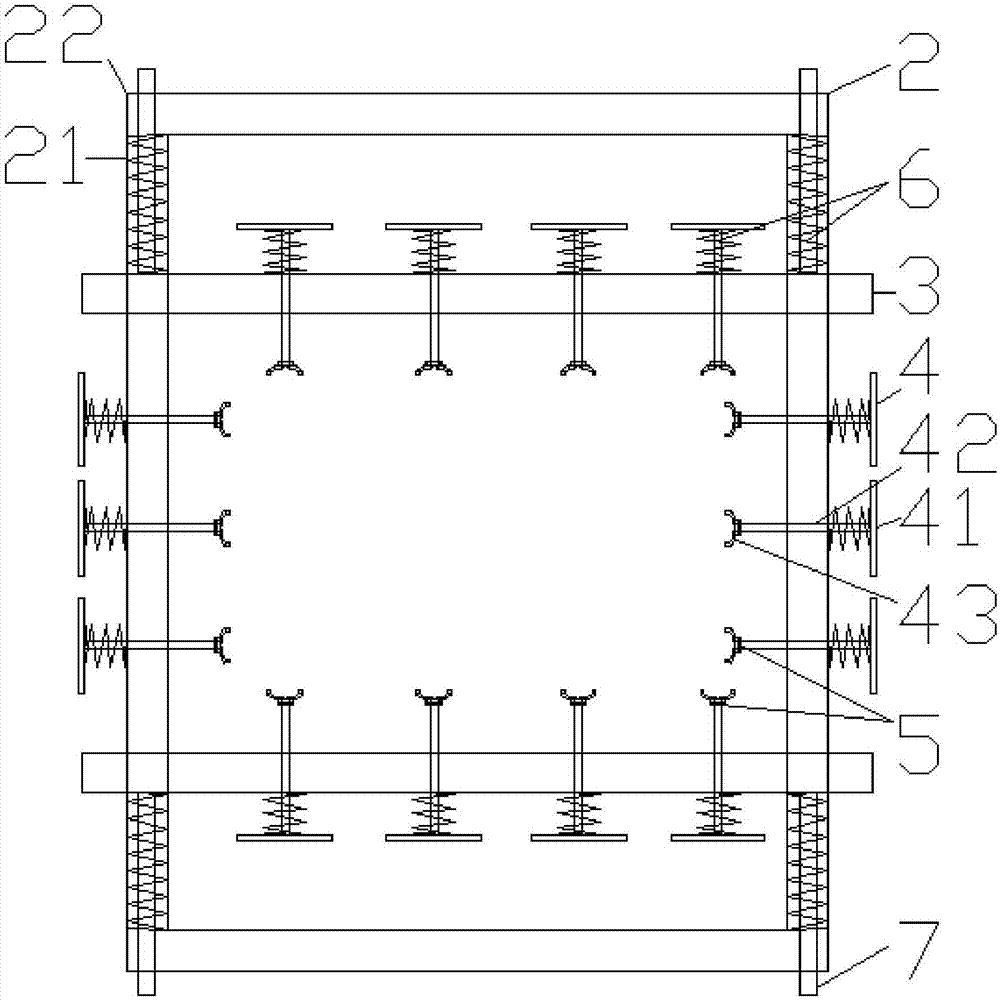

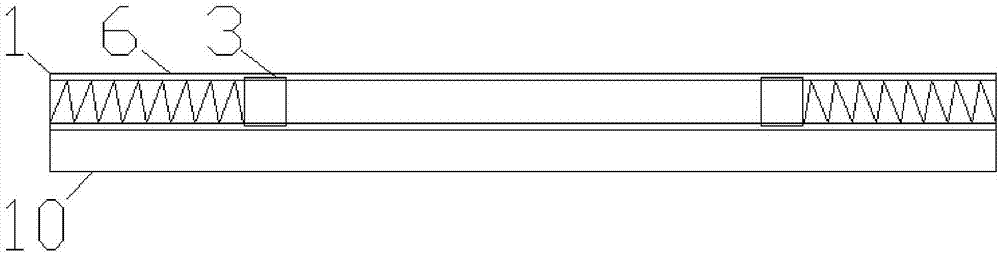

[0018] Such as Figure 1~2 , an auxiliary fixture for a precision grinding machine, comprising an operating panel 1 and a base plate 10 located below the operating panel 1, the operating panel 1 includes an outer frame 2 and a movable panel 3, and the outer frame 2 is a square with a hollow interior Frame shape, with two opposite side edges 21 and two opposite end edges 22, the material of the outer frame 2 is cast iron or carbon steel, the outer frame 2 is closely matched with the bottom plate 10, and the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com