Nozzle regulating mechanism and its regulating method, and device for using the said nozzle regulating mechanism

A technology for adjusting the mechanism and nozzles, which can be applied to inking devices, printing, etc., to solve problems such as nozzle rotation, and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

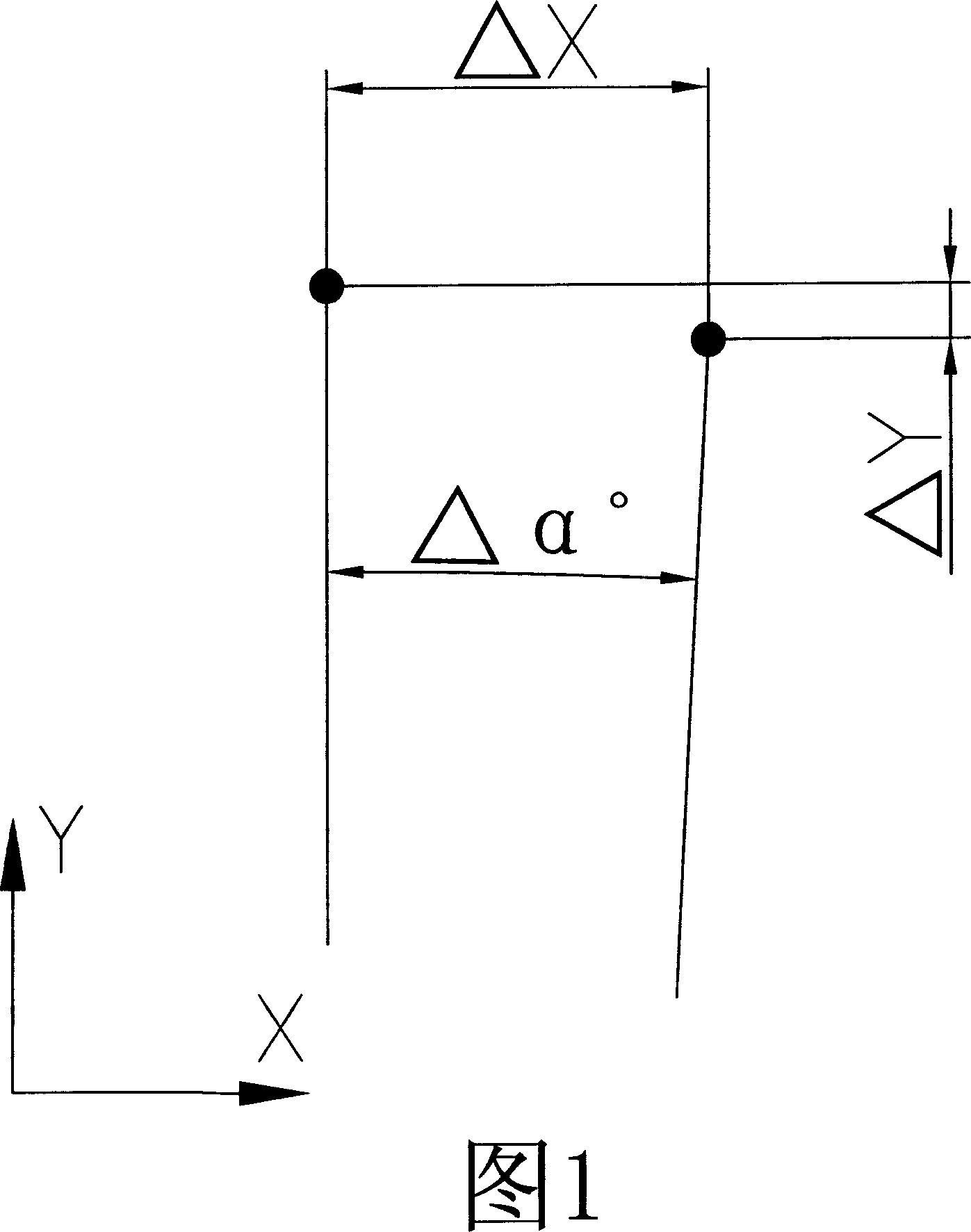

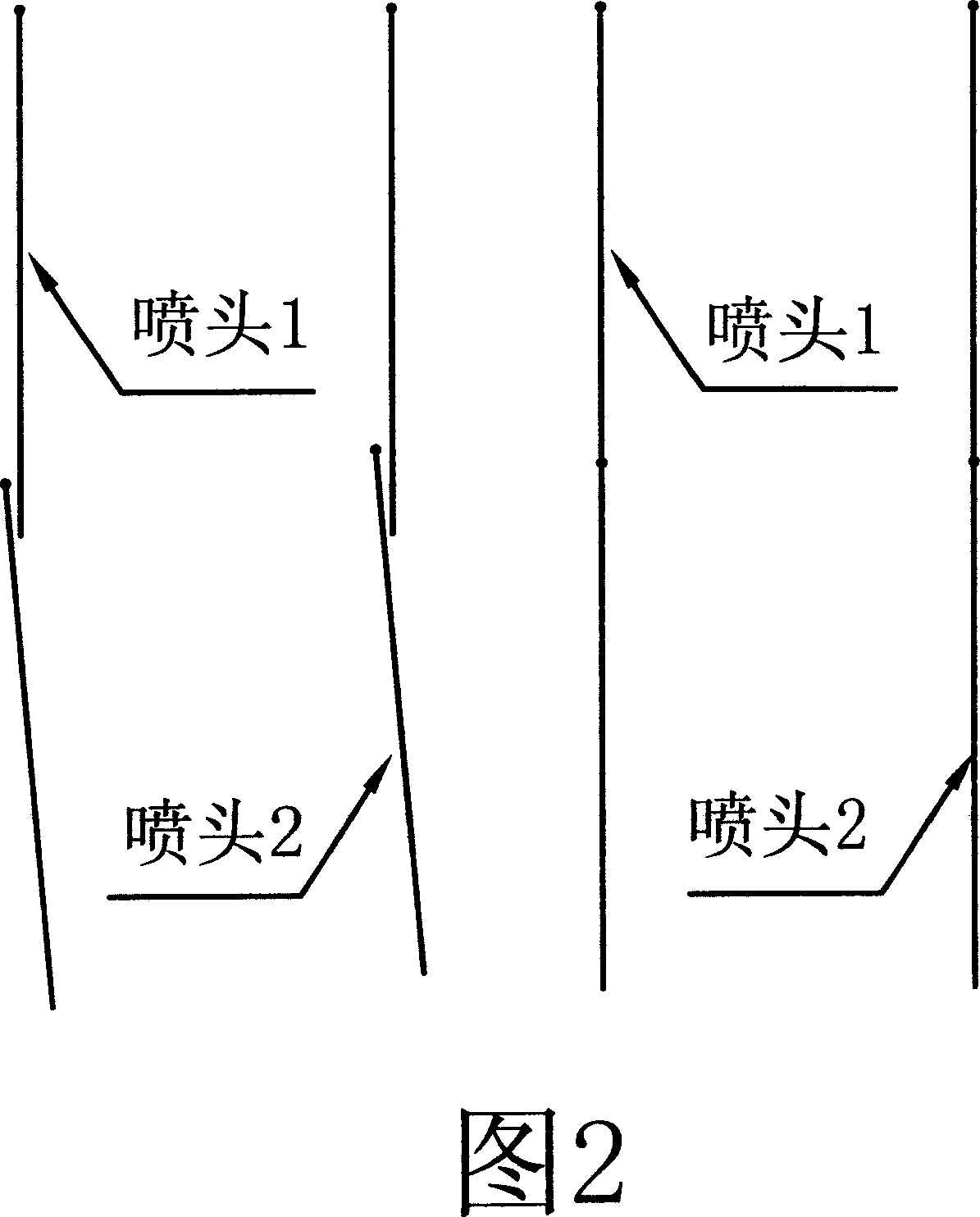

[0059] The spray head adjustment mechanism of the present invention performs angle adjustment and Y-direction adjustment separately, thereby achieving the effect of not affecting each other.

[0060] As shown in Figure 7, the present invention adopts a connecting frame 4 that can slide relative to the bottom plate 1, and a nozzle 8 is inserted on the connecting frame 4, wherein the nozzle 8 is fixed on the connecting frame 4, and the connecting frame 4 is fixed on the bottom plate 1 .

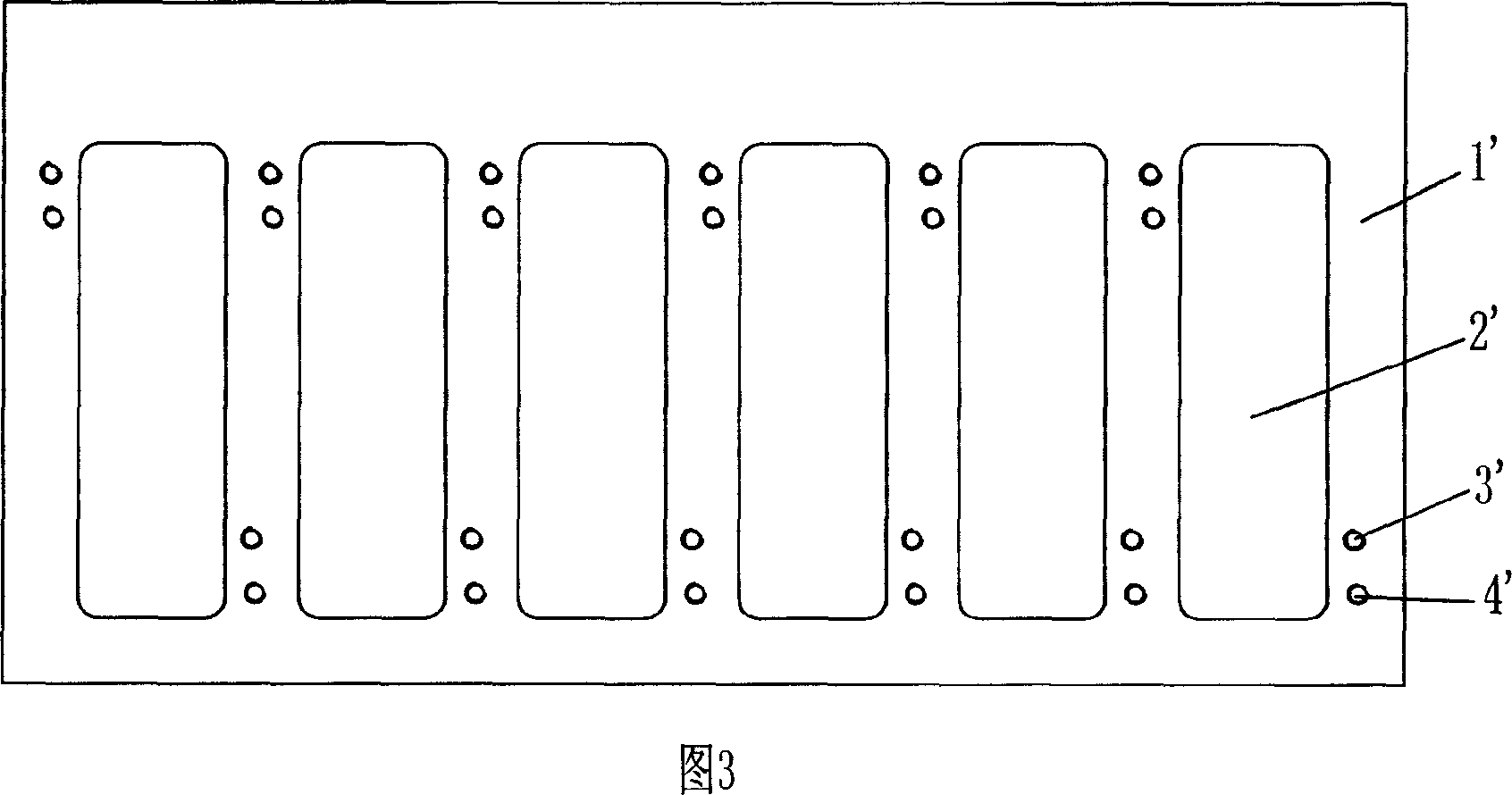

[0061] As shown in Fig. 9 and Fig. 10, six nozzle installation holes 11 are arranged on the bottom plate 1, the installation holes 10 are stepped holes, and a step surface 12 is arranged on the edge of the hole, and a through hole 13 is arranged on the side wall of one end of the installation hole 11, The through hole 13 is also a stepped hole.

[0062] As shown in Figures 11-13, the shape of the connection frame 4 corresponds to the shape of the installation hole 11 on the base plate 1, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com