Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

667results about How to "Not easy to stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic film with self-cleaning function, preparation method thereof and application thereof

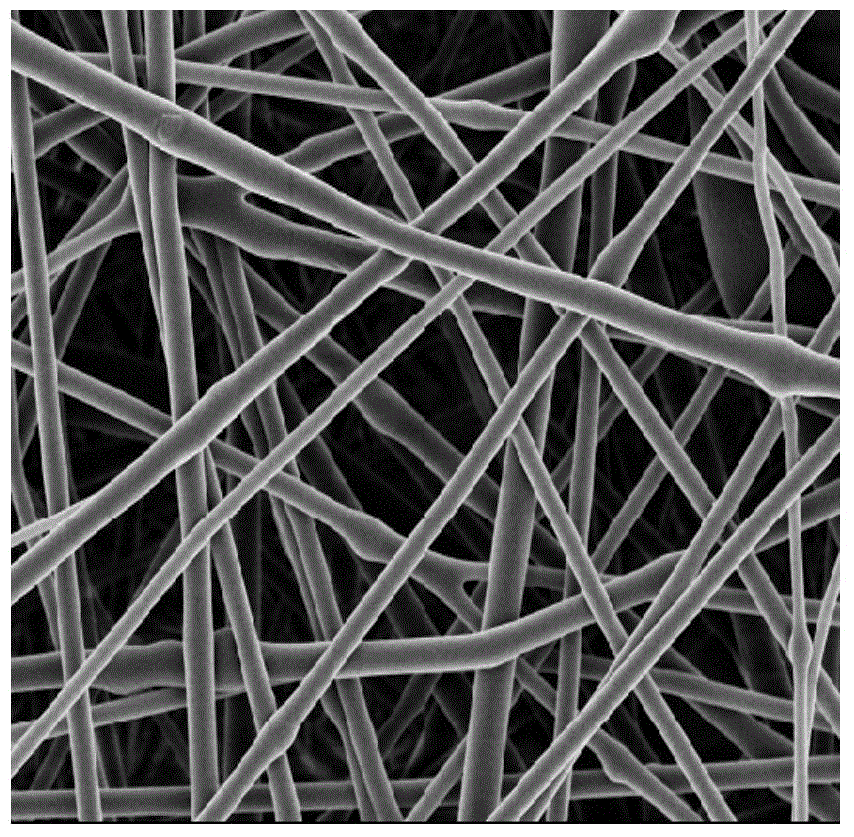

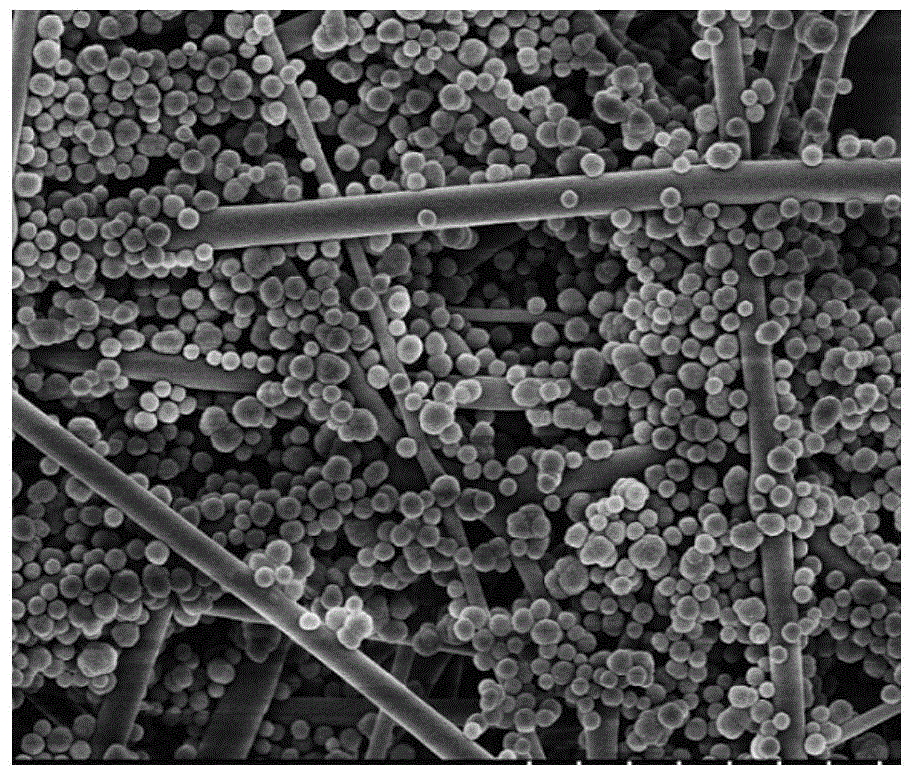

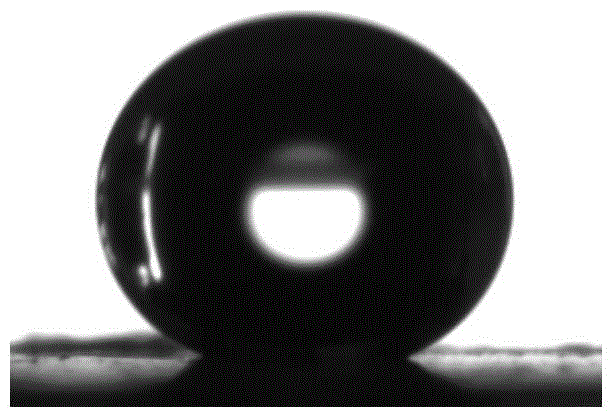

ActiveCN105002656AHigh porosityWith self-cleaning functionSemi-permeable membranesFilament/thread formingPorosityFiber

The invention relates to a hydrophobic film, and specifically relates to a hydrophobic film with a self-cleaning function, and a preparation method thereof and an application thereof. The hydrophobic film is a polymer nanofiber film prepared through an electrospinning fiber technique, the surface of the hydrophobic film is subjected to nanocrystallization modification to improve the surface hydrophobicity, and the contact angle between the hydrophobic film and water is 140-180 DEG. According to the invention, the electrospinning fiber technique and the surface nanocrystallization technique are combined, the preparation technology is simple, and the prepared hydrophobic film has the self-cleaning function and a high porosity factor, and can be applied to fields of air purifying filters, film distillation and oil-water separation and the like.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

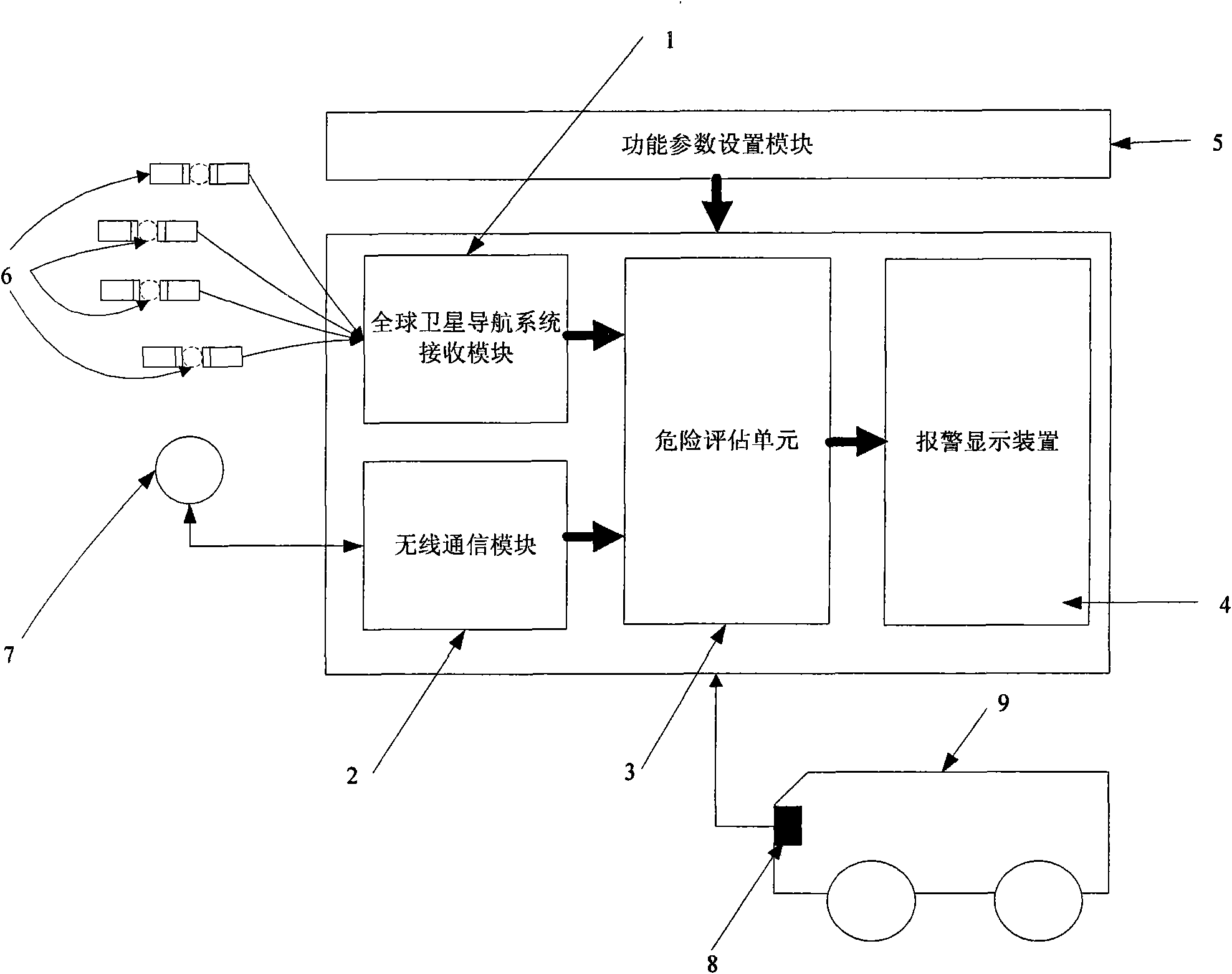

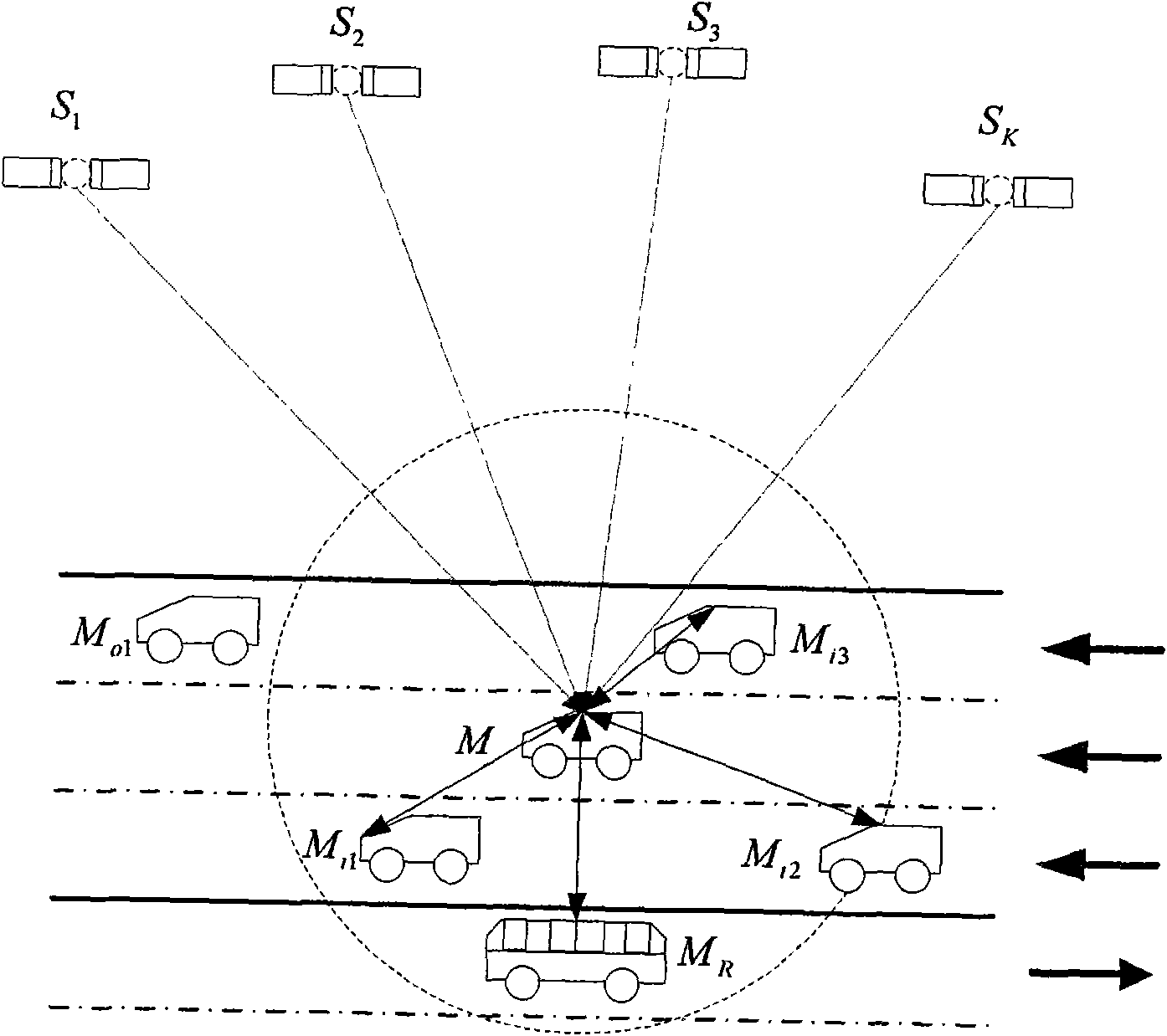

Early warning method when automobile closes at high speed and early warning device

InactiveCN101625797AEfficient use ofLower performance requirementsAnti-collision systemsPosition fixationDisplay deviceEngineering

The invention discloses an early warning method when an automobile closes at high speed and an early warning device. The method comprises the following steps: when the automobile drives at high speed, a navigation signal of a global navigation satellite system defines drive parameter information of the automobile, wireless net receives the drive parameter information of circumambient automobiles, the two drive parameter information are sent into a danger assessment unit, and the danger assessment unit judges whether the danger is existed to send an early warning signal. The device comprises a receiving module of the global navigation satellite system, a warless communication module, the danger assessment unit and a warning display device. The invention is the early warning method when the automobile closes at high speed and the early warning device, having simple and compact structure, low cost, convenient installation, wide application range and high safety.

Owner:NAT UNIV OF DEFENSE TECH

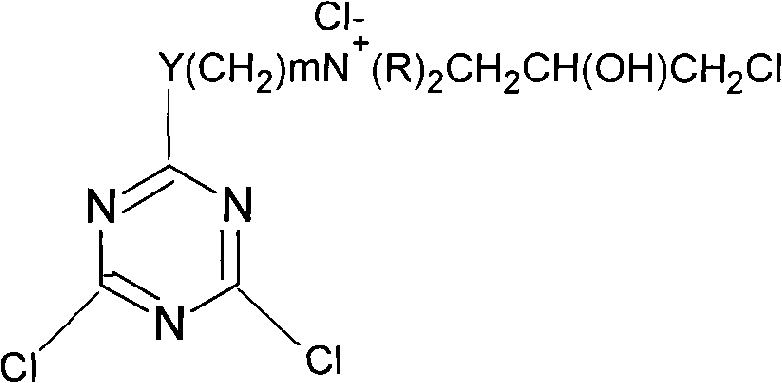

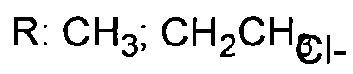

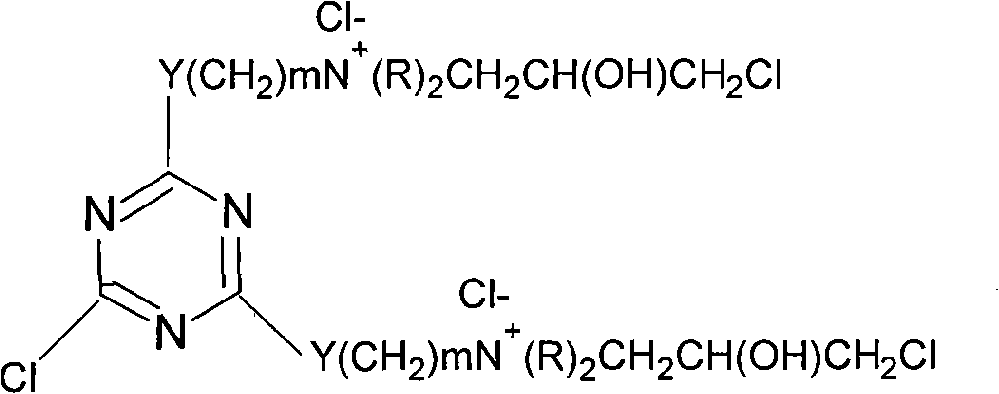

Fabric graft modified full-fixation printing method

InactiveCN101403185AReduced charge repulsionReduce processing burdenDyeing processVegetal fibresSodium bicarbonateWorking fluid

The invention relates to a whole fixation printing method for the graft modification of textiles, and aims at providing the whole fixation printing method that can promote the dye fixation rate from 70 percent to 80 percent to more than 90 percent to 98 percent. The technical proposal is as follows: 1) the pretreatment of a textile, the textile is treated according to the processes of desizing, boiling, smelting and bleaching; 2) the preparation of the graft modification working fluid, the working fluid comprises 0.1 percent to 10 percent of cationic graft agent, 0.1 percent to 20 percent of alkali agent and 0 percent to 1 percent of penetrating agent, and the rest is water; 3) the treatment of the graft modification, the pretreated textile is put into a dyeing machine, and the graft modification working fluid is added; or the pretreated textile is padded with the graft modification working fluid in a padder; the printing formula of the invention comprises 50 grams of protoplasm, 2 grams to 5 grams of urea, 0.5 gram to 8 grams of dye, 1 gram to 2.5 grams of sodium bicarbonate and 0.5 gram to 1.5 grams of reserve salt, and the rest amount of water in every 100 grams according to weight; and 4) the printing technology, the printing is carried out according to the conventional technology. The whole fixation printing method for the graft modification of the textiles is used in the whole fixation printing.

Owner:ZHEJIANG JIAXIN SILK

Thin type reflective insulation exterior wall paint

InactiveCN101210128AFlat surfaceNot easy to stainFireproof paintsReflecting/signal paintsEmulsionThermal insulation

The invention discloses a thin reflective insulation exterior wall paint which is characterized in that the paint is prepared by mixing pigments and fillers as well as multiple synthetic resin solution or emulsion, the pigment ratio 0.9 to 1.3 of the pigment ratio, and the remaining is addition agent and solvent. The invention has good thermal insulation effect, thus reducing the energy consumption of a building. The paint has thin coating and smooth surface, and the contamination is not easy; the painting engineering cost is obviously lowered and the maintenance fee is obviously reduced.

Owner:资阳赛特化工有限公司 +1

Method for producing antifouling PU synthetic leather

The invention, relating to the technical field of producing PU synthetic leather, relates to a method for producing antifouling PU synthetic leather, comprising the three steps of making a wet-process PU semi-finished base, dry-process veneering on the wet-process PU semi-finished base and antifouling printing processing. The produced antifouling PU synthetic leather has a surface which is not easy to be contaminated, has superior antifouling performance, and is cleaned easily without using special cleaning agent when the leather is contaminated by contamination, so as to reduce the damage tothe environment.

Owner:义乌市鑫挺人造革有限公司

Heat insulating coating surface glue and heat insulating coating

ActiveCN102206445AImprove insulation performanceNot easy to stainRubber derivative coatingsConjugated diene hydrocarbon coatingsChemical tankEnergy consumption

The invention discloses heat insulating coating surface glue for insulating heat through reflection and heat conversion. Based on reflection and heat insulation, a heat converting material is added into the heat insulating coating surface glue, after being absorbed by a coating layer, part of unreflected heat energy can be converted by the heat converting material into radiant energy to be released into the atmosphere, thus, 98% of heat from the sun can be insulated. The invention also provides a heat insulating coating which comprises the surface glue, intermediate glue and bottom glue, has excellent heat insulating performance, and can be used for remarkably reducing the temperature of buildings, industrial chemicals tanks and various equipments requiring heat insulation and reducing the energy consumption for temperature reduction.

Owner:开平市日固力涂料有限公司

One bath super dark dyeing technology of polyester-cotton fabric disperse and reactive dyes

InactiveCN101392462AHigh color yieldGood color yieldDyeing processLiquid/gas/vapor textile treatmentReactive dyeColour fastness

The invention provides a super-dark dyeing technology by dispersing the polyester-cotton fabrics and one bath of the reactive dye, which belongs to a dyeing technology of the fabrics. The technology comprises the following steps: selecting the WW series disperse dyes and C series reactive dyes to soak the pure cotton fabrics into the dyeing solution for one time, then rolling with a squeezer for one time, then pre-baking and baking the cloth, then steaming in a steaming chamber, then washing with water after the steaming, then washing with soap after the water washing, then washing the cloth with water again and drying to finish the dyeing process. The disperse dyes and reactive dyes selected by the dyeing technology has high color yield and good color fastness and the loose color on the fabrics can be completely washed during the soap washing process, therefore, the loose color can not dye the surface of the fabrics, which basically solves the color transfer fastness and wet grinding fastness of the super-dark color. The design of the baking temperature is reasonable, which improves the color yield of the disperse dyes and the color fastness of the dye; the adopted one-bath dyeing process is simple in process flow and low in production cost and the amount of the sewage is few and the dyeing quality is stable.

Owner:HUAFANG

Plant functional polyester filament and preparation method thereof

InactiveCN110863252AHigh mechanical strengthImprove wear resistanceMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterFiber

The invention discloses a plant functional polyester filament and a preparation method thereof. The plant functional polyester filament comprises 0.1-1.5% of plant extract. The preparation method includes a step of plant functional polyester master batch preparation, and the step of plant functional polyester master batch preparation includes: slicing PET, heating to melt, adding an antioxidant and a dispersing agent, and stirring; then, adding a protecting agent and the plant extract, and mixing at a high speed; finally, adding a modifying agent, well mixing to obtain a mixture, and extrudingfor granulation. The plant functional polyester filament integrates high mechanical strength of polyester fibers and the anti-mite and antibacterial performance of the plant extract and has advantages of antibacterial and deodorizing effects, high wear resistance, high elasticity, comfort in hand feeling and less proneness to pilling and fouling.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

InactiveCN102614782AUniform pore size distributionLight in massSemi-permeable membranesCeramicwareRare earthPore diameter

Owner:SHANGHAI MARITIME UNIVERSITY

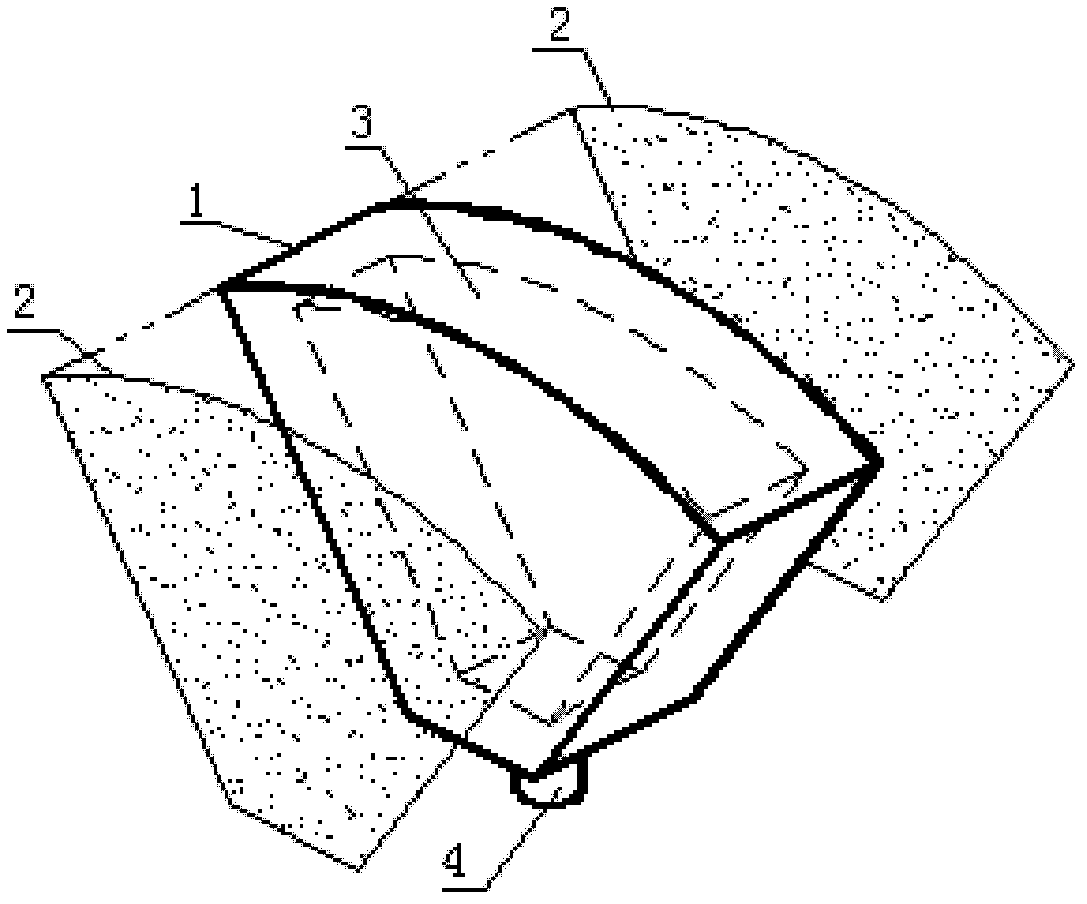

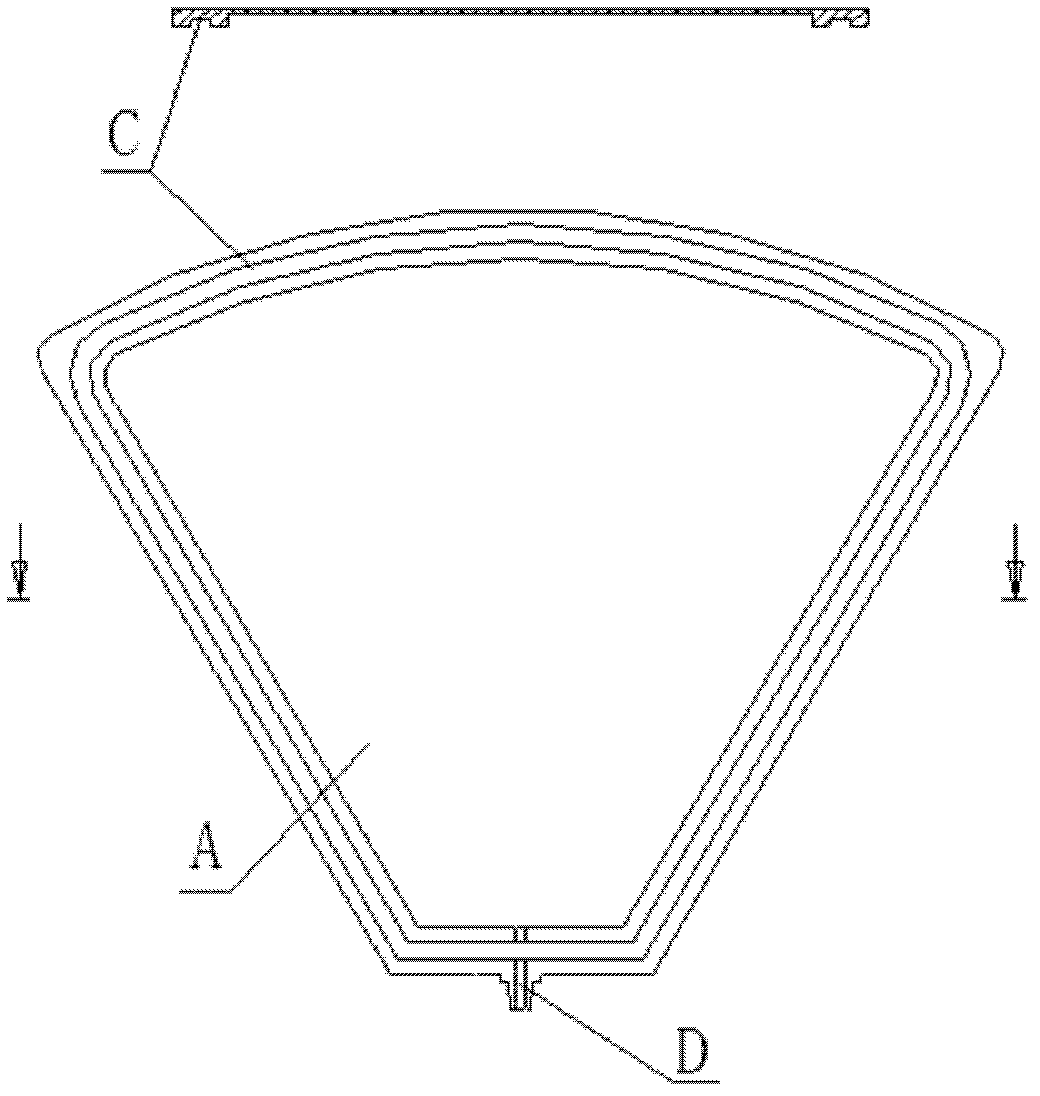

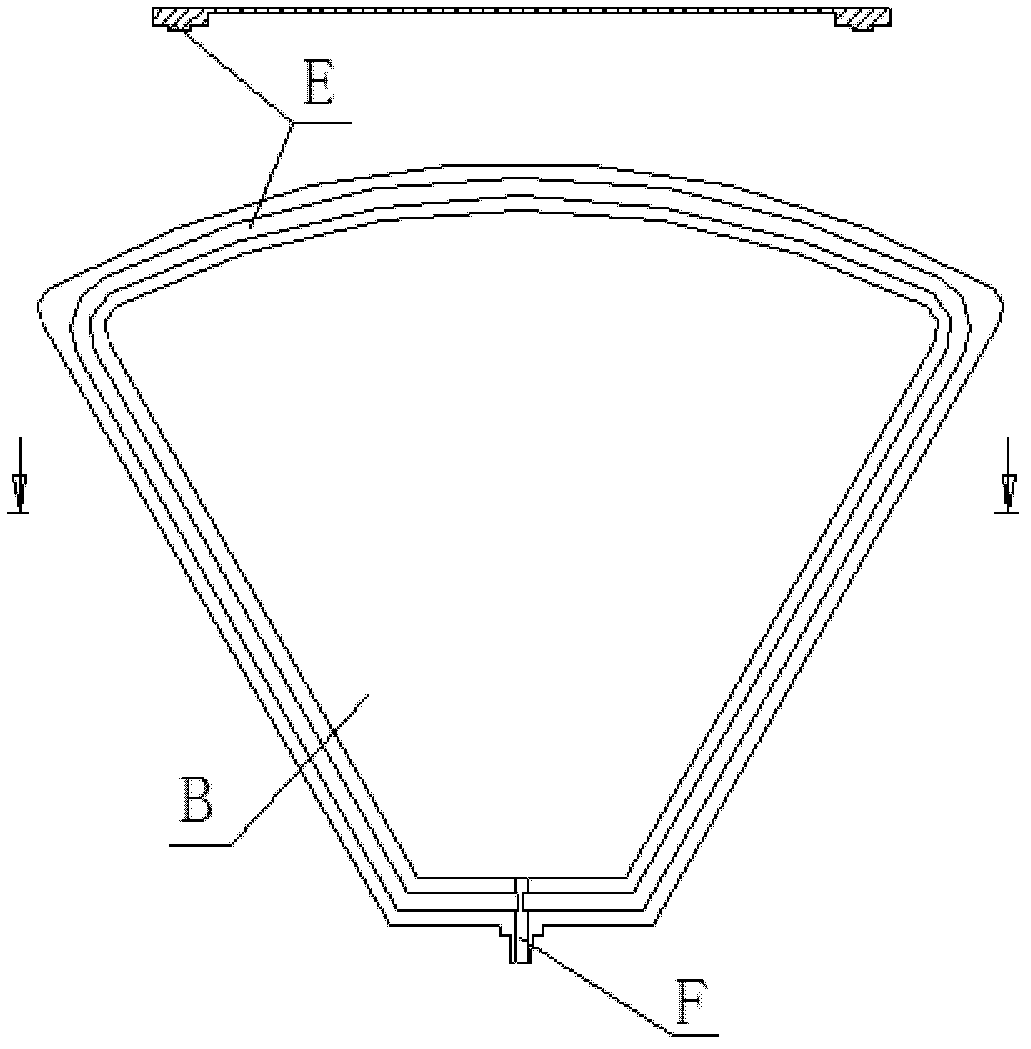

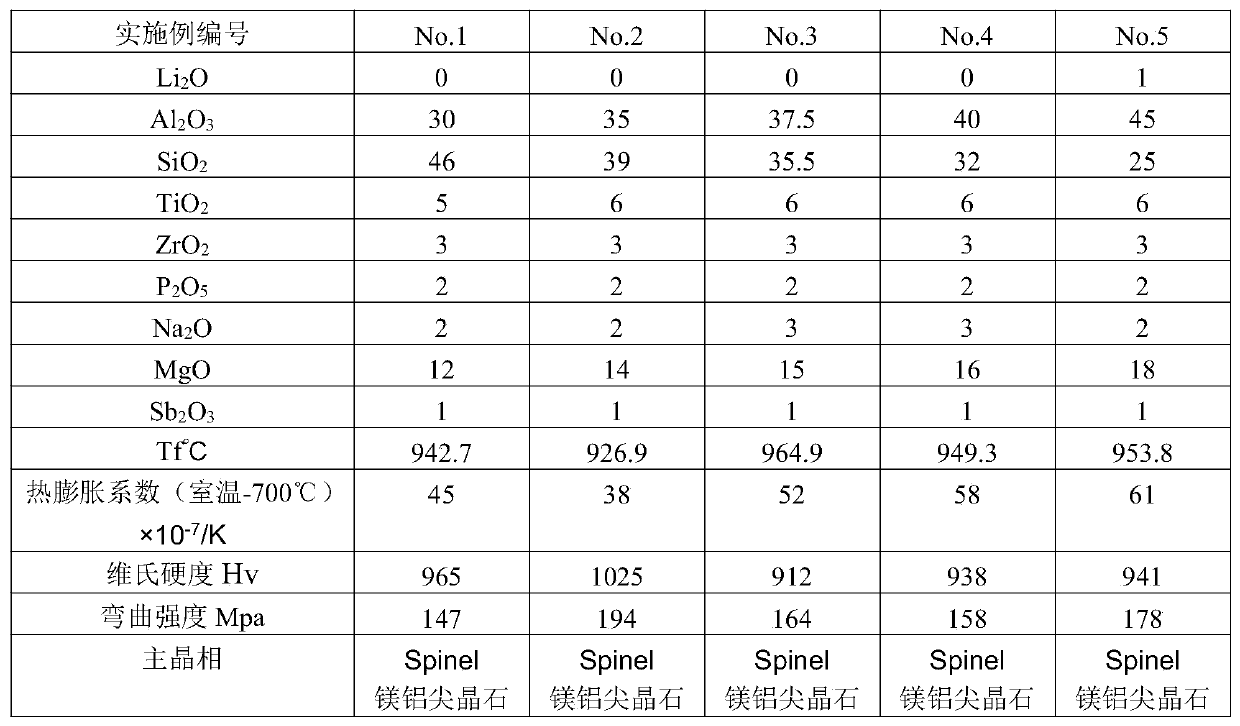

Mg-Al-Si spinelle crystallized glass

InactiveCN109809696AFlat surfaceComplete structureGlass furnace apparatusHigh intensityMaterials science

The invention provides Mg-Al-Si spinelle crystallized glass, which is prepared from the following ingredients in percentage by weight: 20 to 45 weight percent of Al2O3, 25 to 60 weight percent of SiO2, 8 to 18 weight percent of MgO, 3 to 10 weight percent of TiO2, 0 to 5 weight percent of ZrO2, 0 to 3 weight percent of P2O5, 0 to 2 weight percent of Li2O, 0 to 2 weight percent of Na2O, 0 to 2 weight percent of K2O and 0.5 to 3 weight percent of Sb2O3. The product has the characteristics of high intensity, high hardness, dropping resistance, low expansion and excellent dielectric property.

Owner:温州市康尔微晶器皿有限公司

Wind force electric generator blade antifreezing paint

InactiveCN1556161ANot easy to stainHigh bonding strengthAntifouling/underwater paintsPaints with biocidesWind drivenEpoxy

An antifreezing paint for the blades of wind-driven electric generator is prepared from epoxy resin, graphite powder, diluent, modifier and solidifying agent through proportionally mixing. Its advantages are high adhesion and high hydrophobicity.

Owner:卢能晓

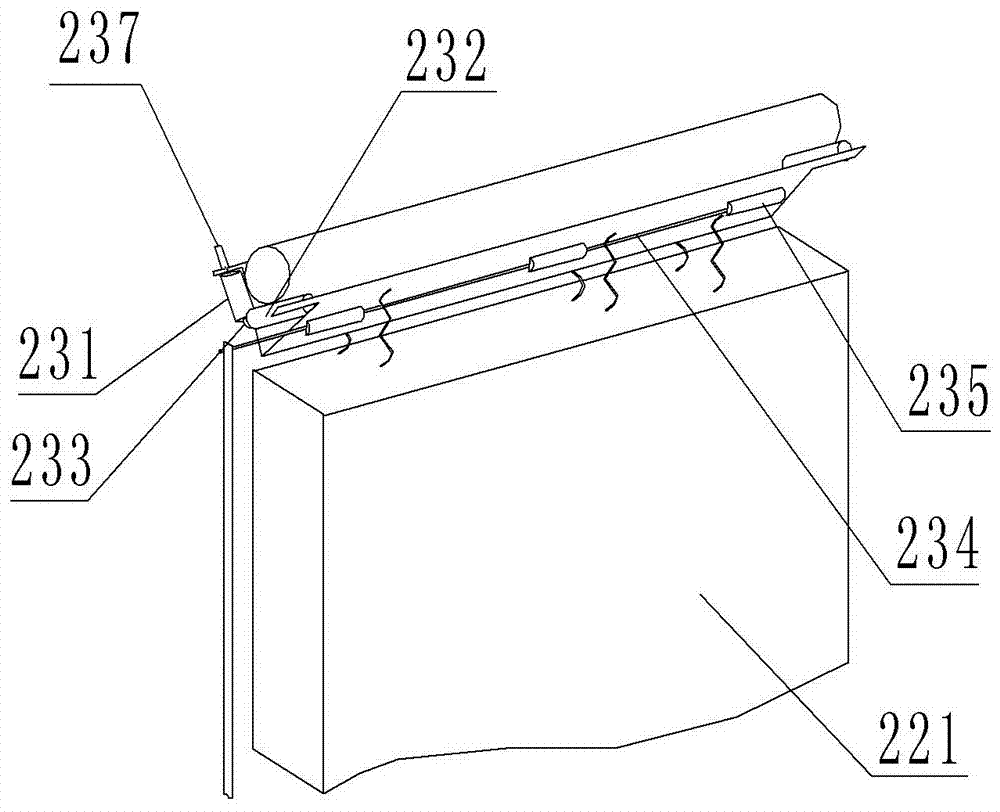

Pipe conveying device

ActiveCN107187850ANot easy to stainHollow article cleaningConveyor partsHydraulic cylinderElectromagnet

The invention relates to the technical field of pipe conveying, in particular to a pipe conveying device. The pipe conveying device comprises a storage rack and a taking and feeding mechanism, wherein a shifting part capable of shifting pipes is arranged on the storage rack; the taking and feeding mechanism comprises a supporting table and a supporting seat which is driven by a hydraulic cylinder and penetrates through the supporting table; a V-shaped taking and placing part is arranged at the upper end of the supporting seat; V-shaped rollers which can be in contact with the pipes are respectively arranged at two ends of the taking and placing part; each V-shaped roller comprises a short roller and a long roller which are hinged to each other; a magnet is arranged at a position where each short roller is hinged to the corresponding long roller; each position where the corresponding short roller is hinged to the corresponding long roller and the lowest position of the taking and placing part are not positioned on the same straight line; the taking and placing part is provided with a rotating shaft, a shaft cavity and dust-removing rollers; the dust-removing rollers are driven by the rotating shaft; a first gear is arranged at one end of the rotating shaft; the shaft cavity is positioned in the side wall of the taking and placing part; a first rack which can be engaged with the first gear is arranged on the supporting table; and an electromagnet is further arranged on the supporting table. By the scheme, dust on the surfaces of the pipes can be removed in a conveying process, and furthermore, the pipes can be taken down from the conveying device conveniently.

Owner:重庆市永川区植成家俱厂

Aluminum alloy for subway station ceiling and preparing method of aluminum alloy

The invention relates to an aluminum alloy for a subway station ceiling and a preparing method of the aluminum alloy. The aluminum alloy is characterized by comprising chemical components, including by mass percent, 0.45% to 0.6% of Mg, 0.3% to 0.5% of Si, 0.1% to 0.3% of Mn, 0.1% to 0.2% of Cr, 0.1% to 0.3% of Zr, 0.1% to 0.3% of Hf, 0.05% to 0.2% of Ta, 0.05% to 0.15% of Cu, not larger than 0.05% of Zn, not larger than 0.20% of Fe, not larger than 0.05% of Ti, and the balance Al, wherein the single content of other impurity elements is not larger than 0.05%, and the total content of other impurity elements is not larger than 0.15%. The aluminum alloy is obtained through the preparing method of smelting, refining, casting and homogenizing. Through optimizing of alloy components, adjustment is carried out, the trace of Zr, Hf and Ta is added, and the strength, the heat dissipation, corrosion resistance, humidity resistance, fatigue resistance, static electricity resistance, recrystallization resistance capacity and breaking resistance performance of the aluminum alloy can be obviously improved.

Owner:ALNAN ALUMINIUM CO LTD

Method for preparing absorbable suture

ActiveCN104491920APromote wound healingLow antigenicitySuture equipmentsTissue CompatibilitySide effect

The invention relates to sutures and in particular relates to a method for preparing an absorbable suture. The method for preparing the absorbable suture disclosed by the invention comprises the following steps: (1) separating protein chorion; (2) purifying collagen fibers; (3) deoiling and degreasing; (4) inactivating viruses; (5) performing chrome tanning; (6) performing crosslinking dehydration; (7) polishing; (8) performing chitosan atomization; and (9) packaging. The absorbable suture prepared by the method disclosed by the invention has the characteristics of high tensile strength, knotting firmness, high biocompatibility and small toxic and side effects, and the suture can be absorbed by the body. The suture is completely absorbed, an absorption reaction is avoided, the suture does not need to be taken out, the tissue compatibility is high, and an adverse reaction in the human body is avoided regardless of the time; and moreover, the surface is smooth, the suture is difficultly infected by germs, and infection can be avoided.

Owner:SHANDONG BODA MEDICAL PROD CO LTD +1

Treating process before spraying aluminum profile

InactiveCN102527609AMeet the chrome-free requirementsImprove attachment conditionsAnodisationPretreated surfacesAnodic oxidationEnvironmental resistance

The invention discloses a treating process before spraying an aluminum profile. Before spraying, a blank is subjected to treatment of deoiling, alkaline degreasing, neutralizing, oxidizing a positive electrode and sealing half of a hole, so that a semi-closed oxidized film is formed on the surface of the blank; and the oxidization treatment is that: the blank is put into H2SO4 with the concentration of between 160 and 180 g / L, the oxidization temperature is of between 18 and 22 DEG C, and the current density is of between 140 and 160 A / dm<2>. By adoption of the oxidization treatment step, the formed semi-closed oxidized film has a pore structure, so that a good attachment condition is supplied to paints; furthermore, compared with a non-closed oxidized film, the semi-closed oxidized film has the advantages that: impurities, such as dust and the like, cannot be attached to the surface of the profile easily before the profile is sprayed, and a subsequent spraying effect can be guaranteed. Meanwhile, a chromizing treatment step is avoided, and the finally obtained aluminum profile product does not contain chromium; and therefore, the aluminum profile can meet a non-chromizing requirement, and is relatively safe and environment-friendly.

Owner:肇庆亚洲铝厂有限公司

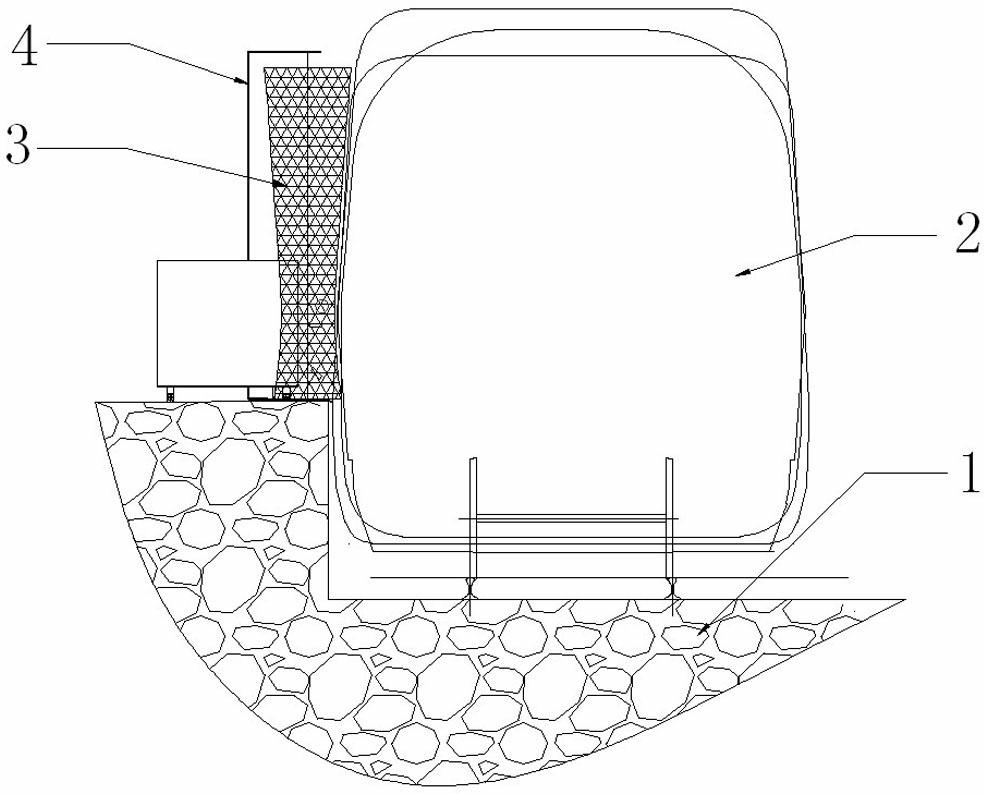

A train cleaning device

InactiveCN102275571AReliable and flexibleSimple and fast operationCleaning apparatus for vehicle exteriorsLaser rangingLoop control

The invention relates to a train cleaning apparatus which is used for cleaning the outer surface of a train carriage and comprises a stand serving as a main body. The train cleaning apparatus is characterized in that: the stand is provided with a cleaning mechanism, a walking mechanism, a sensing system and a control system, wherein the cleaning mechanism is used for cleaning the outer surface of the train carriage; the walking mechanism is used as a moving part of the cleaning machine; the sensing system is used as a monitoring part for detecting the external state of the cleaning machine; and the control system receives, analyzes and calculates the information of the sensing system, and controls the cleaning mechanism and a walking turning mechanism connected with the control system. The train cleaning apparatus provided by the invention has the advantages that: the appearance of a brush is designed according to the profile of the outer surface of a motor train and is compatible with multiple motor train types; the laser positioning and ranging and automatic turning closed-loop control ensure reliable and flexible walking as well as simple operation; and multiple-safety anti-collision protection is provided: laser ranging protection, platform falling-prevention photoelectric sensing and guide wheel collision prevention.

Owner:SHANGHAI RAILWAY ECONOMIC DEV

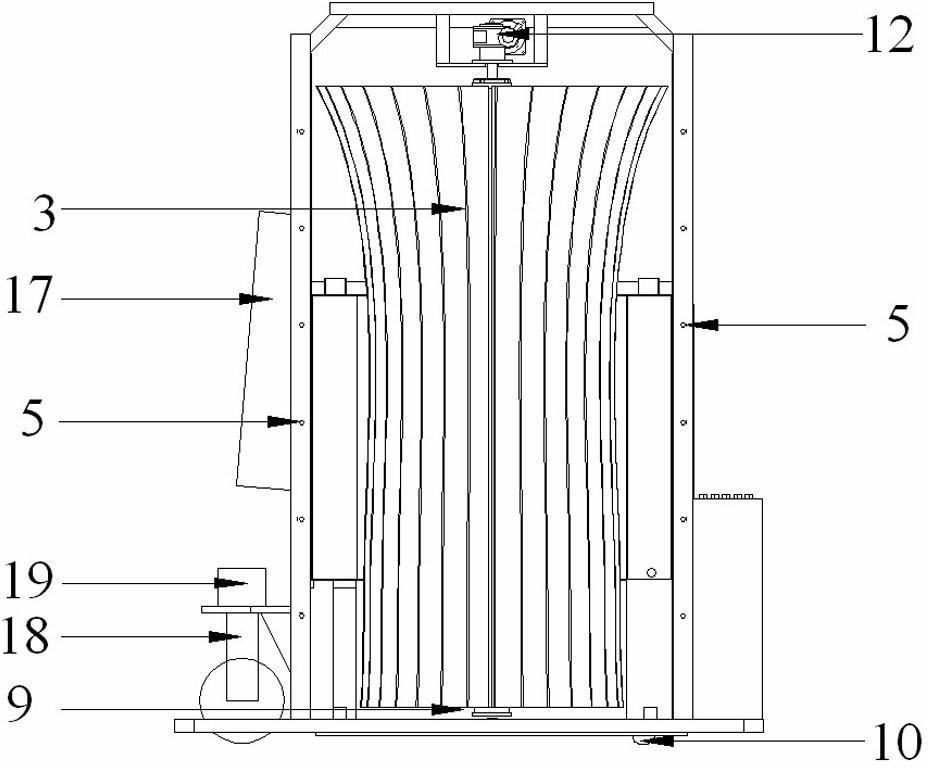

Intelligent toilet lid and working method thereof

Embodiments of the invention disclose an intelligent toilet lid and a working method thereof. The intelligent toilet lid comprises a supporting seat, a closestool upper cover, a toilet seat, a transmission mechanism, and a controller electrically connected with a motor, and an infrared sensor electrically connected with the controller and including a ranging module and a ray module. The closestool upper cover and the toilet seat are fixed on the supporting seat and can rotate around the supporting seat. The transmission mechanism comprises a fixed base, a transmission assembly, a closestool upper cover transmission shaft, and a toilet seat transmission shaft. The transmission assembly is fixed on the fixed base. One end of the transmission assembly is connected with the motor. The fixing end of the closestool upper cover transmission shaft and the fixing end of the toilet seat transmission shaft are coaxially fixed on the other end of the transmission assembly. The connecting end of the closestool upper cover transmission shaft is fixedly connected with the closestool upper cover. The connecting end of the toilet seat transmission shaft is fixedly connected with the toilet seat. A method of infrared induction distance measurement and gesture induction is used, independent start and close of the closestool upper cover and the toilet seat is realized, so as to satisfy different use habits of men and women.

Owner:宁波普天通信技术有限公司

Environment-friendly high-strength nail-free glue not containing organic tin and preparation method thereof

ActiveCN105885766AMeet environmental protection requirementsHigh reactivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesMan-hour

The invention discloses environment-friendly high-strength nail-free glue not containing organic tin and a preparation method thereof. The nail-free glue is prepared from, by mass, 10-50 parts of a silane-terminated polymer, 10-50 parts of reinforced resin, 5-25 parts of a plasticizer, 20-55 parts of a reinforced filler, 1-5 parts of a rheological agent, 0,5-3 parts of a water absorbent, 1-6 parts of a coupling agent, 0.2-1.5 parts of a stabilizer and 0.1-1 part of a non-organic tin catalyst, wherein the silane-terminated polymer contains a polyurethane group. The product has the advantages of being large in initial cohesion, rapid in solidification, high in strength, capable of bonding various base materials, capable of performing construction on the humid surface, capable of coating surfaces, resistant to heat and water and the like, does not contain toxic volatile solvents or organic tin catalysts, is healthy, environmentally friendly and capable of replacing a traditional nail, effectively lowers noise and dust pollution generated in the construction process, saves man hours and is wide in application prospect.

Owner:GUANGZHOU JOINTAS CHEM

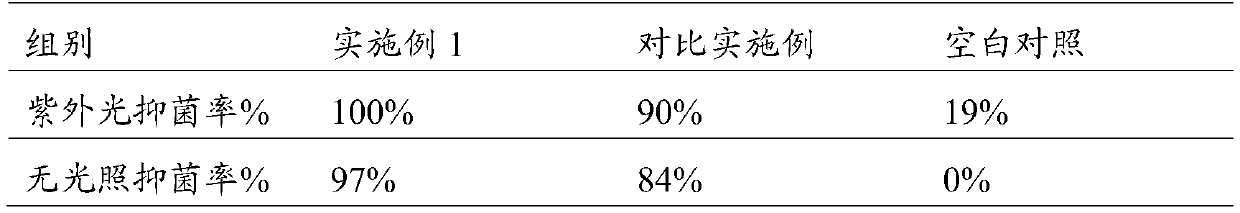

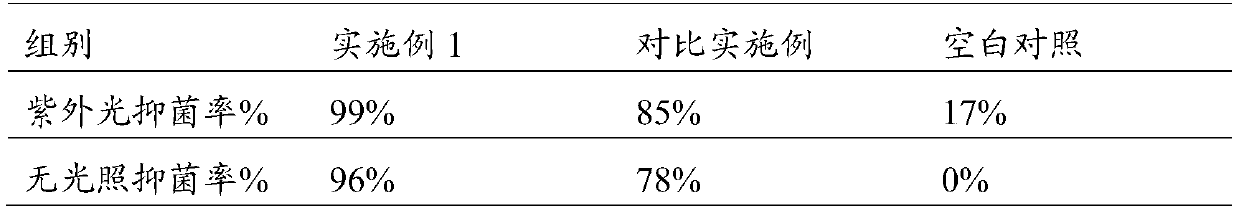

Bacteriostatic isolation coating composition for medical inspection platform and preparation method thereof

PendingCN110144150AImprove mechanical propertiesImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesCompound organicComponent Load

The invention relates to a bacteriostatic isolation coating film-forming liquid for a medical inspection platform and a preparation method thereof. The film-forming liquid containing solid micro-particles comprises a silica sol component loaded with nano silver-titanium dioxide, a nano silver-doped organic-modified mesoporous silica antibacterial composite microsphere component, a composite organic resin component, polyhexamethylene biguanide hydrochloride or phosphate, and an other auxiliary agent component. The bacteriostatic isolation coating film-forming liquid can be used for the surfacefilm-forming isolation use of the hospital inspection platform such as various working or operating tables, appliance storage-taking brackets or working cabinets, and has excellent disinfection bacteriostatic function and hydrophobic and easy-cleaning function.

Owner:杨茂本

Lightweight environment-friendly type pumice for ceramic ware and its production method and usage

InactiveCN1762910AStrong wear resistanceReduce cleanup workloadDry-cleaning apparatus for textilesCeramicwareSewage treatmentMetallurgy

The present invention relates to light environment friendly ceramic pumice and its manufacture and usage. The ceramic pumice is used widely in fading, fluffing, softening, ageing and other processing of clothing, fabric, cloth, etc. The ceramic pumice of the present invention contains no harmful matter, and results in simplified fabric cleaning post-treatment and no environmental pollution. Treating fabric with the ceramic pumice makes fabric soft, good look, personalized, permeable and comfortable.

Owner:何晓洪

Yarn of blended spinning by combing cotton, spun silk and cashmere and its processing method

The invention relates to combed cotton, spun silk and wool blended yarn and a processing method thereof; the yarn is composed of wool, spun silk and combed cotton; the mass proportion is as follows: 10 percent to 25 percent of wool, 10 percent to 25 percent of spun silk and 35 percent to 65 percent of combed cotton; the performance indexes of the blended yarn meet the following requirements: single-yarn fracture strength: 8.0cN / tex to 16.0cN / tex, single-yarn fracture strength variation coefficient CV: less than or equal to 12.0 percent, yarn evenness variation coefficient CV: 11.0 percent to 17.5 percent; the processing method of the yarn comprises strip making, three-in-one strip combination, roving, spinning, winding and the like. The fabric spun by the yarn has a plurality of advantages of cotton fiber, silk and wool fabric, and the products are smooth to touch, thick and tough. Meanwhile, after process adjustment, the method can greatly save production cost when producing similar high-grade blended yarn on cotton spinning equipment.

Owner:江阴市茂达棉纺厂有限公司

Method for preparing antistatic anti-felting wool fabric with good dyeing property

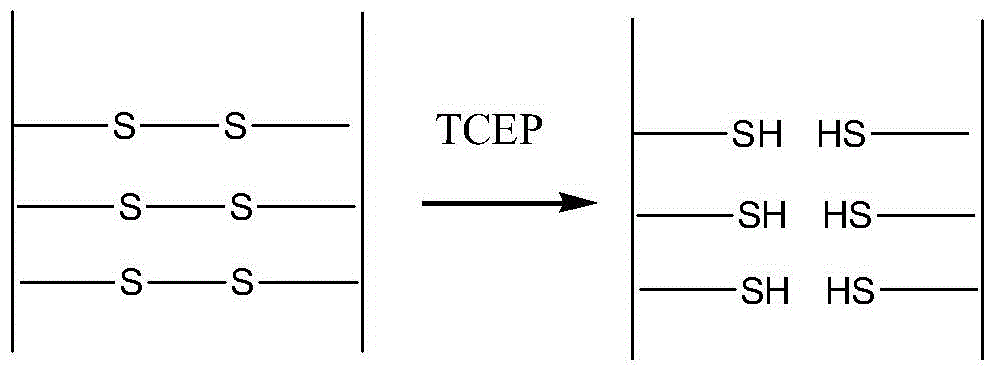

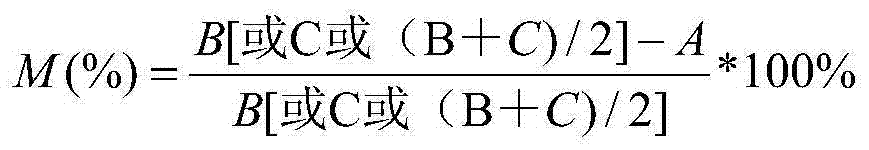

InactiveCN104404763AGood drapabilityGood warmth retentionAnimal fibresEnvironmental resistanceChemical reaction

The invention relates to a method for preparing an antistatic anti-felting wool fabric with good dyeing property. The method comprise the following steps: pre-treating wool fabric with tris(2-carboxyethyl) phosphine (TCEP) to break disulfide bonds in wool fabric keratin to form sulphydryl with higher activity, and then grafting molecular chains containing acrylate in the presence of triethylamine through the thiol-ene click chemical reaction to obtain the wool fabric. The method disclosed by the invention not only has remarkable effect but also is safe and environment-friendly, has no harm to human bodies and environments, and is simple and effective as the groups of the wool are directly used as the active groups.

Owner:DONGHUA UNIV

Composite material for multifunctional rubber and plastic car foot mats and preparation method

ActiveCN104119621AImprove self-cleaning abilityStrong ability to absorb volatile gasesTributyl citrateCalcium

The invention discloses a composite material for multifunctional rubber and plastic car foot mats. The composite material comprises the following main raw materials in parts by weight: 50-100 parts of polyvinyl chloride (medical grade, molecular weight: 2500), 5-25 parts of styrene-isoprene-styrene block copolymer, 40-100 parts of tributyl citrate, 5-8 parts of epoxy resin (E-51), 0.5-1 part of 2-methylimidazole, 5-10 parts of nano titanium dioxide, 20-30 parts of calcium carbonate, 1-2 parts of antibacterial agent, 3-10 parts of epoxy soybean oil, 1-2 parts of polyoxyethylene polyoxypropylene polyether and 2-5 parts of calcium-zinc stabilizer. The composite material has the advantages of good self-cleaning property, volatile solvent removing property and antibacterial property.

Owner:SANMEN YONGDING RUBBER & PLASTIC CO LTD

Self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating

InactiveCN106590385AGood gloss and color retentionThe advantage is: polyurethane resin has good heat resistanceAntifouling/underwater paintsPaints with biocidesDibenzoyl PeroxideOrganic inorganic

The invention discloses a self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating which is prepared from the following raw materials: perfluoroalkyl ethanol, methyl isobutyl ketone, HDI trimer, methyl methacrylate, styrene, hydroxyethyl methacrylate, perfluorooctyl methacrylate, benzoyl peroxide, 25-28 parts of methanol silica sol, propylene glycol methyl ether acetate, titanium dioxide, sodium hexametaphosphate, ethyl orthosilicate, vinyl triethoxysilane, an appropriate amount of ammonia water, an appropriate amount of silane coupling agent KH570, an appropriate amount of methyl hydroxyl silicone oil, an appropriate amount of 10% dibutyltin dilaurate, a dispersant, a leveling agent, a defoamer, an appropriate amount of butyl acetate, an appropriate amount of anhydrous ethanol, and an appropriate amount of deionized water. The super-amphiphobic polymer coating provided by the invention is simple and feasible in preparation method, can be firmly combined with a variety of substrates, and has universality, good self-cleaning performance, dirt resistance, scrub resistance, corrosion resistance and other performance, and good application prospects.

Owner:TIANCHANG YINHU PAINT

Porcelain enamel glaze for acid-resistant cast iron sanitary ware

InactiveCN101037294AImprove craftsmanshipImprove acid chemical stabilityChemical stabilityMaterials science

The invention discloses an enamel glaze for cast iron plumbing fittings with acid resistance, of which composition (wt.%) is: SiO2 40.0-60.0, Al2O3 0.1-5.0, B2O3 1.0-10.0, K2O 0.1-5.0, Na2O 6.0-17.0, Li2O 0.5-5.0, CaF2 1.5-7.0, Na2SiF6 2.0-6.0, Sb2O3 5.0-15.0, ZrO2 1.0-5.0, TiO2 1.0-10, PbO 0-8.0, CeO2 0.5-6.0, La2O3 0.3-5.0. The enamel glaze for cast iron plumbing fittings with acid resistance has a high chemical stability, a good processing property and a good opacifying capacity.

Owner:SHANGHAI INST OF TECH

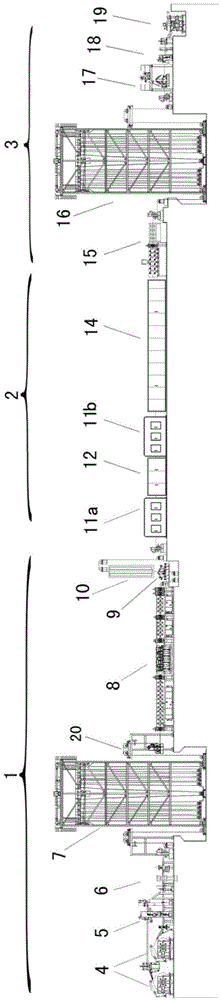

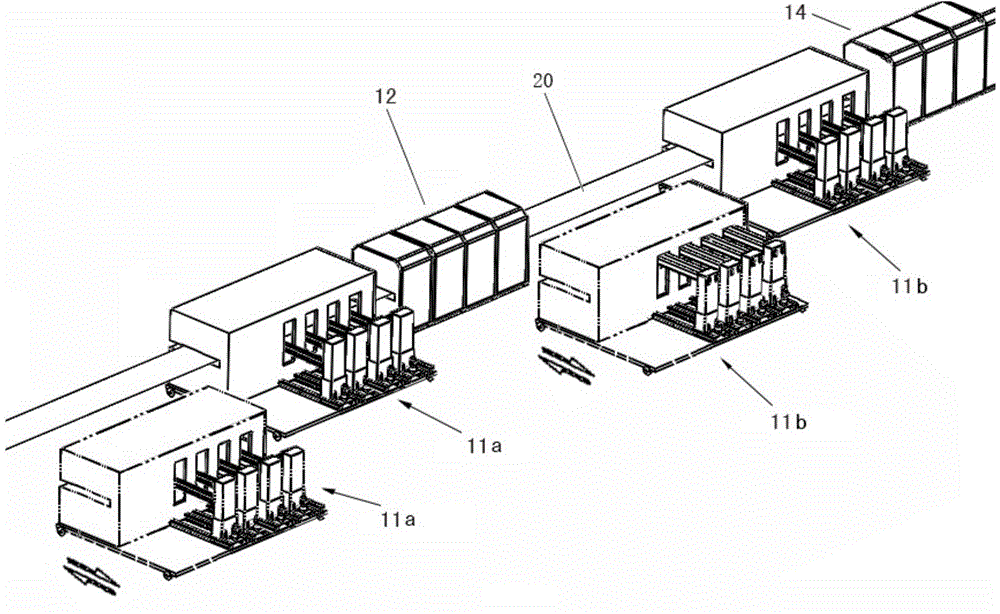

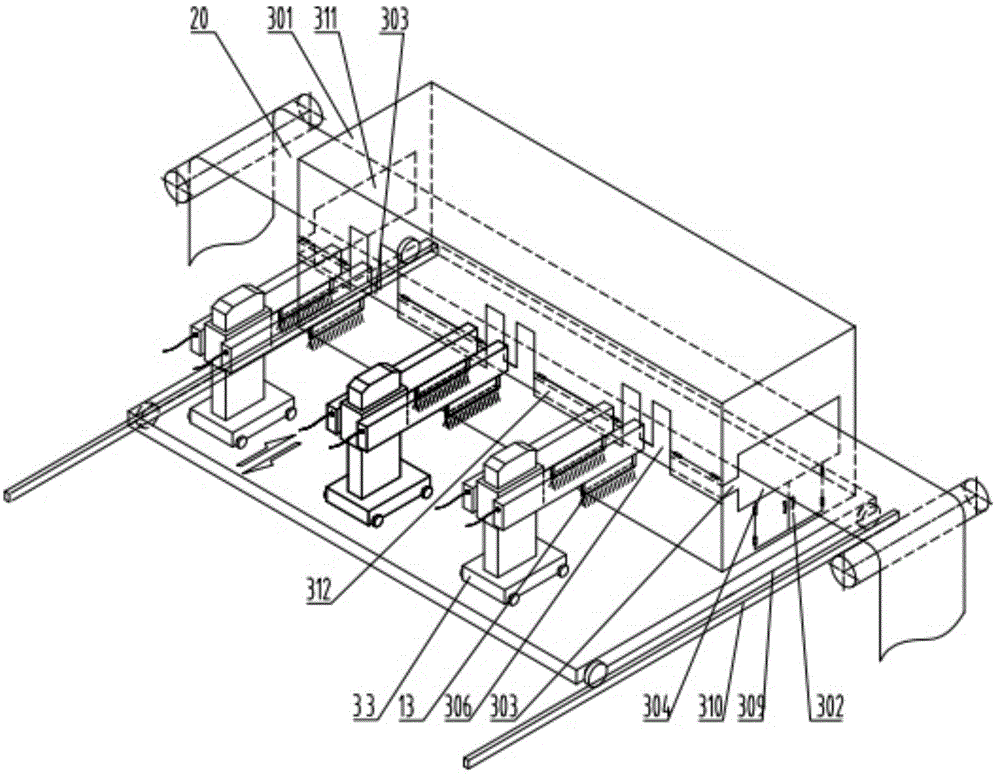

Continuous powder coating production equipment of metal coils and plates and production method thereof

ActiveCN104668139ANot easy to stainNot easy to damageLiquid spraying plantsPretreated surfacesDrying timeOperating speed

The invention discloses continuous powder coating production equipment of metal coils and plates. The continuous powder coating production equipment comprises a coating curing section unit, wherein the coating curing section unit is provided with production coating units and a coating curing oven, the production coating units include a first production coating unit and a second production coating unit, a coating preheating oven is arranged between the two production coating units, and the coating curing oven is arranged behind the second production coating unit and is close to the second production coating unit. The invention further discloses a continuous powder coating production method of the metal coils and the plates. The continuous powder coating production method comprises the following steps of preparing the units, feeding, cleaning, coating electrostatic powder, preheating and curing coatings, and processing finished products. According to the continuous powder coating production equipment and the continuous powder coating production method, continuous electrostatic powder coating production of different colors can be performed on the upper surfaces and the lower surfaces of to-be-coated base materials, a movable powder room is provided, the continuous powder coating production equipment and the continuous powder coating production method have the advantages of short preheating and drying time, mechanization in dustproof protection, large coating area in unit time, low cost, low energy consumption, variety diversity, multiple purposes of one machine and the like, the production operating speed is increased to 150 meters per minute, and the market demand is satisfied.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

High-shrinkage blended yarn and processing method thereof

The invention discloses high-shrinkage blended yarn and a processing method thereof. The blended yarn comprises 80-90% of acrylic fibers, 3-15% of wool fibers, 2-10% of rabbit hair fibers by weight. Part or all of at least one kind of the fibers above are dyed fibers. After being blended uniformly, the dyed and undyed fibers are woven into the high-shrinkage blended yarn by the spinning process. The processing method comprises the following steps: dying the fibers; then spraying oil agent water on the dyed fibers and braising for more than ten hours; weighing and then uniformly blending the fibers in different colors and proportions; and installing the fibers on a spinner to be woven into colored blended yarns. The shrinkage rate of the blended yarn is as high as 15-45%. The products havethe advantages as follows: the products are light, fluffy, soft and satiny, and are strong in moisture absorption, not easy to contaminate and good in heat preservation and the like, and can bring theconsumers with comfort, beauty, dignity and elegance.

Owner:江阴市茂达棉纺厂有限公司

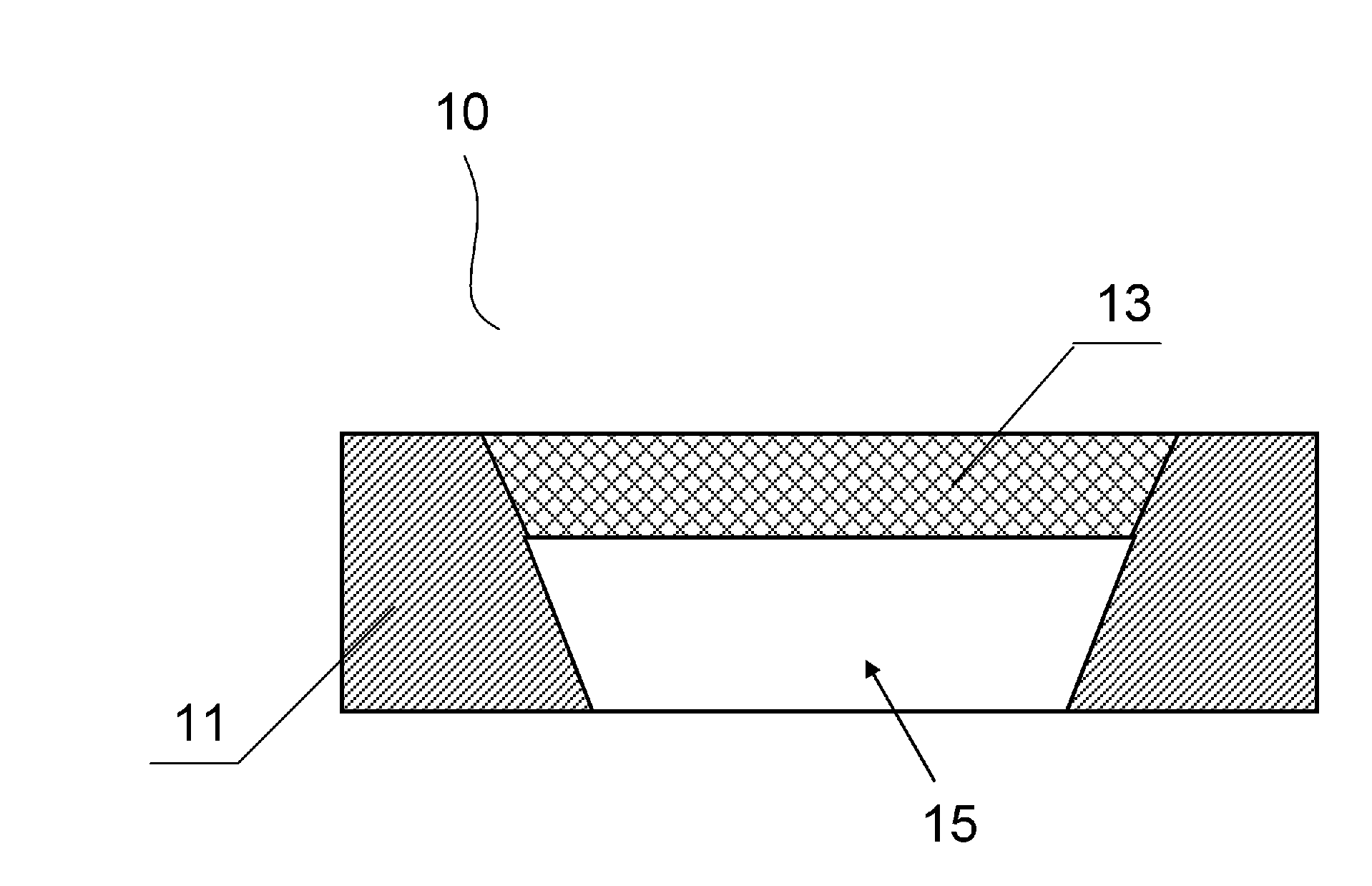

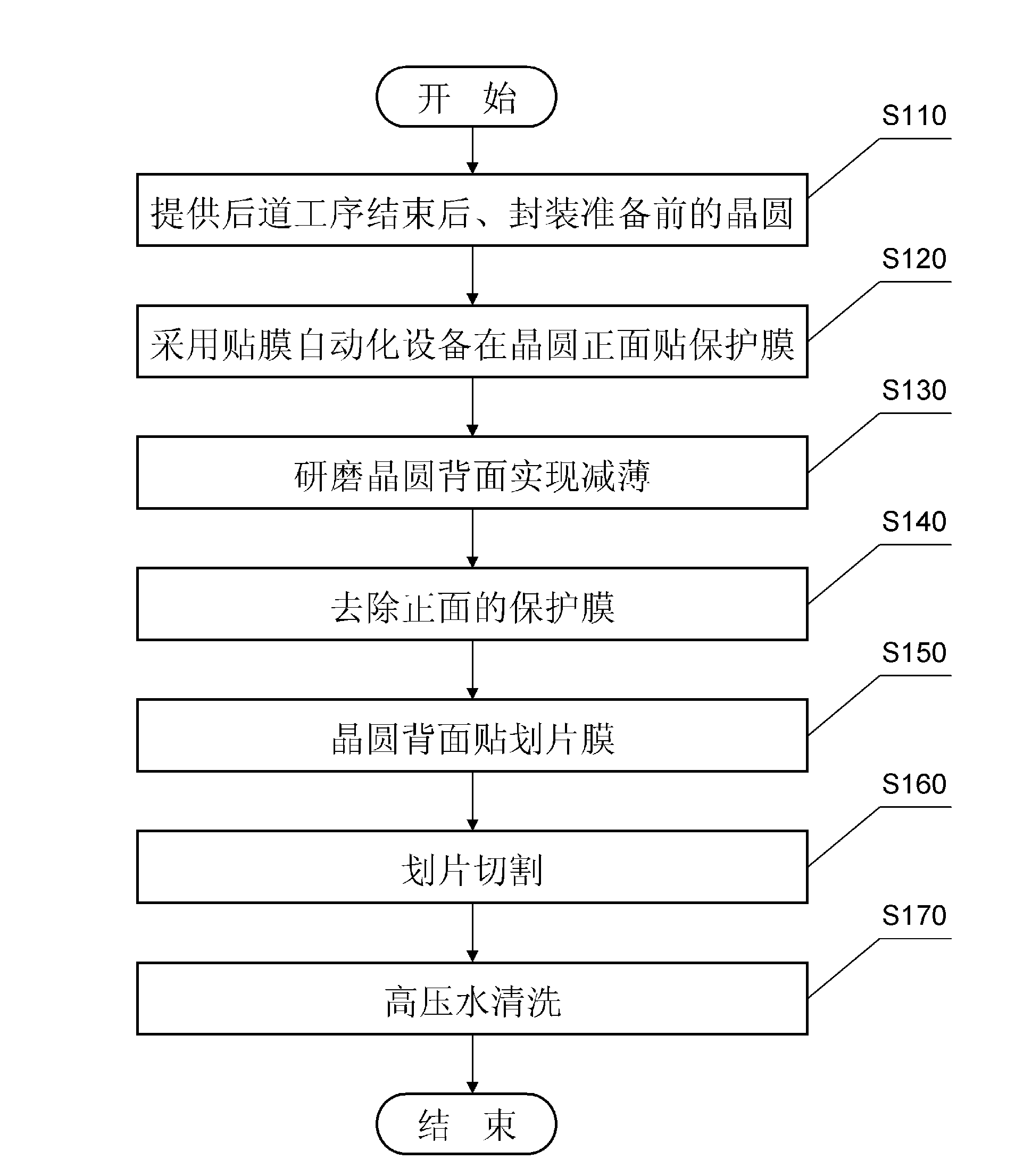

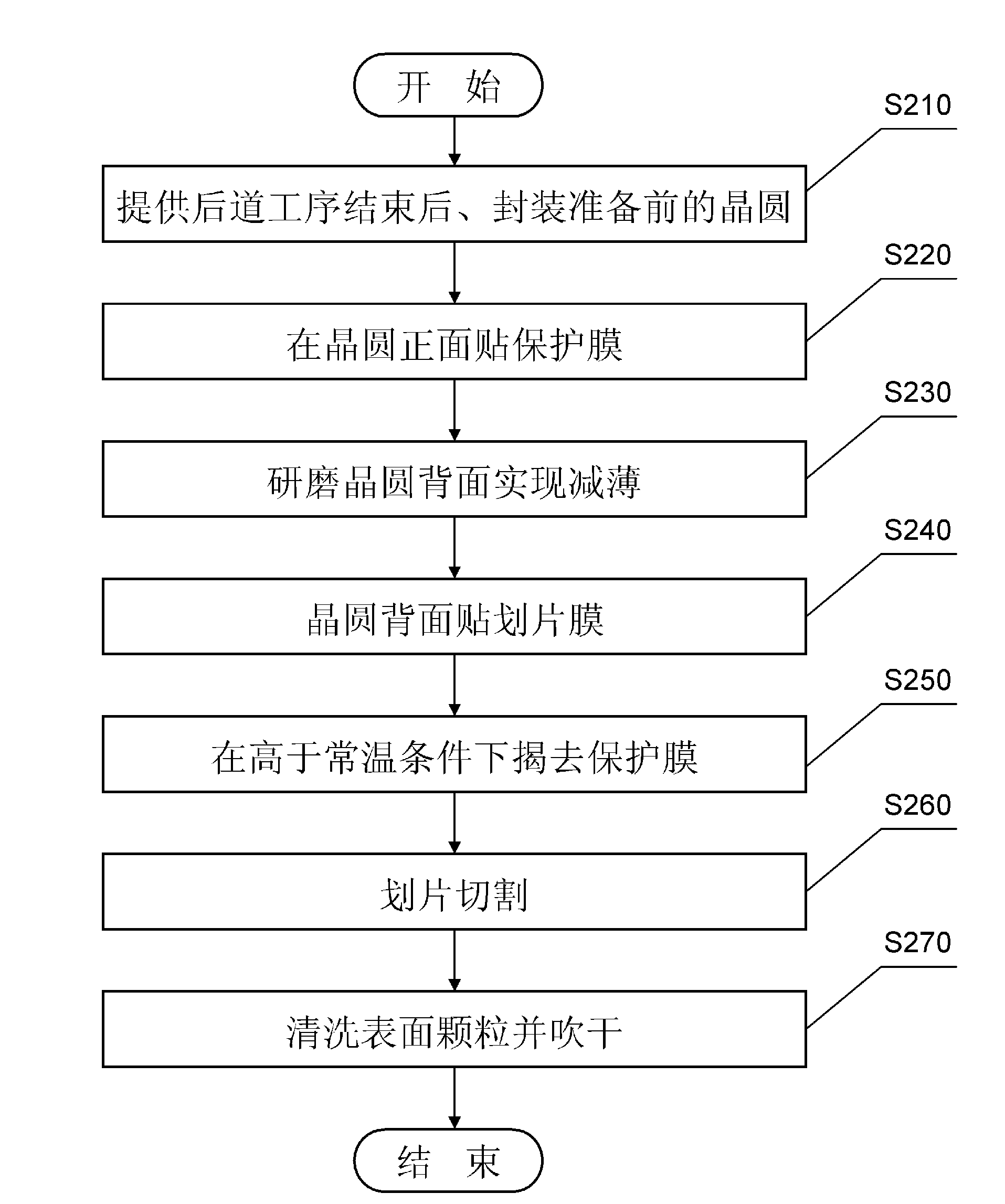

Method of cutting wafer used for preparation of sensor chip into grains

ActiveCN102760699AAvoid breakingAvoid damageSemiconductor/solid-state device manufacturingFine working devicesTectorial membraneRoom temperature

The invention provides a method of cutting wafer used for preparation of a sensor chip into grains, and the method belongs to the technical field of semiconductor chip packaging. The method comprises the steps as follows: (1) a wafer after a latter process is completed and before packaging is prepared is provided; (2) a protective film is pasted on the front of the wafer; (3) the back of the wafer is ground to realize reduction of thickness; (4) a scribing film is pasted on the back of the wafer; (5) the protective film is torn off under a condition above the room temperature; (6) the wafer is scribed and cut; and (7) the grains on the surface of the wafer are cleaned and blown dry. The method has the characteristic that the yield of the cut grains is high.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

Anti-ultraviolet self-cleaning water scattering vehicle glass water

InactiveCN106367217AWith cleaningNot easy to stainInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsScattering functionCoconut oil

The invention discloses anti-ultraviolet self-cleaning water scattering vehicle glass water which comprises the following raw materials in percentage by weight: 97.49-99.48 percent of water, 0.3-0.8 percent of coconut oil diethanolamide, 0.01-2 percent of nano titania and 0.01-0.05 percent of a corrosion inhibitor, and the sum of the percentages by weight of all the components is 100 percent. The anti-ultraviolet self-cleaning water scattering vehicle glass water disclosed by the invention not only has self-cleaning, antibacterial and deodorant functions, but also has an anti-ultraviolet function and a water scattering function.

Owner:焕宇热力科技(昆山)有限公司

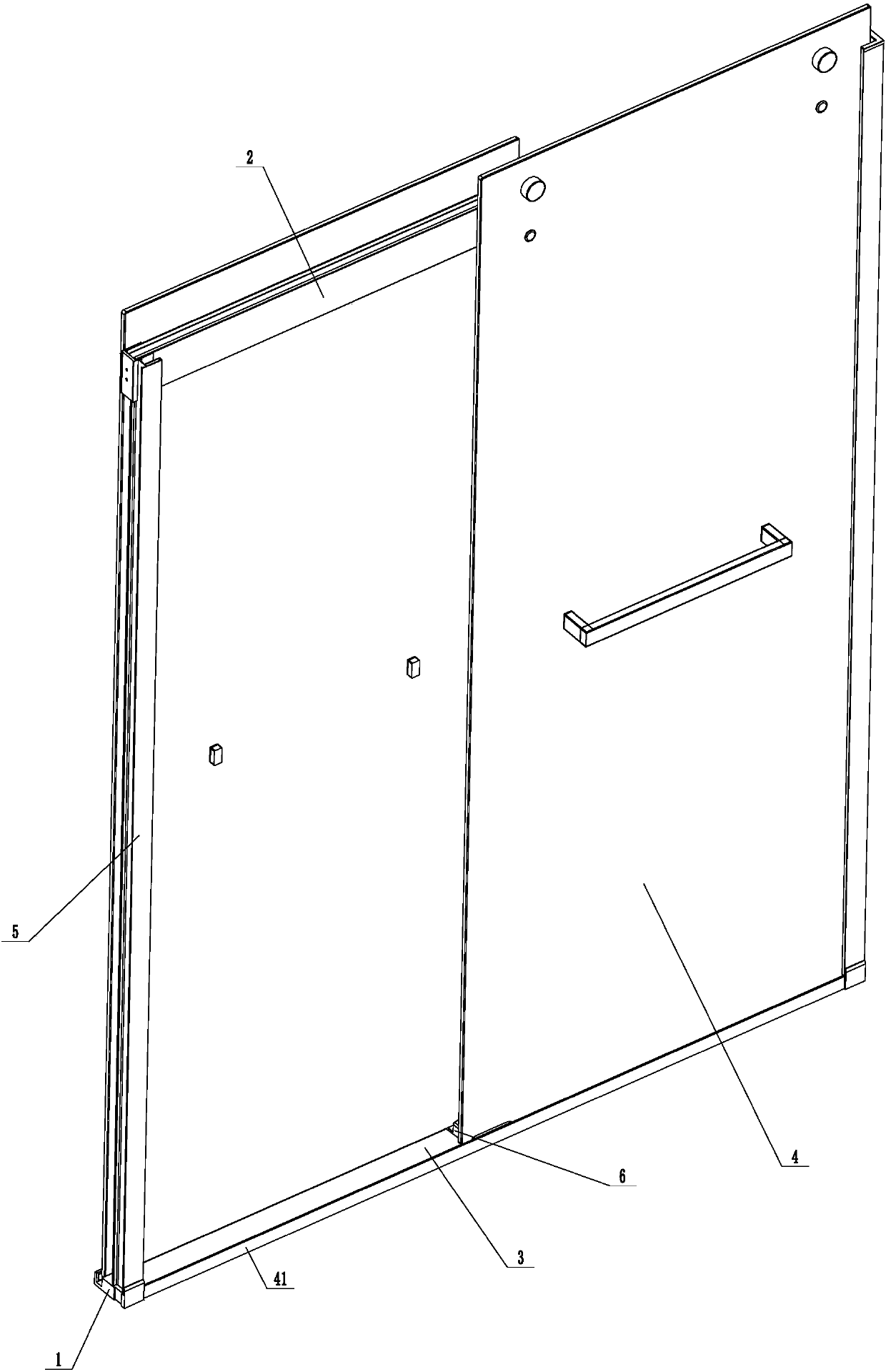

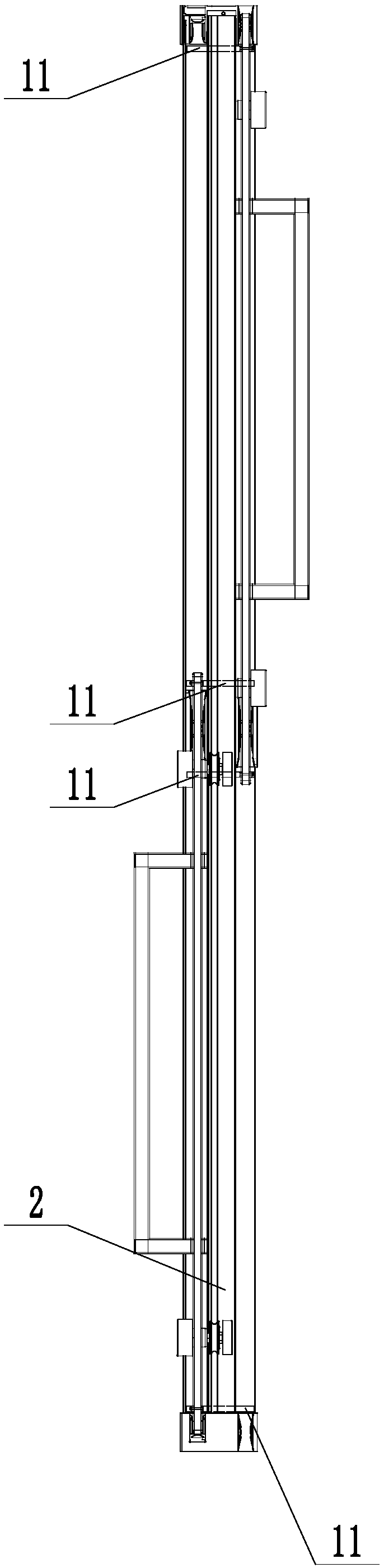

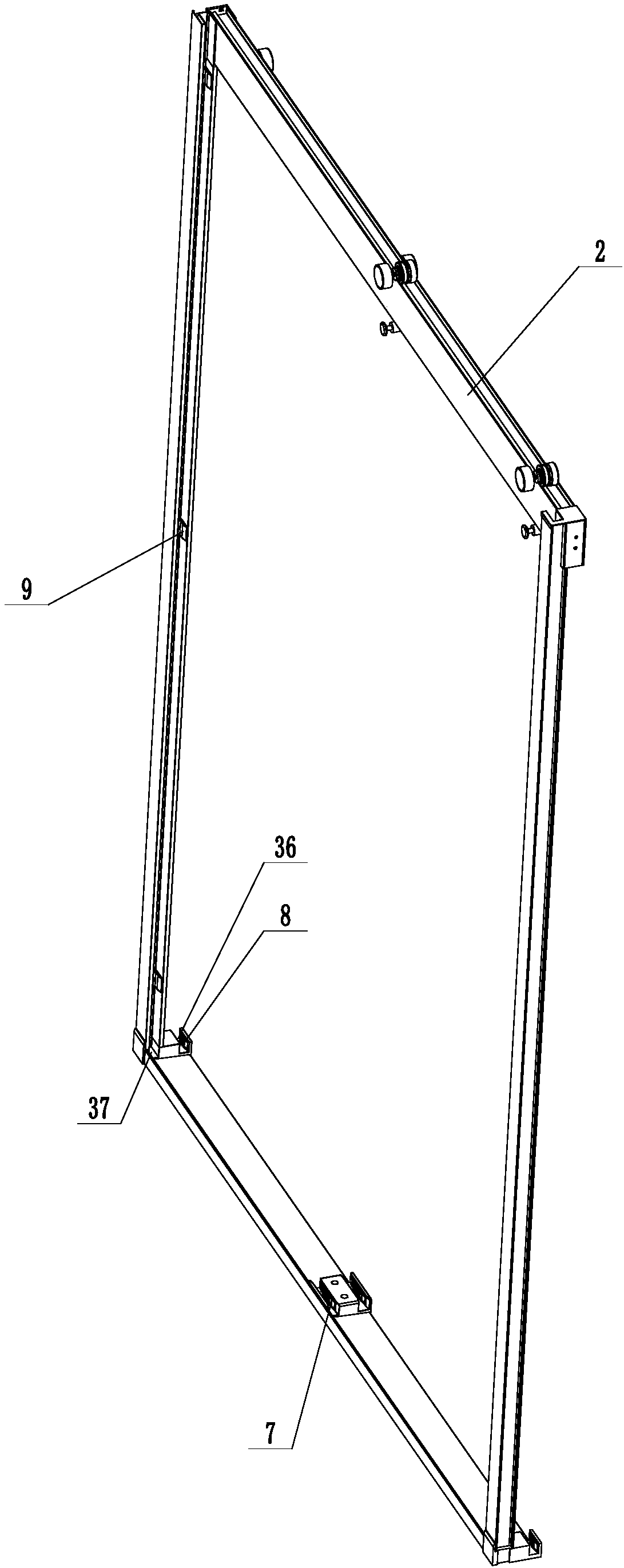

Shower room sliding door structure

ActiveCN107747455AImprove stabilityImprove the anti-collision effectBathsDouchesEngineeringGlass slide

The invention discloses a shower room sliding door structure which aims at solving the problems that an existing normally-used shower room glass sliding door is bad in anti-collision effect in the sliding process, and stains are prone to being left on a supporting crossbeam on the lower portion of the glass sliding door. The shower room sliding door structure comprises an upper crossbeam, a lowercrossbeam, two sliding doors and two vertical beams connected between the two ends of the upper crossbeam and the lower crossbeam. The opposite faces of the two vertical beams are each provided with aplurality of anti-collision seats, and supporting cushions and reset springs are arranged in buffer through holes in the bottoms of the anti-collision seats. The reset springs abut against the supporting cushions, and each supporting cushion is hinged to two symmetrically-arranged connecting rods. Piston cylinders are arranged in the positions, corresponding to the connecting rods, in the anti-collision seats, and pushing pistons are mounted at the opening ends of the piston cylinders. The connecting rods are hinged to the pushing pistons, and air bags are mounted in the buffer through holesin the two side portions of the anti-collision seats. The closed ends of the piston cylinders communicate with the air bags through pipelines, and clearing brushes are connected to the two sides of the lower ends of the sliding doors. The clearing brushes are arranged between the lower ends of the sliding doors and the upper surface of the lower crossbeam and attached to the upper surface of the lower crossbeam.

Owner:ZHEJIANG YUQUAN BATHROOM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com