Ceramic filter film of rare-earth modified attapulgite with nano coating and preparation method thereof

An attapulgite and nano-coating technology is applied in the field of rare earth modified attapulgite nano-coating ceramic filter membrane and its preparation, which can solve the problems of easy cracking and falling off of the membrane layer, poor surface performance, etc. The effect of shedding, light weight and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

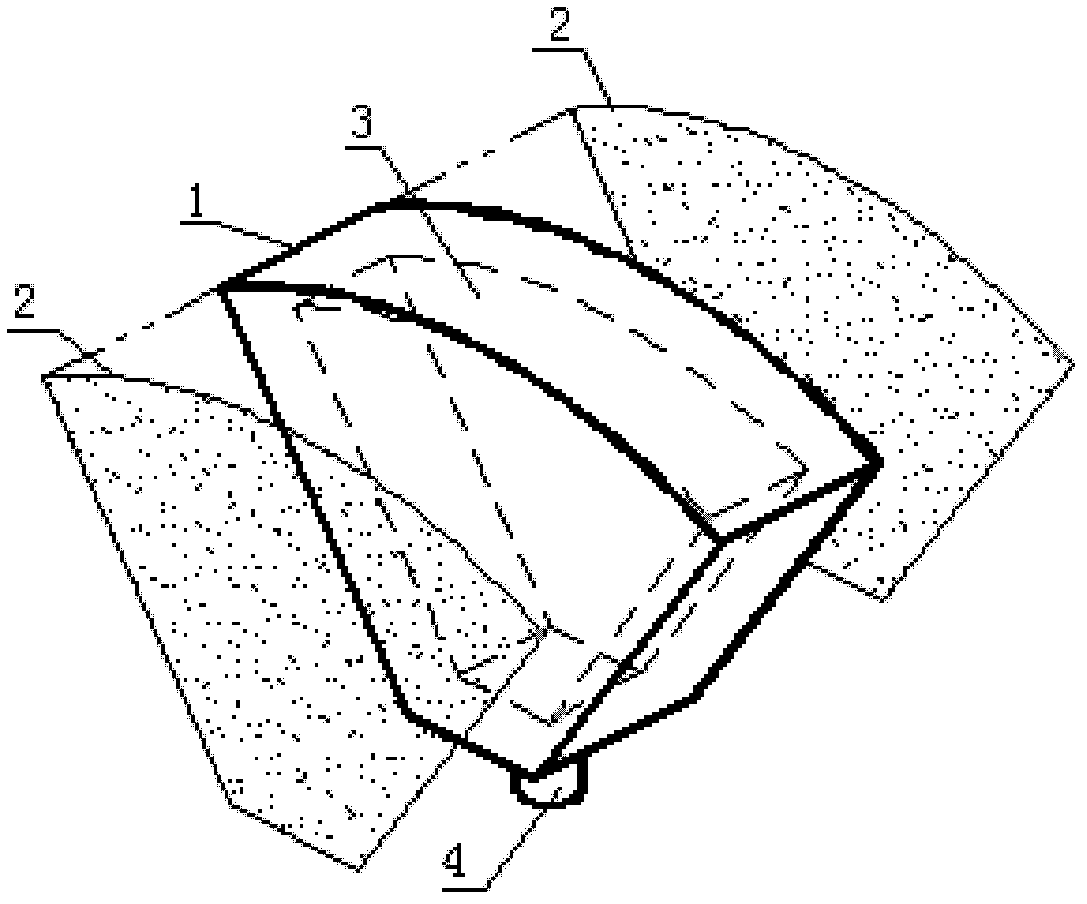

[0036] like figure 1 As shown, the rare earth modified attapulgite nano-coated ceramic filter membrane of the present invention comprises a ceramic support body 1 and a separation membrane 2 arranged on the surface of the ceramic support body, and a hollow cavity 3 is arranged inside the ceramic support body, The bottom end of the ceramic support body is provided with an outflow nozzle 4, and the outflow nozzle communicates with the hollow cavity.

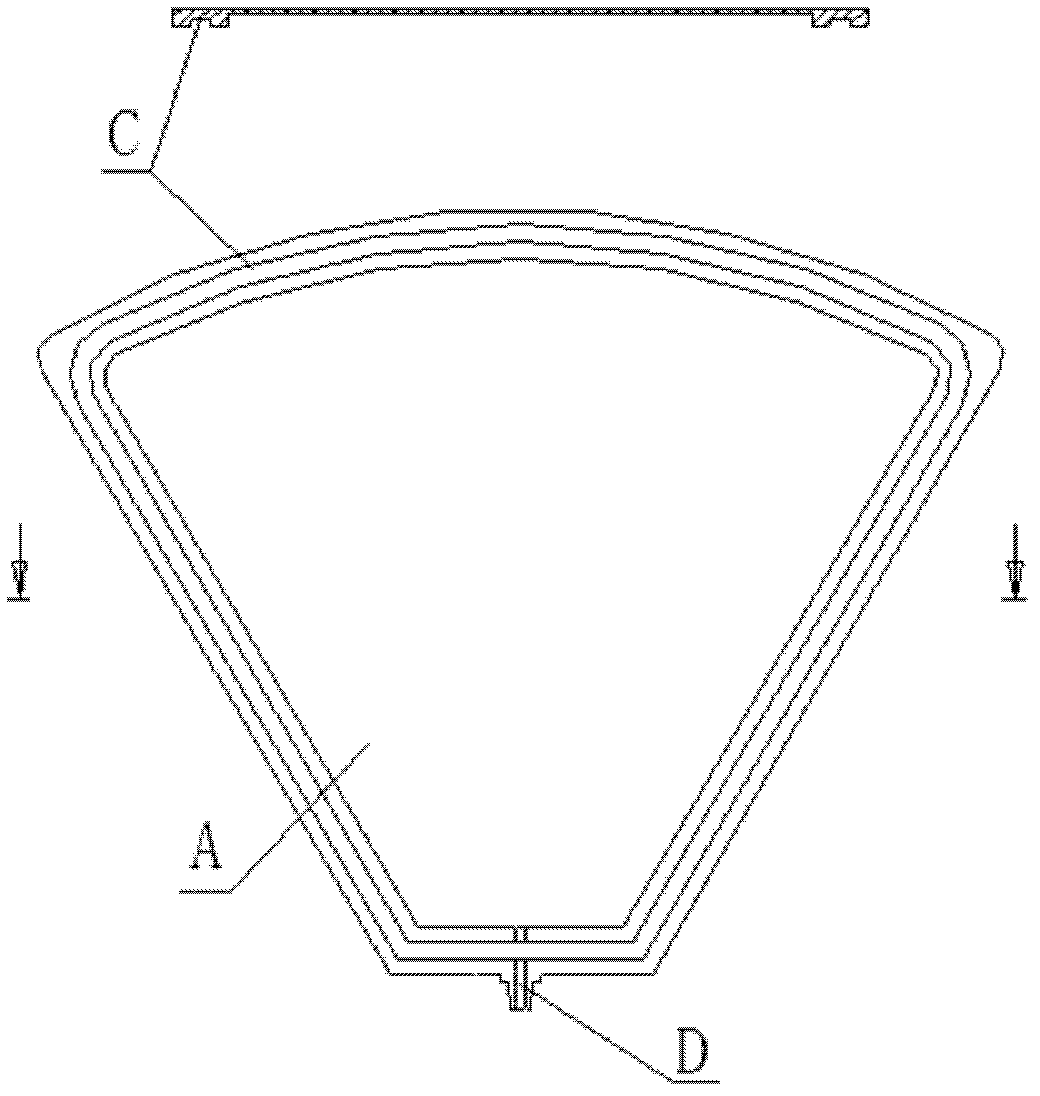

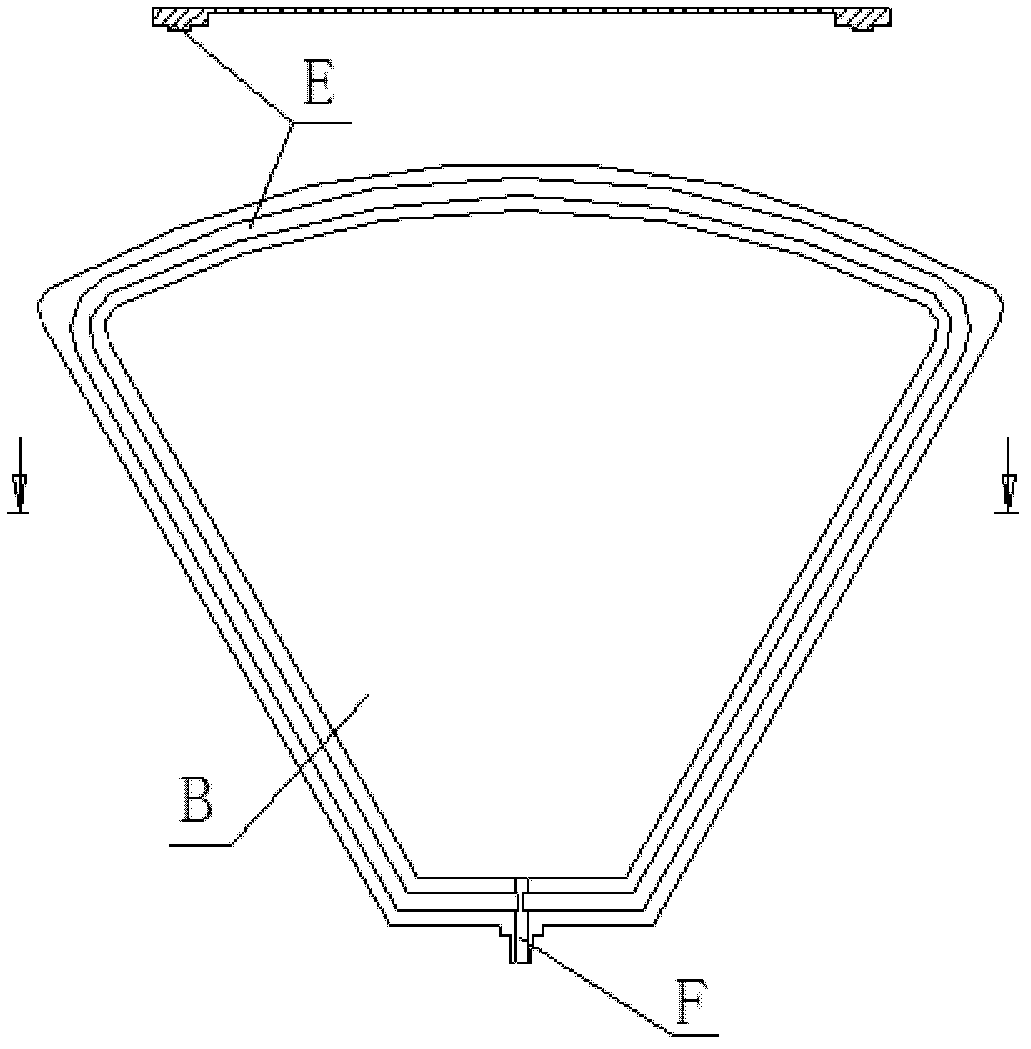

[0037] like figure 2 and image 3As shown in the figure, the ceramic support body is formed by sintering two ceramic blanks, the negative plate A and the positive plate B, which are made respectively. Its shape is a 60° sector, the radius of the sector is 35mm, the thickness of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com