Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Easy delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving discharging-reducing fire coal synergistic addition agent

The invention discloses an additive capable for enhancing energy-conservation and emission-reduction of coals. The product is produced by mixing matrix material, active material and soda lime according to a proper ratio (calculated by weight percent) of 20-30 percent : 30-60 percent : 20-40 percent. The matrix material refers to one of or a mixture of several materials of zeolite molecular sieve, kaolin, bentonite and flyash. The active material consists of oxidant and catalyst. The soda lime is produced by adding industrial solution to limestone, mainly used for swelling and sulfur solidifying. The additive has eminent effect in improving energy conservation and energy efficiency, and capable to reduce emission of flue gas and other harmful gases. The additive is also characterized by simple production process, low cost, small dosage and user-friendly features.

Owner:赵宏

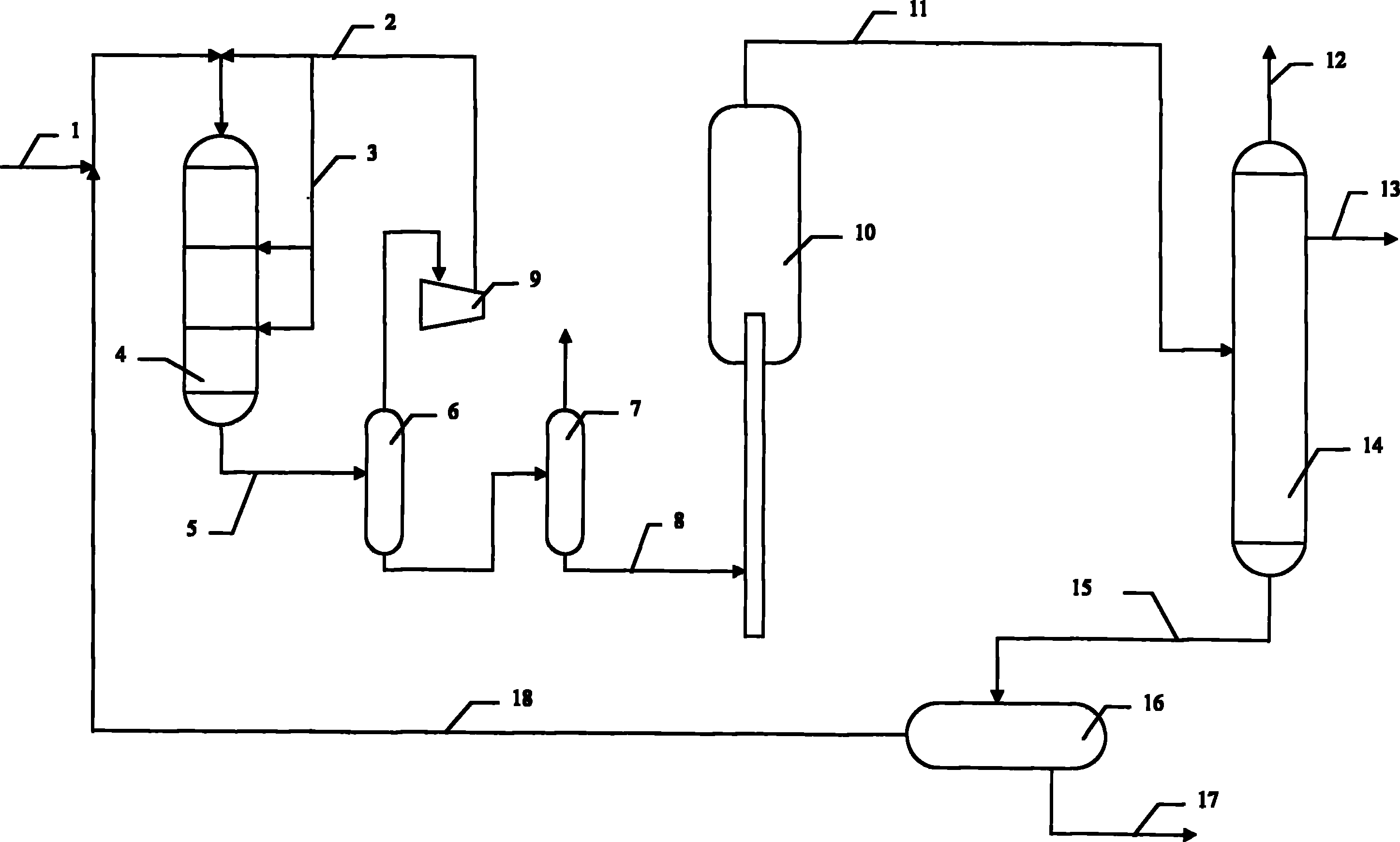

Wax oil hydrogenated treatment and catalytic cracking combined method

ActiveCN101875856AGuarantee normal productionSolve the problem that it is difficult to separate the catalyst solid powderTreatment with hydrotreatment processesGas phaseCombined method

The invention discloses a wax oil hydrogenated treatment and catalytic cracking combined method, which comprises the following steps of: performing hydrogenated reaction on hydrogenated treatment raw materials in the presence of hydrogen and hydrogenated treatment catalyst, performing gas-liquid separation on the hydrogenated reaction effluent, circulating the gas phase for the hydrogenated reaction, directly feeding the liquid phase into a catalytic cracking device without fractionation, and mixing dry gas and liquefied gas separated from the catalytic cracking reaction effluent, catalytic cracking heavy fraction formed by catalytically cracking gasoline and the hydrogenated treatment raw materials to perform hydrogenated reaction. Compared with the prior art, the method can produce maximum gasoline, meanwhile saves equipment investment, makes full use of reaction heat energy and reduces the production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

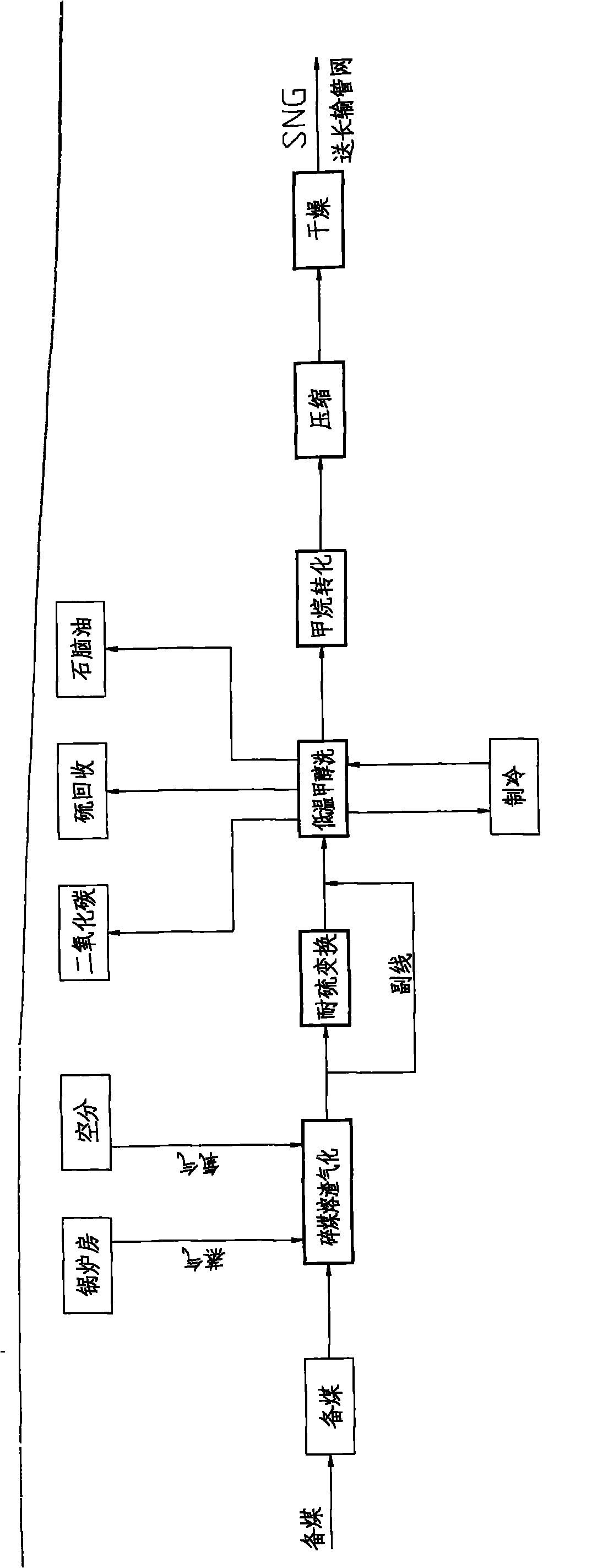

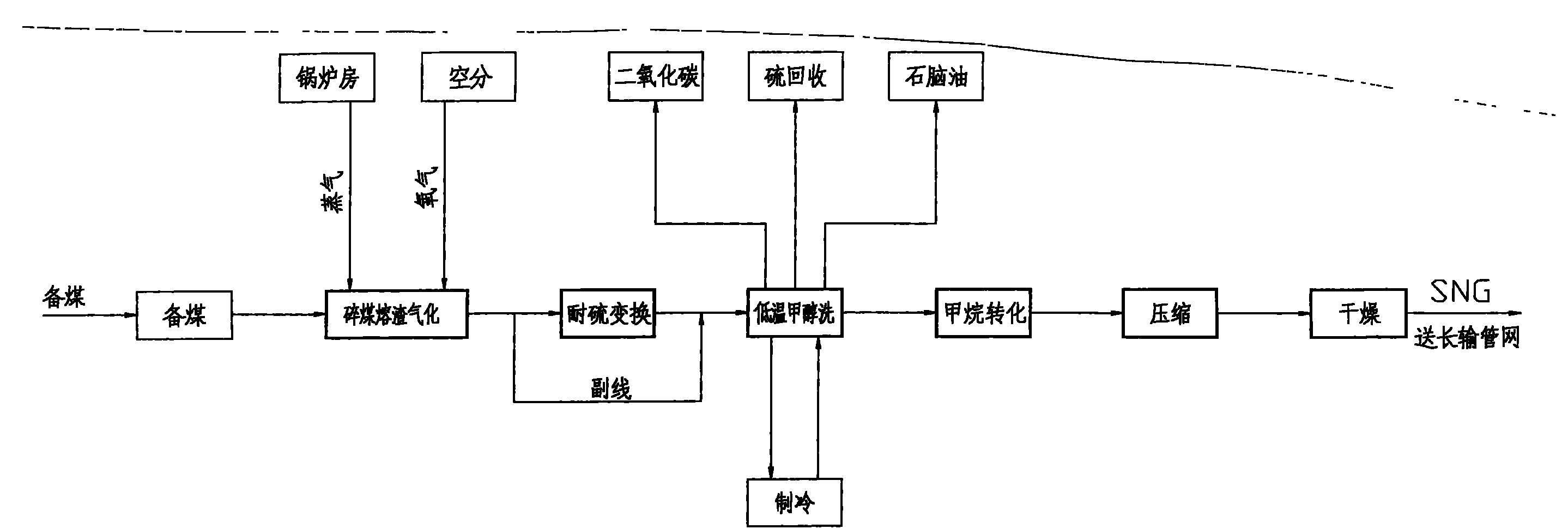

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

ActiveCN101768488AMature and reliable technologyStable operation and maintenanceGaseous fuelsCombustible gas catalytic treatmentNaphthaSulfur

A technique for producing coal natural gas by utilizing crushed coal slag through gasification includes that part of crude coal gas containing CH4 produced by crushed coal slag through gasification receives sulfur tolerant shift, the other part of crude coal gas is conveyed in a sub-line and converges with the gas after sulfur tolerant shift to be cooled, the cooled gas is purified to remove CO2,H2S, naphtha and H2O and other impurities to obtain synthesis gas meeting the methane synthesis H / C ratio, the synthesis gas performs methane synthesis under the effect of methane conversion catalyst, and the methane-synthesis natural gas (SNG) is transmitted in long-distance pipeline network after compression and drying. The invention has the advantages of high gasification rate, high gasification intensity, low consumption and low water content of coal gas.

Owner:SEDIN ENG

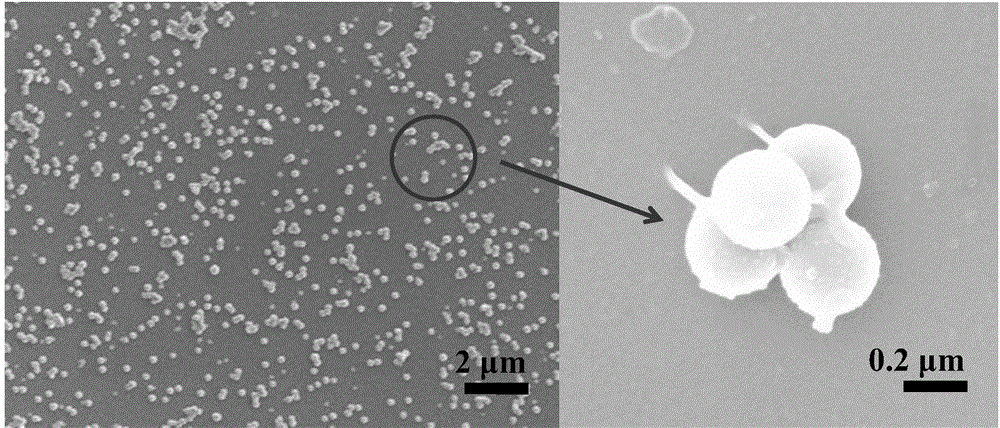

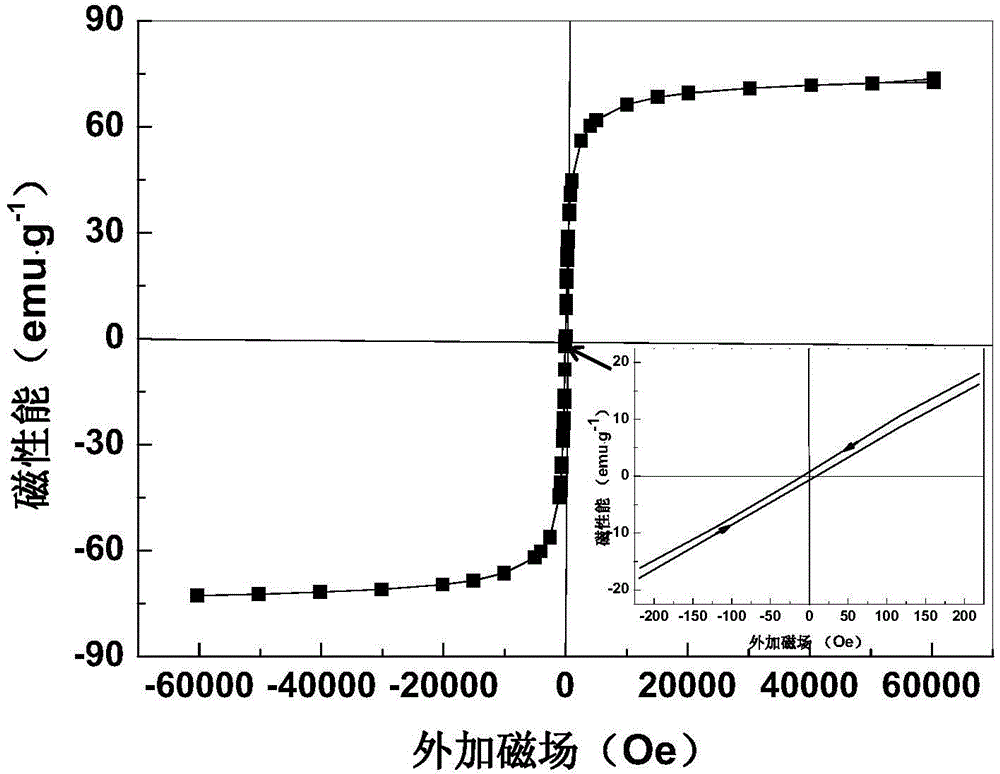

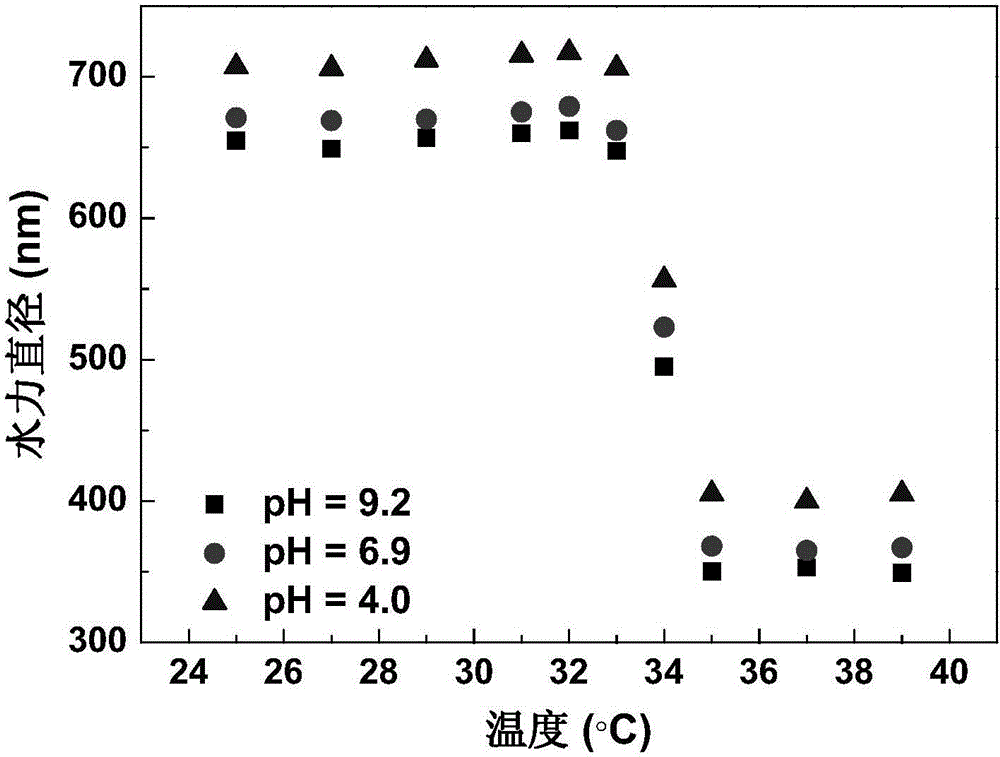

Intelligent hydrogel as well as preparation method and application thereof

ActiveCN104592449ALarge adsorption capacityEasily achieve separabilityOther chemical processesWater/sewage treatment by sorptionSmart hydrogelsDesorption

The invention discloses an intelligent hydrogel as well as a preparation method and an application thereof and a hydrogel. The intelligent hydrogel is P(NIPAM-co-CS) / Fe3O4 and comprises iron oxide, N-isopropyl acrylamide and chitosan. The preparation method comprises the following steps: dissolving FeCl2.4H2O and FeCl3.6H2O in a mixed solvent of ethanol and water and reacting to prepare hydrophilic Fe3O4 nanoparticles under the protection of nitrogen and by adopting ammonia water as a precipitating agent; ultrasonically dispersing the prepared Fe3O4 nanoparticles in a chitosan liquid, adding a temperature-sensitive monomer N-isopropyl acrylamide and in the presence of a crosslinking agent and an initiator and by adopting tetramethylethylenediamine as an accelerator, carrying out polymerization reaction to prepare the intelligent hydrogel P(NIPAM-co-CS) / Fe3O4 by virtue of a micro-emulsion polymerization method. The intelligent hydrogel can be applied in the preparation of a water body heavy metal ion adsorption-desorption agent for removing heavy metal ions in water body.

Owner:XIAMEN UNIV

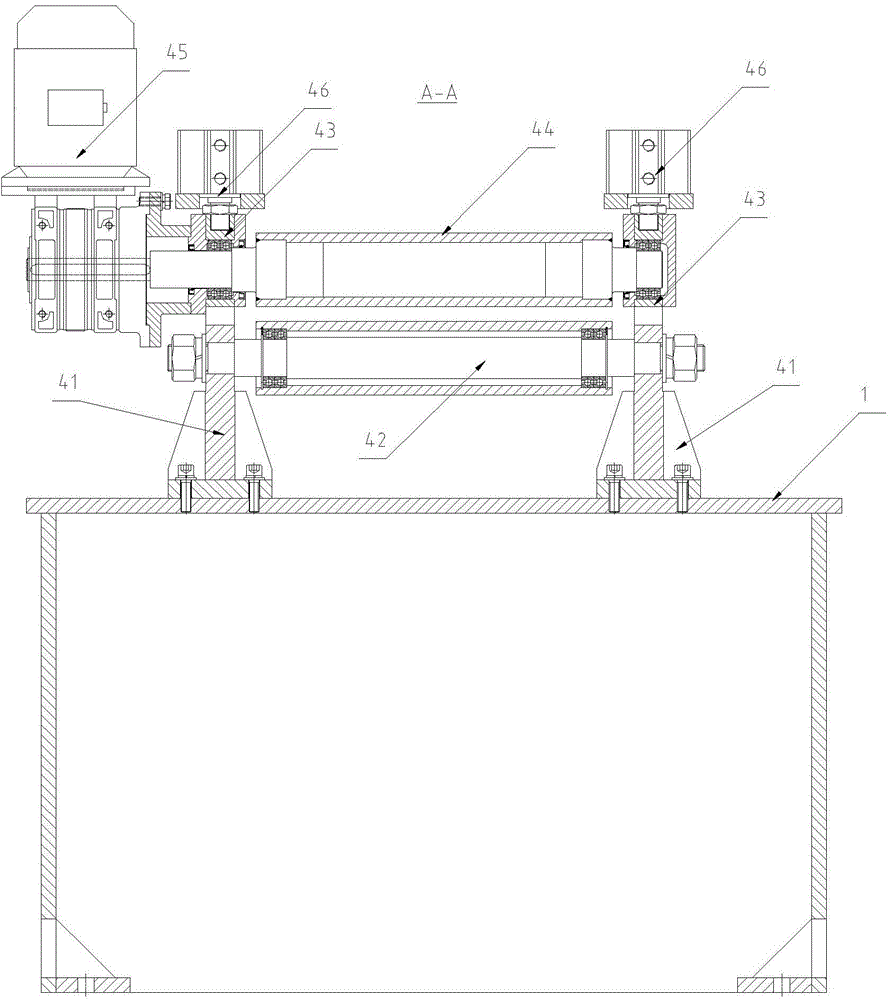

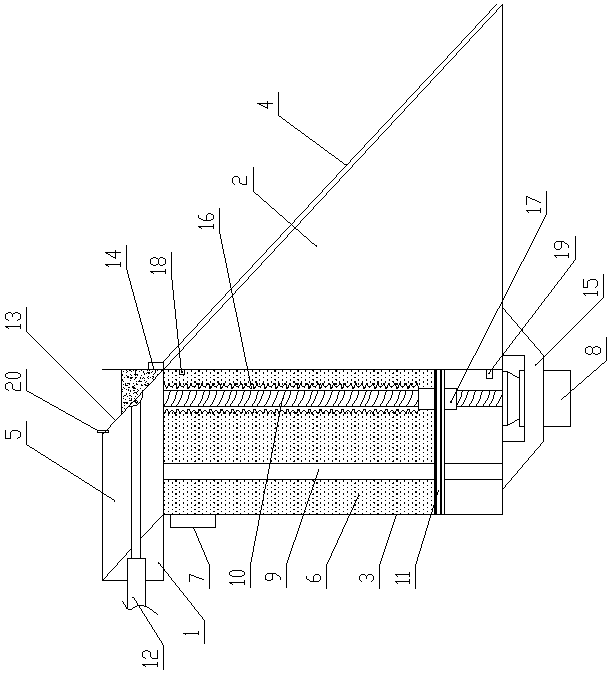

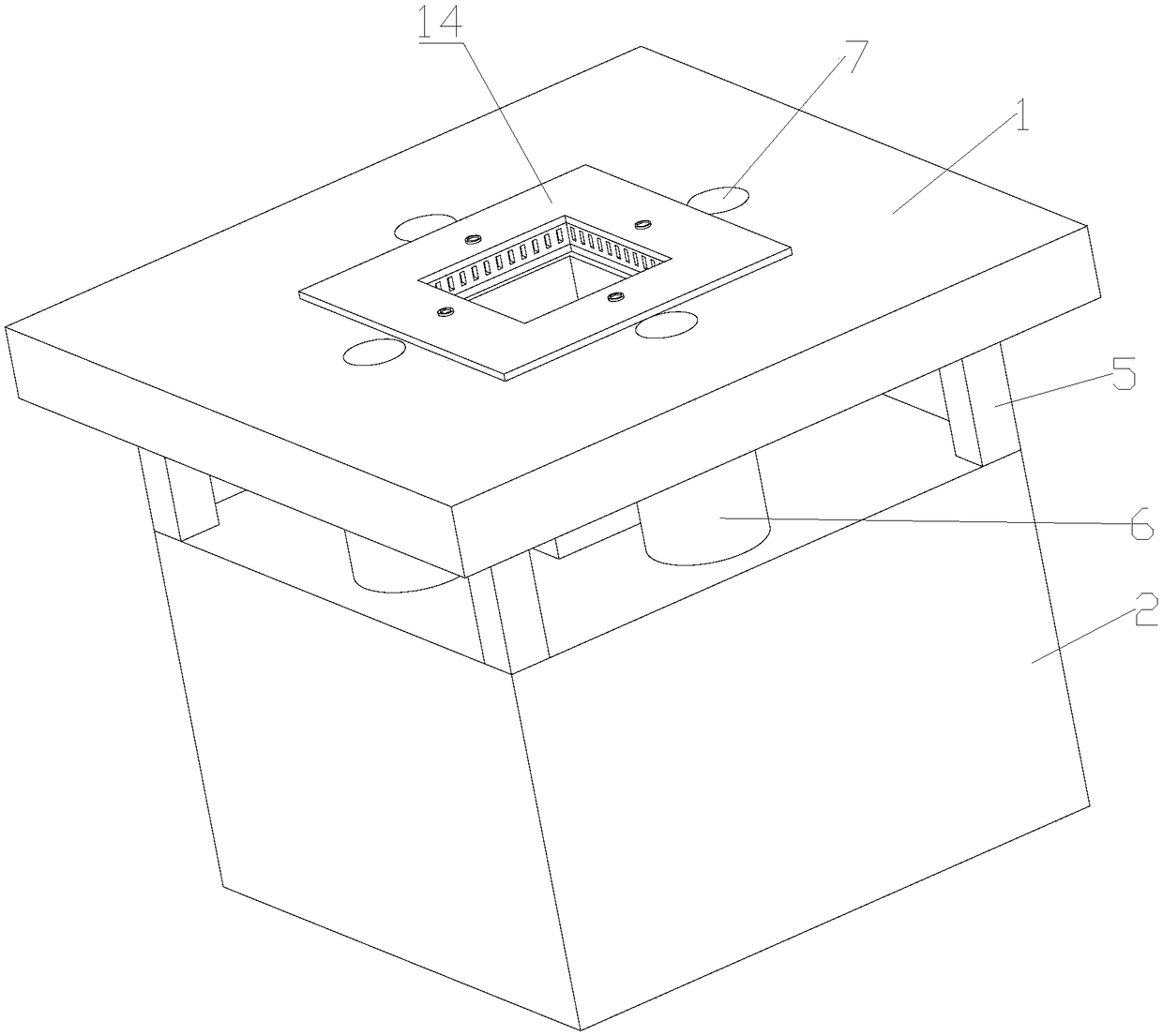

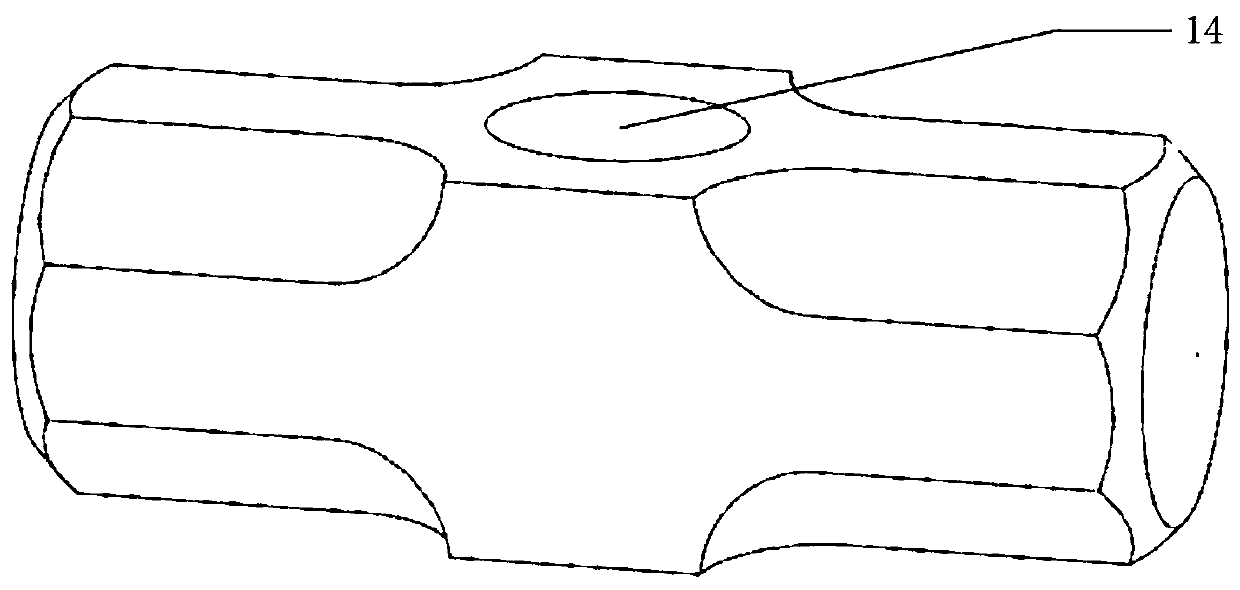

Butt welding platform for steel band

ActiveCN104384803AEasy deliveryReduce resistanceWelding/cutting auxillary devicesAuxillary welding devicesForce outputPiston rod

The invention discloses a butt welding platform capable of automatically adjusting the position of a steel band on the platform and enabling the steel band to be smoothly conveyed. The butt welding platform comprises a base, wherein a clamping butting device is arranged on the base; guide devices are respectively arranged on two sides of the clamping butting device on the base; a clamping conveying device is arranged on one side, which is far away from the clamping butting device, of each of the two guide devices on the base and comprises two brackets arranged on the base; a lower pressing roller is erected between the brackets; sliding chutes are formed in the middle of the brackets; sliding blocks are arranged in the sliding chutes; an upper pressing roller matched with the lower pressing roller is erected between the sliding blocks on the two brackets; one end of the upper pressing roller is connected with a force output shaft of a clamping conveying motor arranged on the sliding block at the end; stroke-adjustable pressurization cylinders are arranged on the tops of the brackets; through holes communicated with the sliding chutes are formed in the upper parts of the brackets; the end parts of piston rods of the pressurization cylinders penetrate through the through holes and are connected with the sliding blocks.

Owner:张家港市中悦冶金设备科技有限公司

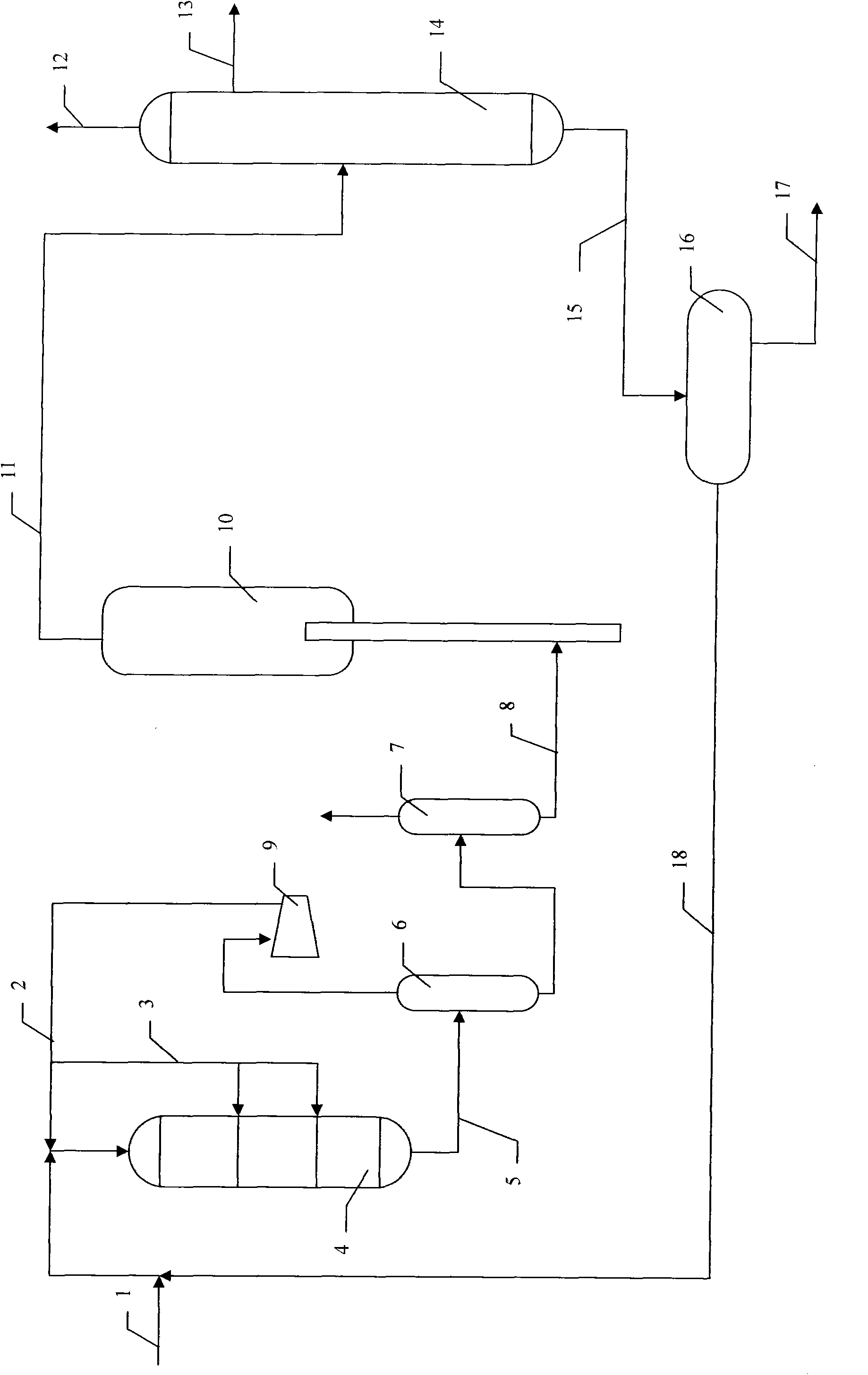

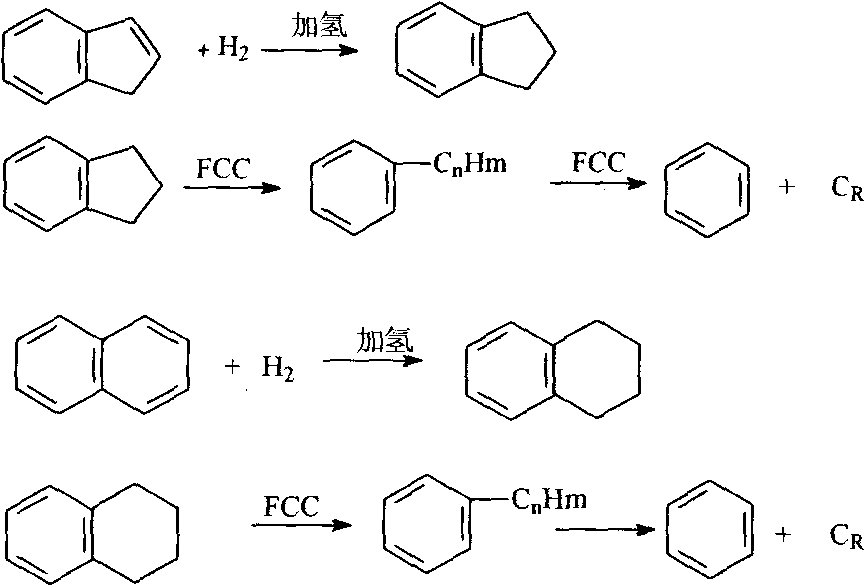

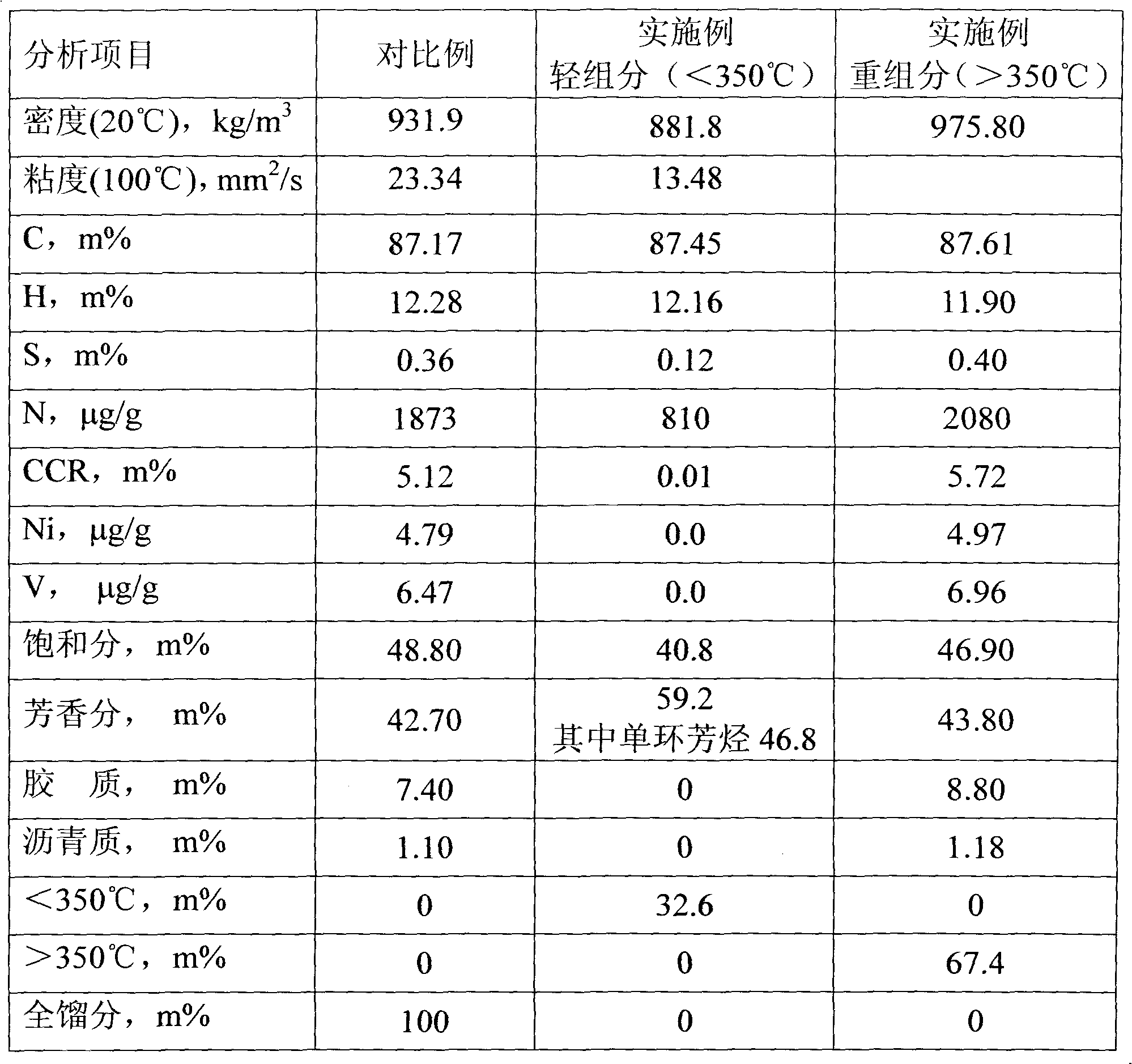

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732314AHigh aromatic contentHigh content of impurities such as sulfurTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of a catalytically cracked diesel fraction undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked recycle oil and catalytically cracked slurry are separated out; a part or all of the catalytically cracked diesel fraction is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction; and the catalytically cracked recycle oil is fed back to the catalytic cracking device and then undergoes a catalytic cracking reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

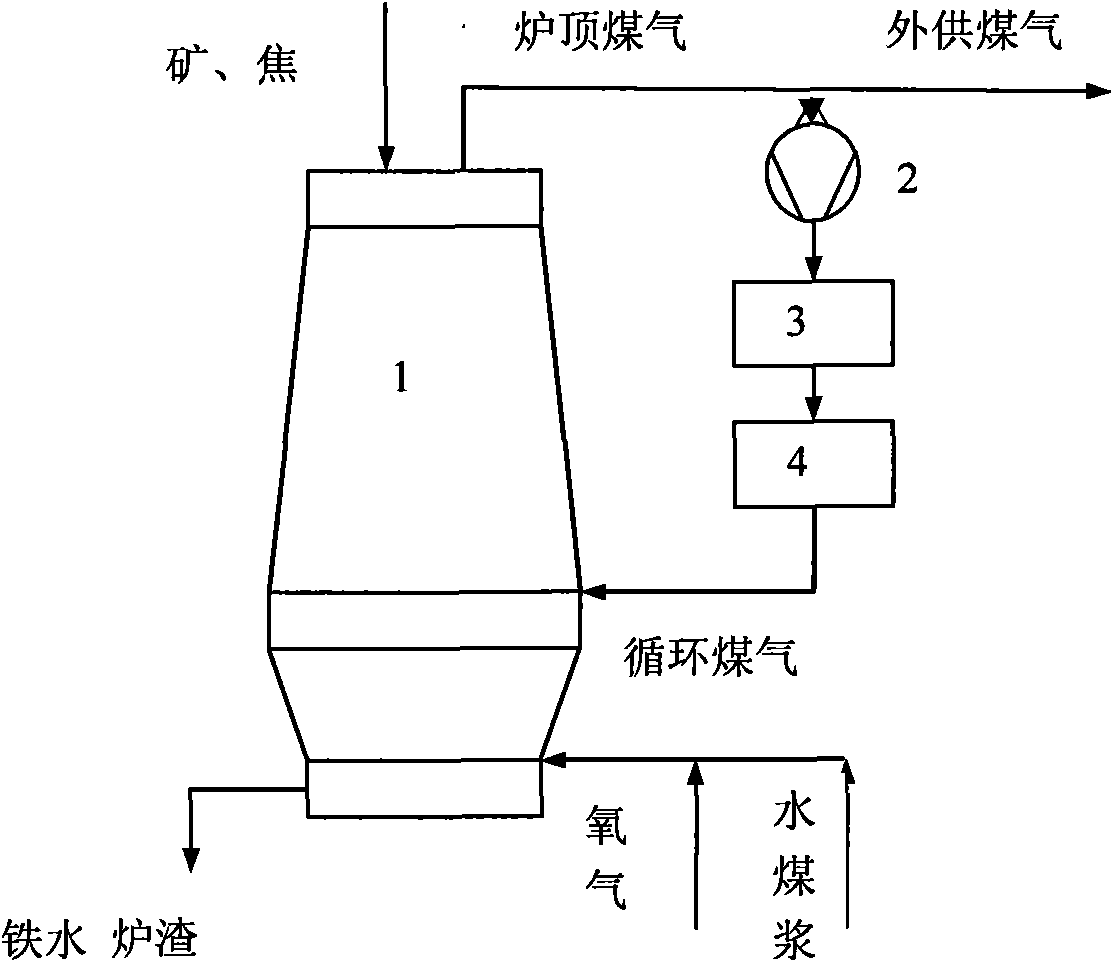

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

InactiveCN101555533AImprove productivityReduce adverse effectsBlast furnace detailsDecompositionCoal dust

The invention belongs to the field of ferrous metallurgy and relates to a blast furnace iron-making process using water-coal-slurry as fuel and reducer for iron-making. The process using water-coal-slurry is simple and safe, and the injecting process of water-coal-slurry provides convenience for accurate control and precise measurement. A water-coal-slurry oxygen blast furnace utilizes normal-temperature oxygen and water-coal-slurry as fuel which is injected into the blast furnace so as to partially displace coke and coal dust; the injected amount of oxygen is 200 to 500 Nmt HM, the injected amount of water-coal-slurry is 200 to 400 Nm / t HM, the required weight ratio between coal and water in the water-coal-slurry is 7:3, and the required thermal value of the water-coal-slurry is larger than 20 MJ / kg. The water-coal-slurry is decomposed and burnt to generate water-gas reaction in a circulation zone of a blast-furnace tuyere, the absorbed heat can be adopted to solve the problem of 'lower hot' caused by smelting with prior oxygen blast furnaces, and a large amount of gas generated by the decomposition and burning of the water-coal-slurry raises and can relieve the problem of 'upper cold' caused by the full-oxygen injection of the blast furnace; and the water-coal-slurry oxygen blast furnace contains rich H2 so as to enhance the penetrating power and reduction performance of blast-furnace coal gas, raise the indirect reduction degree of the blast furnace and reduce the emission amount of CO2 by 200 to 500 Nm / t HM. The process reduces both manufacturing cost and pollution to environment.

Owner:UNIV OF SCI & TECH BEIJING

Medicine for preventing fish bacterial enteritis

InactiveCN101757605AGood treatment effectEasy deliveryAntibacterial agentsOrganic active ingredientsDiseaseBacteroides

The invention discloses medicine for preventing fish bacterial enteritis, and relates to the field of aquaculture, in particular to Chinese and western compound medicine for preventing fish diseases. The medicine comprises the following components by weight parts: 10 to 20 parts of colistin sulfate, 30 to 50 parts of rhubarb, 40 to 60 parts of radix isatidis and 10 to 20 parts of garlicin. The medicine of the invention adopts a Chinese and western compound prescription, overcomes the problems that the fish suffers from bacterial enteritis in high-temperature seasons and the bacterial enteritis is easy to reoccur, has very good treatment effect to inflammatory bowel diseases caused by aeromonas hydrophila and other bacteria, and is characterized by significant therapic effect and no any toxic and side effect.

Owner:TIANJIN SHENGJI GRP CO LTD

Efficient nano fuel coal reinforcer and its prepn

The fuel coal intensifier consists of active matter and carrier. By means of multi-element nano mesopore assembling technology, active matter is assembled into nano holes in carrier to obtain the high-activity long-acting fuel coal intensifier. The carrier is zeolite molecular sieve, pearlite, Kaolin, bentonite or their mixture; and the active matter consists of oxidant, catalyst, puffing agent, sulphur fixing agent and activating agent and includes the compound of K, Na, Mn, Co, La, Zn and Ce as well as ethyl hydrogen silane. The intensifier can raise heat efficiency obviously, save coal, fix sulphur and reduce dust and its cost is low.

Owner:青岛科亚纳米有限公司

Combined roller bed

ActiveCN105460488AEasy to liftSmooth rotationRoller-waysStructural engineeringIndustrial engineering

The invention relates to a combined roller bed which is characterized by comprising a base, a floating frame, a lifting guide connecting mechanism, a lifting driving mechanism, a conveying mechanism and a rotating mechanism, wherein the floating frame is connected to the base through the lifting guide connecting mechanism and can lift and move under the driving of the lifting driving mechanism; the conveying mechanism is mounted on the conveying mechanism and is used for supporting and driving a workpiece to transversely move and convey when the floating frame lifts up to a high position; the rotating mechanism is mounted on the base and is used for supporting and driving the workpiece to rotate around the axis of the workpiece when the floating frame lifts down to a low position. The combined roller bed has functional diversity and can conveniently realize the lifting, rotation and conveying of the cylinder workpiece. Workpiece cutting and welding can be carried out on the roller bed, most production demands are met, and the production efficiency is improved. The combined roller bed has the advantages of compact in structure and low in maintenance cost.

Owner:WUXI HUALIAN SCI & TECH GROUP

Combined artificial fish reef

InactiveCN105010175AVarious functionsEasy deliveryClimate change adaptationPisciculture and aquariaImpellerSeawater

The present invention relates to the technical field of an artificial fish reef, and discloses a combined artificial fish reef that comprises a fish reef body and a suspension substrate. The fish reef body comprises a base, a rotary shaft that is perpendicular to the base, and a plurality of fish reef base blocks that are disposed on the rotary shaft; the fish reef base blocks are separately rotatably-connected with the rotary shaft; a side surface of each fish reef base block is provided with a plurality of cavities; a side surface of a concrete base block is further provided with a plurality of inclined impellers; an upper end of the rotary shaft is provided with a connecting block; a bottom of the suspension substrate is provided with a plurality of connecting grooves; a metal bar that is apt to be corroded by seawater is provided in each connecting groove; an upper end surface of the connecting block is provided with connecting rings that correspond to the connecting grooves in quantity; the metal bar runs through the connecting rings so that the fish reef body and the suspension substrate are connected together; a lower end center of the suspension substrate is connected, by a steel strand, with the connecting block. The combined artificial fish reef is convenient to come into use as a whole and controls the state of the fish reef body on the seabed so as to prevent the fish reef body from being blocked.

Owner:ZHEJIANG OCEAN UNIV

Hydrotreatment and catalytic cracking deeply-combined method for residuum

InactiveCN102732315AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking deeply-combined method for residuum. The hydrotreatment and catalytic cracking deeply-combined method for residuum comprises the following steps that a residuum raw material, at least part of catalytically cracked heavy recycle oil and at least part of catalytically cracked slurry undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil and the catalytically cracked slurry are fed back to the hydrotreatment device and then undergo a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking deeply-combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

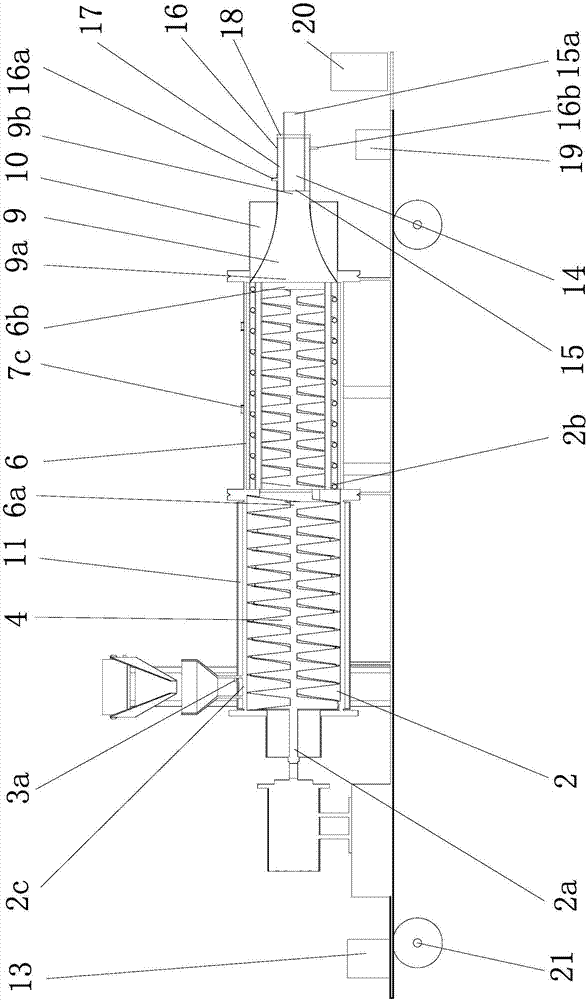

Special type sludge dewatering extrusion granulator

InactiveCN101121107AReduce energy consumptionSave energySludge treatment by de-watering/drying/thickeningGranulation by material expressionWater vaporScrew thread

The present invention provides a novel technical device of sludge dehydration and belongs to the solid waste disposal field. The device is applicable to the dehydration and granulation requirements of sludge with various components. A single screw and reverse screw threads and a peculiar structure arrangement are adopted to make the water of the sludge (a moisture content of which is about 80 percent) is dehydrated as a form of liquid, and make the sludge form a sludge dehydration and granulation process, the moisture content of which is 30 percent to 35 percent. A special sludge dehydration and granulation machine fills a blank that the sludge dehydration has to be dehydrated as the form of water vapor, which greatly reduces the energy cost of the sludge dehydration. With small size, low operation cost, high production efficiency, high mechanization degree and wide scope of application, the present invention is a novel and most energy-saving and cleanly-produced sludge dehydration device.

Owner:朱清海

Automatic screw driving device

PendingCN107470898AEfficient delivery methodSimple structureMetal working apparatusEngineeringAutomation

The invention discloses an automatic screw driving device. A workbench is provided with an automatic screw feeding mechanism, a screw guiding tube, an automatic screw driving mechanism and a workpiece feeding mechanism, and the automatic screw feeding mechanism, the automatic screw driving mechanism and the workpiece feeding mechanism are fixed to the workbench by screws. The screw guiding tube is connected between the automatic screw feeding mechanism and the automatic screw driving mechanism, and the vibration disk of the automatic screw feeding mechanism is fixed to a vibration disk installation plate by screws. According to the automatic screw driving device, automatic screw driving is basically realized, the problems that screws are prone to loosing or gear smooth is caused by over high twisting force because the manner of manual screw driving is adopted in traditional assembly operation, the production efficiency is low, the labor cost is high, screw driving is inaccurate, and the twisting force for screw driving is over low are solved, and meanwhile, the defects of the existing screw driving machines in the market of being uncontrollable in pressure and low in safety and degree of automation are overcome.

Owner:上海莘翔自动化科技有限公司

Mixed feed stirring device

InactiveCN109012379AGood effectEasy deliveryRotating receptacle mixersShaking/oscillating/vibrating mixersMixed feedEngineering

The invention discloses a mixed feed stirring device. The device comprises a first bracket, a first support plate, a first motor, a box body, a transmission mechanism, a second support plate, a secondmotor, a feeding port, a first spiral blade, a rotating shaft, a feeding tube, a telescopic motor, a lifting rod, a second bracket, a stop valve, a water inlet tube, a motor seat, a third motor, nozzles, a spraying tube, stirring rods, a stirring shaft, a second spiral blade, a valve, a discharging port, a storage box, a third bracket, a stirring box, a rotating seat and a stirring barrel. The second motor drives the rotating shaft to rotate in order to drive the first spiral blade to rotate and convey a feed into the feeding tube, the stirring barrel is arranged on the rotating seat, the transmission mechanism is connected between the rotating seat and the first motor, and the first motor drives the rotating seat to rotate through the transmission mechanism in order to drive the stirringbarrel to rotate. The device has the advantages of excellent use effect, convenience in material feeding, high efficiency and fastness in stirring, high fullness and uniformity in stirring, convenience in operation, strong practicability, and great saving of the labor intensity.

Owner:石忠辉

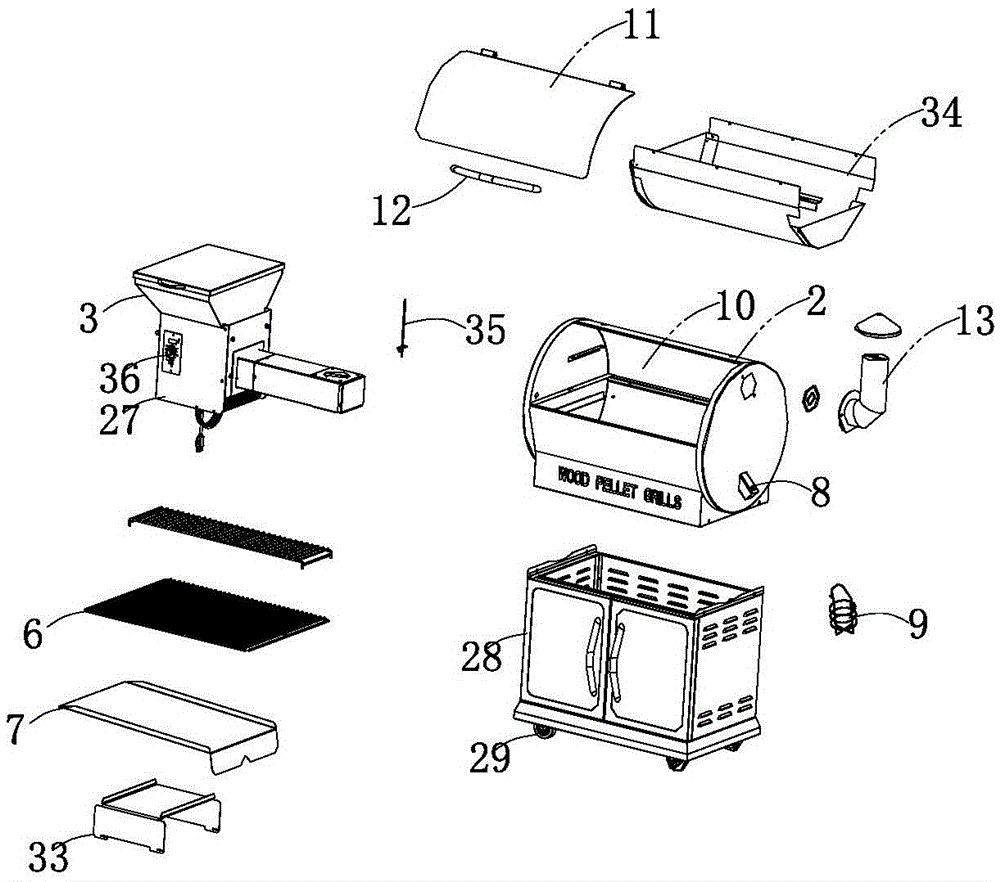

Energy-saving environment-friendly barbecue oven

The invention relates to an energy-saving environment-friendly barbecue oven which comprises an oven body. A combustion furnace is arranged in the oven body, a feeding hopper is arranged on one side of the oven body and is connected with the combustion furnace through a fuel feeding mechanism and an ignition combustion mechanism, the oven body is composed of an upper cover and a base, a barbecue cavity is formed between the upper cover and the base, a grill is arranged in the barbecue cavity, and an oblique oil collecting plate is arranged under the grill. The oil collecting plate comprises an upper end and a lower end. An oil outlet nozzle is arranged on the side, at the lower end of the oil collecting plate, of the oven body of the barbecue oven. A basket is hung on the oil outlet nozzle. The oven body is provided with a feeding opening, a cover plate movably connected with the upper cover is arranged on the feeding opening, and a handle is arranged on the cover plate. A chimney communicated with an inner cavity of the oven body is arranged on one side of the oven body, a smoke exhaust fan is arranged at the end of the chimney, and a plurality of dust collecting plates are disposed on the pipe wall of the chimney. Automatic fuel supply, oxygen supplement and purification of combustion smoke and dust are achieved, and energy conservation and environmental protection are achieved.

Owner:周秉寅

Residual oil hydrogenation treatment and catalytic cracking combined processing method

ActiveCN102311798AIncrease processing costReduce investmentTreatment with hydrotreatment processesFiltrationGas phase

The invention discloses a residual oil hydrogenation treatment and catalytic cracking combined processing method, which comprises: performing the hydrogenation reaction of a residual oil raw material in the presence of hydrogen and a hydrogenation treatment catalyst, and performing gas-liquid separation of efflux of hydrogenation reaction, wherein a gas phase is circularly used in a hydrogenation reaction, and a liquid phase is fractioned to form a light component and a heavy component; allowing a light component to enter a reactor from the bottom of a catalytic cracking riser reactor, allowing a heavy component to enter the reactor as secondary feed of the catalytic cracking riser reactor and performing a catalytic cracking reaction; and separating a dry gas, a liquefied gas and a gasoline fraction from efflux of a catalytic cracking reaction, wherein the fractions of diesel are not separated and enter a residual oil hydrogenation device after filtration. Compared with the prior art, the method can produce high-octane number gasoline and high-added-value liquefied gas to a maximum degree; meanwhile, the method can fully utilizes reaction heat and reduces production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732311AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of catalytically cracked heavy recycle oil undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of embedding dark lines in sheet

InactiveCN1912864ADoes not damage aestheticsEasy to achieve cross-media connectionCharacter and pattern recognitionSpecial data processing applicationsDark lineComputer science

This invention relates to a method for inserting hidden lines in sheets, which sets up a corresponding list to search for the numbers of the corresponding hidden lines of the being inserted content and computes the current typeset region when setting up a type then to fill in hidden lines pictures repeatedly in this region, which can fit the hidden lines at suitable positions to realize the synchronization of hidden lines information and content.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

Coated composite material

PendingUS20190099100A1Easily delivered and mountedEasy deliveryElectrocardiographySurgeryWater solubleBiological body

An object of the present invention is to provide a composite material that may be easily delivered and mounted in the living body. The object can be solved by a coated composite material characterized in that a composite material, in which a porous body is bounded to a substrate, is coated with at least one soluble component selected from a group consisting of a water-soluble compound, a temperature-sensitive soluble compound, and a pH sensitive soluble compound.

Owner:TOHOKU UNIV

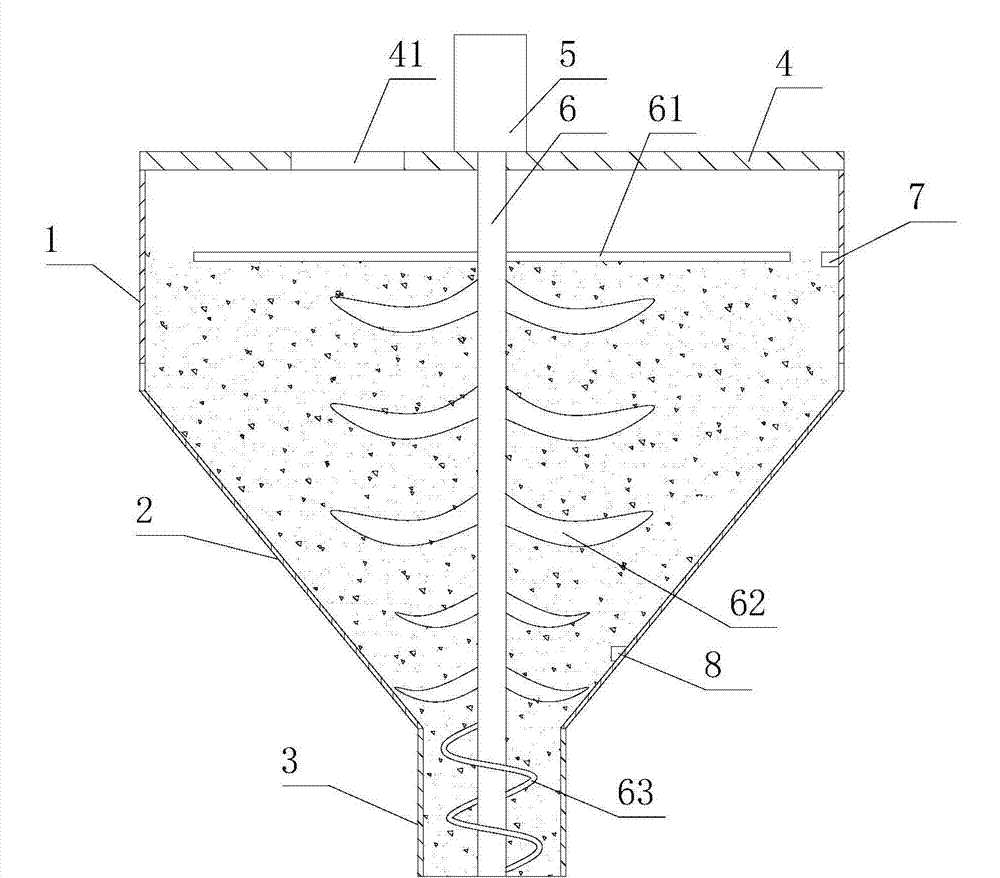

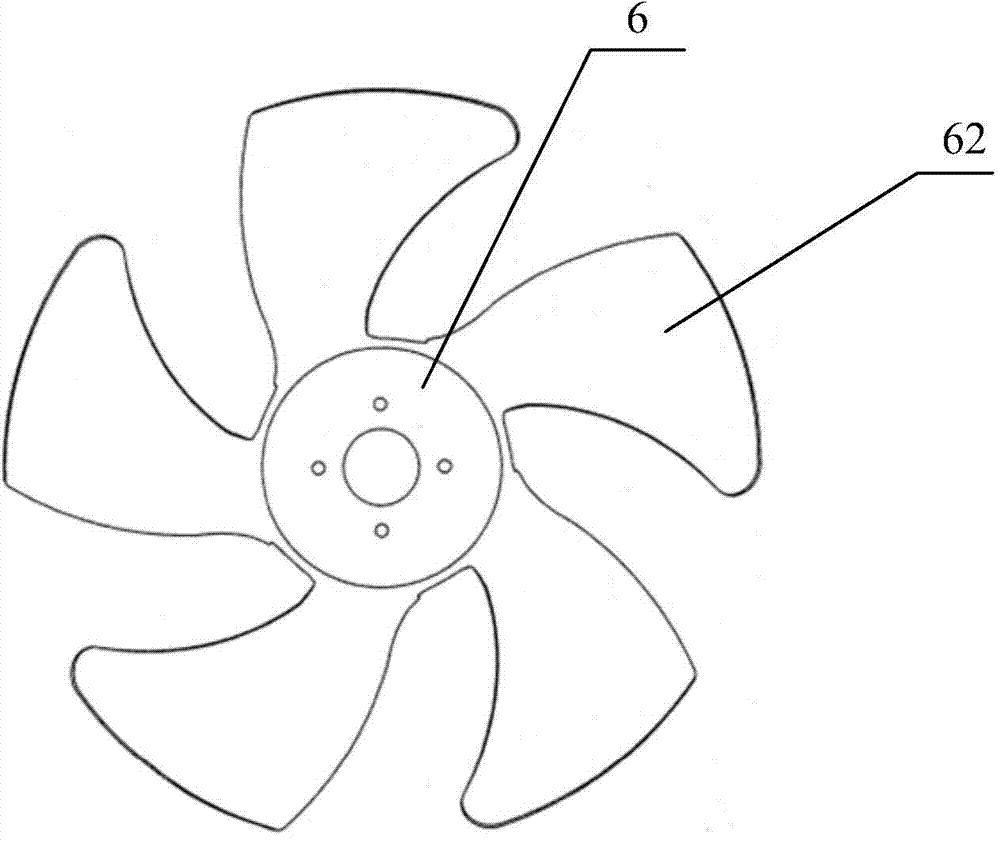

Feeding hopper of extruding machine

The invention discloses a feeding hopper of an extruding machine. The feeding hopper comprises a hopper body, wherein the hopper body comprises an inverted-cone-shaped storing section and an annular discharging section; the storing section and the discharging section are coaxially arranged; the top of the storing section is provided with a cover plate, the cover plate is provided with a feed port, and the top of the cover plate is provided with a driving motor; the driving motor is connected with a main shaft which is arranged in a manner of stretching into the hopper body, the main shaft is provided with multiple groups of loose blade structures at intervals, the loose blade structures are positioned in the storing section, and each loose blade structure comprises at least four loose blades which are uniformly distributed in an annular manner, and each loose blade is arranged in an inclined manner; the blade surface of each loose blade is arranged in a manner of facing the rotating direction of the main shaft, the tail end of the main shaft is provided with a helical blade, and the helical blade is positioned in the discharging section. The feeding hopper of the extruding machine, provided by the invention, has the advantages that the feed is easy, and the power consumption is low.

Owner:昆山市华浦塑业有限公司

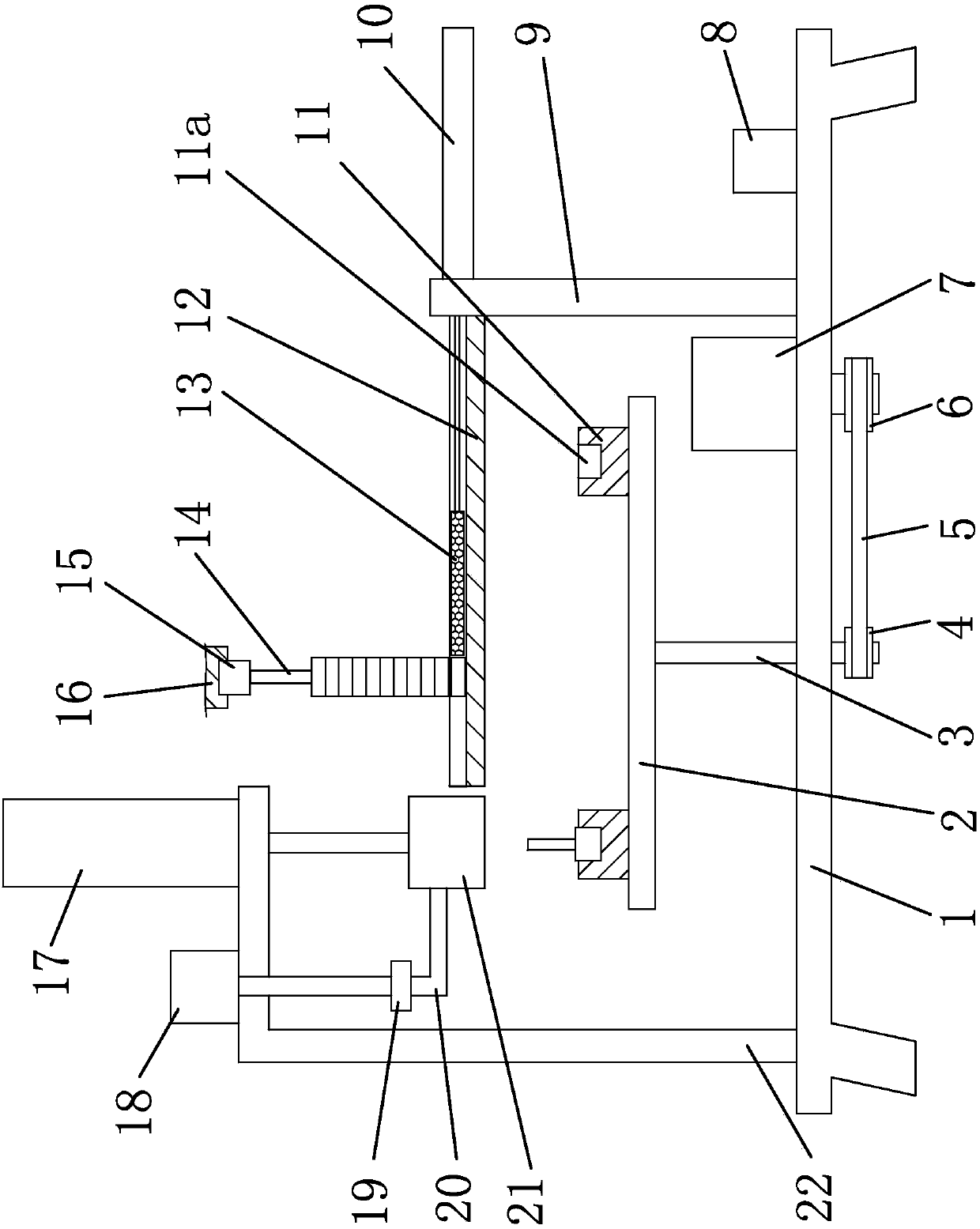

Automatic pipeline feeding device

ActiveCN107570576AEasy deliveryEasy to operateConveyorsMetal-working feeding devicesEngineeringMachining

The invention discloses an automatic pipeline feeding device and relates to the technical field of pipeline machining equipment. The automatic pipeline feeding device comprises an outer frame. A top plate and a bottom plate are fixedly connected between the two sides of the inner wall of the outer frame in sequence from top to bottom. The bottom of the inner wall of the outer frame is fixedly connected with a first motor. One end of an output shaft of the first motor is fixedly connected with a first belt wheel. The surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The back face of the second belt wheel is fixedly connected with a first gear. One side of the first gear is engaged with a second gear. According to the automatic pipeline feeding device, a pipeline can be clamped and fixed to be prevented from deviating in the cutting process, and the fixing effect is improved; manual clamping and manual feeding are not needed, operationis easy, the labor quantity of workers is relieved, and using of people is facilitated; and feeding is facilitated, the using performance of the device is improved, feeding precision is guaranteed, and errors caused by manual feeding are avoided.

Owner:GUANGDONG JUNCHI TECH HLDG

Solar street lamp system preventing ice, snow and hail

ActiveCN107559760AEasy to installSolve problemsElectric circuit arrangementsProtective devices for lightingSnowpackSolar generator

The invention discloses a solar street lamp system preventing ice, snow and hail. The solar street lamp system comprises a street lamp post and a street lamp. The street lamp post is of a hollow structure. The street lamp is connected to the upper portion of the street lamp post through a lamp post support. The upper end of the street lamp post is fixedly connected with a solar cell panel device located above the street lamp. The solar cell panel device comprises a master controller, a solar power generation mechanism, a solar cell panel installation box, a solar cell panel ice and snow removing assembly and a solar cell panel hail preventing assembly. By means of the solar street lamp system preventing ice, snow and hail, a solar cell panel ice and snow preventing device is used for conducting accumulated snow removing work; a screw rod of the device is sleeved with a corrugated pipe which is used for preventing a salt body in a salt storage box from making direct contact with the screw rod to corrode a thread on the screw rod; and in addition, the salt body is prevented from entering the thread connecting position between the screw rod and a threaded casing pipe to prevent the thread engaging degree of the screw rod and the threaded casing pipe. The solar cell panel hail preventing assembly is further designed, and the mechanism is used for preventing a cell panel from beingdamaged by the hail severe weather.

Owner:西藏世峰高科能源技术有限公司

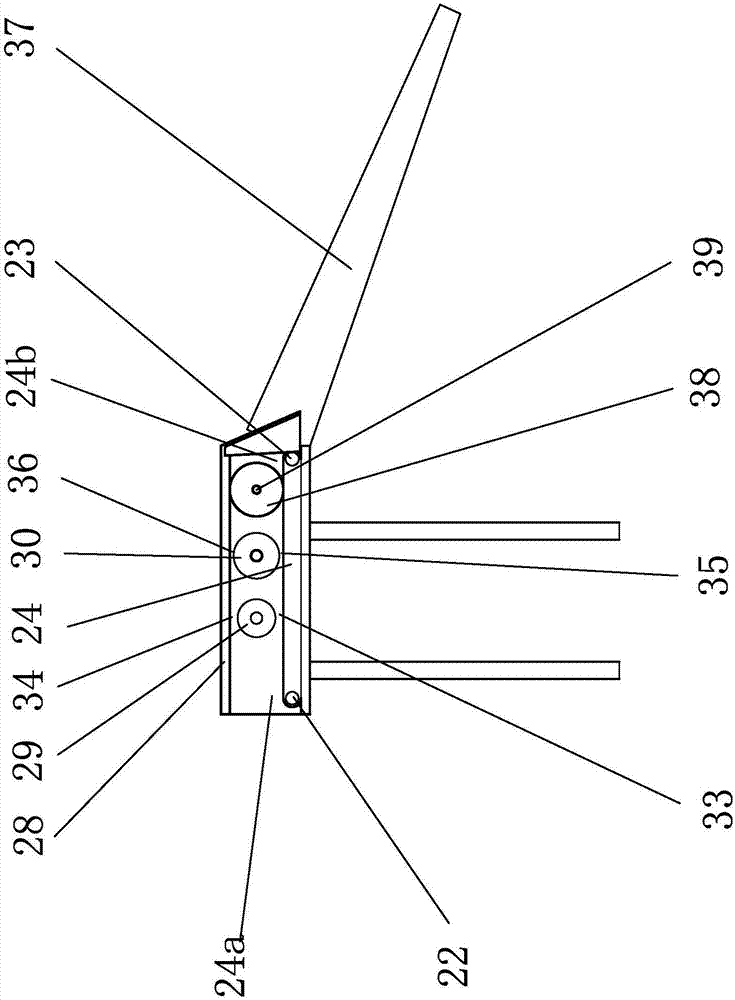

Feeding device in assembly production line

ActiveCN108032060AEasy deliveryReduce deliveryMetal working apparatusIndustrial engineeringProduction line

The invention provides a feeding device in an assembly production line, and solves such technical problems as simpler structure, need of manual feeding and complicated feeding in a traditional device.According to the feeding device in the assembly production line, the assembly production line comprises a frame; a bracket is fixed on the frame; a first push rod motor is fixed on the bracket; the end part of a push rod of the first push rod motor is connected with a positioning block with a working cavity inside; the positioning block is provided with a positioning groove for placing a nylon gasket; and the feeding device comprises a mounting frame, a positioning frame, a guide plate and a feeding block. The feeding device in the assembly production line has the advantage of convenience tofeed.

Owner:灵璧县浩翔信息科技有限公司

Hot pot device without cooking fume convenient to use

InactiveCN109315934AEasy to useEasy deliveryServing tablesCooking vessel supportEngineeringComputer engineering

Owner:重庆鑫韵峰工贸有限公司

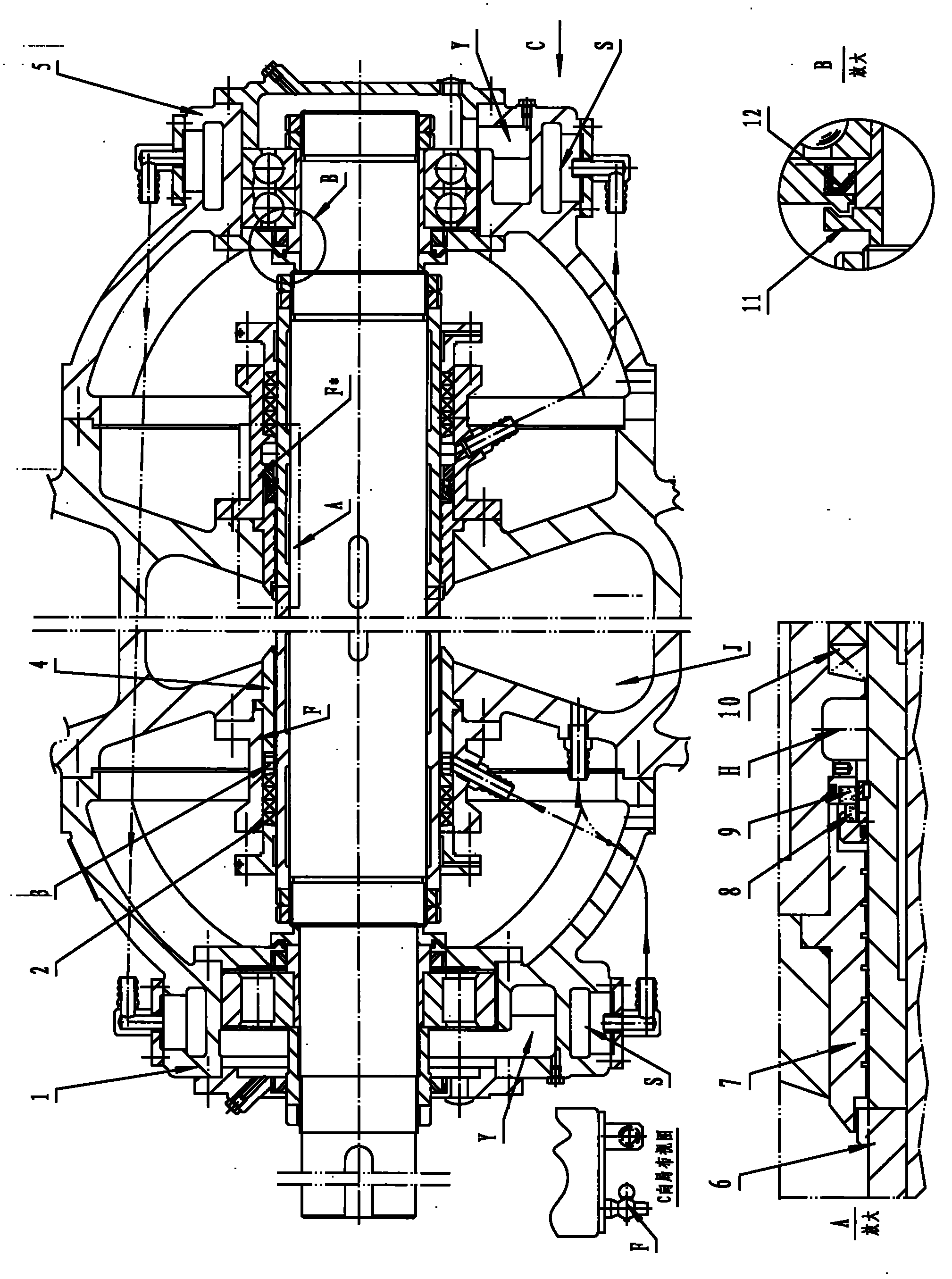

Sections-distributed-in-pairs twin-volute mine wearable multi-stage pump

InactiveCN102080659AEasy deliveryEfficient Zone WidthPump componentsRadial flow pumpsImpellerAxial force

The invention relates to a sections-distributed-in-pairs twin-volute mine wearable multi-stage pump suitable for conveying sewage with different granules and concentrations in a mine. The sections-distributed-in-pairs twin-volute mine wearable multi-stage pump is characterized in that an effluent stage of the pump is arranged in the middle of the pump, and impeller assemblies at both sides are oppositely arranged, and a final-stage impeller and the middle segment of a final-stage double volute are oppositely arranged. When the pump is provided with an oven number of stages, the impeller assemblies at both sides are symmetrically arranged. When the pump is provided with an odd number of stages, the front impeller assembly is provided with one more pulley. The sections-distributed-in-pairs twin-volute mine wearable multi-stage pump is innovated and improved in the aspects in axial force balance of the pump, the over-current piece and the clearance sealing life of the pump, the diluted oil lubrication of the bearing, circular cooling by utilizing shaft seal leakage, and the like. Accordingly, in the service life of the pump, the axial force of the pump is basically balanced, and residential axial force is borne by angular contact bearings in pair at the back of the pump which keeps long-term high-efficiency operation, and the fault-free working time and the overhaul-period average life of the pump are greatly improved.

Owner:荆锁祥

Fully-automatic demolding device for automobile production

The invention discloses a fully-automatic demolding device for automobile production. The device comprises a bottom plate horizontally arranged; two clamp plates are hinged on both sides of the top ofthe bottom plate; first springs are connected to the bottoms of the sides, close to each other, of the two clamp plates; the ends, away from the clamp plates, of the first springs are connected to the bottom plate; a connecting rod hinged to the corresponding clamp plate is arranged above each first spring; a squeezing block is welded to the end, away from the corresponding clamp plate, of each connecting rod; a pushrod motor fixedly connected with the top end of the bottom plate is arranged below the squeezing blocks; a horizontally-arranged layer board is welded to the tail end of an outputshaft of the pushrod motor; two support plates welded to the bottom plate are arranged on both sides of the pushrod motor; and fixing blocks are welded to the top of the sides, close to each other, of the two support plates. The fully-automatic demolding device is novel in design and simple in operation, and combination and separation of a main body of a mold are convenient, so that a workpiece is easily separated from the main body of the mold to facilitate the output of the workpiece.

Owner:盐城新岩汽车配件有限公司

Device for carbonizing biomass by electromagnetic wave

InactiveCN107057731AImprove carbonization efficiencySlow down or speed upBiofuelsSpecial form destructive distillationEngineeringMechanical engineering

The invention provides a device for carbonizing biomass by electromagnetic wave, and belongs to the technical field of a machine. The device solves the technical problems that efficiency of the existing carbonizing device is low and the heat energy cannot be recycled, and others. The device for carbonizing biomass by the electromagnetic wave comprises a frame, wherein a feeding device is arranged on the frame and comprises a feeding cylinder with a first channel inside; the upper part of the feeding cylinder is provided with a feeding opening, and the feeding opening is connected with the first channel at inside of the feeding cylinder; the feeding opening is provided with a feeding hopper, and a spiral feeder is arranged in the feeding cylinder; a carbonizing cylinder is further fixed on the frame, one end of the carbonizing cylinder is provided with a carbonizing cylinder inlet while the other end is provided with a carbonizing cylinder outlet; the carbonizing cylinder and the feeding cylinder are sealed; a discharging cylinder is further fixed on the frame, the discharging cylinder and the carbonizing cylinder are sealed; a heat recycling device for recycling heat in the discharging cylinder is further arranged at outside of the discharging cylinder. The device for carbonizing biomass by the electromagnetic wave has the advantages of high carbonizing efficiency, good carbonizing quality, and the like.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Washing machine which can be conveniently used by old people

ActiveCN108560224ARealize functionEasy deliveryIroning apparatusTextiles and paperHydraulic cylinderOlder people

The invention provides a washing machine which can be conveniently used by old people. The washing machine comprises a washing machine body, a clothes collecting basket, a clothes lifting passage, a clothes delivering trolley, a clothes delivering passage and a control system; the washing machine is a general household pulsator washing machine, a roller inner container and a clothes collecting fixed groove are arranged inside the washing machine, and a second-level hydraulic cylinder is arranged at the bottom of the washing machine; the clothes lifting passage is arranged right above the washing machine, and a lower track board, an upper track board, a lifting hydraulic cylinder and a clothes lifting track are arranged in the clothes lifting passage; a clothes lifting guide pulley is arranged on the clothes collecting basket; the clothes lifting guide pulley corresponds to the clothes lifting track; the clothes delivering passage is communicated with the clothes lifting passage; the clothes delivering trolley and a clothes delivering track are arranged in the clothes delivering passage; the clothes delivering trolley sleeves the clothes delivering track; the clothes delivering track is divided and communicated with a clothes air-drying area, bedrooms and a bathroom, and a fan and an operative control panel are arranged at the exit of the clothes delivering track. The washing machine achieves that clothes can be automatically sent for washing and air-drying, the washing machine can be ventilated to avoid unpleasant odor, the structure is simple, the operation is simple, andthe washing machine is quite suitable for old people who is unable to move freely to use independently.

Owner:唐广纯

Method for manufacturing beryllium bronze explosion-proof hammer

The invention relates to a method for manufacturing a beryllium bronze explosion-proof hammer. The method is characterized in that a metal casting mold is used for forming, and a metal column comprises an upper half mold and a lower half mold which are horizontally split; an upper casting mold half cavity is formed in the upper half mold, a lower casting mold half cavity corresponding to the uppercasting mold half cavity is correspondingly formed in the lower half mold, an upper half core is arranged in the center of the top surface of the upper casting mold half cavity, and a lower half coreis arranged in the center of the bottom surface of the lower casting mold half cavity; an exhaust channel is formed in the position, positioned on the parting surface of the upper half mold and the parting surface of the lower half mold, of the outer side of an explosion-proof hammer head cavity; an upper pressing head is arranged on the upper half mold; a material storage cavity is formed in thecenter of the lower half mold, and a lower pressing head is arranged at the bottom of the material storage cavity; and a flow channel is formed between the material storage cavity and the lower casting mold half cavity. The invention further relates to the method for manufacturing the beryllium bronze explosion-proof hammer by utilizing the metal casting mold, so that the problems that the density is low, the structure is thick and large, and blocks are prone to jumping in the using process in the process of producing the beryllium bronze explosion-proof hammer by an existing casting technology are solved.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com