Intelligent hydrogel as well as preparation method and application thereof

A hydrogel and intelligent technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as difficult heavy metal ions, complex preparation process of adsorbents, high cost, etc., to achieve the required time Short, product yield is green and environmentally friendly, and the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

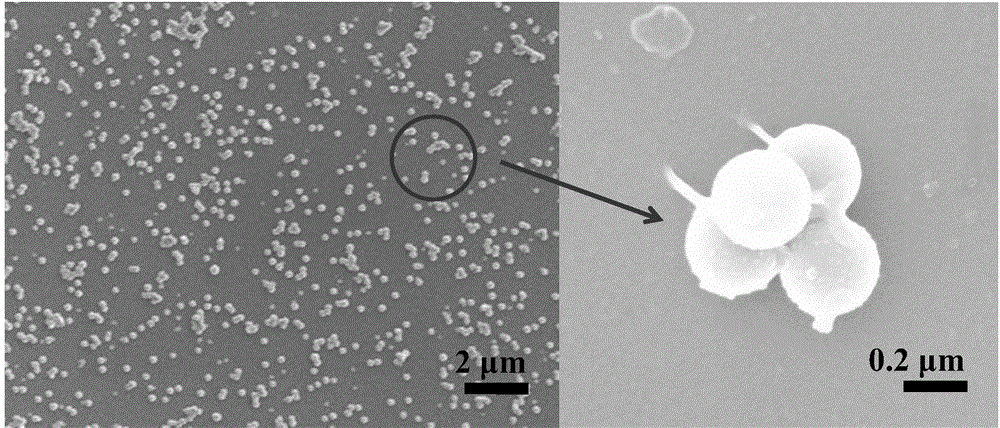

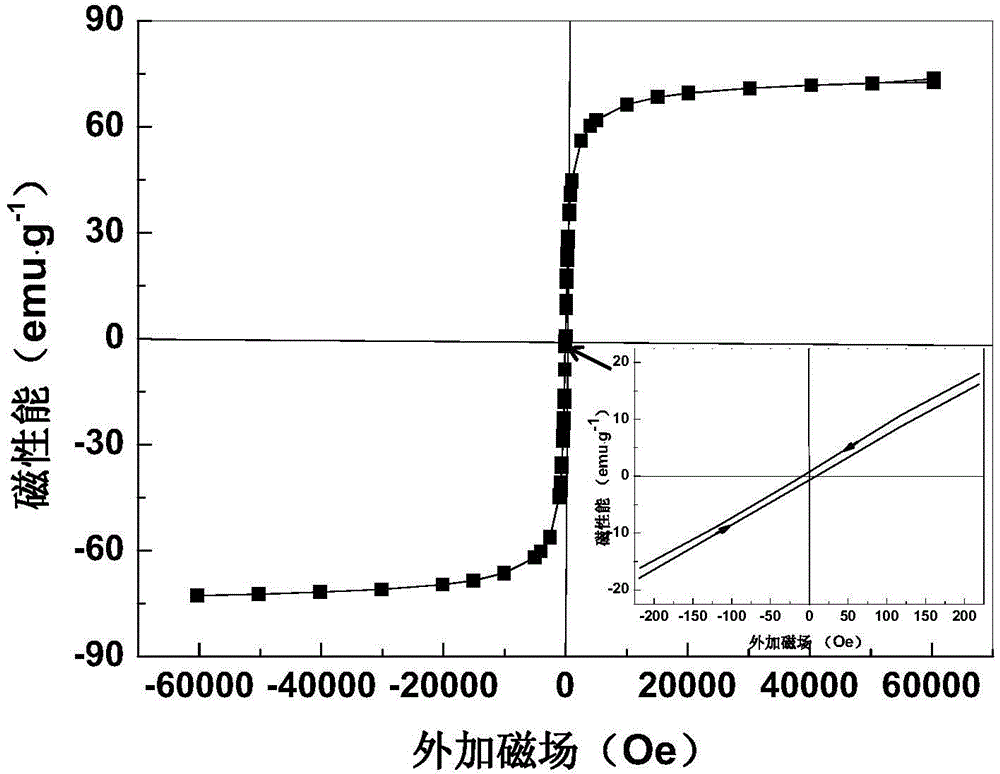

[0023] (1) Weigh 4.2g FeCl 2 4H 2 O and 8.5g of FeCl 3 ·6H 2 O was completely dissolved in 150mL of ethanol-water mixed solvent with a volume ratio of 1:1 to form a mixed solution. Under nitrogen protection, it was placed in a constant temperature water bath at 60°C for mechanical stirring at a speed of 250r / min, and slowly added dropwise Ammonia water was added until the pH of the solution was 10. At this time, a black precipitate was precipitated, and the reaction was continued for 3 hours before stopping. The black precipitate after magnetic separation was washed repeatedly with water until the washing liquid was neutral. The washed product was dried in a vacuum oven. After drying, the hydrophilic Fe 3 o 4 nanoparticles.

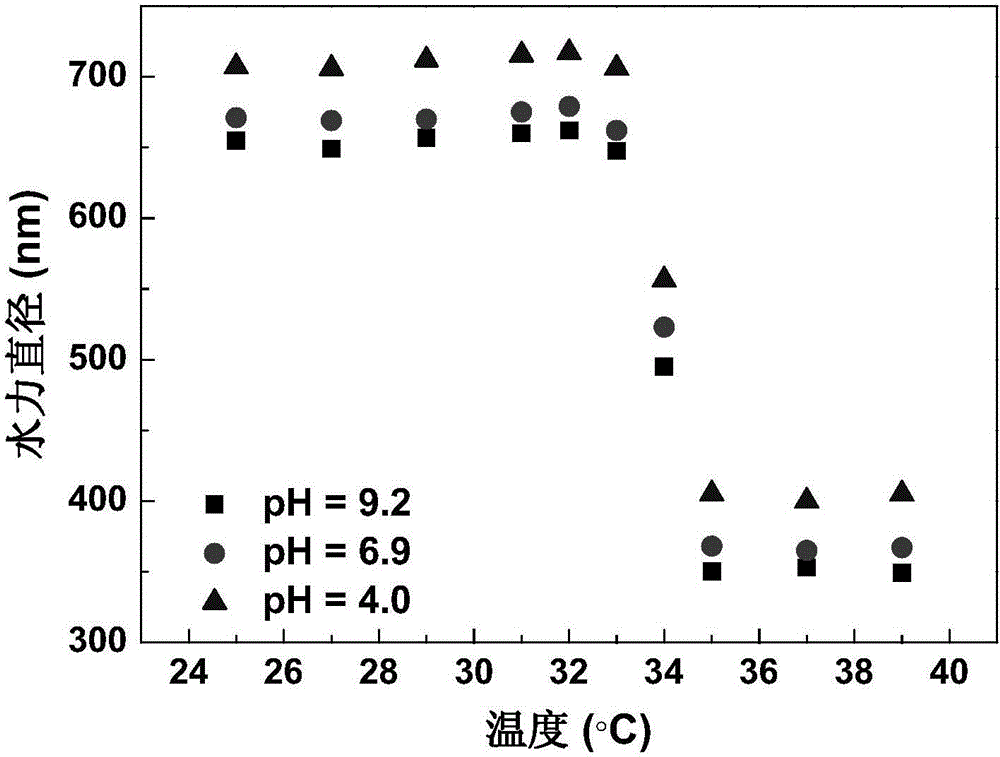

[0024] (2) Ultrasonic dispersion of 0.5 g of iron ferric oxide nanoparticles in 20 mL of chitosan solution with a concentration of 5 g / 200 mL to form an aqueous phase, and then adding 0.5 g of N-isopropylacrylamide therein. Then, 0.010 g of N,N'-m...

Embodiment 2

[0027] The difference between this example and Example 1 is that the amount of N,N'-methylenebisacrylamide and ammonium persulfate used are both 0.022g, and the rest are the same as those described in Example 1.

Embodiment 3

[0029] (1) Weigh 3.5g FeCl 2 4H 2 O and 7.7g of FeCl 3 ·6H 2 O was completely dissolved in 200mL of ethanol-water mixed solvent with a volume ratio of 1:1 to form a mixed solution. Under nitrogen protection, it was placed in a constant temperature water bath at 70°C for mechanical stirring at a speed of 300r / min, and slowly added dropwise Ammonia water was added until the pH of the solution was 11. At this time, a black precipitate was precipitated, and the reaction was continued for 3 hours before stopping. The black precipitate after magnetic separation was washed repeatedly with water until the washing liquid was neutral. The washed product was dried in a vacuum oven. After drying, the hydrophilic Fe 3 o 4 nanoparticles.

[0030] (2) Ultrasonic dispersion of 0.2 g of iron ferric oxide nanoparticles in 20 mL of chitosan solution with a concentration of 4 g / 200 mL to form an aqueous phase, and then adding 0.4 g of N-isopropylacrylamide. Then, 0.015 g of N,N'-methylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com