Polyurethane adhesive, adhesive for solar cell protective sheet, and backside protective sheet for solar cell

A solar cell, polyurethane technology, applied in the direction of adhesive types, adhesives, circuits, etc., can solve the problems of inability to maintain strong adhesive strength for a long time, decrease in water vapor barrier property, decrease in adhesive strength, etc. Good bonding strength, good bonding strength, and the effect of maintaining bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21、 comparative example 1~15

[0189] Various main agents and the following curing agents were prepared at 100:10 (weight ratio), diluted with ethyl acetate to adjust the solid content to 30%, and the obtained solutions were used as the adhesive solutions of each example and each comparative example, Evaluation was performed by the method described below.

[0190] Each combination which is Examples 1-21 and Comparative Examples 1-15 is described in Table 4A and Table 4B.

[0191] Curing agent D1

[0192] The trimer of isophorone diisocyanate was diluted with ethyl acetate to obtain a resin solution with a solid content of 50%, thereby obtaining curing agent D1.

[0193] Curing agent D2

[0194] The trimer of hexamethylene diisocyanate was diluted with ethyl acetate to form a resin solution with a solid content of 50%, thereby obtaining curing agent D2.

[0195] Curing agent D3

[0196] Mix 100 parts of the trimer of isophorone diisocyanate and 100 parts of the adduct of hexamethylene diisocyanate and tr...

Embodiment 22、 comparative example 16

[0216] According to the same 100:10 (weight ratio) as in Example 1, in the case of Example 22, the main agent 1 and curing agent D1 are prepared, and in the case of Comparative Example 16, the main agent 19 and curing agent D1 are prepared. It was diluted with ethyl acetate, and the solution adjusted to a solid content of 30% was used as a binder solution.

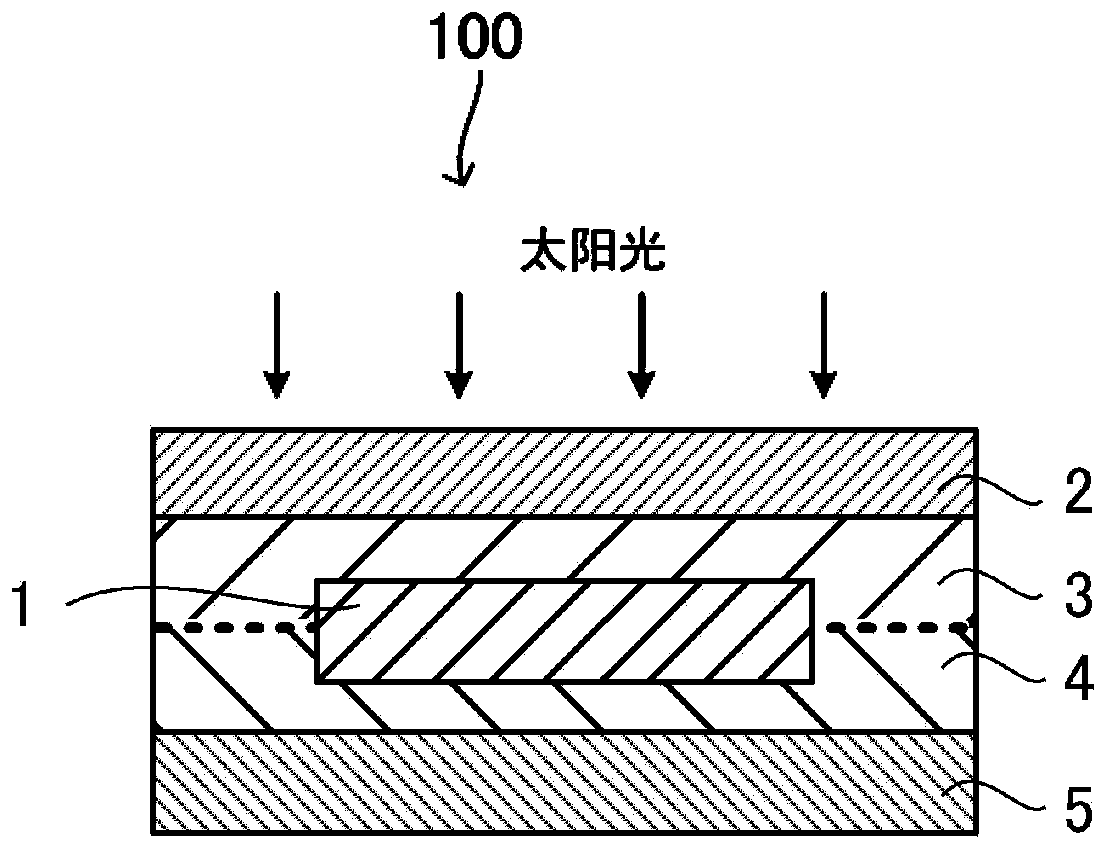

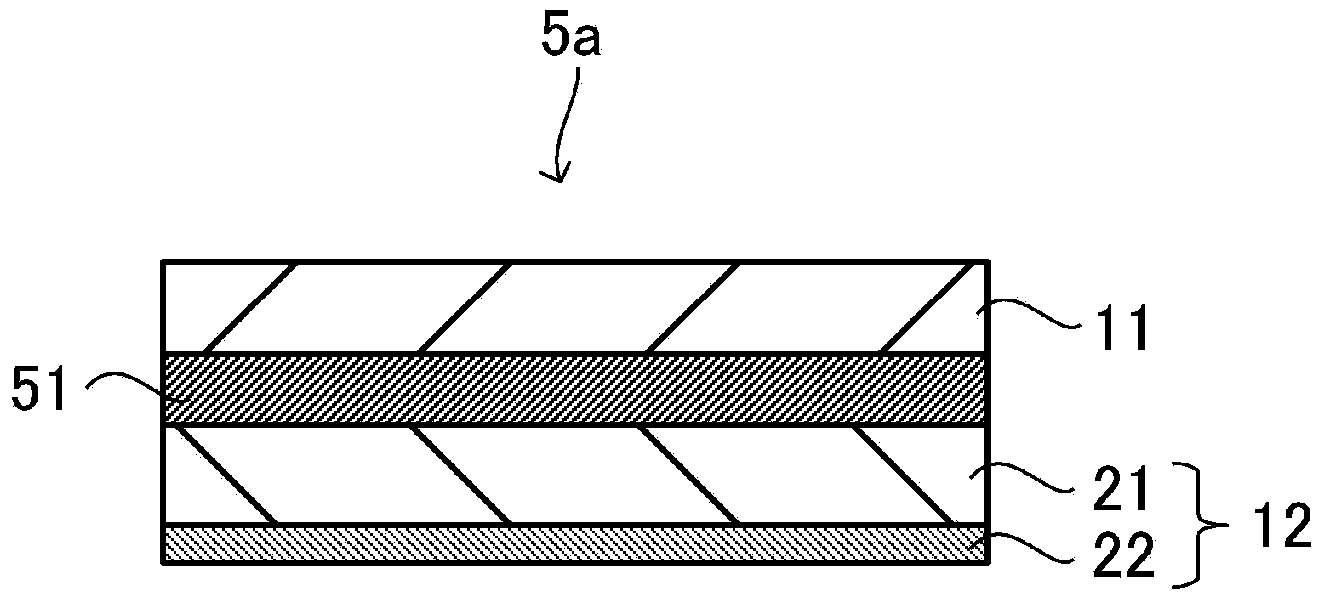

[0217] Use a dry film laminating machine to coat the adhesive on one side of the untreated polyester film (thickness 125μm) with a coating amount of 8-10g / square meter. After the solvent evaporates, laminate the white PVF film (thickness 37.5μm) ). Then use a dry film laminating machine to coat the adhesive on one side of the untreated polyester film that is not laminated with white PVF film at a coating amount of 8-10g / square meter. After the solvent evaporates, laminate the EVA film (Thickness 100μm). Thereafter, curing (aging) was performed at 60° C. for 7 days, and the adhesive was cured to obtain a back surface prot...

Embodiment 23、 comparative example 17

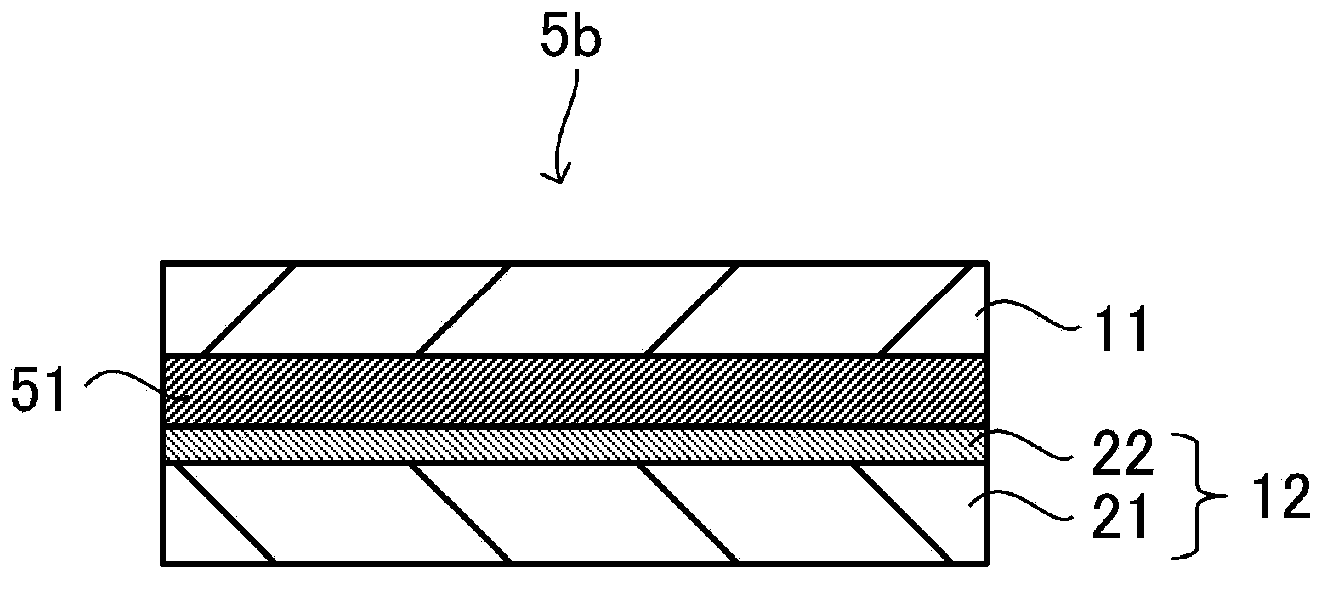

[0219] Apply the same adhesive used in Example 22 and Comparative Example 16 to one side of an untreated polyester film (thickness 75 μm) with a dry film laminating machine at a coating amount of 8 to 10 g / square meter. Laminate aluminum foil (thickness 17.5μm) after the solvent evaporates. Then use a dry film laminating machine to coat the adhesive on the laminated aluminum foil surface with a coating amount of 8-10g / square meter, and laminate a white PVF film (thickness 37.5μm) after the solvent evaporates. Then use a dry film laminating machine to coat the adhesive on one side of the untreated polyester film that is not laminated with aluminum foil with a coating amount of 8-10g / square meter. After the solvent evaporates, laminate the EVA film (thickness 100μm). Thereafter, curing (aging) was performed at 60° C. for 7 days, and the adhesive was cured to obtain a back surface protection sheet for solar cells, which was evaluated by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com