Adhesive for soft package compound and preparation method thereof

A flexible packaging and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of unusable, slow drying, product contamination, etc., and achieve the effect of reducing pollution and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

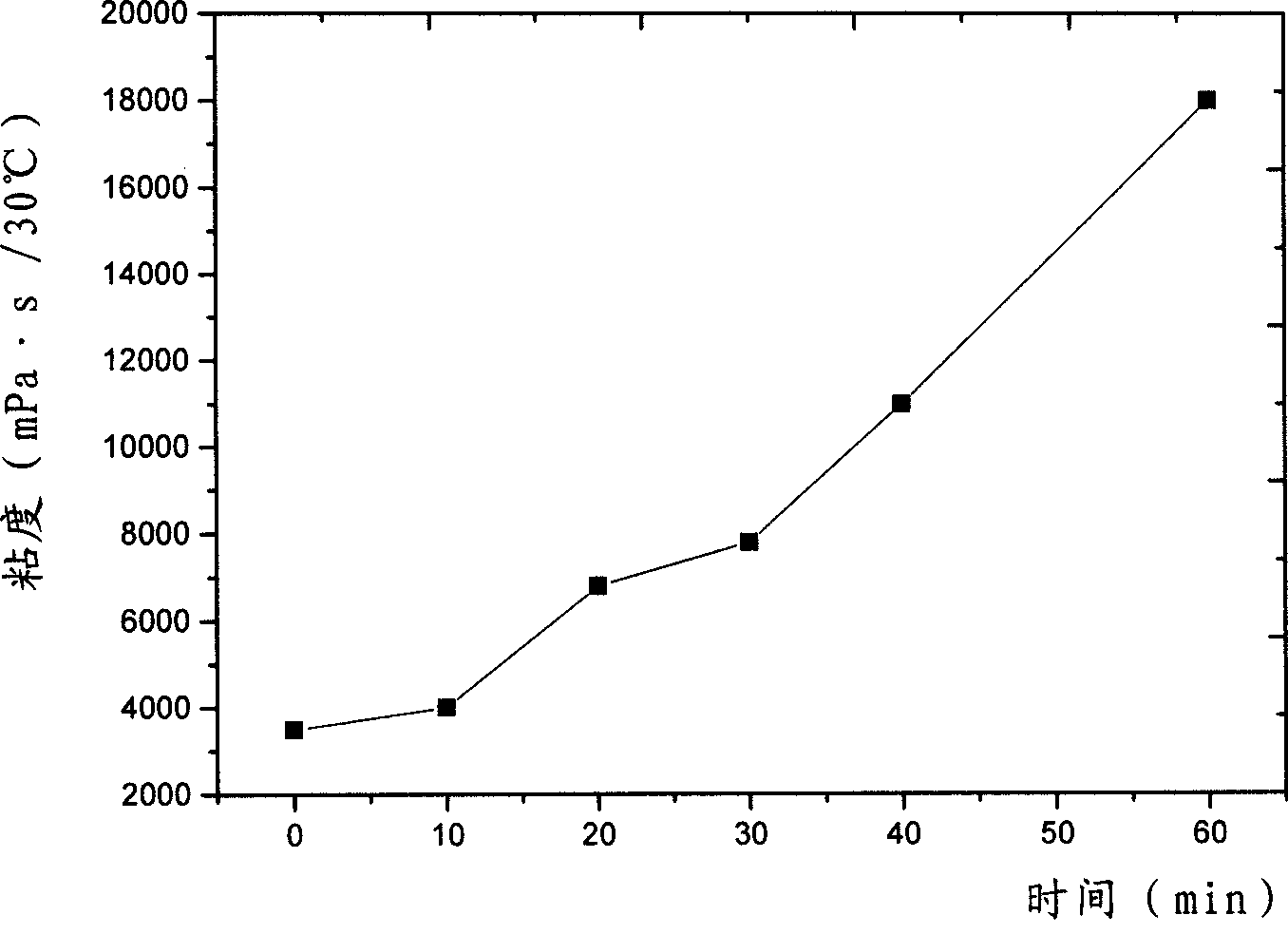

Image

Examples

Embodiment 1

[0094] (1) Hydroxyl polyester polymer component (A):

[0095] The preparation of hydroxyl polyester polymer (I):

[0096] First, add 970g of adipic acid, 600g of diethylene glycol, 300g of 1,2- Propylene glycol and 0.2 g of catalyst tetrabutyl titanate. Then, the temperature was raised to 160°C for 2 hours, and then the temperature was gradually raised to 230°C at a rate of 10-15°C per hour. Finally, the reaction was incubated at 230° C. for 2.5 h. When the measured acid value is less than 20, start vacuuming for 1 hour under the condition of negative pressure less than 0.08MPa and temperature of 230°C. Finally, under the condition of a negative pressure of 0.1MPa, vacuumize for 1 hour to obtain the hydroxyl polyester polymer (I).

[0097] Preparation of hydroxyl polyester polymer (II):

[0098] First, add 1000g of adipic acid, 800g of ethylene glycol, 400g of glycerol, 500g of ortho Phthalic anhydride and 0.27 g of catalyst tetrabutyl titanate. Then, the temperature was ...

Embodiment 2

[0111] (1) Hydroxyl polyester polymer component (A):

[0112] The preparation of hydroxyl polyester polymer (I):

[0113] First, add 487g of adipic acid, 290g of diethylene glycol, 147g of 1,2- Propylene glycol and 0.09 g of catalyst tetrabutyl titanate. Then, the temperature was raised to 160°C for 2 hours, and then the temperature was gradually raised to 230°C at a rate of 10-15°C per hour. Finally, the reaction was incubated at 230° C. for 2.5 h. When the measured acid value is less than 20, start vacuuming for 1 hour under the condition of negative pressure less than 0.08MPa and temperature of 230°C. Finally, under the condition of a negative pressure of 0.1MPa, vacuumize for 1 hour to obtain the hydroxyl polyester polymer (I).

[0114] Preparation of hydroxyl polyester polymer (II):

[0115] First, in a reactor with stirrer, thermometer, straight cooler, horizontal cooler and nitrogen sealed tube, add 1080g of adipic acid, 790g of ethylene glycol, 580g of trimethylol...

Embodiment 3

[0128] (1) Hydroxyl polyester polymer component (A):

[0129] The preparation of hydroxyl polyester polymer (I):

[0130] First, add 241g of adipic acid, 150g of diethylene glycol, 75g of 1,2- Propylene glycol and 0.05 g of catalyst tetrabutyl titanate. Then, the temperature was raised to 160°C for 2 hours, and then the temperature was gradually raised to 230°C at a rate of 10-15°C per hour. Finally, the reaction was incubated at 230° C. for 2.5 h. When the measured acid value is <20, start vacuuming for 1 hour under the condition of negative pressure <0.08MPa and temperature of 230°C. Finally, under the condition of a negative pressure of 0.1MPa, vacuumize for 1 hour to obtain the hydroxyl polyester polymer (I).

[0131] Preparation of hydroxyl polyester polymer (II):

[0132] First, add 250g of adipic acid, 200g of ethylene glycol, 100g of glycerol, 125g of ortho Phthalic anhydride and 0.06 g of catalyst tetrabutyl titanate. Then, the temperature was raised to 150°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com