Styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and preparation method and application thereof

A technology of surface sizing agent and core-shell structure, applied in the direction of water repellent addition, paper, textiles and papermaking, etc., can solve the problems of poor film formation, affect the strength of paper, weaken the bonding force between fibers, etc., and achieve water resistance Reinforcement and adhesion improvement, sizing performance and effect are remarkable, and the effect of improving printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

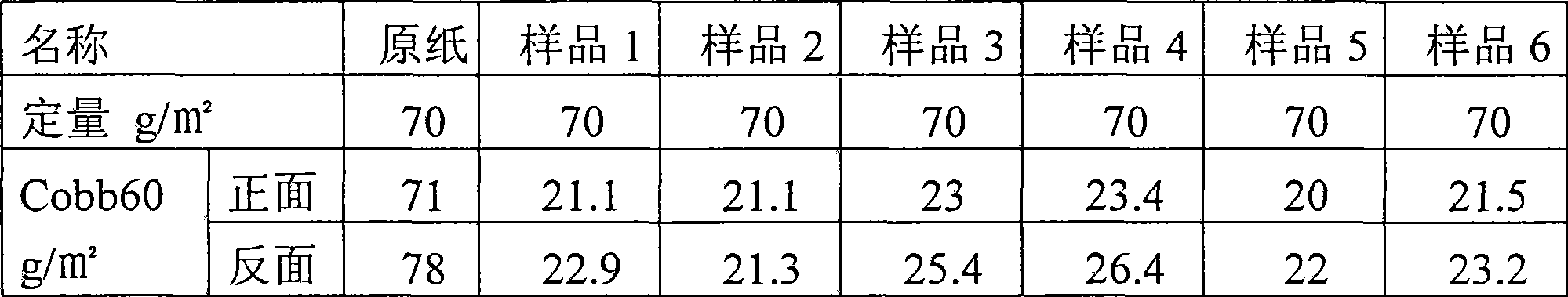

Image

Examples

Embodiment 1

[0062] Preparation solid content is the core-shell structure styrene-acrylic microemulsion surface sizing agent of 40%, comprises the following steps:

[0063] (1) Preparation of shell pre-emulsion:

[0064] Get 25g butyl acrylate, 0.5g n-octyl methacrylate, 0.5g α-methacrylic acid, 0.25g sodium bicarbonate, 0.25g compound emulsifier (sodium lauryl sulfate and undecyl glucamide by mass ratio 1:1 mixing) and 8.86g of distilled water were mixed, at 30°C, stirred at a speed of 500rpm for 20 minutes, the soft monomer was fully pre-emulsified, and the shell part pre-emulsion was obtained;

[0065] (2) Preparation of nuclear emulsion:

[0066] A. Mix 75g methyl styrene and 1g allyl glycidyl ether evenly to obtain a mixed monomer solution at the nucleus;

[0067] B, then, take 11.4g nuclear part mixed monomer solution, 0.75g compound emulsifier (sodium lauryl sulfate and undecylglucamide mix by mass ratio 1:1), 0.75g sodium bicarbonate and 56.73g Mix with distilled water and stir ...

Embodiment 2

[0075] Preparation solid content is the core-shell structure styrene-acrylic microemulsion surface sizing agent of 43%, comprises the following steps:

[0076] (1) Preparation of shell pre-emulsion:

[0077] Get 75g isooctyl acrylate, 1g methyl methacrylate, 0.8g itaconic acid, 0.38g sodium dihydrogen phosphate, 1.13g compound emulsifier (sodium lauryl sulfate and undecyl glucamide by mass ratio 3 : 1 mixed) mixed with 11.07g distilled water, at 40°C, stirred at a speed of 700rpm for 40 minutes to fully pre-emulsify the soft monomer to obtain a shell pre-emulsion;

[0078] (2) Preparation of nuclear emulsion:

[0079] A, 25g of hard monomers (styrene and chlorostyrene are mixed in a mass ratio of 1:1), 1.5g of N-carboxymethoxymethyl acrylamide are mixed uniformly to obtain a mixed monomer solution at the core;

[0080] B, then, take 9.28g nuclear mixed monomer solution, 1g compound emulsifier (sodium dodecylbenzenesulfonate and octylphenol polyoxyethylene ether are mixed in ...

Embodiment 3

[0088] Preparation solid content is the core-shell structure styrene-acrylic microemulsion surface sizing agent of 43%, comprises the following steps:

[0089] (1) Preparation of shell pre-emulsion:

[0090] Get 70g soft monomer (ethyl acrylate and butyl acrylate are mixed in mass ratio 1:2), 1g n-octyl methacrylate, 1g maleic anhydride, 0.7g sodium bicarbonate, 1.05g compound emulsifier (dodecane Sodium sulfate and undecyl glucamide in a mass ratio of 1:4) mixed with 11.01g of distilled water, stirred at 38°C at a speed of 650rpm for 35 minutes, fully pre-emulsified the soft monomer, and obtained shell pre-emulsification liquid;

[0091] (2) Preparation of nuclear emulsion:

[0092] A. Mix 30g methyl styrene and 1.5g allyl glycidyl ether evenly to obtain a mixed monomer solution at the nucleus;

[0093] B, then, get 12.6g core portion mixed monomer solution, 0.9g compound emulsifier (sodium lauryl sulfate and octylphenol polyoxyethylene ether mix by mass ratio 2:1), 0.15g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com