Preparation method of high-safety lithium ion battery diaphragm

A lithium-ion battery, high-safety technology, used in secondary batteries, battery pack components, circuits, etc., can solve the problems of limited improvement effect, inability to block heat-producing side reactions, and inability to be widely used, and achieve high thermal stability. performance and mechanical strength, avoid contact between positive and negative electrodes, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

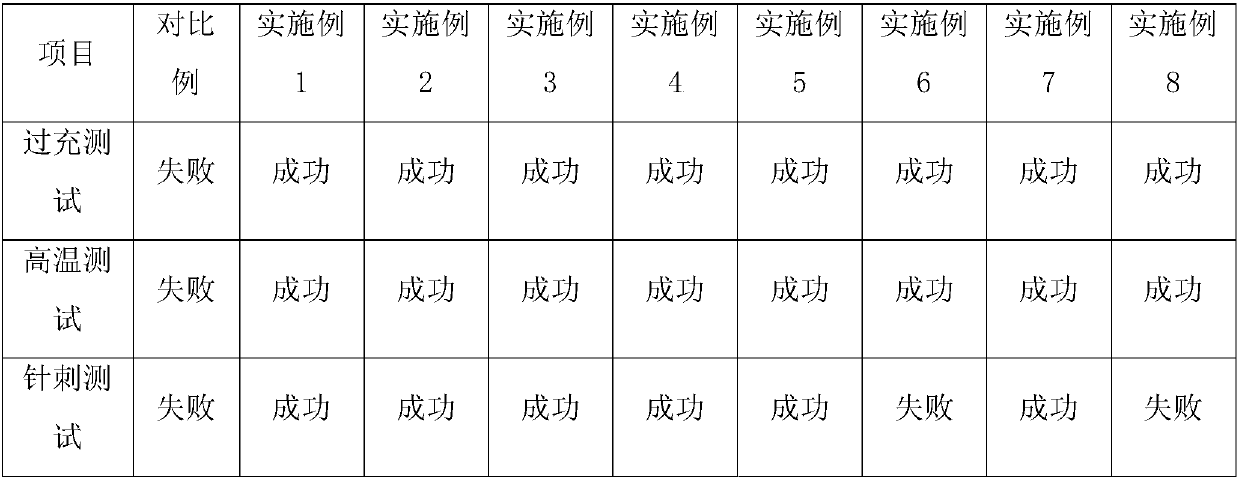

Examples

Embodiment 1

[0033] Except for the preparation method of the diaphragm and the diaphragm, everything else is the same as that of the comparative example.

[0034] Preparation steps of high-safety lithium-ion battery separator:

[0035] a) Mix and stir cis-polyisoprene rubber microspheres, isoprene rubber microspheres and paraffin evenly, the weight of paraffin is 10% of the rubber beads; the rubber microspheres are hollow rubber microspheres, and the inside of the hollow rubber microspheres It is air, and the particle diameter of the hollow rubber microsphere is 50 nanometers;

[0036] b) coating the rubber balls treated in step a on both surfaces of the diaphragm base material, the weight of the rubber balls being 10% of the diaphragm base material, to obtain the primary product of the high-safety lithium-ion battery diaphragm; polyethylene film or polypropylene film, the thickness of the diaphragm substrate is 20 microns;

[0037] c) Stretch the primary product of the high-safety lithi...

Embodiment 2

[0042] Except that the cis-polyisoprene rubber microspheres in Example 1 were replaced by isoprene rubber microspheres, the rest were the same as in Example 1.

Embodiment 3

[0044] Except for the preparation method of the diaphragm and the diaphragm, everything else is the same as that of the comparative example.

[0045] Preparation steps of high-safety lithium-ion battery separator:

[0046] a) Mix and stir the fluororubber microspheres and paraffin evenly, the weight of the paraffin is 25% of the rubber microspheres; the rubber microspheres are hollow rubber microspheres, the inside of the hollow rubber microspheres is air, and the particle diameter of the hollow rubber microspheres is 1000 Nano;

[0047] b) coating the rubber balls treated in step a on both surfaces of the diaphragm base material, the weight of the rubber balls being 20% of the diaphragm base material, to obtain the primary product of the high-safety lithium-ion battery diaphragm; polyethylene film or polypropylene film, the thickness of the diaphragm substrate is 20 microns;

[0048] c) Stretch the primary product of the high-safety lithium-ion battery separator under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com