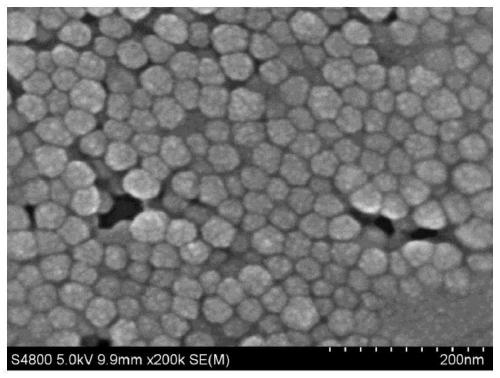

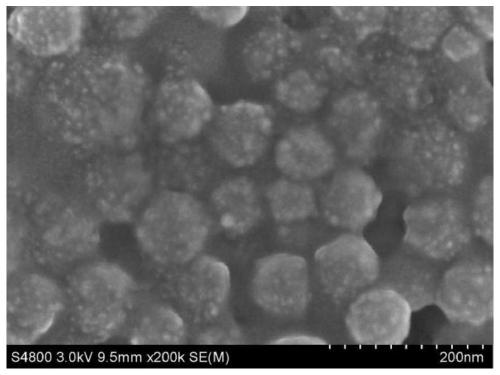

Strawberry-shaped silver-loaded polysilsesquioxane nano hybrid antibacterial material and preparation method thereof

A polysilsesquioxane and antibacterial material technology, applied in the field of polymer nanocomposite preparation, can solve problems such as affecting the antibacterial properties of coatings, reduce bacterial adhesion behavior, improve thermal stability and mechanical strength, The effect of improving the bactericidal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

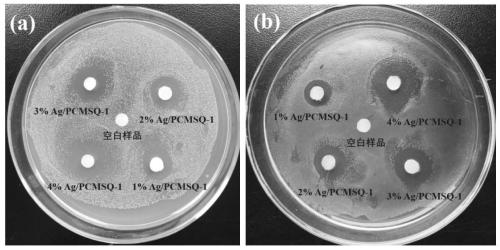

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of strawberry shape loaded silver polysilsesquioxane nano-hybrid antibacterial material, comprises the steps:

[0029] Step 1: Add aminosilane into a three-necked flask equipped with a condensing device, raise the temperature of the system to 60-125°C, control the stirring speed at 100-300rpm, and start adding aliphatic dibasic acid anhydride, aliphatic dibasic acid anhydride and aminosilane in batches The ratio of the amount of the substance is 1:1-1.05. After the addition of the aliphatic dibasic acid anhydride, the heat preservation reaction is carried out for 2-3 hours to obtain a transparent liquid, which is the reactive monomer carboxysilane (CTES);

[0030] Aminosilane is selected from one of 3-aminopropyltriethoxysilane (KH-550) and 3-aminopropyltrimethoxysilane (KH-540);

[0031] The aliphatic dibasic acid anhydride is selected from one of succinic anhydride and glutaric anhydride.

[0032] Step 2: Ad...

Embodiment 1

[0039] A preparation method of a strawberry-like silver-loaded polysilsesquioxane nano-hybrid antibacterial material, comprising the steps of:

[0040] (1) Accurately weigh 30.5g of KH-550 and add it to a three-neck flask equipped with a condensing device. The system is heated to 120°C, the stirring speed is controlled at 150rpm, and 13.8g of succinic anhydride (commonly known as succinic anhydride) is added in batches. Afterwards, keep warm for 3 hours to obtain a transparent liquid, i.e. reactive monomeric carboxysilane (CTES-1);

[0041] (2) Accurately weigh 0.2g AEO3 and 0.2g AEO9, 0.18g sodium hydroxide catalyst and 100.2g distilled water and add successively in a three-necked flask equipped with a condensing device, stir at room temperature at 20°C for 0.5h (stirring speed is 200rpm), and then Begin to slowly add 12.8g methyltriethoxysilane (MTES) (drop speed is 20 drops / min) to carry out emulsion polymerization, MTES drop finishes, begin to slowly add 2.3g CTES-1 again ...

Embodiment 2

[0046] A preparation method of a strawberry-like silver-loaded polysilsesquioxane nano-hybrid antibacterial material, comprising the steps of:

[0047] (1) Accurately weigh 33.0g of KH-540 and add it into a three-necked flask equipped with a condensing device. The system is heated up to 70°C, the stirring speed is controlled at 200rpm, and 20.0g of glutaric anhydride is added in batches. After the addition of glutaric anhydride is completed, Insulated for 2.5 hours to obtain a transparent liquid, i.e. reactive monomeric carboxysilane (CTES-2);

[0048] (2) Accurately weigh 1.2g of AEO3 and 1.2g of AEO9, 0.8g of sodium hydroxide catalyst and 500g of distilled water into a three-necked flask equipped with a condensing device in turn, stir at room temperature at 15°C for 0.5h (stirring speed is 300rpm), and then start Slowly add 37.1g methyltrimethoxysilane (MTMS) (dropping speed is 20 drop / min) to carry out emulsion polymerization, MTMS drops complete, begin to slowly add 10g CT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com