Epoxy resin composition for printed circuit copper-clad plate

An epoxy resin, printed circuit technology, applied in printed circuit parts, circuit substrate materials, layered products, etc., can solve the problems of harsh resin Tg and heat resistance, large thermal expansion coefficient, and large performance drop, and achieve excellent Heat resistance, high glass transition temperature, small effect of Z-axis thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

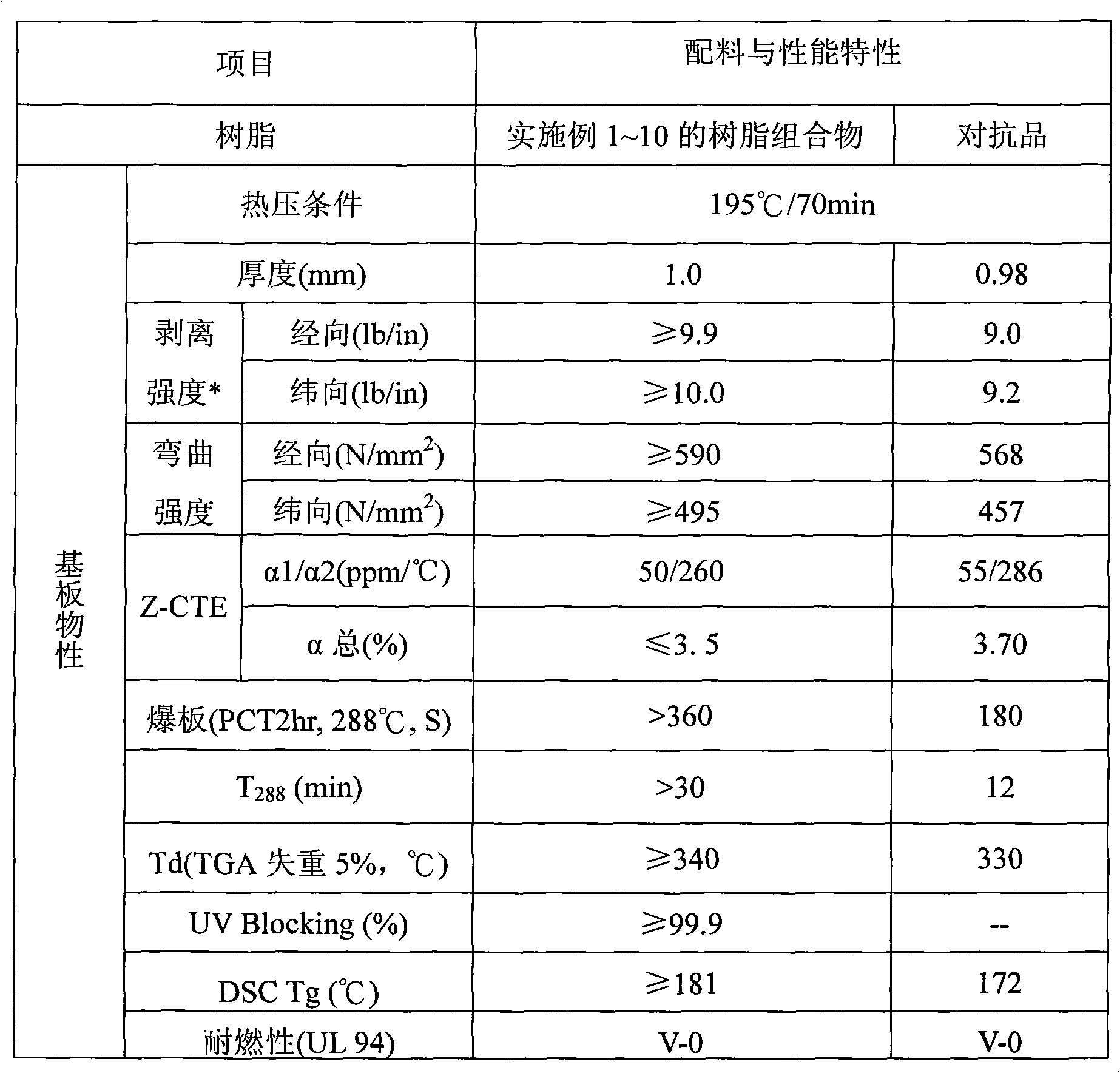

Examples

Embodiment 1

[0042] (1) Preparation of butanone solution containing modified epoxy resin:

[0043] Add 230 parts of bisphenol A epoxy resin, 64 parts of brominated bisphenol epoxy resin, 82 parts of novolac epoxy resin and 0.7 part of 30% tetramethylammonium chloride methanol solution into the reaction tank and mix well and heated. When the temperature was 90°C, 38 parts of isocyanate were added at one time, and reacted at 165°C for 3 hours. Cool down to 130°C again, add 129 parts of o-cresol novolac epoxy resin and 219 parts of brominated bisphenol type epoxy resin to mix, add methyl ethyl ketone to dissolve into a modified epoxy resin containing 75% solid content butanone solution. The above-mentioned consumptions are all parts by weight.

[0044] The epoxy resin mixture in the butanone solution containing modified epoxy resin has the following physical parameters:

[0045] epoxy equivalent

(g / eq)

(cps / 25℃)

Hydrolyzable Chlorine

(ppm)

bro...

Embodiment 2

[0052] (1) Preparation of butanone solution containing modified epoxy resin:

[0053] 230 parts of bisphenol A epoxy resin, 55 parts of brominated bisphenol type epoxy resin, 85 parts of novolac epoxy resin and 0.6 part of 30% tetramethylammonium chloride methanol solution are added to the reaction tank and mixed. heating. When the temperature was 90°C, 35 parts of isocyanate was added at one time, and reacted at 165°C for 3 hours. Cool down to 130°C again, add 132 parts of o-cresol novolac epoxy resin and 220 parts of brominated bisphenol type epoxy resin to mix, add methyl ethyl ketone to dissolve into a butylated solution of modified epoxy resin with a solid content of 75%. Ketone solution. The above-mentioned consumptions are all parts by weight.

[0054] The physical parameters of the epoxy resin mixture in the butanone solution containing the modified epoxy resin are the same as in Example 1.

[0055] (2) Preparation of epoxy resin composition:

[0056] Add inorgani...

Embodiment 3

[0062] (1) Preparation of butanone solution containing modified epoxy resin:

[0063] Add 40 parts of bisphenol A epoxy resin, 15 parts of brominated bisphenol type epoxy resin and 0.8 part of 30% methanol solution of tetramethylammonium chloride into the reaction tank, mix uniformly and heat. When the temperature was 90°C, 19 parts of tetrabromobisphenol A were added at one time, and reacted at 165°C for 3 hours. Then lower the temperature to 130° C., add 25 parts of o-cresol novolac epoxy resin for mixing, add methyl ethyl ketone to dissolve into a methyl ethyl ketone solution with a solid content of 75% of the modified epoxy resin. The above-mentioned consumptions are all parts by weight.

[0064] The physical parameters of the epoxy resin mixture in the butanone solution containing the modified epoxy resin are the same as in Example 1.

[0065] (2) Preparation of epoxy resin composition:

[0066] With embodiment 2.

[0067] (3) Curing of resin composition and preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com