Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186 results about "Porous polymer membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

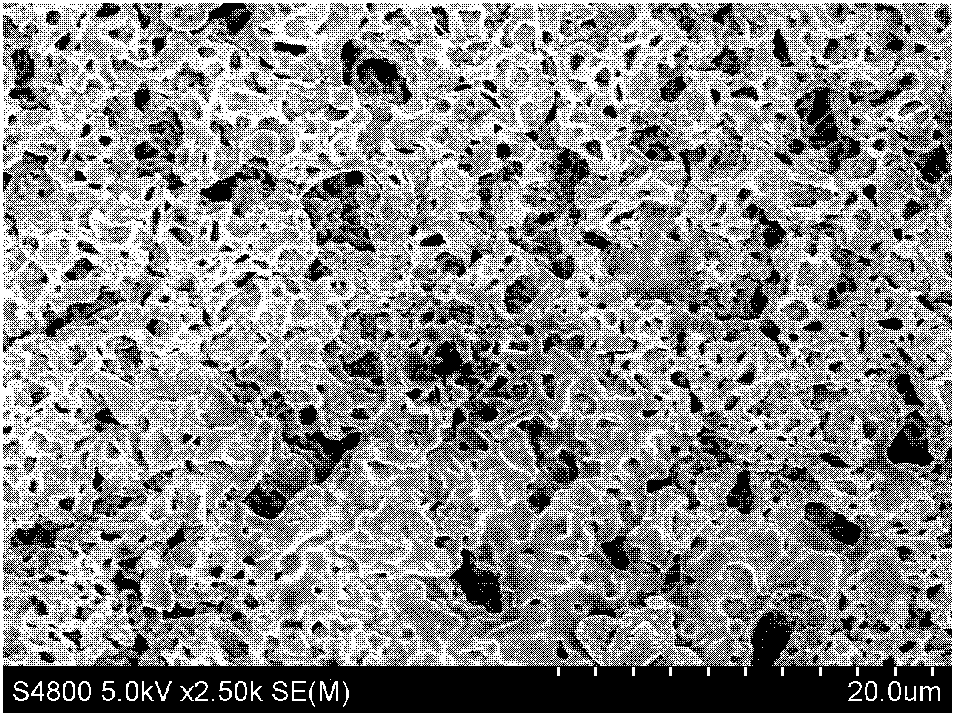

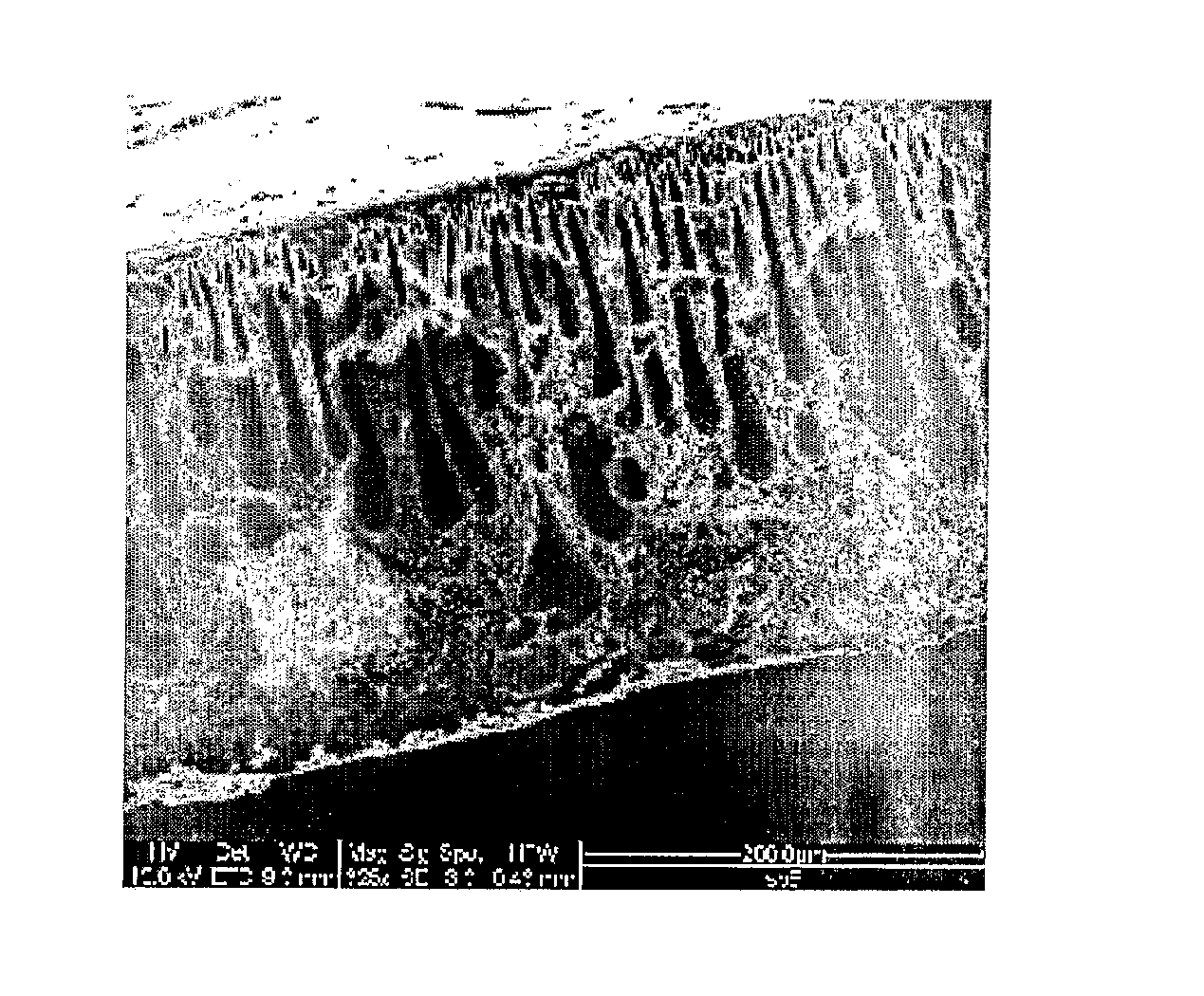

Definition of Porous and Polymeric Membranes. Porous and polymeric membranes have a thin layer of semi-permeable material that is used for solute separation as transmembrane pressure is applied across the membrane.

Poly(ethylene chlorotrifluoroethylene) membranes

InactiveUS7247238B2Improve permeabilityImprove integrityMembranesSemi-permeable membranesFiberGlycerol

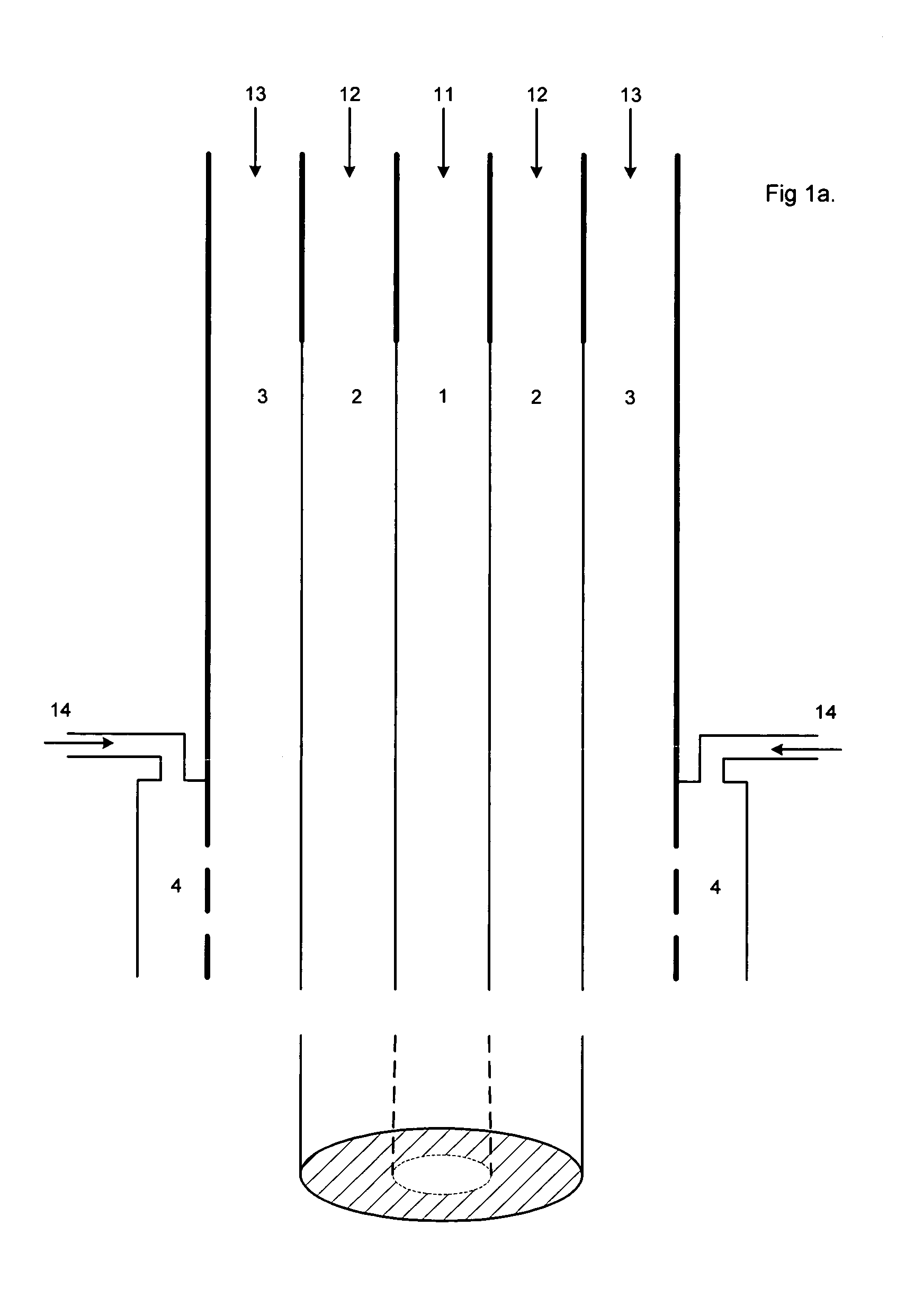

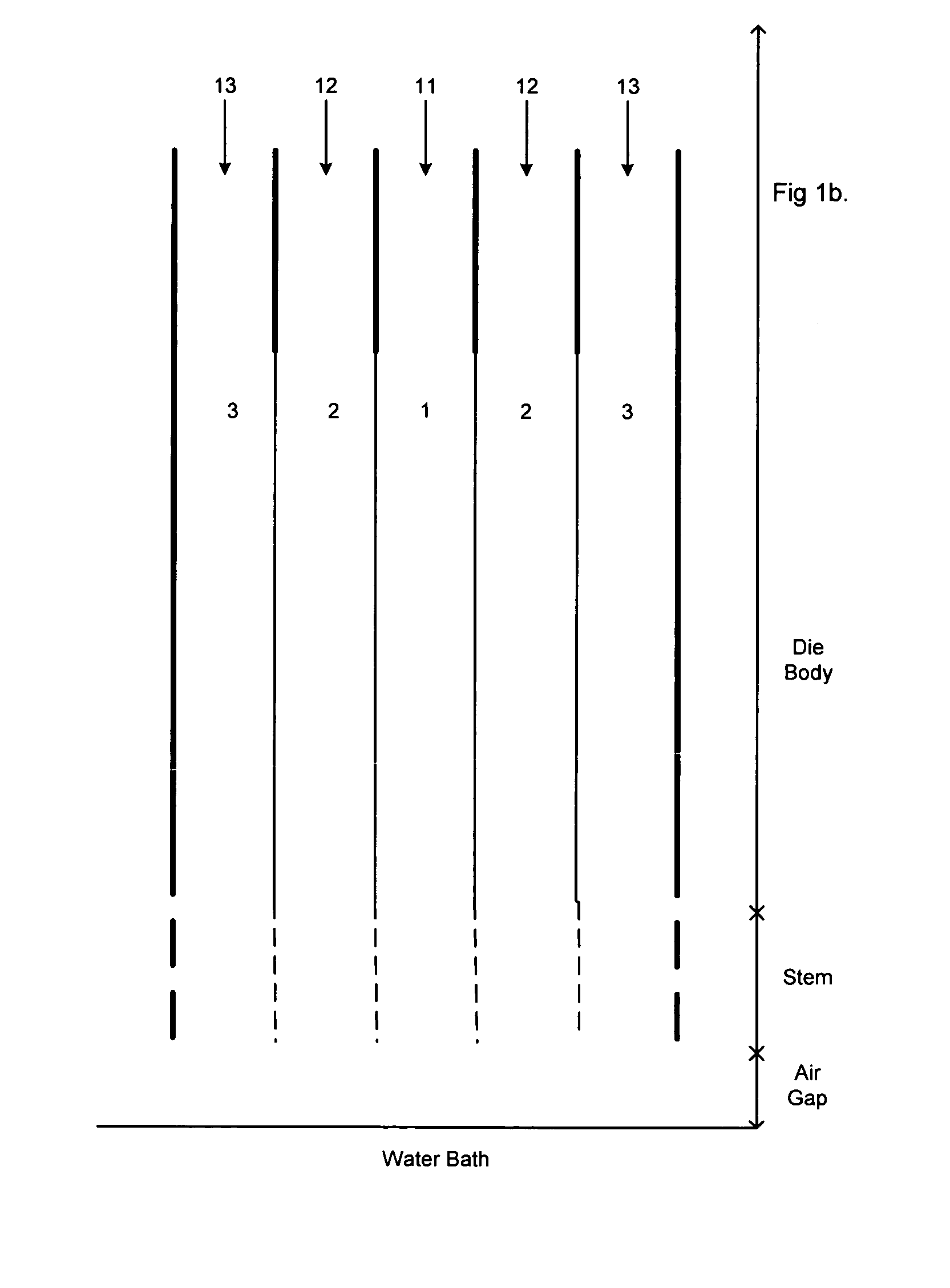

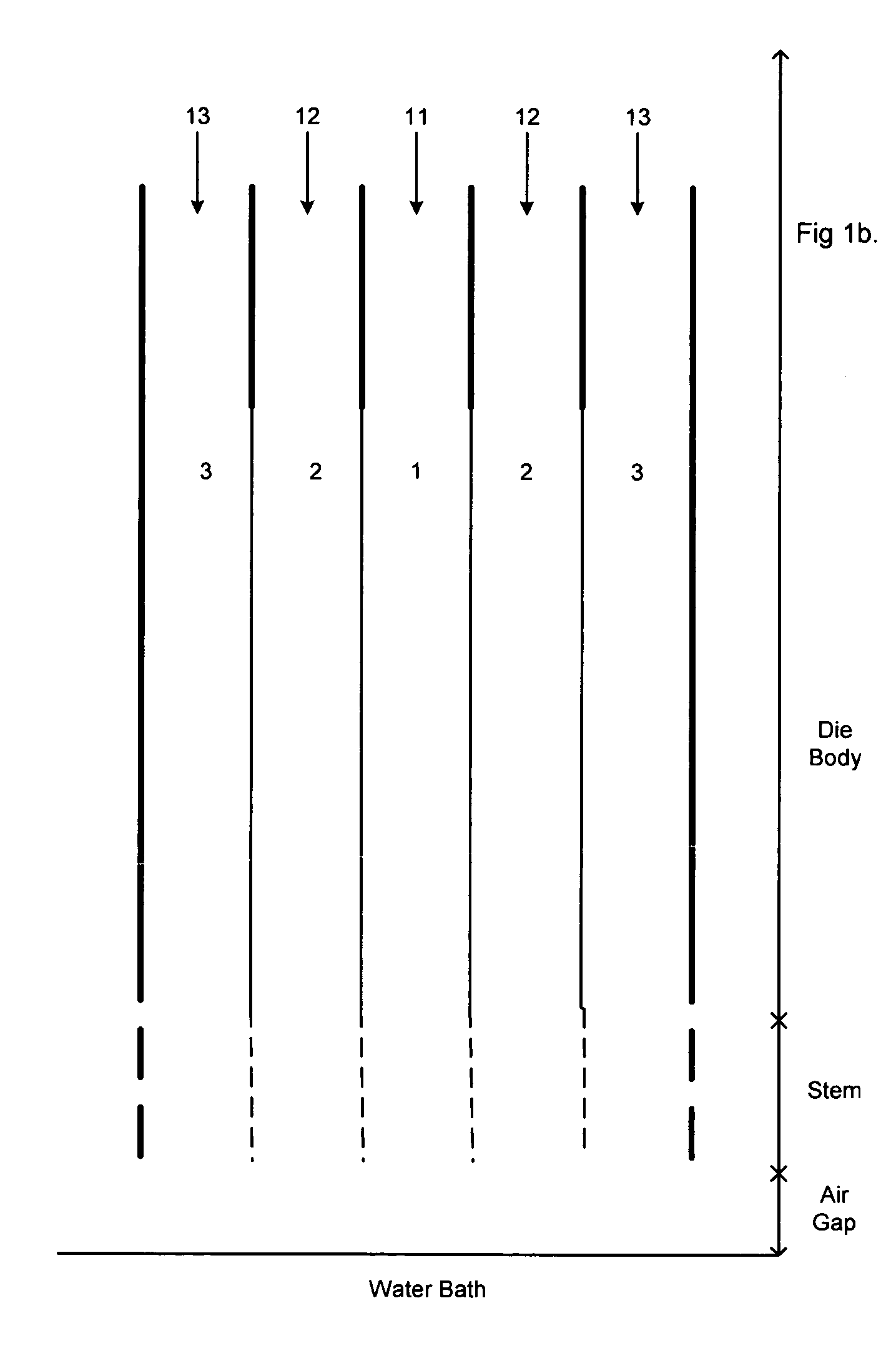

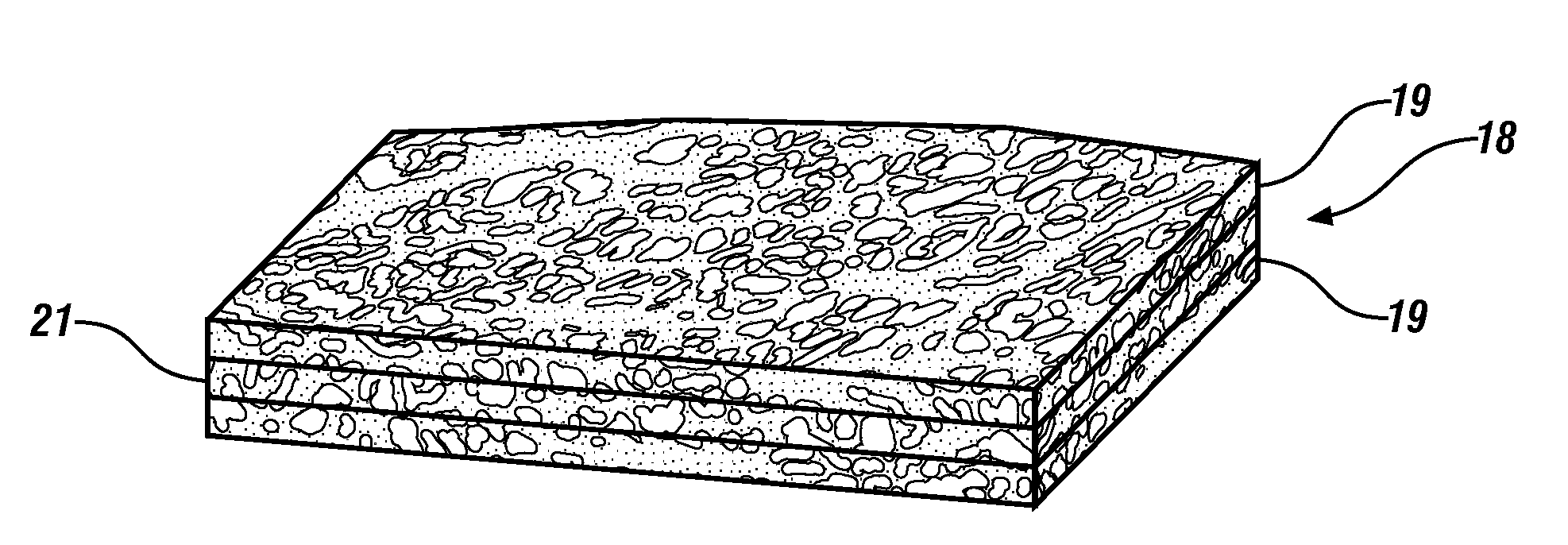

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fiber or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

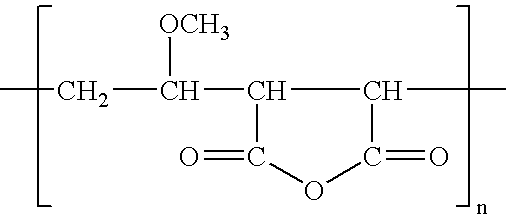

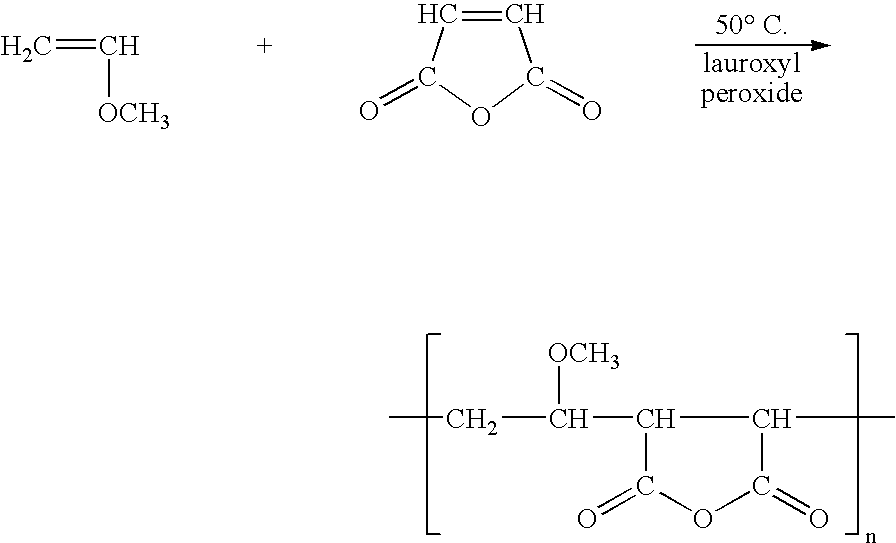

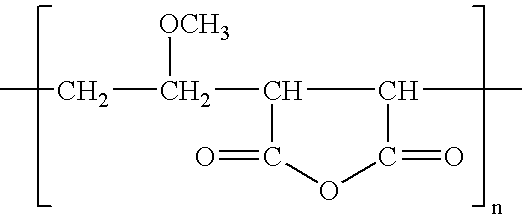

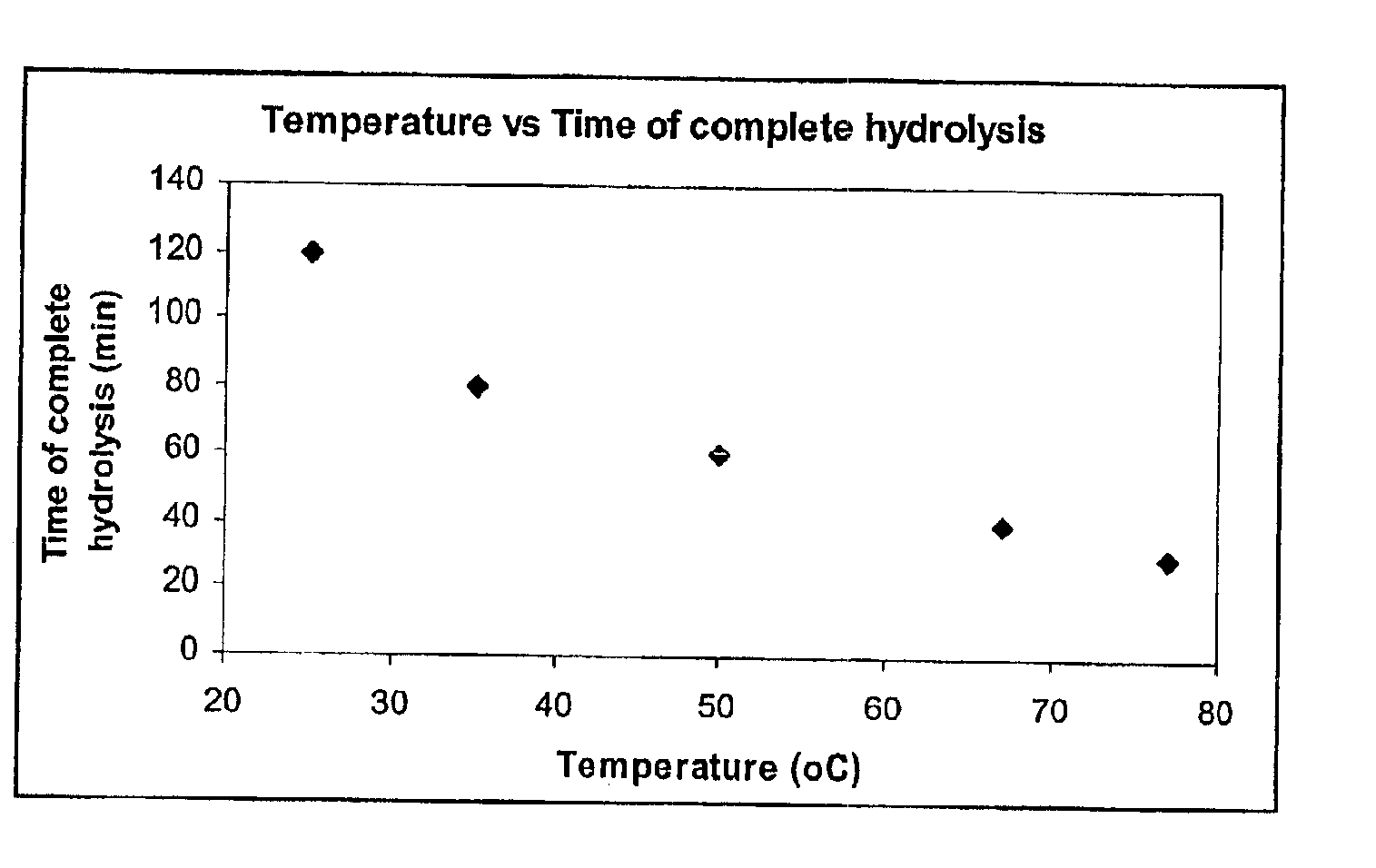

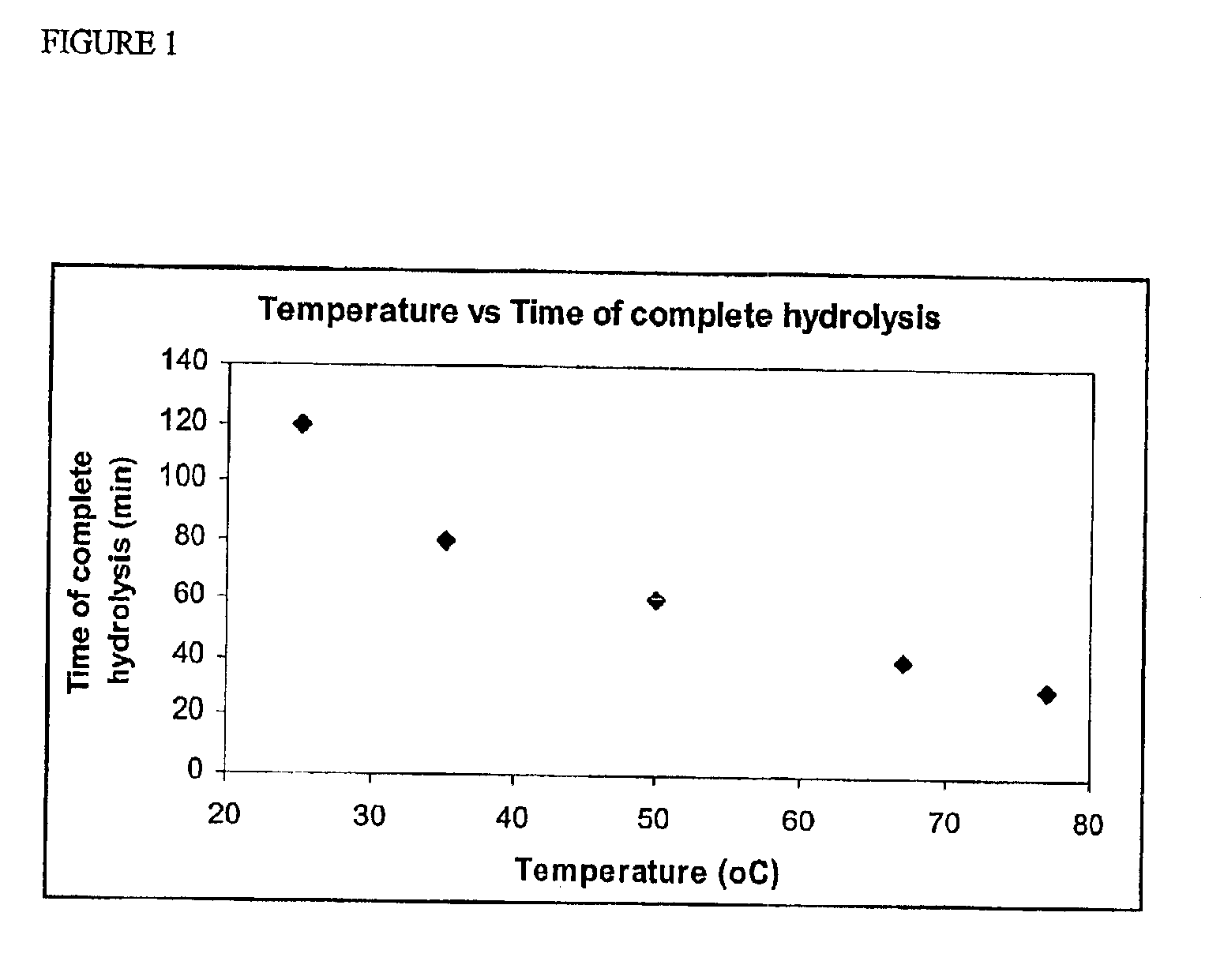

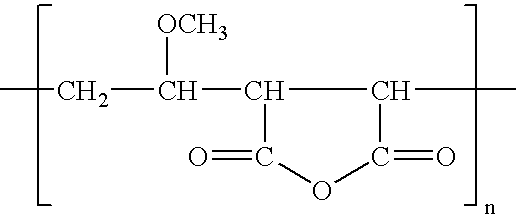

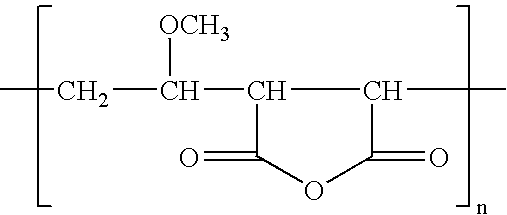

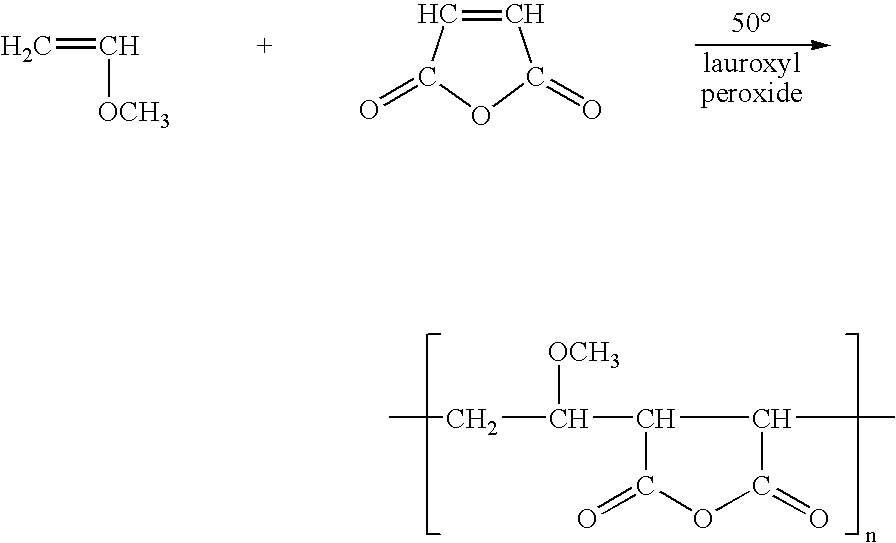

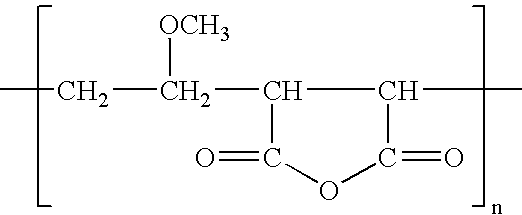

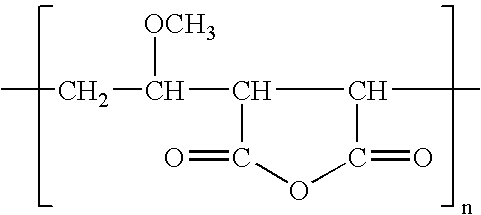

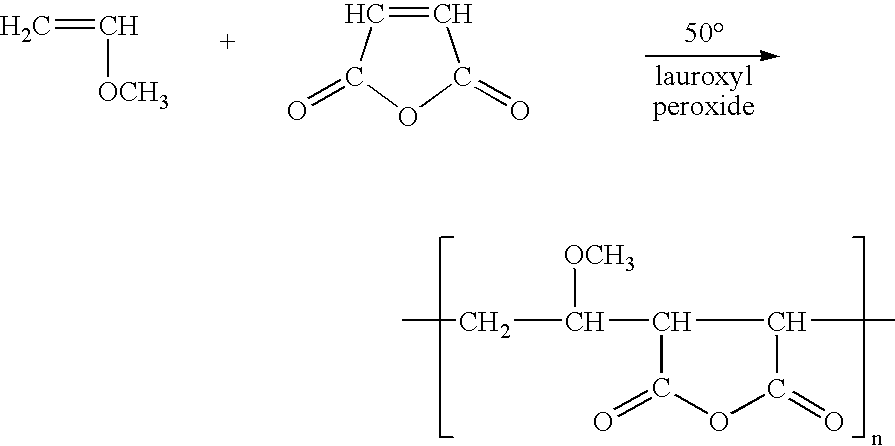

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Halar membranes

InactiveUS20050098494A1Low toxicityImprove permeabilityMembranesSemi-permeable membranesFiberGlycerol

Porous polymeric membranes including Halar (poly (ethylene chlorotrifluoroethylene)) and related compounds and the methods of production thereof which avoid the use of toxic solvents. Preferred solvents, coating agents and pore forming agents are citric acid ethyl ester or glycerol triacetate. The membranes may be in the form of a hollow fibre or flat sheet, and may include other agents to modify the properties of the membrane, such as the hydrophilic / hydrophobic balance. Leachable agents may also be incorporated into the membranes.

Owner:EVOQUA WATER TECH LLC

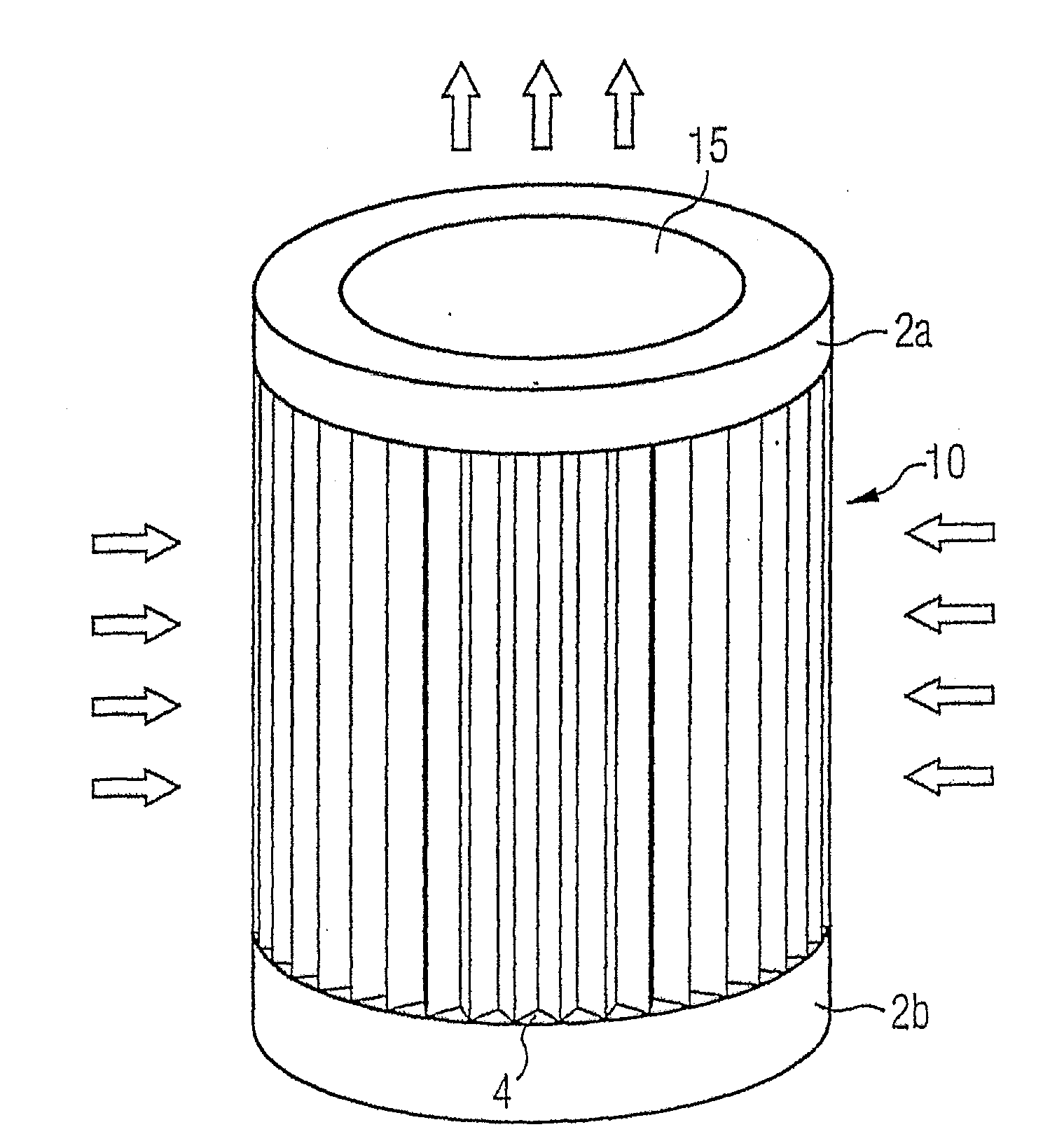

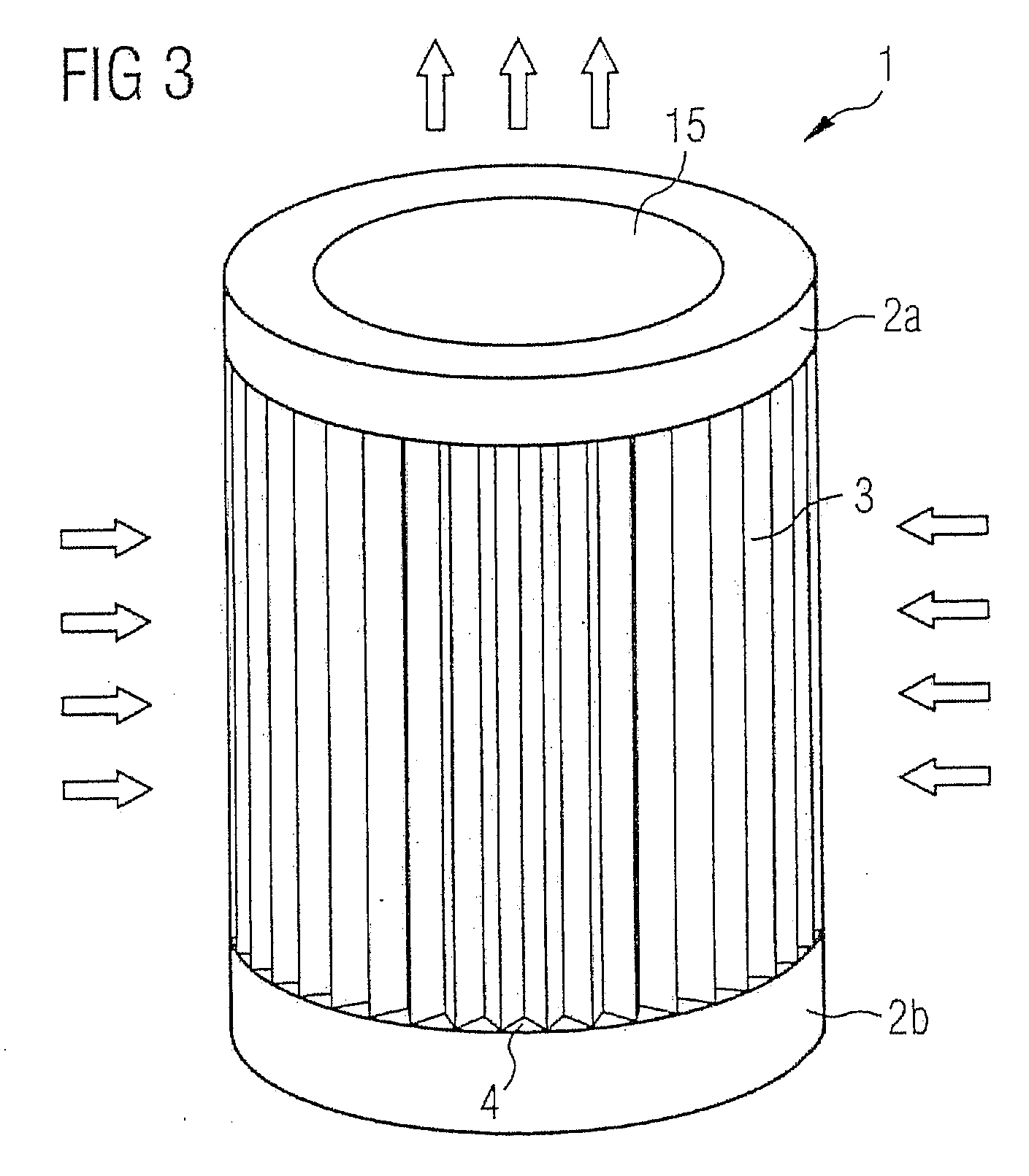

Turbine Air-Intake Filter

InactiveUS20090266048A1Improve filtering effectSimple wayGas treatmentDispersed particle filtrationFiberFiltration

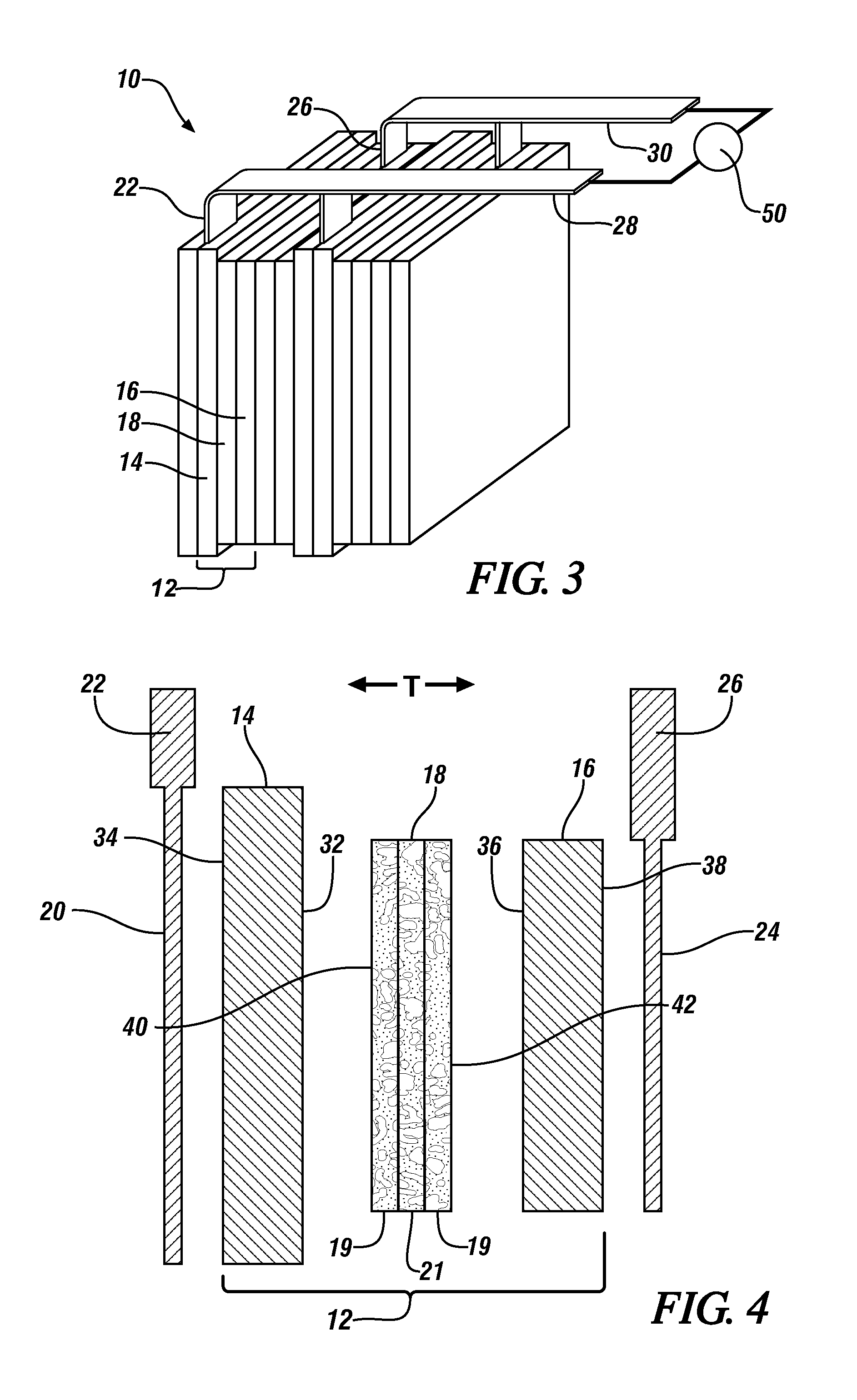

A turbine air-intake filter for removal of particles from an air stream entering a gas turbine comprises a composite filter media (10) being made from a membrane filtration layer (20) comprising a porous polymeric membrane, such as porous polytetrafluoroethylene (ePTFE), and at least one depth filtration media layer (18) comprising fibers, such as a melt blown web, and being disposed on an upstream side of the membrane filtration layer (20) relative to a direction of gas flow through the filter. The fibers of the depth filtration media layer (18) have an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT

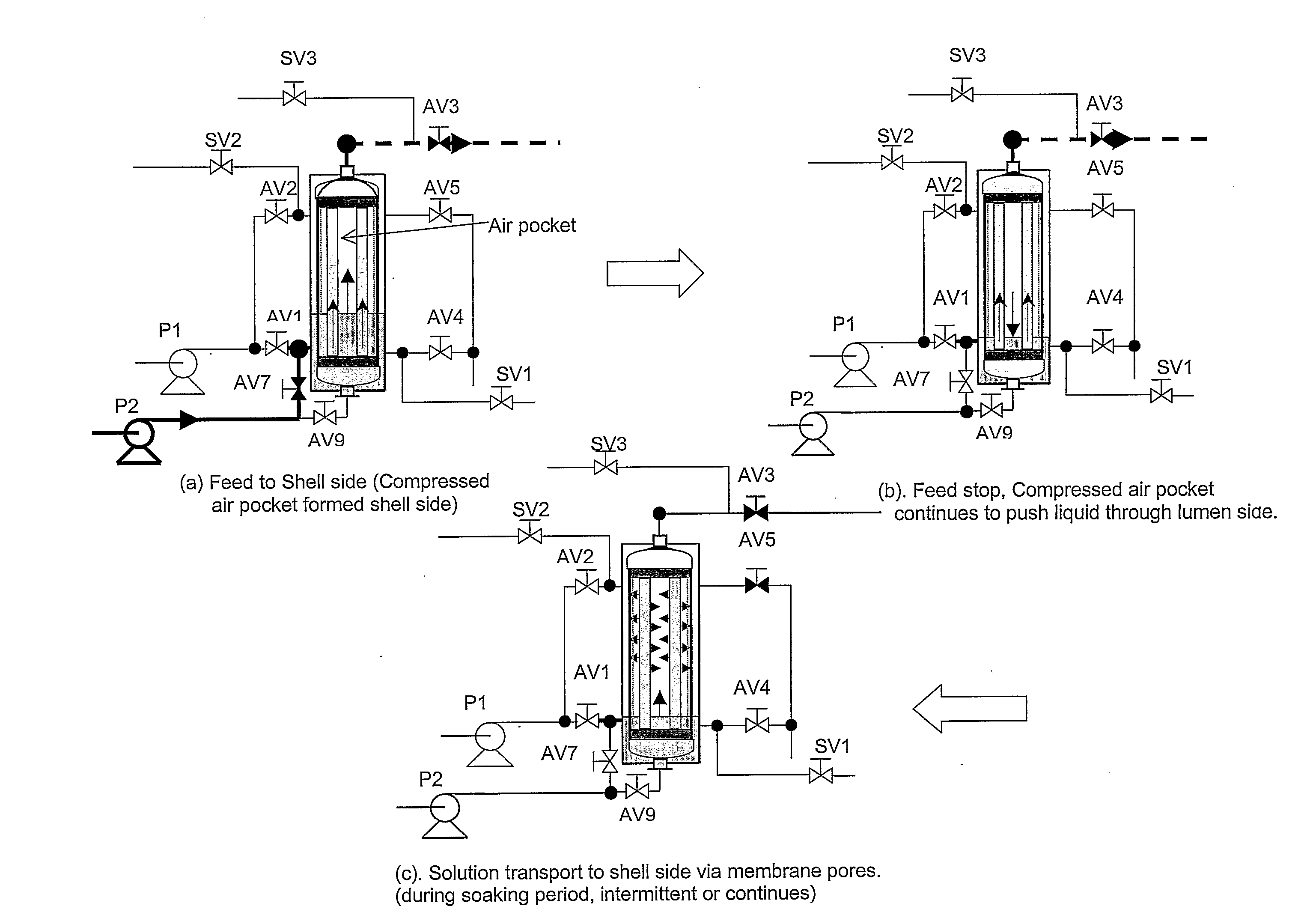

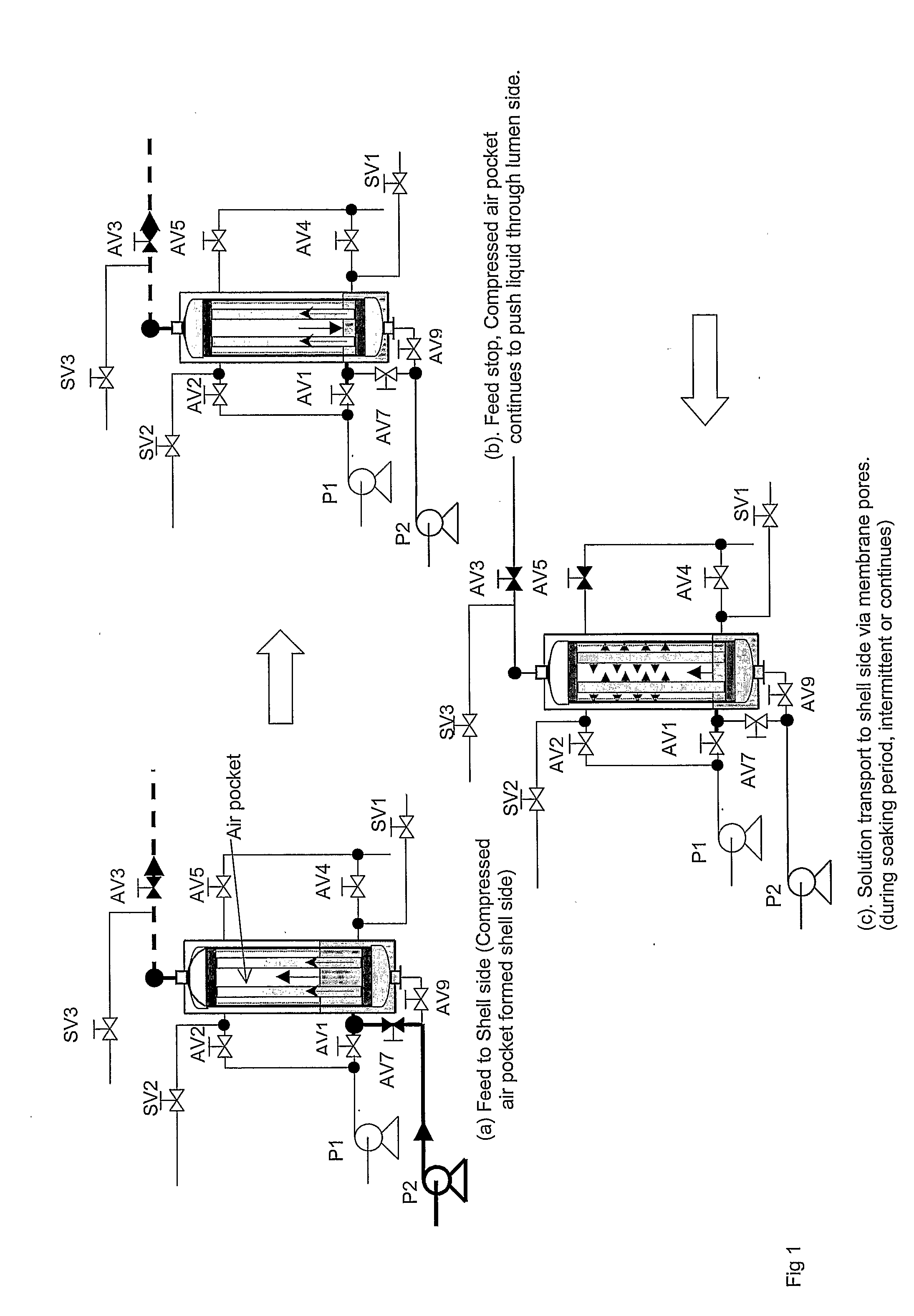

Chemical Clean For Membrane Filter

ActiveUS20080203017A1Facilitate wetting out and dissolvingLower the volumeSpecific water treatment objectivesUltrafiltrationConcentration gradientCleansing Agents

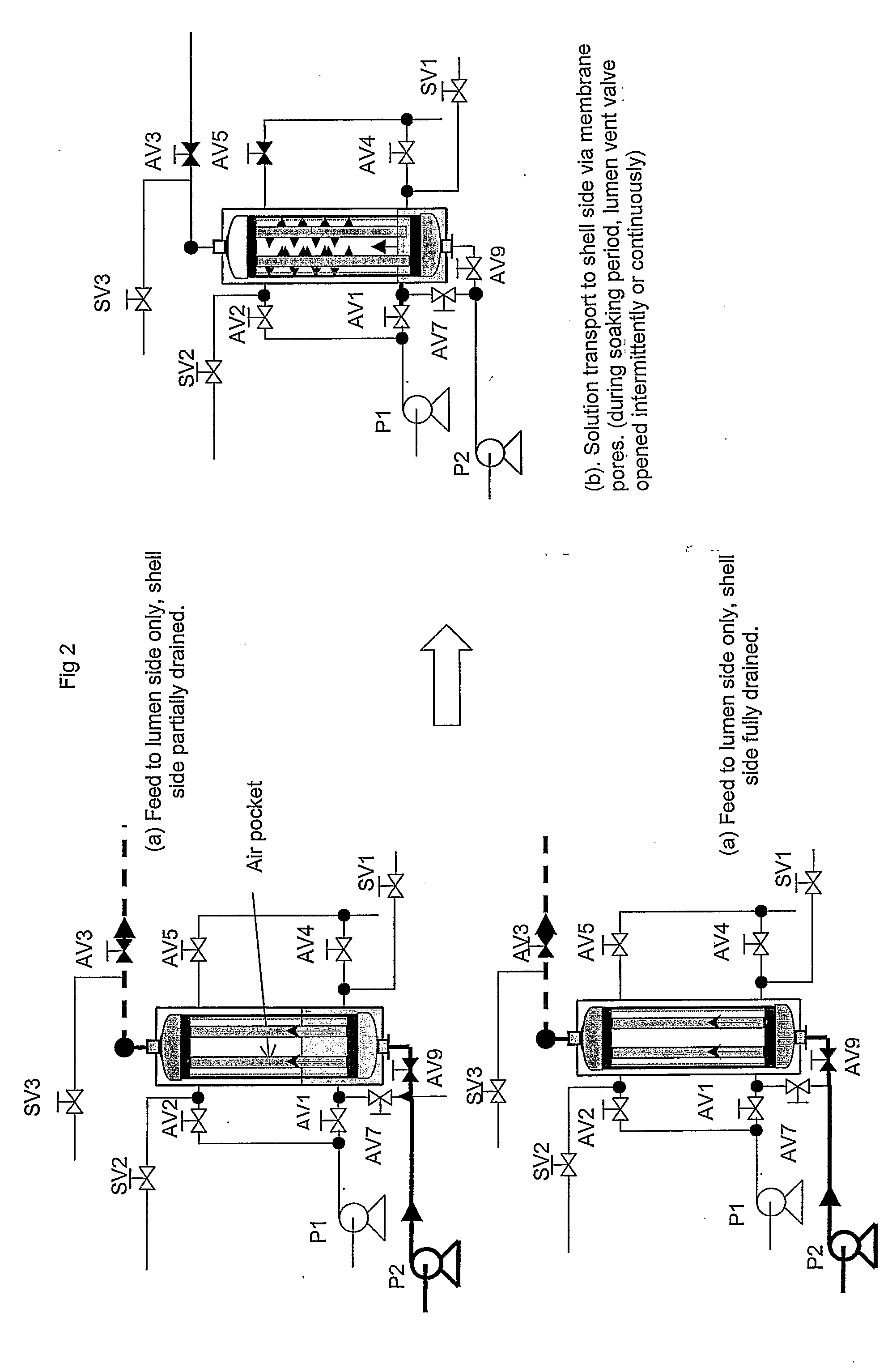

A method of cleaning a porous polymeric membrane having a feed side and a permeate side including the steps of introducing a fluid containing a cleaning agent to the permeate side of a membrane allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane, or introducing a fluid containing a cleaning agent to the feed side of a membrane; applying a transmembrane pressure to force the fluid containing the cleaning agent from the feed side to the permeate side of the membrane; allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane. Preferably a concentration gradient between the feed side fluid and the lumen side fluid containing the cleaning agent causes cleaning agent to diffuse into the feed side fluid. Pressure may be applied to the fluid containing a cleaning agent to dislodge, where present, dissolved and undissolved solid from the membrane pores. The pressure may be applied in a pulsed fashion, and can be by way of compressed air at a pressure not more than the membrane's bubble point. The methods of the present invention may be preceded by, or followed with a backwash.

Owner:EVOQUA WATER TECH LLC

Polyelectrolyte membrane and production method therefor

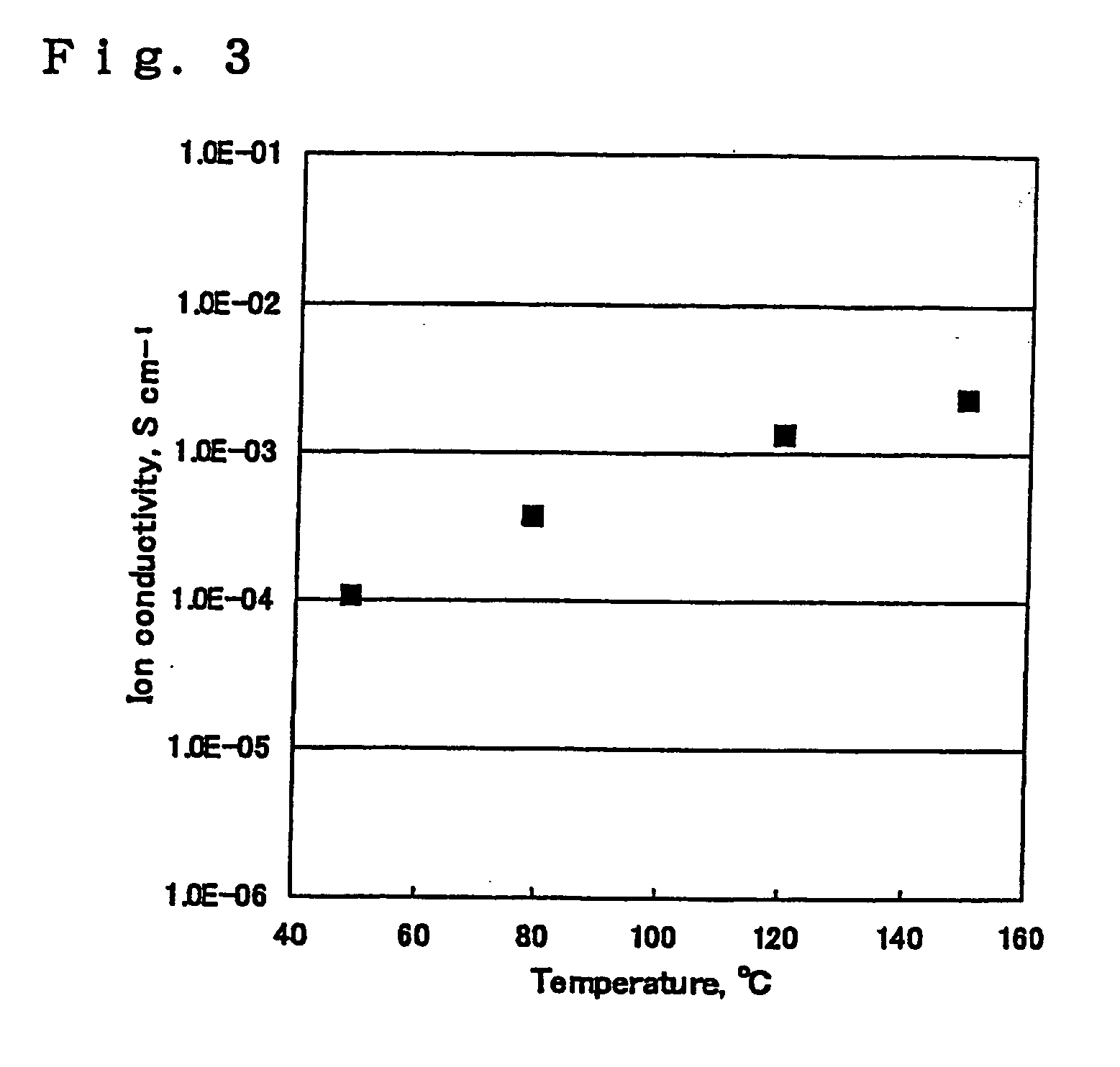

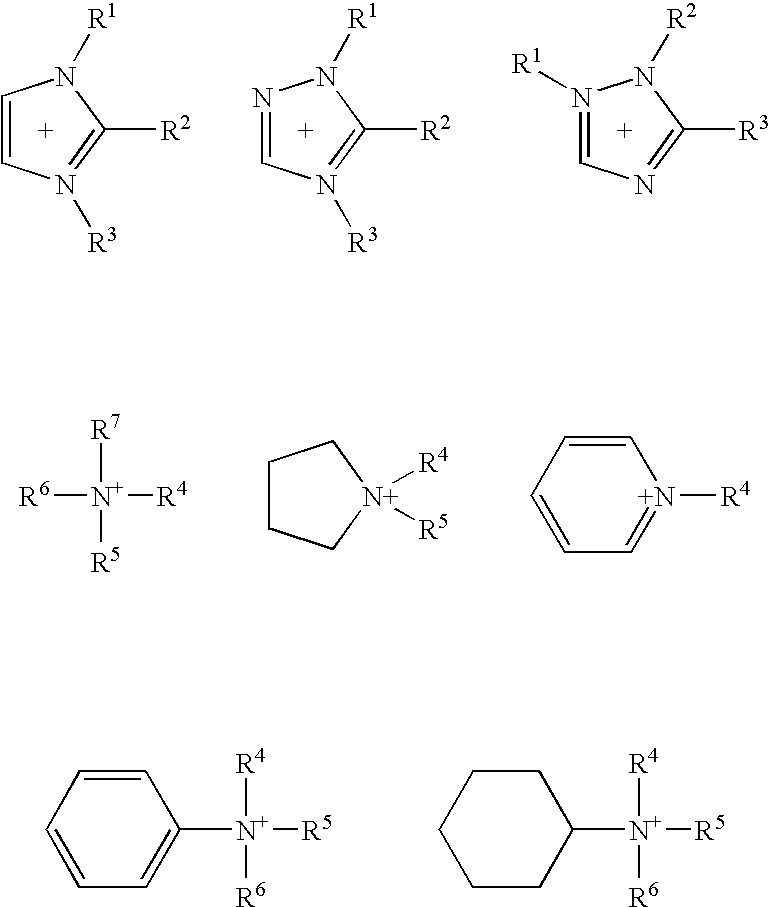

InactiveUS20050221193A1High mechanical strengthSecures high ion conductivityCell electrodesFuel cell auxillariesPolymer scienceElectrolysis

A polymer electrolyte membrane comprising a microporous polymer membrane having pores penetrating through the opposite sides thereof. The microporous polymer membrane holds a mixture of a polymer and a molten salt at a weight ratio of 1 / 99 to 99 / 1 and / or a molten salt. The polymer electrolyte membrane is inexpensive, durable, excellent in mechanical strength, excellent in structural retention in high temperatures, and capable of stably holding a molten salt in its porous polymer membrane structure, shows high heat resistance, and secures high ionic conductivity in the absence of water or a solvent and is therefore useful in fuel cells, secondary batteries, electric double layer capacitors, electrolytic capacitors, and the like.

Owner:UBE IND LTD

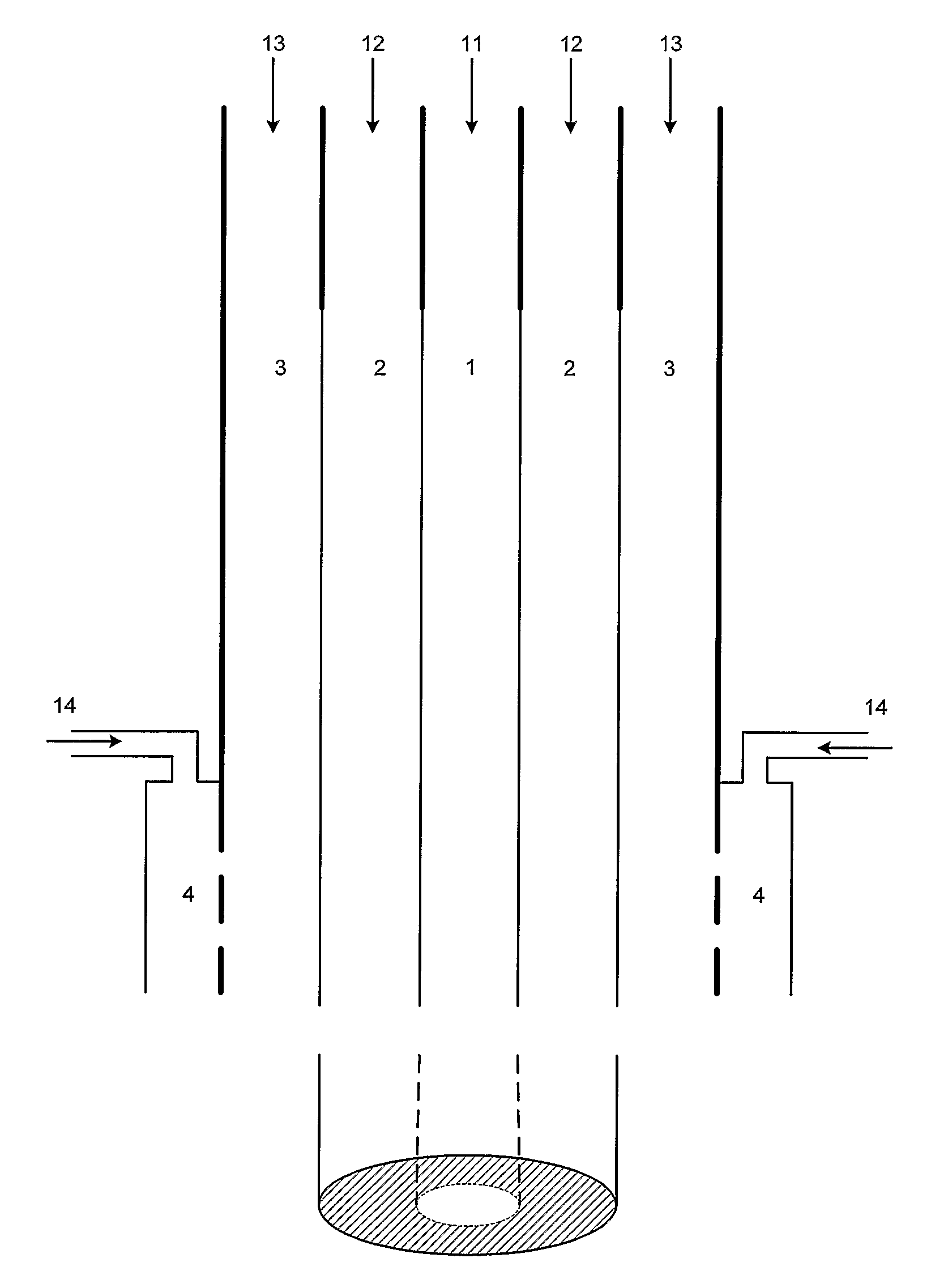

Gas transfer membrane

Porous polymeric membranes formed from a hydrophobic polymer, such as halar having membrane pores of a size sufficient to permit gas and / or vapor permeation 0.05 μm to 5 μm without permitting the flow of a hydrophilic fluid across the membrane. Pore distribution is uniform and porosity is high, in some cases up to 80%. Membranes may be in the form of a flay sheet or hollow fibre for example and can be used in a variety of applications such as stripping HF gas, degassing of caustic solution, chlorine gas / alkaline filtration, degassing tap water to remove dissolved chlorine. Processes used to make such membranes can be carried out using relatively non toxic solvents such as citric acid ethyl ester or glycerol triacetate.

Owner:EVOQUA WATER TECH LLC

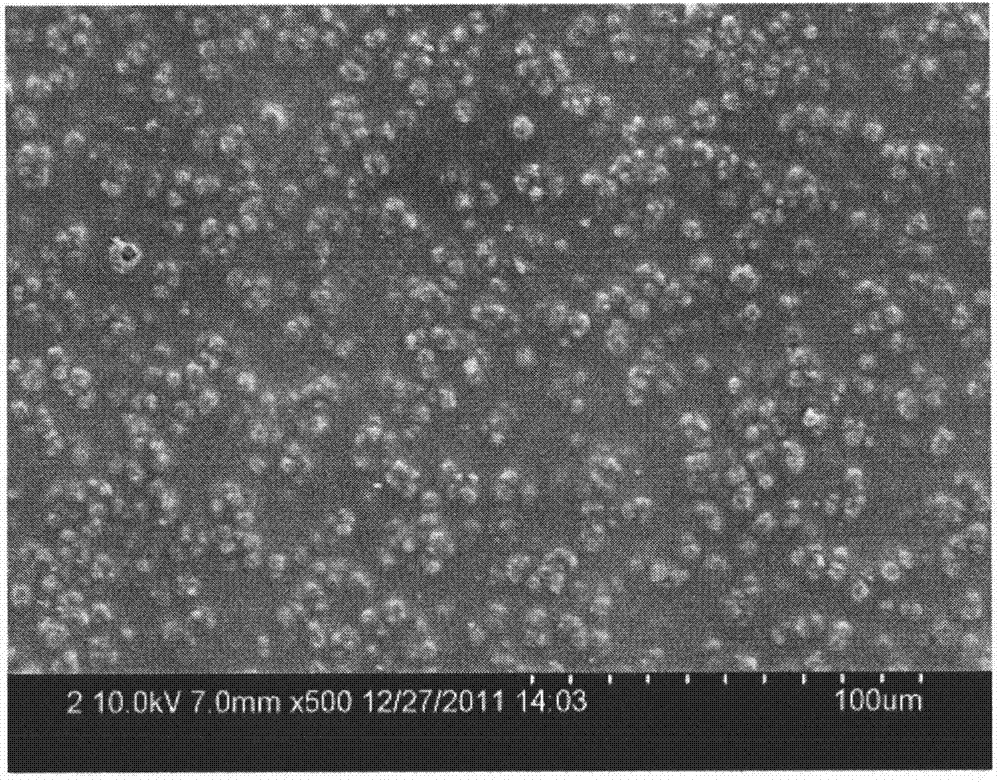

Bacterial cellulose/polymer composite film and preparation method thereof

The invention relates to a bacterial cellulose / polymer composite film and a preparation method thereof. The bacterial cellulose / polymer composite film is formed by compounding bacterial cellulose fibers on a polymer porous material in situ. The method comprises the following steps of: (1) activating strains, finally inoculating into a liquid culture medium to culture, infiltrating the surface of the porous polymer film in the liquid culture medium and exposing in air; (2) repeating the operation every 2-3 days until a composite film is formed; (3) post-treating the composite film to be neutral to obtain a bacterial cellulose / polymer composite gel film; and (4) drying the gel film obtained in the step (3) to constant weight to obtain the bacterial cellulose / polymer composite dry film. The invention solves the problem of low mechanical strength of a single bacterial cellulose film. By utilizing hydrogen bonding produced by hydroxyl groups on cellulose macromolecules, the strength, the durability and the water absorbability of the bacterial cellulose / polymer composite gel film and the composite dry film are improved.

Owner:DONGHUA UNIV

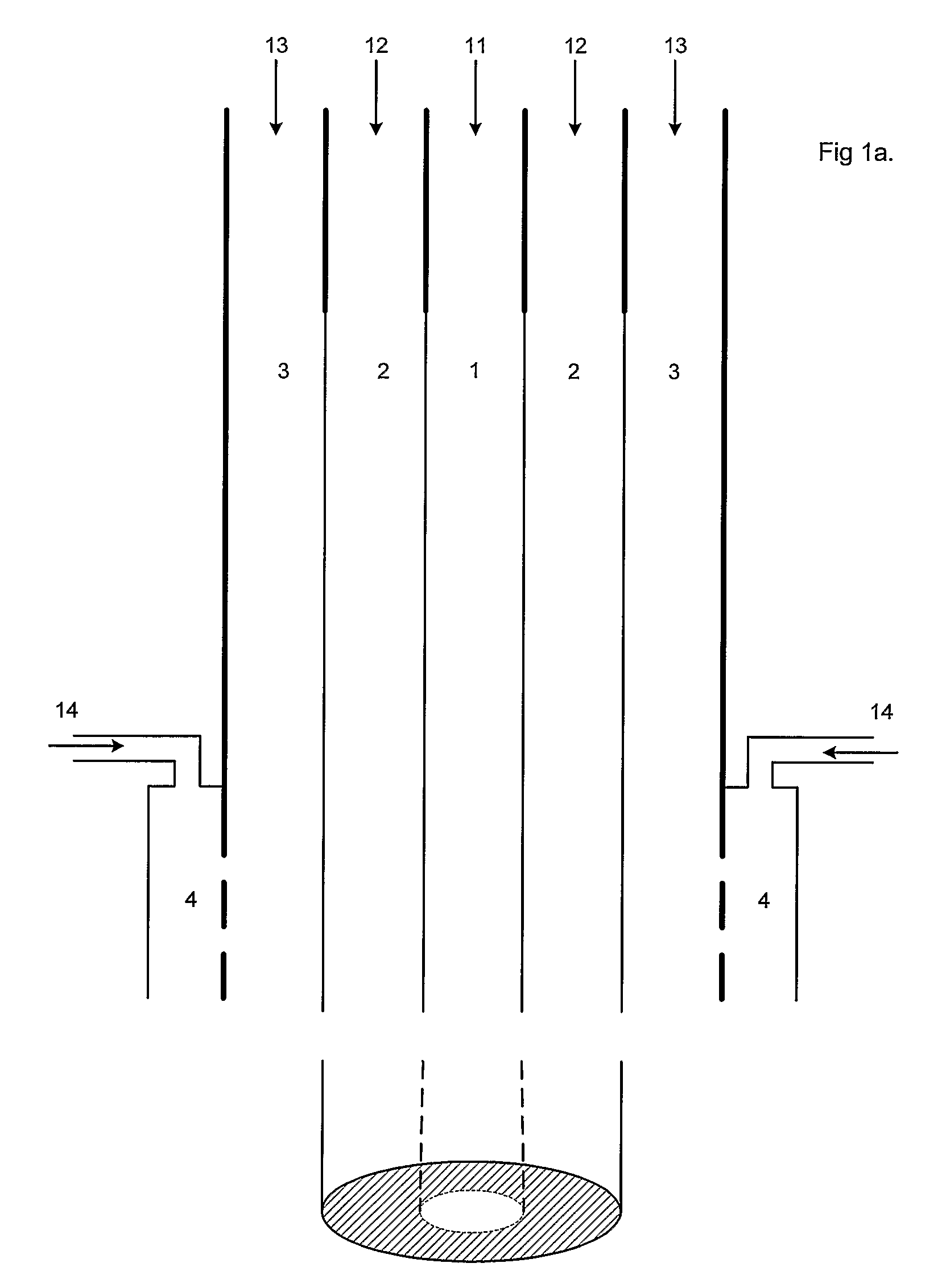

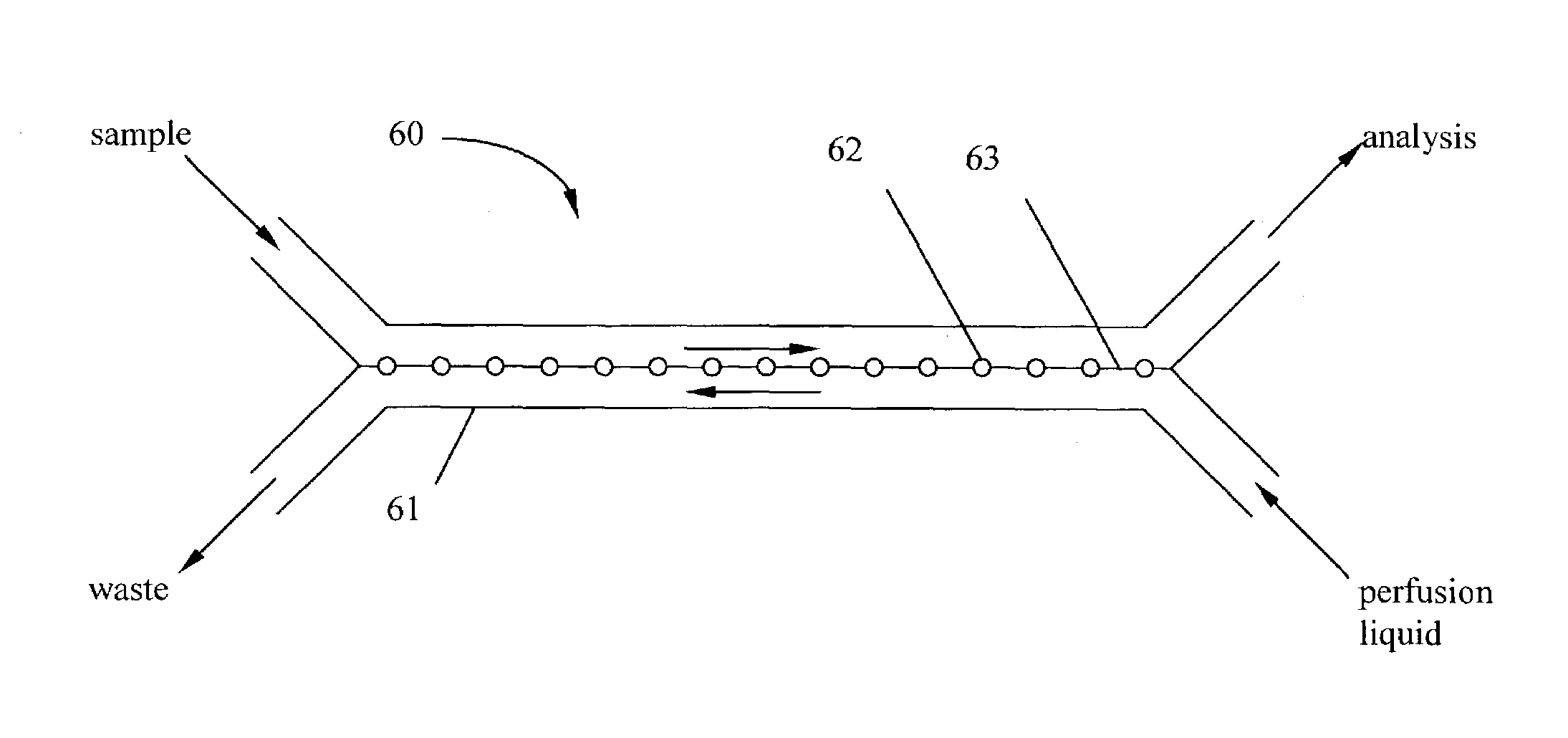

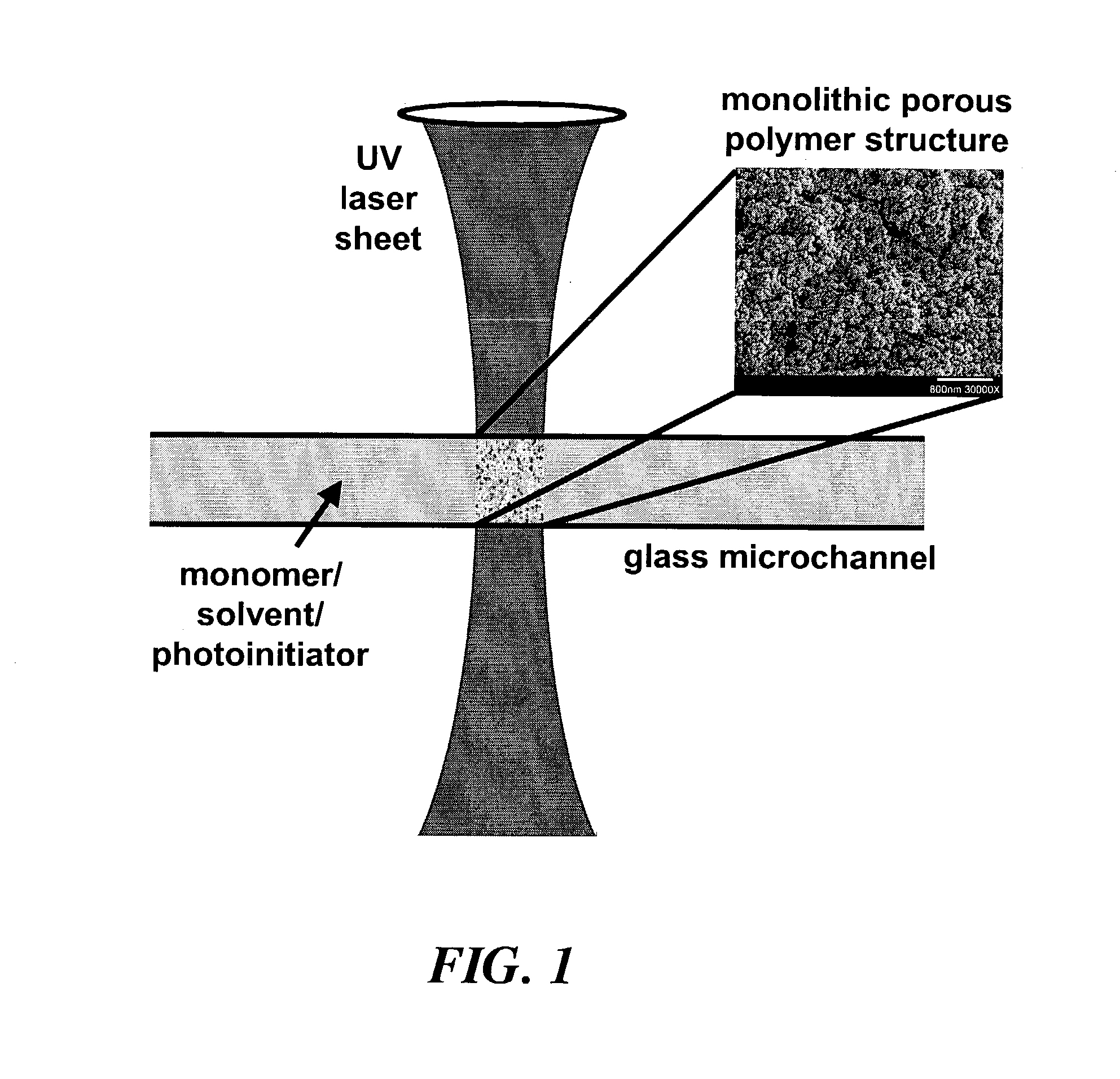

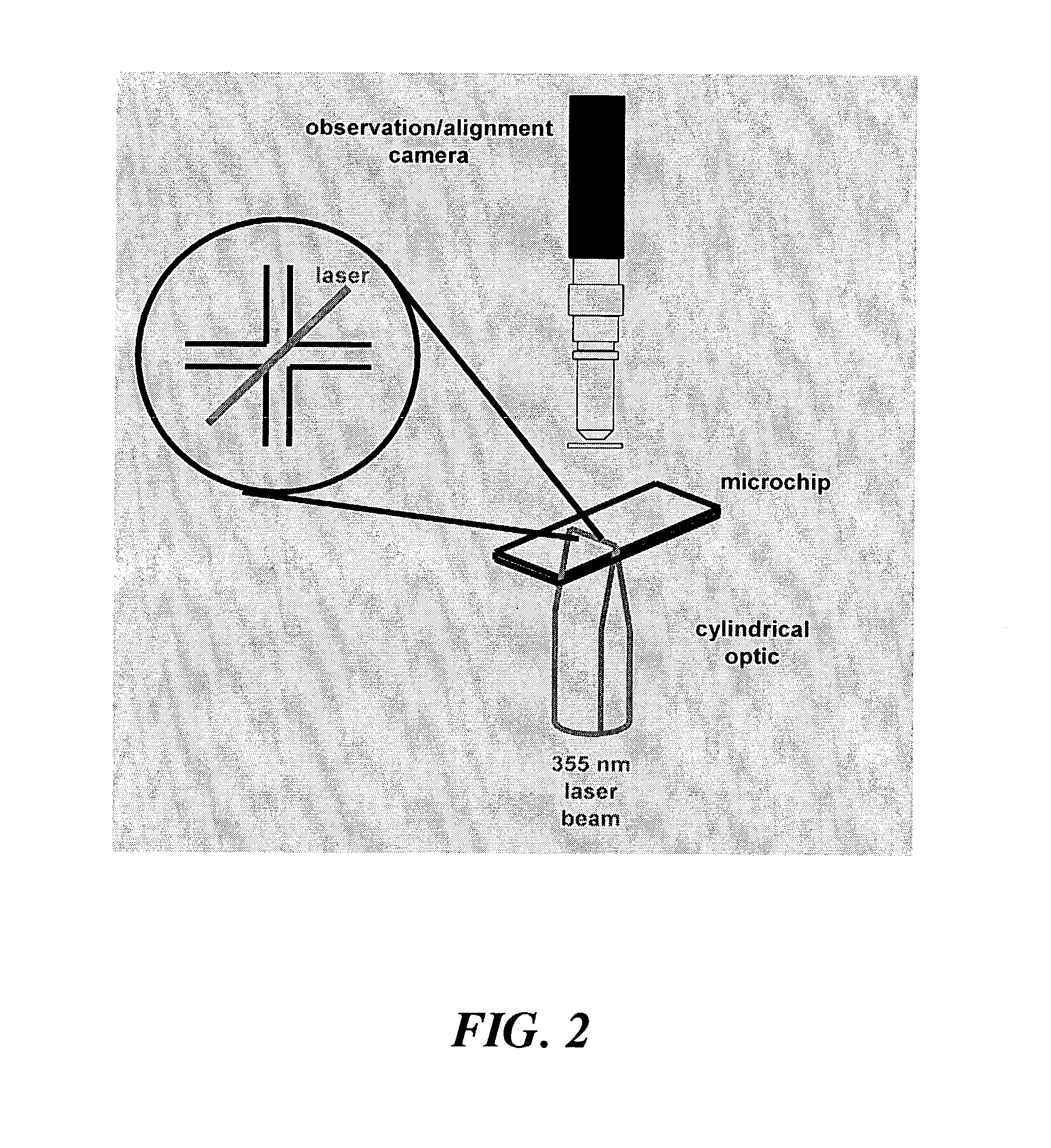

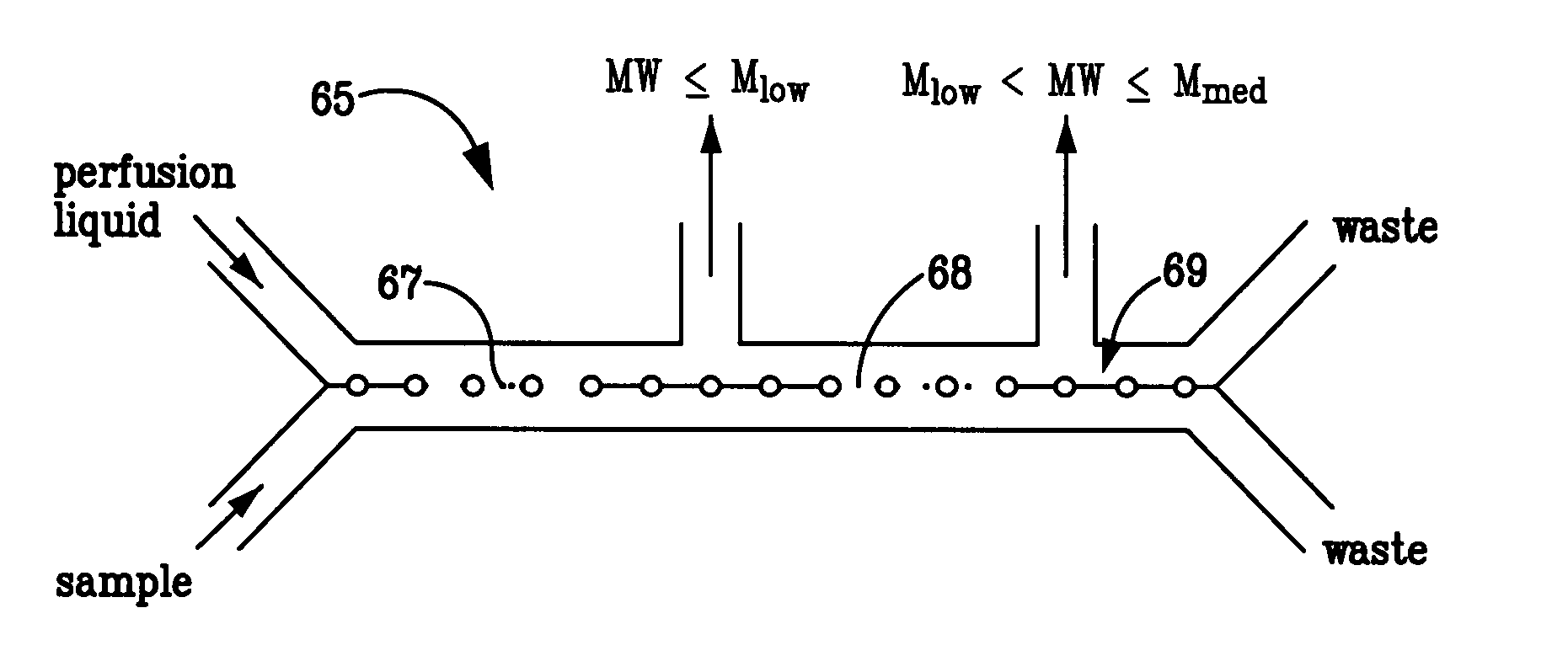

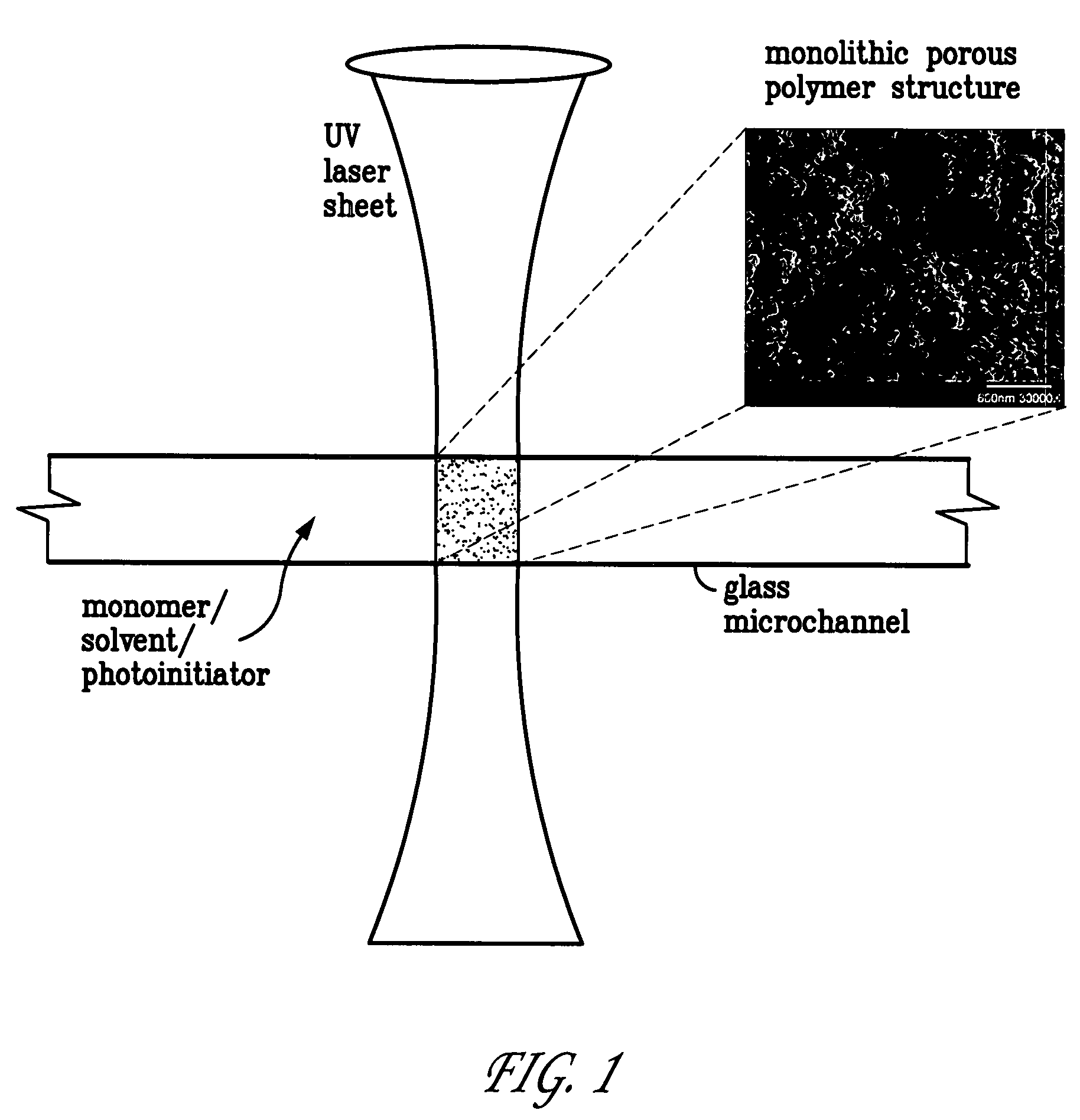

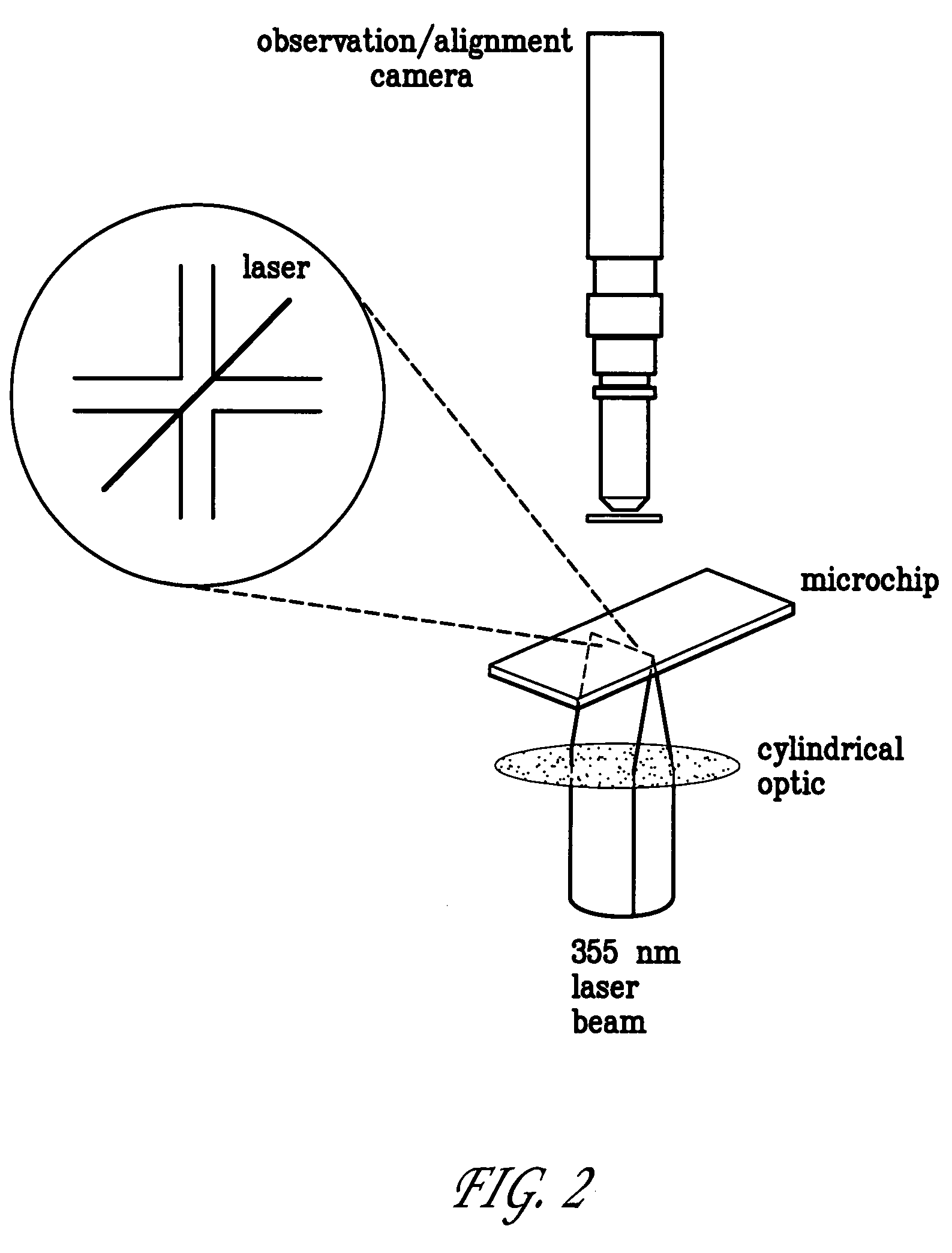

Dialysis on microchips using thin porous polymer membranes

ActiveUS7264723B2Minimize handlingComplicated operationSolvent extractionTransportation and packagingDialysis membranesMeth-

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and form a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:SANDIA NAT LAB

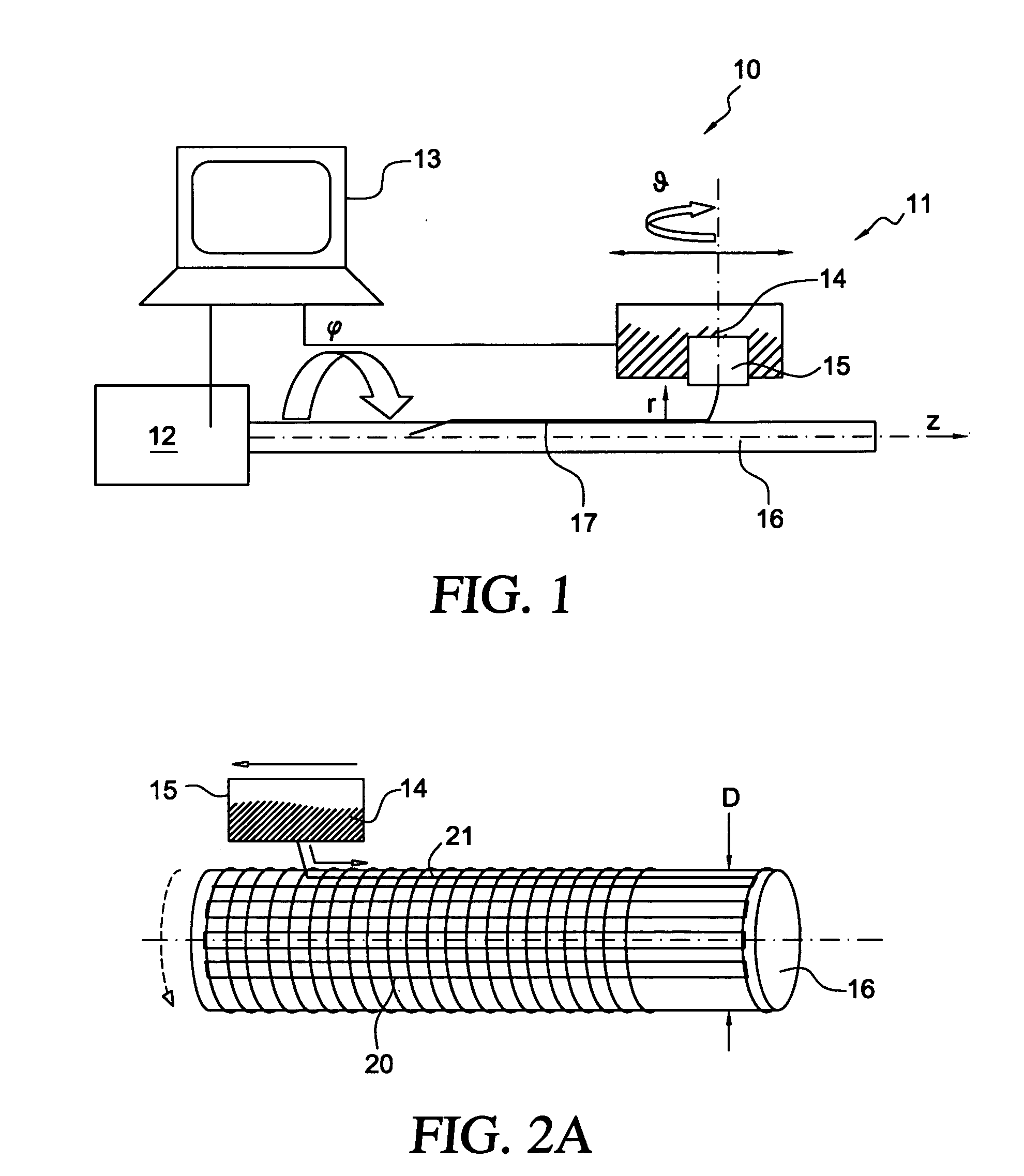

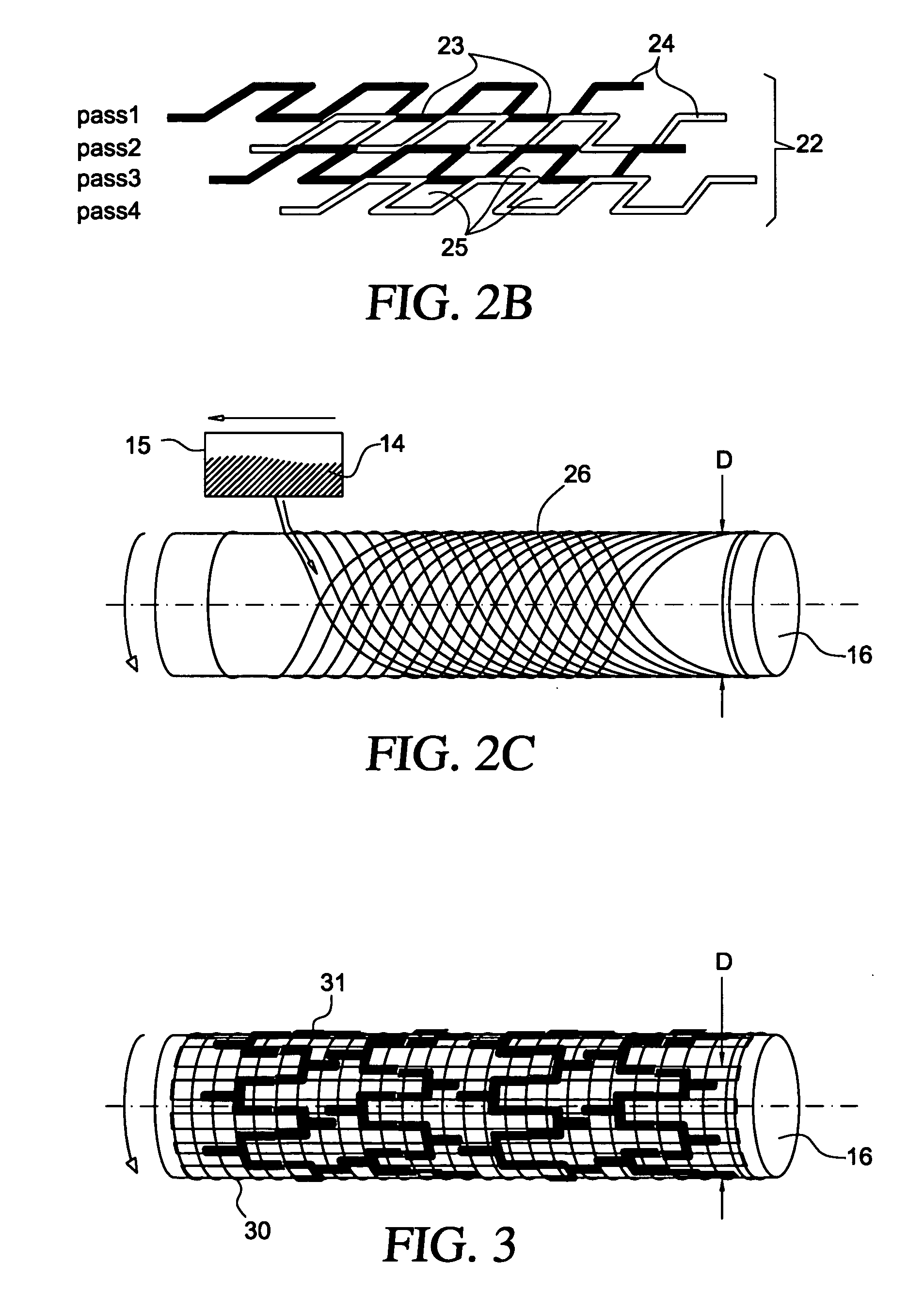

Porous membranes for medical implants and methods of manufacture

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Porous membranes for medical implants and methods of manufacture

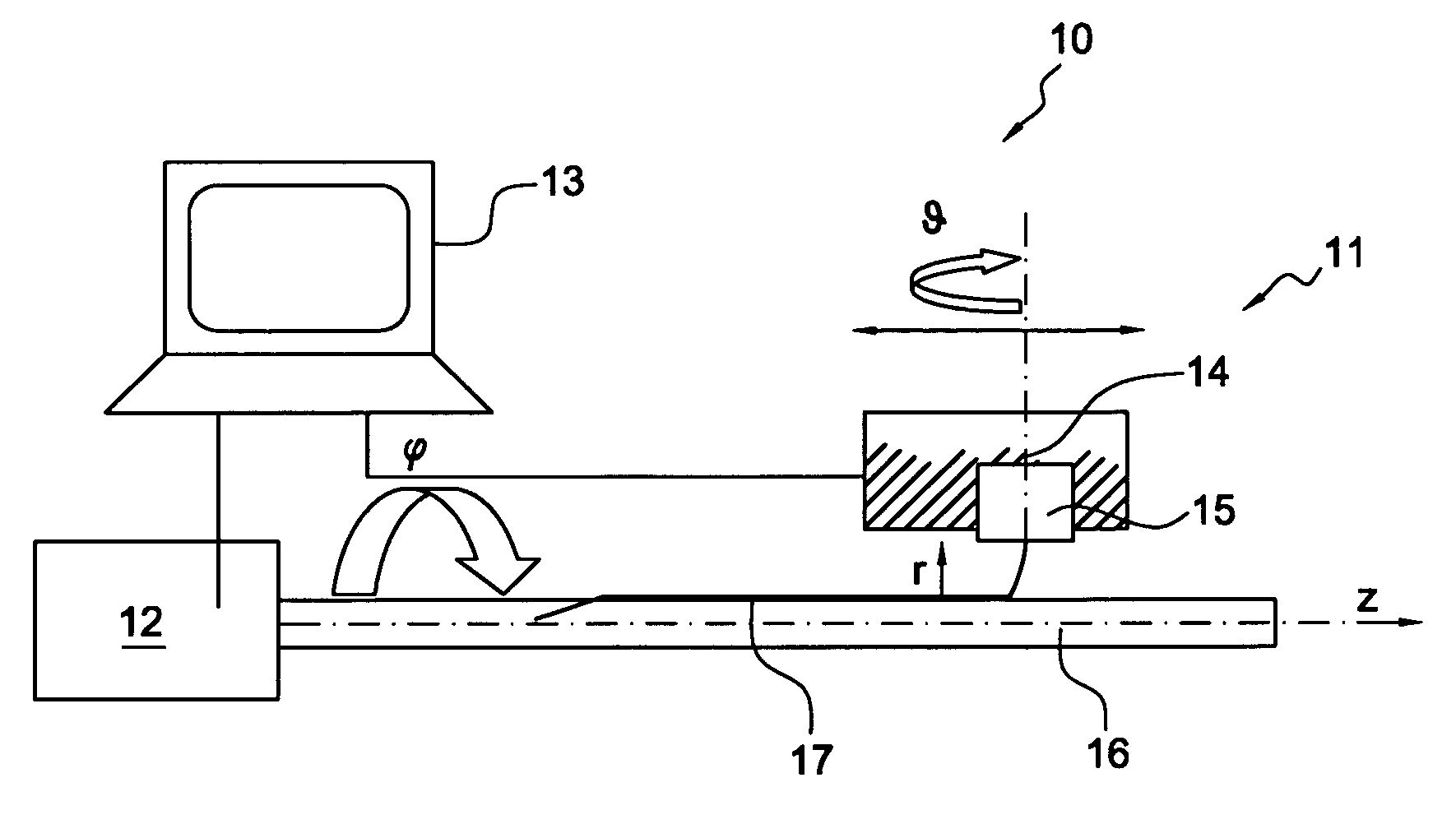

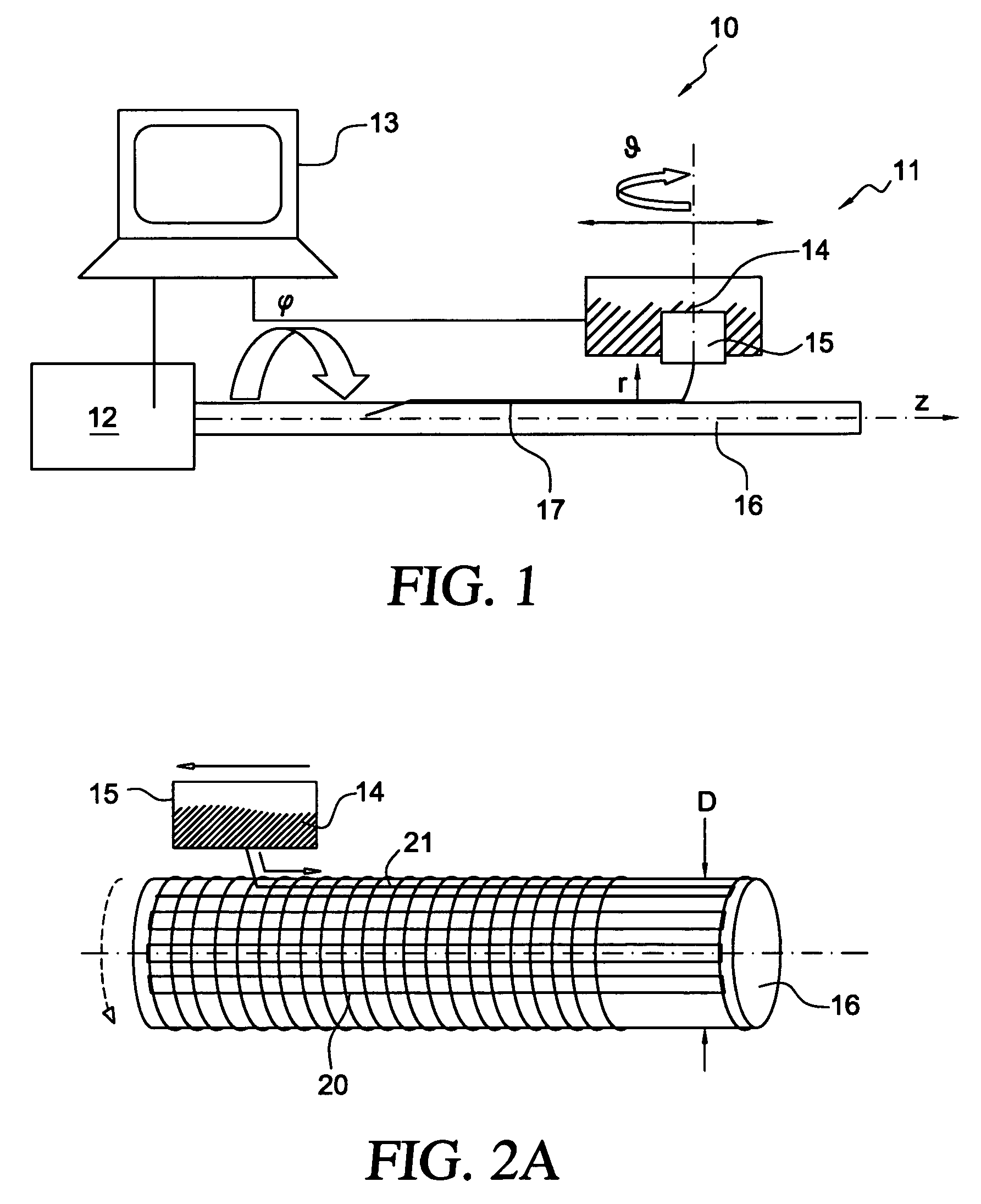

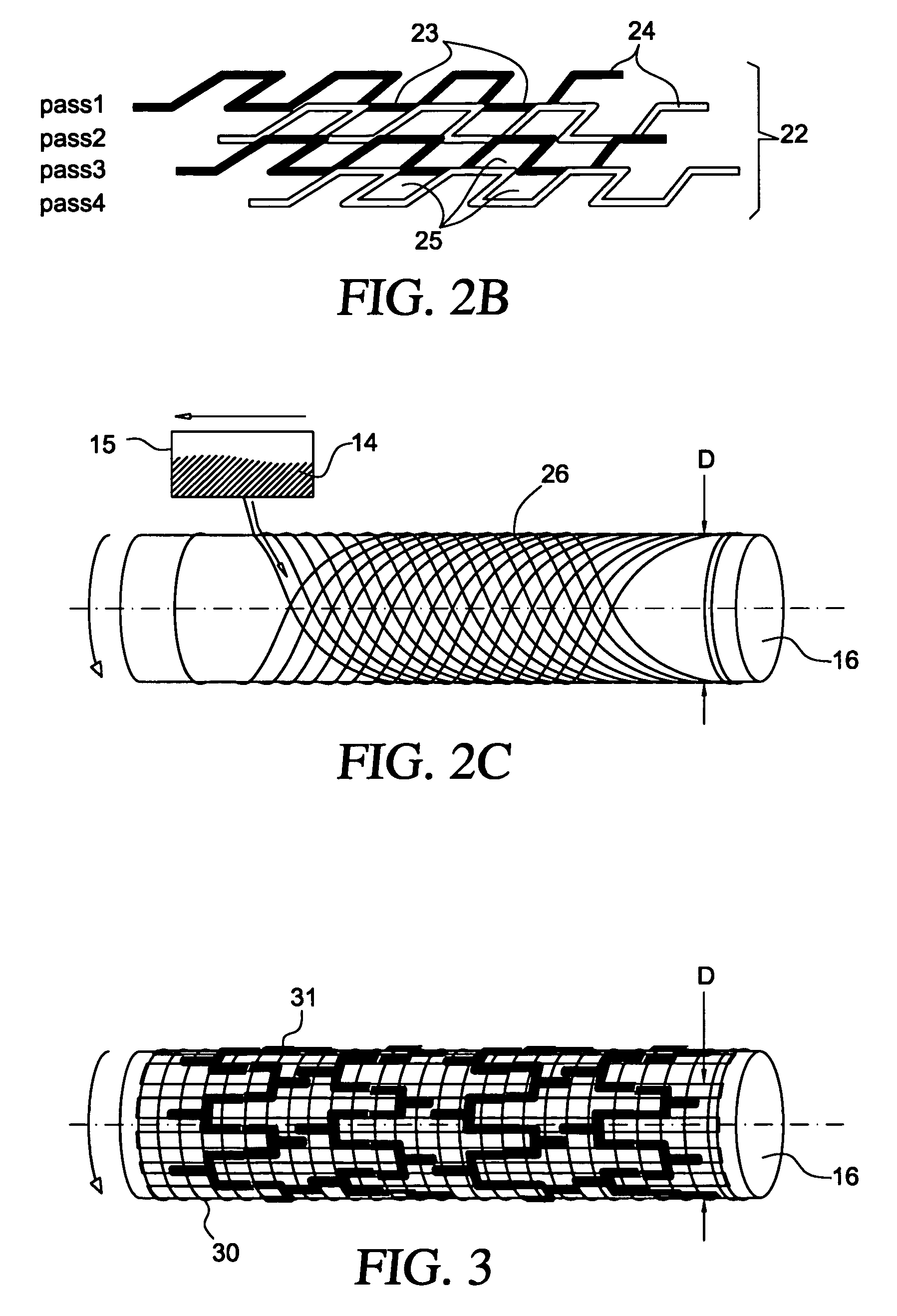

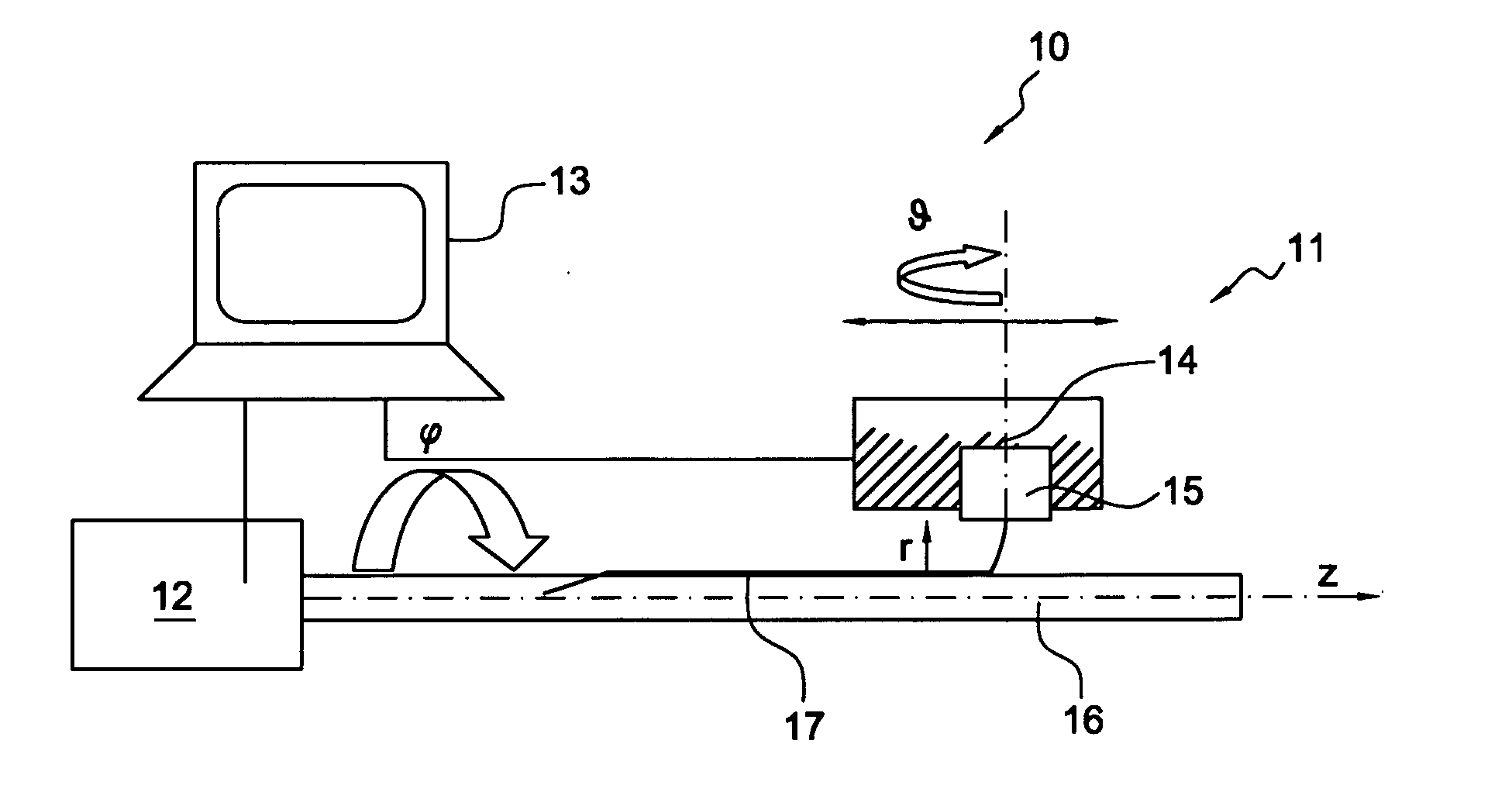

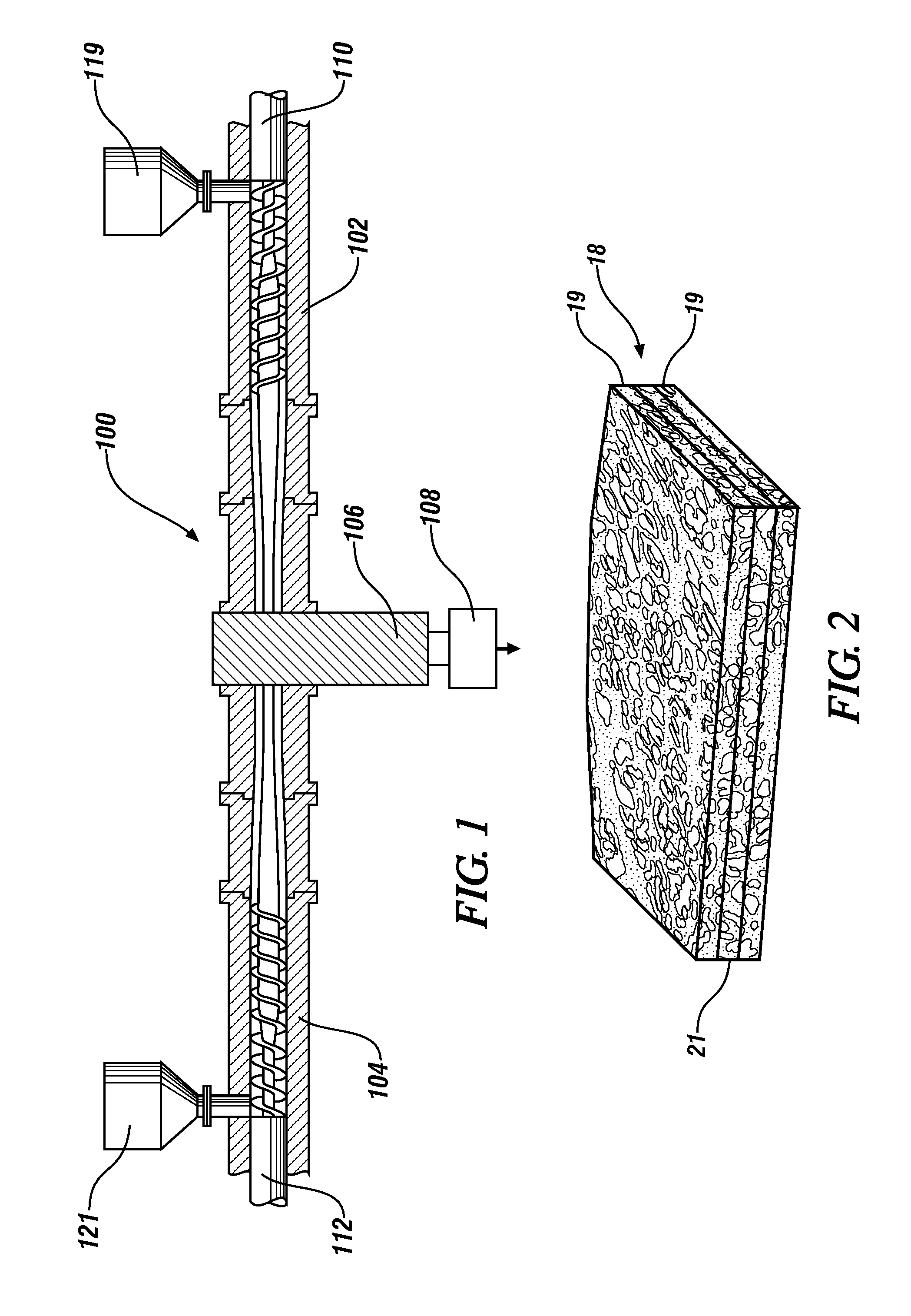

The present invention involves porous polymer membranes, suitable for use in medical implants, having controlled pore sizes, pore densities and mechanical properties. Methods of manufacturing such porous membranes are described in which a continuous fiber of polymer is extruded through a reciprocating extrusion head and deposited onto a substrate in a predetermined pattern. When cured, the polymeric material forms a stable, porous membrane suitable for a variety of applications, including reducing emboli release during and after stent delivery, and providing a source for release of bioactive substances to a vessel or organ and surrounding tissue.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

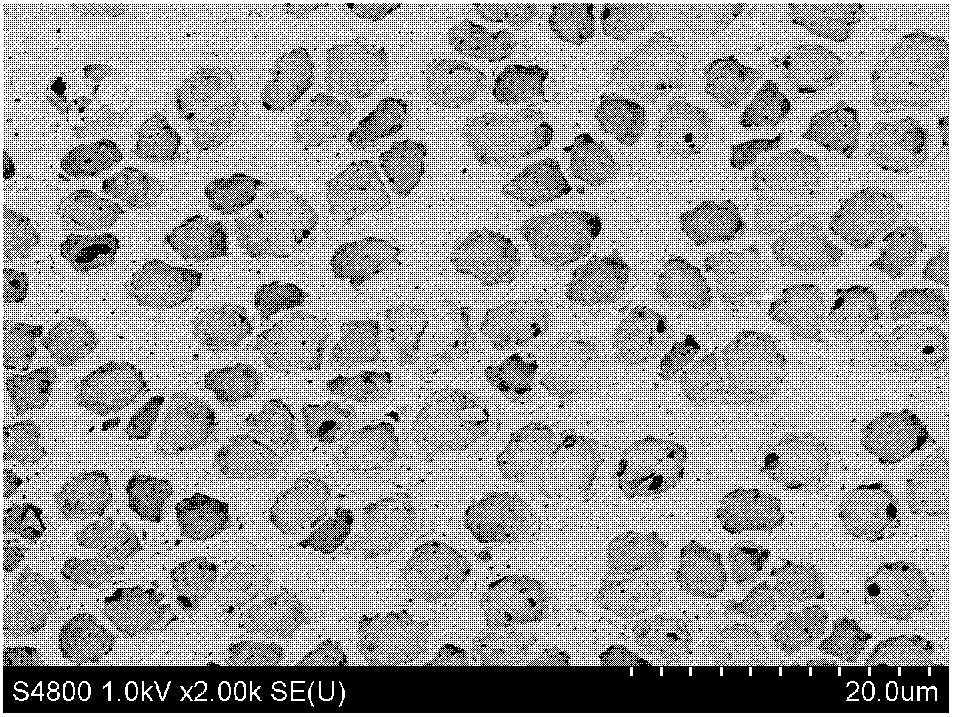

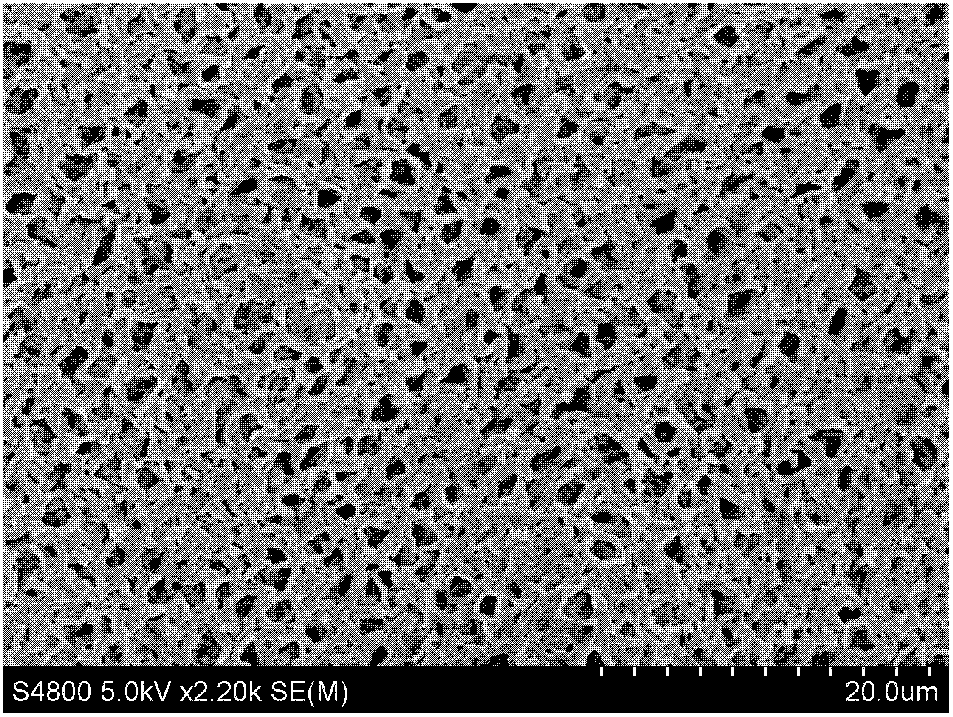

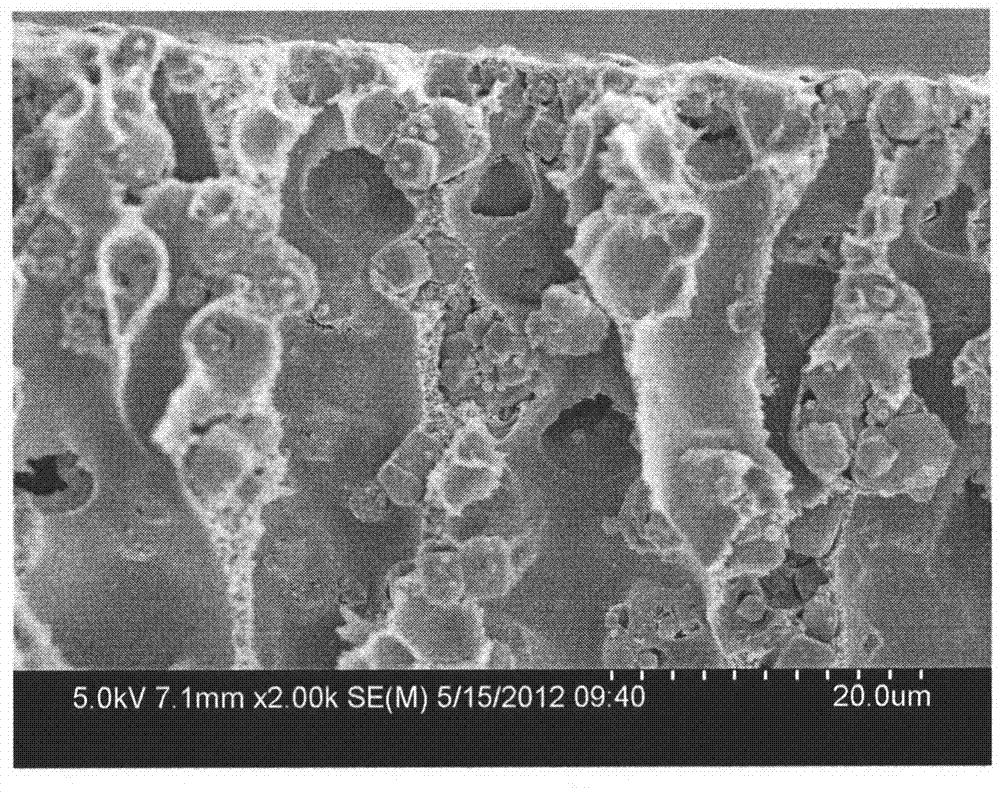

Carbon material modified porous polymer electrolyte membrane and preparation method thereof

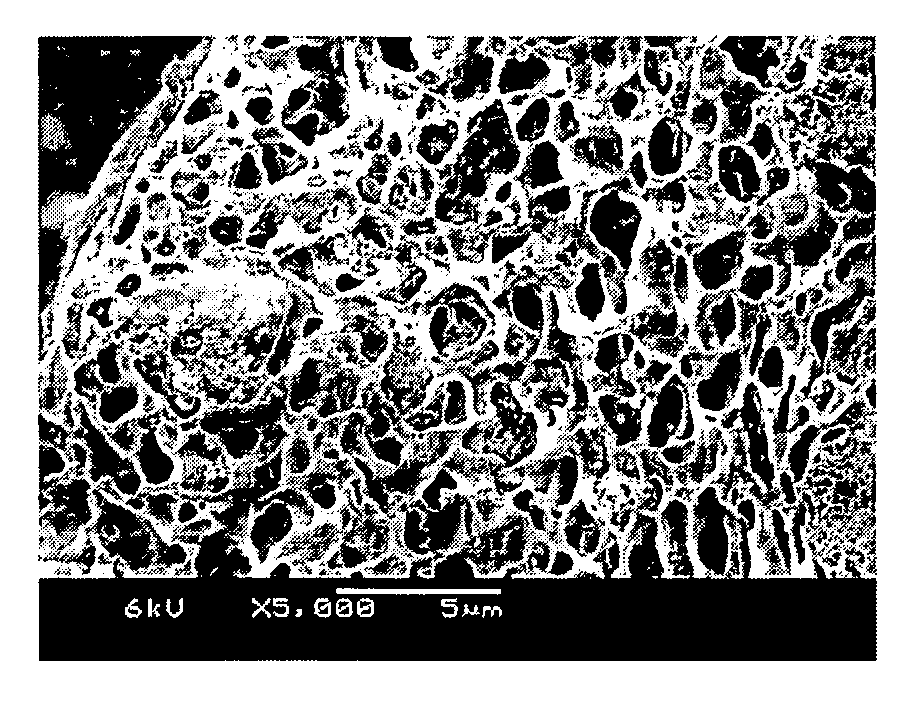

InactiveCN102585280ASmall apertureEvenly distributedCell component detailsPolymer scienceHexafluoropropylene

The invention discloses a carbon material modified porous polymer electrolyte membrane and a preparation method thereof, and relates to the polymer electrolyte membrane and the preparation method thereof. The invention aims at solving the problems of low ionic conductivity, small lithium ion transference number and poor electrochemical stability of the conventional porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membrane is prepared by soaking the porous polymer membrane in an electrolyte of a lithium ion battery for 1h-4h; and the porous polymer membrane is prepared from PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene), a solvent, a plasticizer and a modified carbon material. The method comprises the following steps of: (1) preparing theporous polymer membrane; and (2) performing soaking treatment to get the carbon material modified porous polymer electrolyte membrane. The carbon material modified porous polymer electrolyte membranehas the advantages that the ionic conductivity achieves 10-3S / cm order of magnitude, the lithium ion transference number is 0.80-0.95, and an electrochemical stability window is 5.5V-6.0V. The preparation method disclosed by the invention is mainly used for preparing the carbon material modified porous polymer electrolyte membrane.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

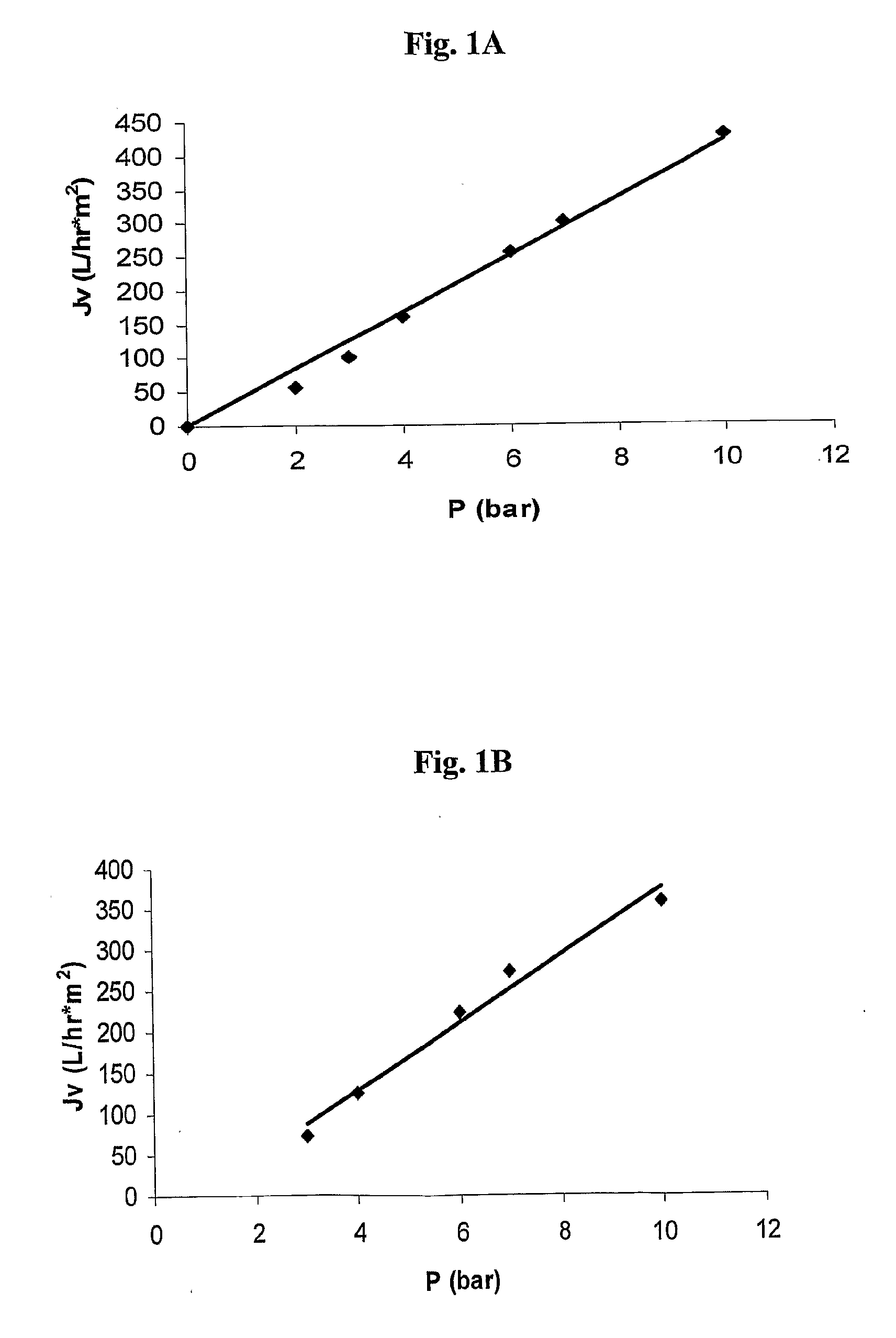

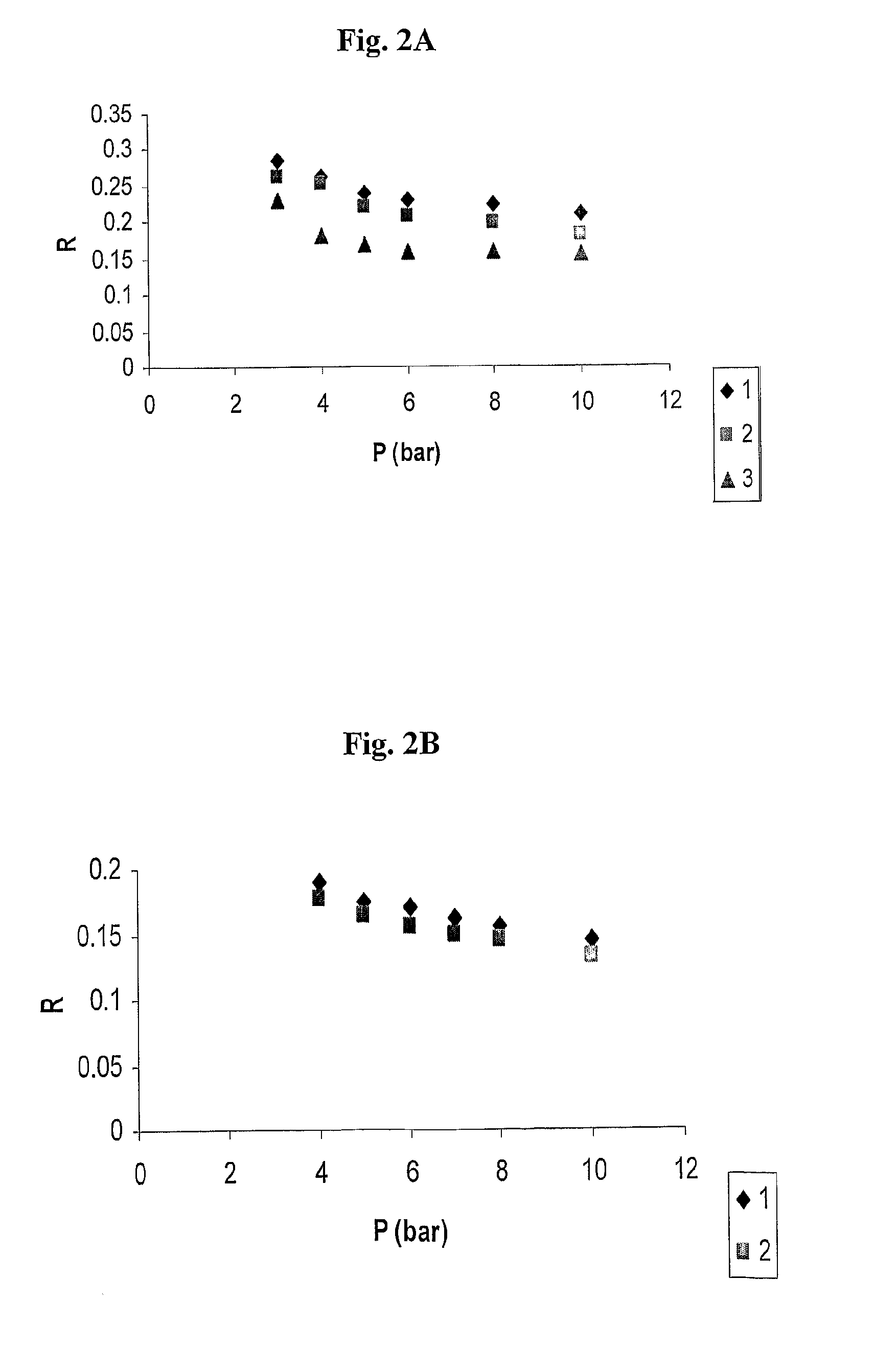

Polysulfone polymers and membranes for reverse osmosis, nanofiltration and ultrafiltration

The invention provides modified polysulfones substituted in one or more of the phenyl rings by functional groups and membranes composed of the modified polysulfones. Also provided are methods for the preparation of monodispersed nanoporous polymeric membranes. The membranes are useful for reverse osmosis, nanofiltration, and ultrafiltration, particularly for purification of water.

Owner:TECHNION RES & DEV FOUND LTD

Method of producing nanoparticle-filled phase inversion polymer electrolyte

InactiveUS20060057464A1Good physical propertiesImprove compatibilityMaterial nanotechnologySemi-permeable membranesPolymer electrolytesLithium

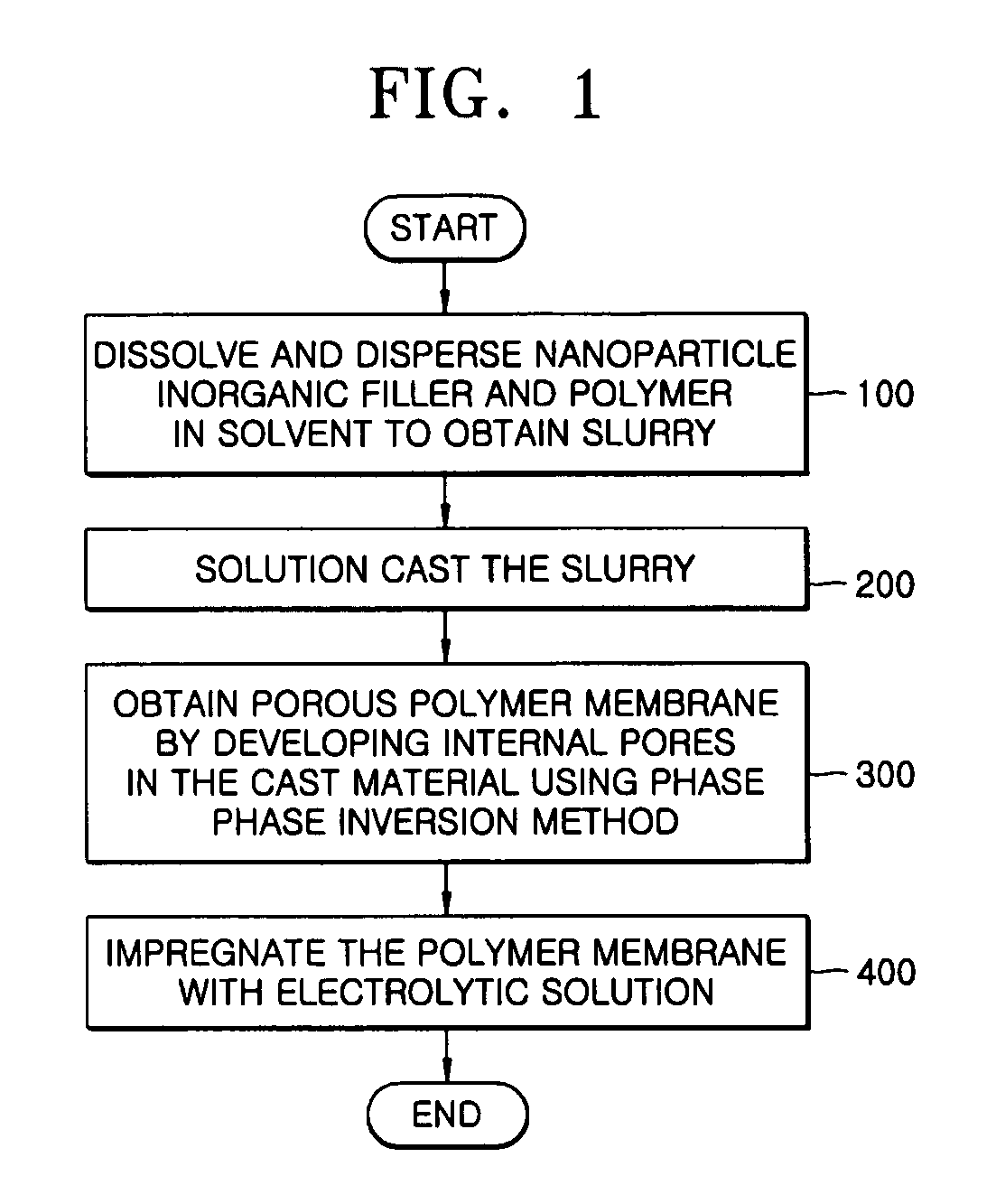

Provided is a method of producing a nanoparticle-filled phase inversion polymer electrolyte. The method includes mixing a nanoparticle inorganic filler and a polymer with a solvent to obtain a slurry; casting the obtained slurry to form a membrane; obtaining an inorganic nanoparticle-filled porous polymer membrane by developing internal pores in the cast membrane using a phase inversion method; and impregnating the inorganic nanoparticle-filled porous polymer membrane with an electrolytic solution. The polymer electrolyte produced using the method can be used in a small lithium secondary battery having a high capacity, thereby providing an excellent battery property.

Owner:ELECTRONICS & TELECOMM RES INST

Non-flammable quasi-solid electrolyte-separator layer product for lithium battery applications

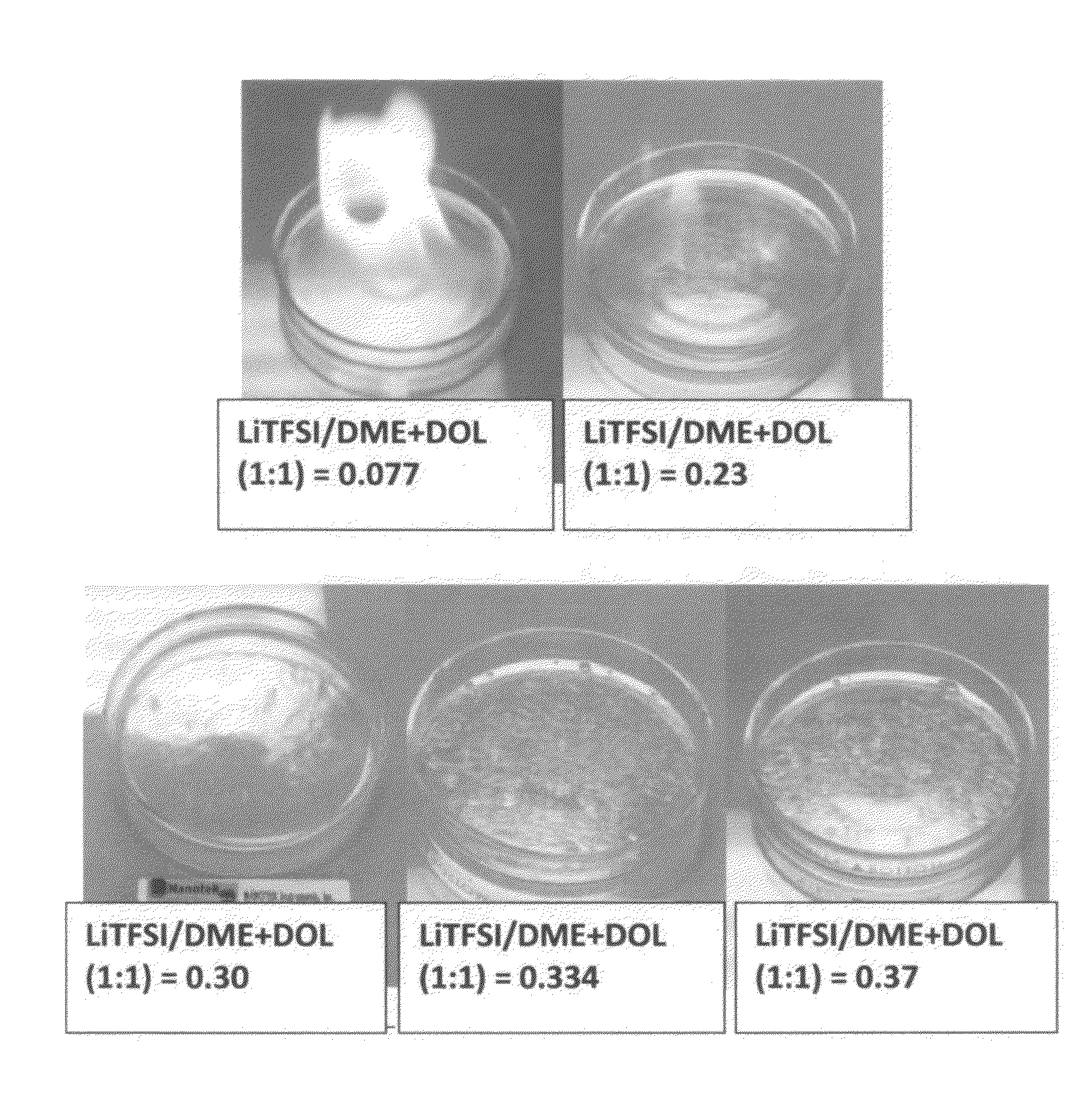

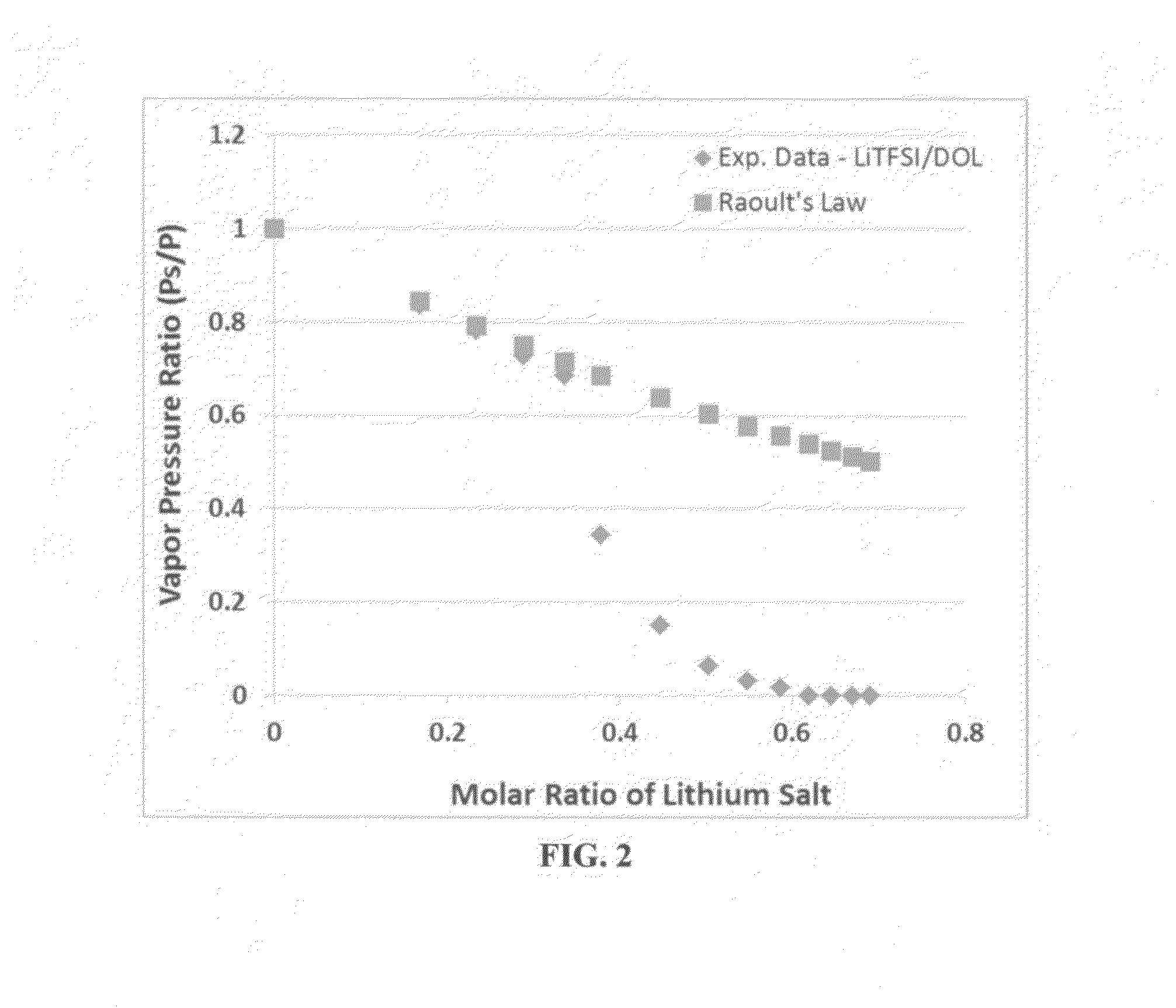

ActiveUS20150024248A1Reduce electrical conductivityLow ionic conductivityFinal product manufactureLi-accumulatorsGlass fiberCelsius Degree

A separator-electrolyte layer product for use in a lithium battery, comprising: (a) a porous thin-film separator selected from a porous polymer film, a porous mat, fabric, or paper made of polymer or glass fibers, or a combination thereof, wherein the separator has a thickness less than 500 μm; and (b) a non-flammable quasi-solid electrolyte containing a lithium salt dissolved in a liquid solvent up to a concentration no less than 3 M; wherein the porous thin-film separator is coated with the quasi-solid electrolyte so that the layer product exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the first liquid solvent alone, a flash point higher than 150° C., or no detectable flash point.

Owner:GLOBAL GRAPHENE GRP INC

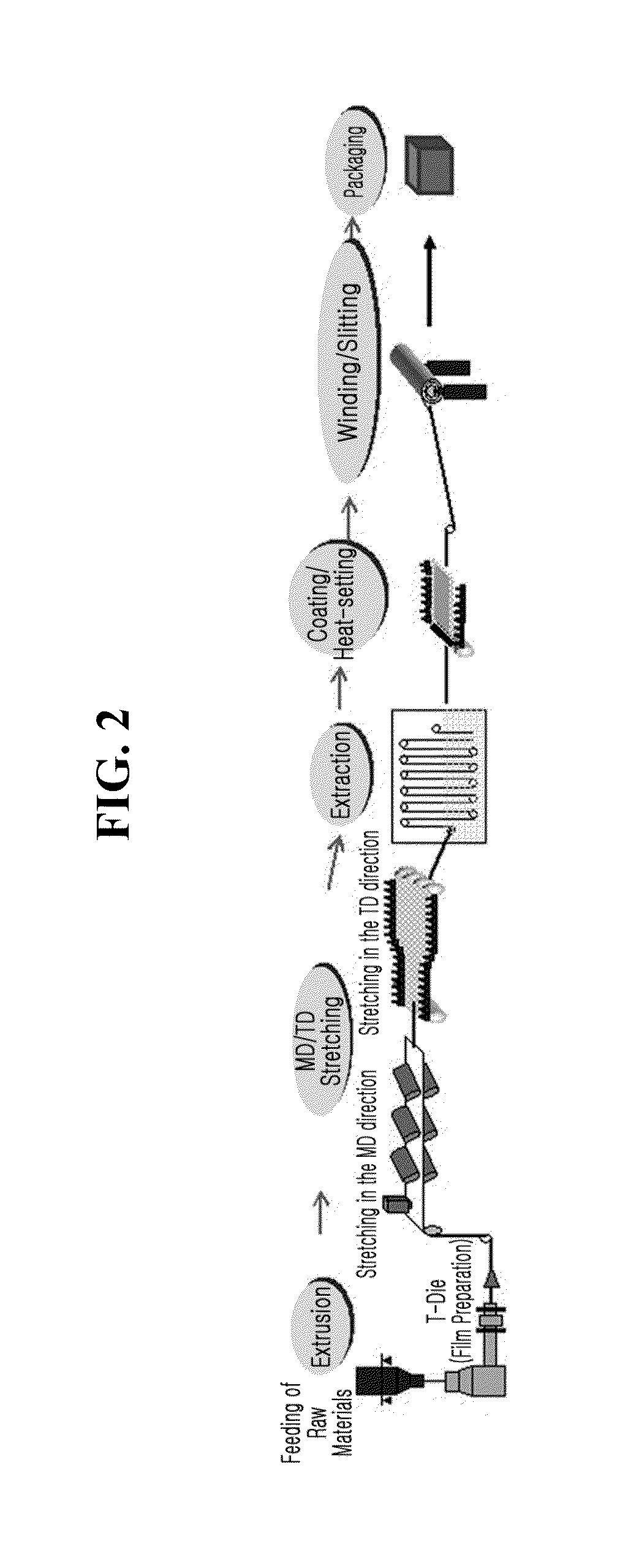

Cross-linked multilayer porous polymer membrane battery separators

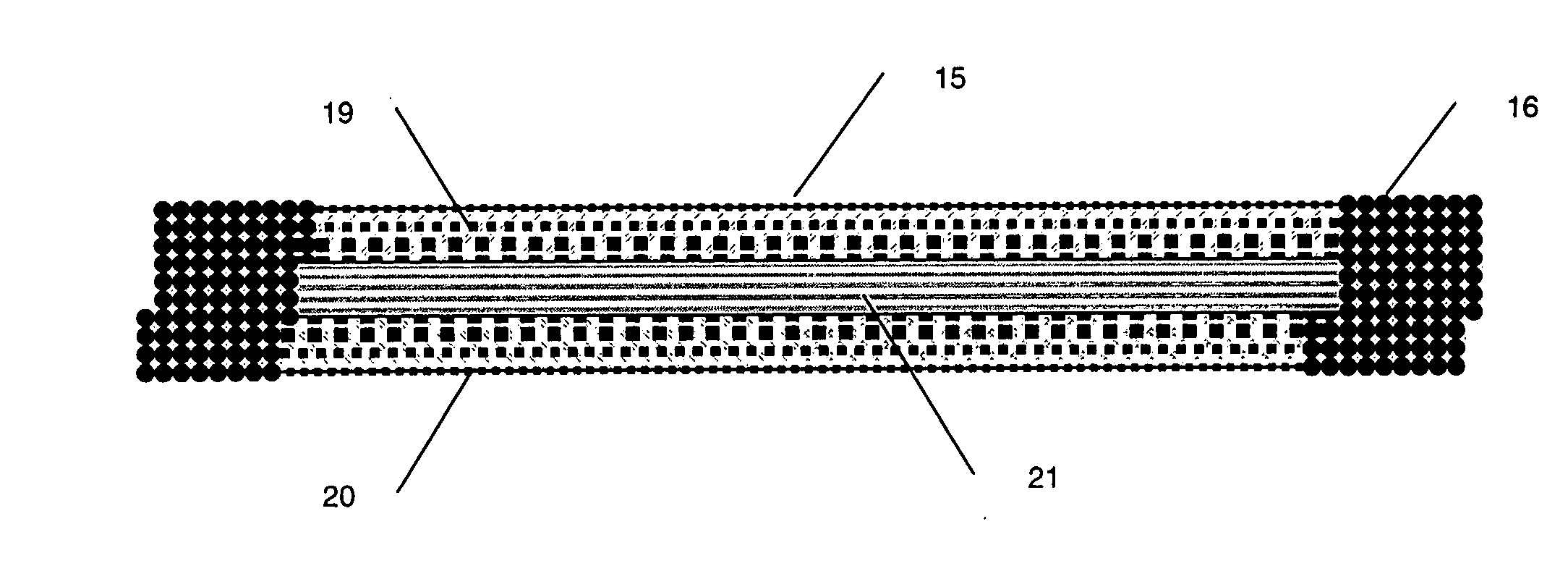

ActiveUS20150056492A1Improve compatibilityImprove mechanical propertiesSecondary cellsCell component detailsCross-linkPolyolefin

A cross-linkable polyolefin composition (polyethylene, polypropylene or an ethylene-propylene copolymer) is coextruded with ultrahigh molecular weight polyethylene to form two-layer separator membranes, or three-layer separator membranes, for lithium-ion battery cells. In three-layer separator membranes, the cross-linkable polyolefin is formed as the outer faces of the separator for placement against facing surfaces of cell electrodes. The polymer materials initially contain plasticizer oil, which is removed from the extruded membranes, and the extruded membranes are also stretched to obtain a suitable open pore structure in the layered membranes to provide for suitable infiltration with a liquid electrolyte. The cross-linked polyolefin layer provides strength at elevated temperatures and the lower-melting, ultrahigh molecular weight polyethylene layer provides the separator membrane with a thermal shutdown capability.

Owner:GM GLOBAL TECH OPERATIONS LLC

Membrane electrode assembly and its manufacturing method

InactiveUS20070269698A1Superior water managementHigh mechanical strengthElectrolyte holding meansCell electrodesIonomerPolymer science

A membrane electrode assembly including comprising of a central electrolyte layer a catalyst film layer adjacent to each side of the electrolyte layer, wherein the catalyst film layer includes a hydrophobic porous polymer membrane containing a mix of catalyst particles and ionomers inside the porous polymer membrane and on the surface of the porous polymer membrane.

Owner:SHANGHAI HORIZON FUEL CELL TECH

Porous polymer membrane of inlaid molecular sieve with adsorption function

ActiveCN104492287AImprove adsorption capacityImprove interception effectSemi-permeable membranesOther chemical processesEutrophicationPorous polymer membrane

The invention provides a porous polymer membrane of an inlaid molecular sieve with an adsorption function, and particularly relates to a preparation method of the porous polymer membrane of the inlaid molecular sieve, which can remove heavy metal ions and nitrogen phosphorous and other pollutants in water by adopting membrane adsorption technology. A casting solution for preparing the porous polymer membrane of the inlaid molecular sieve comprises the following components in percentage by mass: polymer / molecular sieve adsorption material with the mass ratio being 90 / 10-10 / 90 and the concentration sum being 20%-50%, 4%-30% of pore-forming additives, 1%-5% of a particle dispersion-suspension stabilizer, 30%-75% of solvents, wherein the percentage sum of all the components is 100%. The molecular sieve adsorption material is evenly inlaid and dispersed into a porous membrane matrix material, the adsorption rate is high, the dynamic adsorption capacity is large, pollutants in water can be fast removed with a broad spectrum, and the eutrophication problem of a water body can be solved.

Owner:天津鼎芯膜科技有限公司

Cross Linking Treatment of Polymer Membranes

InactiveUS20080214687A1Improve permeabilityImprove stabilitySemi-permeable membranesMembranesCross-linkMembrane method

Methods of forming a hydrophilic porous polymeric membrane which include preparing a porous polymeric membrane from a polymer blend which typically contains a hydrophobic non crosslinkable component (e.g. PVdF) and a component which is cross-linkable (for instance, PVP) and treating said porous polymeric membrane under cross linking conditions to produce a modified membrane with greatly improved water permeability and hydrophilic stability. Cross linking condition include chemical (e.g. peroxodisulfate species), thermal or radiation and / or combinations thereof. Non cross linked material may be washed out if desired.

Owner:SIEMENS IND INC

Cross linking treatment of polymer membranes

InactiveCN101203554AIncrease hydrophilic stabilityGood water permeabilityMembranesSemi-permeable membranesMembrane methodCross-link

Owner:SIEMENS IND INC

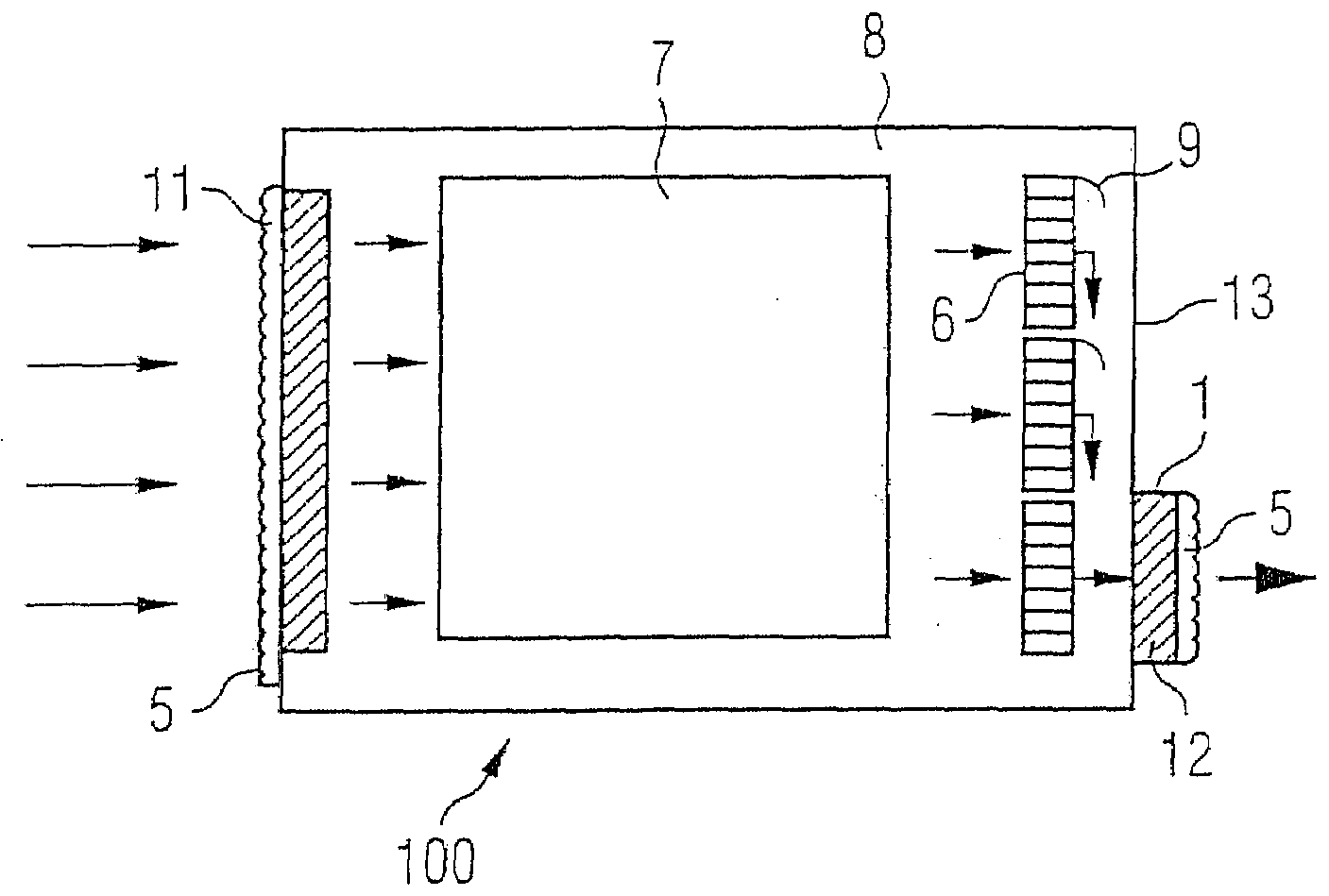

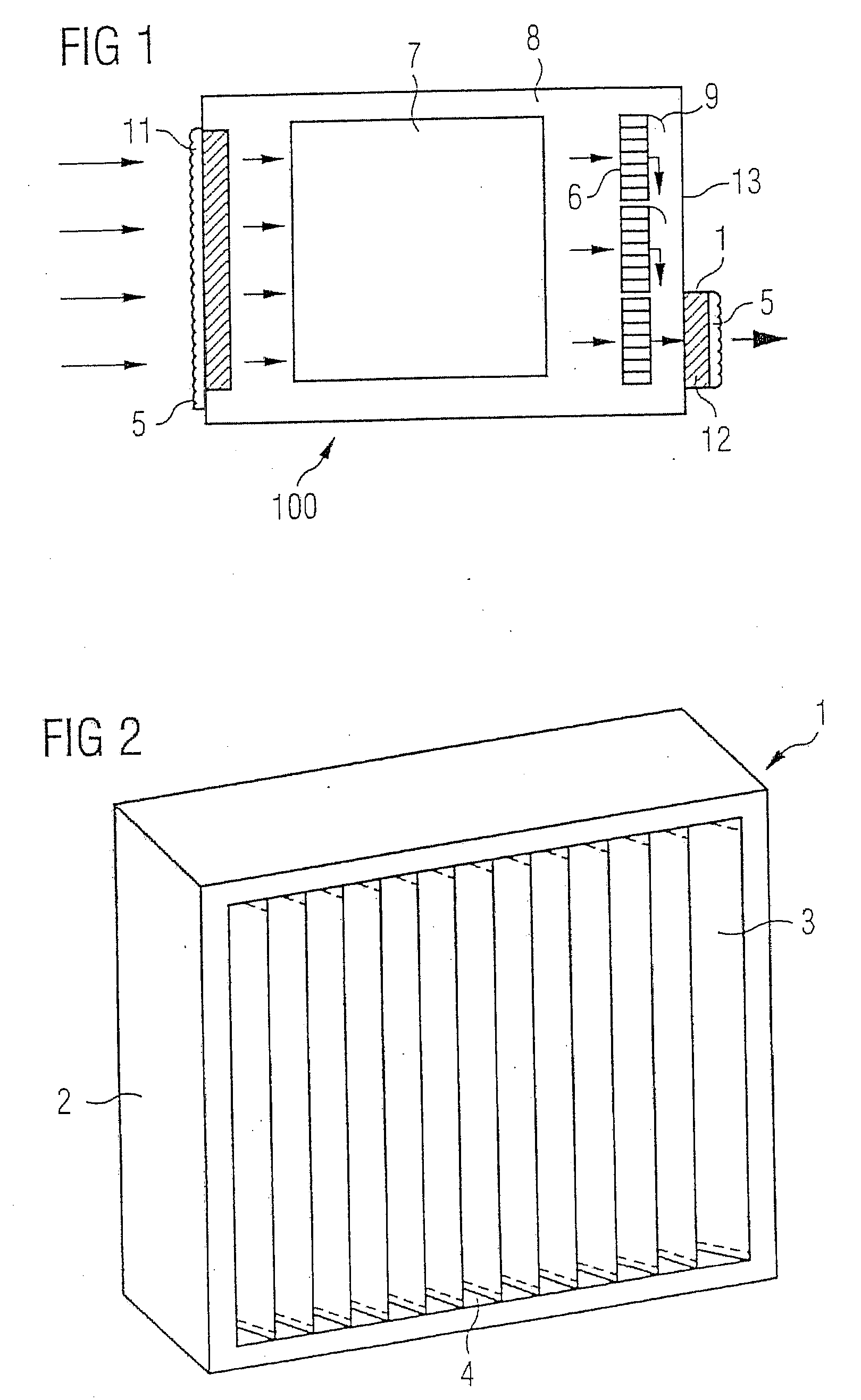

Fan cooling unit for cooling electronic components

InactiveUS20090139405A1Improve filtering effectEasy to chargeElectrostatic separationFiltration separationFiberEngineering

A fan cooling unit (10) for cooling electronic components, such as for an air-cooled telecommunications base station, comprises a protective covering for at least the air inlet opening (11) of a casing (8) in which the electronic components are housed. The protective covering (1) has a frame (2) into which a composite filter media (3) is mounted so as to create an air-tight fit. The composite filter media (3) comprises a membrane filtration layer (20) with a porous polymeric membrane, such as expanded polytetrafluoroethylene (ePTFE), and at least one depth filtration layer (18) disposed on an upstream side of the membrane filtration layer (20). The depth filtration media layer comprises fibers having an electrostatic charge. The ePTFE membrane is preferably made from a blend of a PTFE homopolymer and a modified PTFE polymer.

Owner:SCHWARZ ROBERT +3

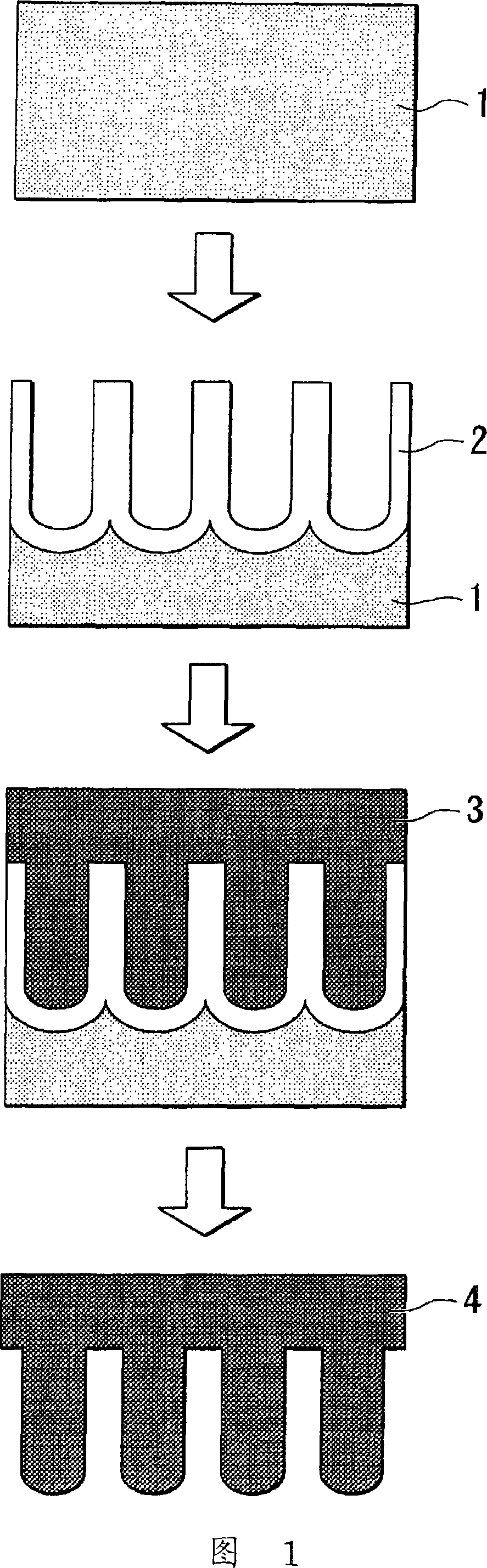

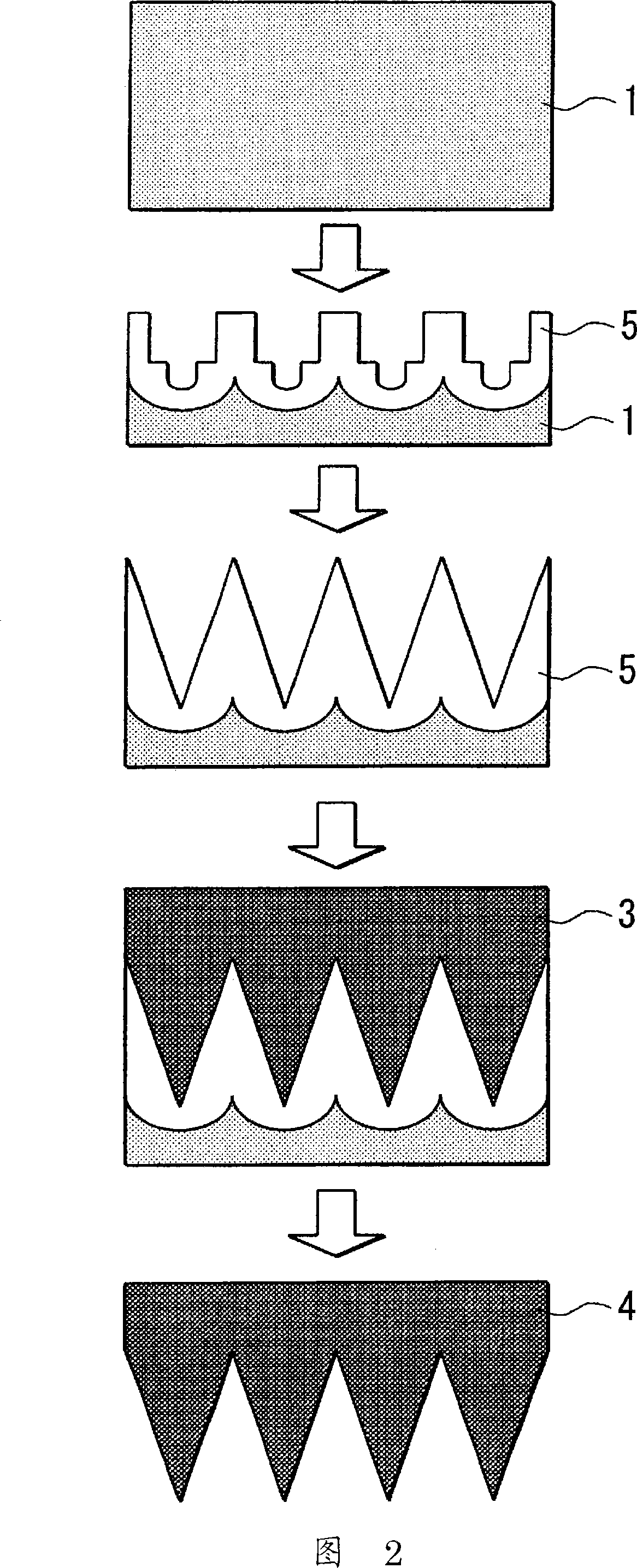

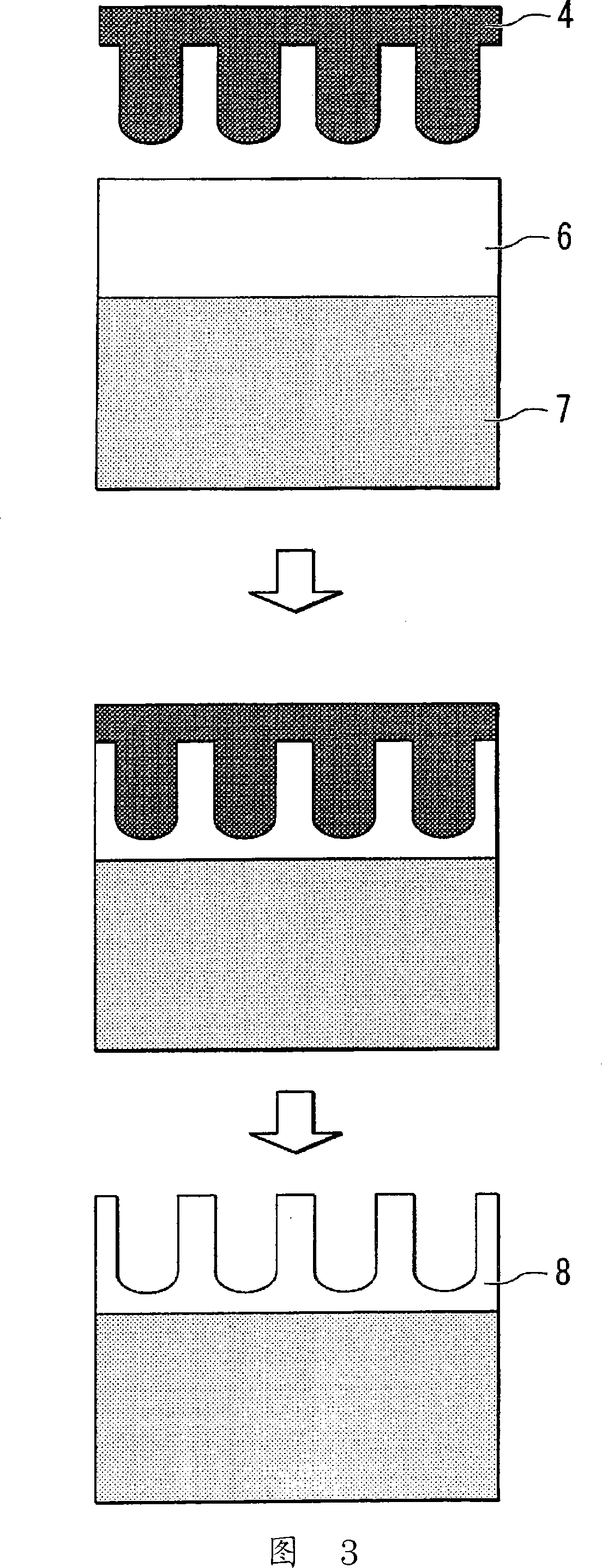

Porous polymer membrane, method for producing same, and method for manufacturing stamper used for production of same

InactiveCN101248219AEasy to manufactureEfficient preparationAnodisationNanostructure manufacturePolymer sciencePorous polymer membrane

By filling the pores of anodized porous alumina having a porous surface structure with a substance, and dissolving and removing the aforementioned anodized porous alumina, a stamper having an inverse structure of the aforementioned substance and having the aforementioned surface structure is manufactured. The aforementioned reverse structure of the aforementioned stamper is transferred to the polymer to manufacture a porous polymer film having the aforementioned surface structure. A large-area porous polymer membrane can be produced without complicated steps, and the porous polymer membrane has a surface structure in which pores of uniform size are perpendicular to the membrane surface.

Owner:KANAGAWA ACADEMY SCI & TECH

Preparation method and application of single ion conductor nano-particle reinforced lithium battery diaphragm or polymer electrolyte

The invention belongs to the technical field of a lithium battery diaphragm, and in particular relates to a nanometer single ion conductor coated lithium battery diaphragm and a preparation method thereof. The lithium battery diaphragm adopts a porous polymer membrane or a non-woven fabric as a base material, and adopts single ion conductor nano-particles and polymers for modifying the surface of the base material. The prepared high-performance low-temperature lithium battery diaphragm is 5-100 microns in thickness, is 1-1000s / 100cc in air permeability, is 30-85% in porosity, is 0.02-8 microns in a pore diameter range, and is 100-800% in electrolyte absorptivity. The coated diaphragm has the good low temperature performance, high ionic migration number and ionic conductivity, and good rate capability and long cycle performance, and can improve the stability of an interface with positive and negative materials; and besides, the preparation process is simple and easy to operate, and low in production cost, and the mass production is easy to realize.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for dialysis on microchips using thin porous polymer membrane

InactiveUS7534315B1Minimize handlingComplicated operationGlovesPretreated surfacesDialysis membranesMicrosphere

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and forms a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for wetting hydrophobic porous polymeric membranes to improve water flux without alcohol treatment

A method is provided for substantially instantaneously wetting hydrophobic, porous polymeric membranes and for rendering hydrophobic membranes hydrophilic. The method involves treating the membrane with a non-alcoholic aqueous solution of a low molecular weight surfactant, and then drying the treated membrane. The low molecular weight surfactant exhibits high polymer affinity for the hydrophobic membrane substrate as well as high water solubility; a preferred surfactant is sodium dodecylbenzenesulfonate (SDBS). The method is particularly useful for treating hydrophobic membranes such as those made of polyolefins, fluorinated or chlorinated polymers, polysulfone, or polyethersulfone, preferably having a pore size of about 0.01 microns to about 1 micron. A wettable membrane is thus provided as the aqueous surfactant solution is absorbed into the hydrophobic membrane.

Owner:HYDRANAUTICS

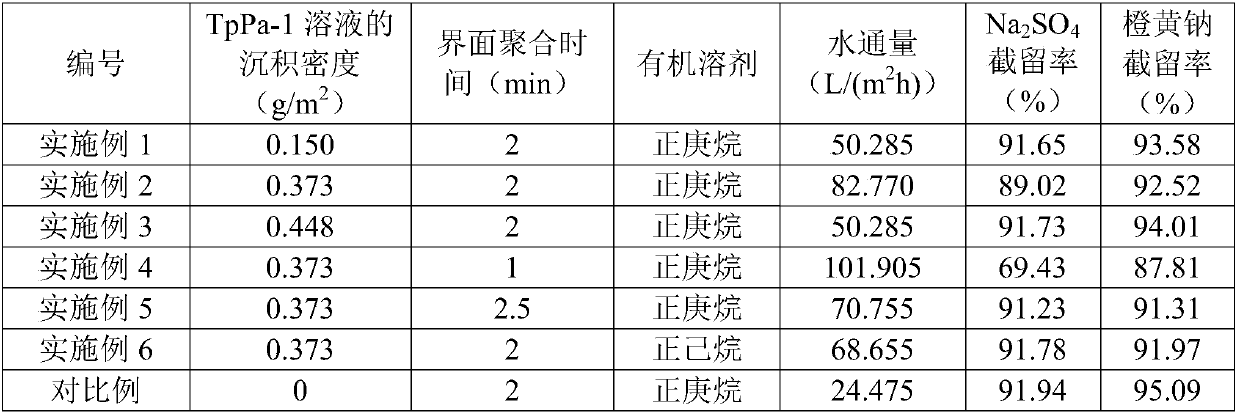

Preparation method of modifying composite nanofiltration membrane by building pure COFs interlayer

InactiveCN107789992AImprove hydrophilicityHigh porositySemi-permeable membranesPorous substrateFiltration

The invention discloses a method for preparing a modified composite nanofiltration membrane by constructing a pure COFs intermediate layer, which mainly includes: preparing TpPa-1 by using Schiff base condensation, constructing a pure COFs intermediate layer on a porous base membrane by vacuum filtration, and then A composite nanofiltration membrane is obtained through interfacial polymerization, wherein the porous base membrane is a polymer porous membrane with a pore diameter of 0.1 μm. In the present invention, by controlling the concentration of the aqueous phase monomer and the organic phase monomer in the interfacial polymerization step and the drying time after the interfacial polymerization reaction ends, the internal pore moisture and piperazine of the formed composite nanofiltration membrane can be effectively controlled. Molecules, that is, the hydrophilicity and porosity of the polyethersulfone-based membrane surface are optimized by vacuum filtration of the hydrophilic COFs intermediate layer, thereby realizing precise regulation of the interfacial polymerization process. The polyamide separation layer prepared by this method is thin and dense, Under the lower operating pressure (0.2MPa), it has higher water flux and maintains excellent separation performance.

Owner:TIANJIN UNIV

Separator for electrochemical device

ActiveUS20160204406A1Improve mechanical propertiesImprove thermal propertiesFinal product manufactureLi-accumulatorsFiberPorous coating

The present disclosure provides a separator for an electrochemical device, comprising: a porous polymer film; and a porous coating layer formed on one or both surfaces of the porous polymer film and comprising at least one of inorganic particles and organic particles, and a binder polymer, wherein fibrils in the surface of the porous polymer film are entangled with the particles in the porous coating layer in the contact surface between the porous polymer film and the porous coating layer, and the separator has an air permeability of 100 to 800 sec / 100 cc, an electrical resistance of 0.5 to 1.5Ω, and a heat-shrinkage rate of 8% or less in each of machine and transverse directions, and an electrochemical device having the same.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com