Porous polymer membrane, method for producing same, and method for manufacturing stamper used for production of same

A technology of polymer film and manufacturing method, which can be used in nanostructure manufacturing, semiconductor/solid-state device manufacturing, anodizing and other directions, and can solve problems such as difficulty in manufacturing large-area concave-convex patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

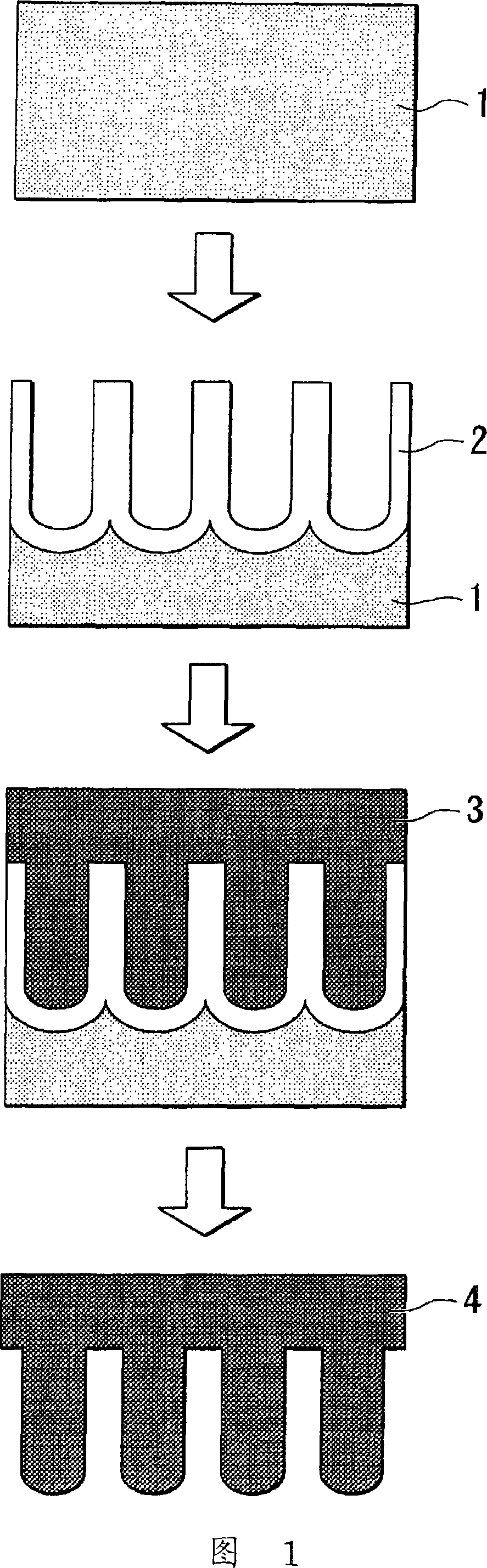

[0071] Example 1 [Manufacture of Porous Polymer Membrane Using a Stamper Produced Using Anodized Porous Alumina as a Casting Mold]

[0072] An aluminum plate with a purity of 99.99% was subjected to electrolytic polishing in a mixed solution of perchloric acid and ethanol (volume ratio 1:4). The mirror-finished aluminum plate was anodized in an aqueous solution of oxalic acid adjusted to a concentration of 0.3M, and then anodized for 15 hours at a bath temperature of 17°C and a direct current of 40V. Anodized in seconds, thereby forming anodized porous alumina with a pore depth of 150nm. Thereafter, the sample was immersed in a 5% by weight phosphoric acid aqueous solution for 30 minutes, and a pore diameter expanding treatment was performed to adjust the pore size to 70 nm. Ni electrodeposition was performed after coating 50 nm of Pt-Pd on this surface using a sputtering apparatus. The mold was then removed by dissolving in an aqueous solution of sodium hydroxide, thereby o...

Embodiment 2

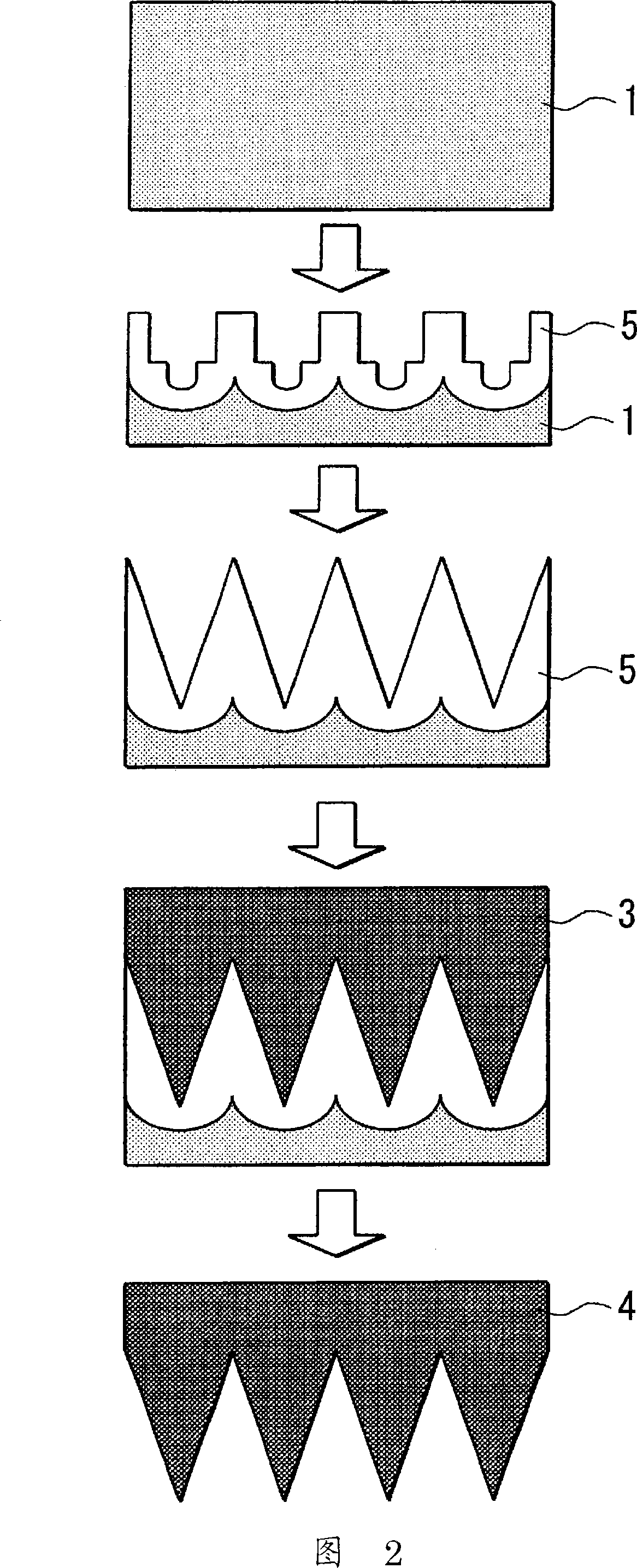

[0073] Example 2 [Manufacture of polymethyl methacrylate (PMMA) porous film by thermal imprint method using a stamper with controlled protrusion shape]

[0074] On the surface of an aluminum plate with a purity of 99.99%, a SiC mold having a structure in which protrusions are regularly arranged at a period of 200 nm is pressed to form a fine concave-convex pattern on the surface. The texturing-treated aluminum plate was anodized for 2 seconds in an oxalic acid aqueous solution adjusted to a concentration of 0.05 M under conditions of a bath temperature of 17° C. and a direct current of 80 V. Then, it was immersed in 10 weight% phosphoric acid aqueous solution for 25 minutes, and the pore diameter expansion process was implemented. This operation was repeated five times to obtain a porous alumina having tapered pores with a pore period of 200 nm, a pore opening of 200 nm, a bottom of 50 nm, and a pore depth of 300 nm. Ni electrodeposition was performed after coating the surfac...

Embodiment 3

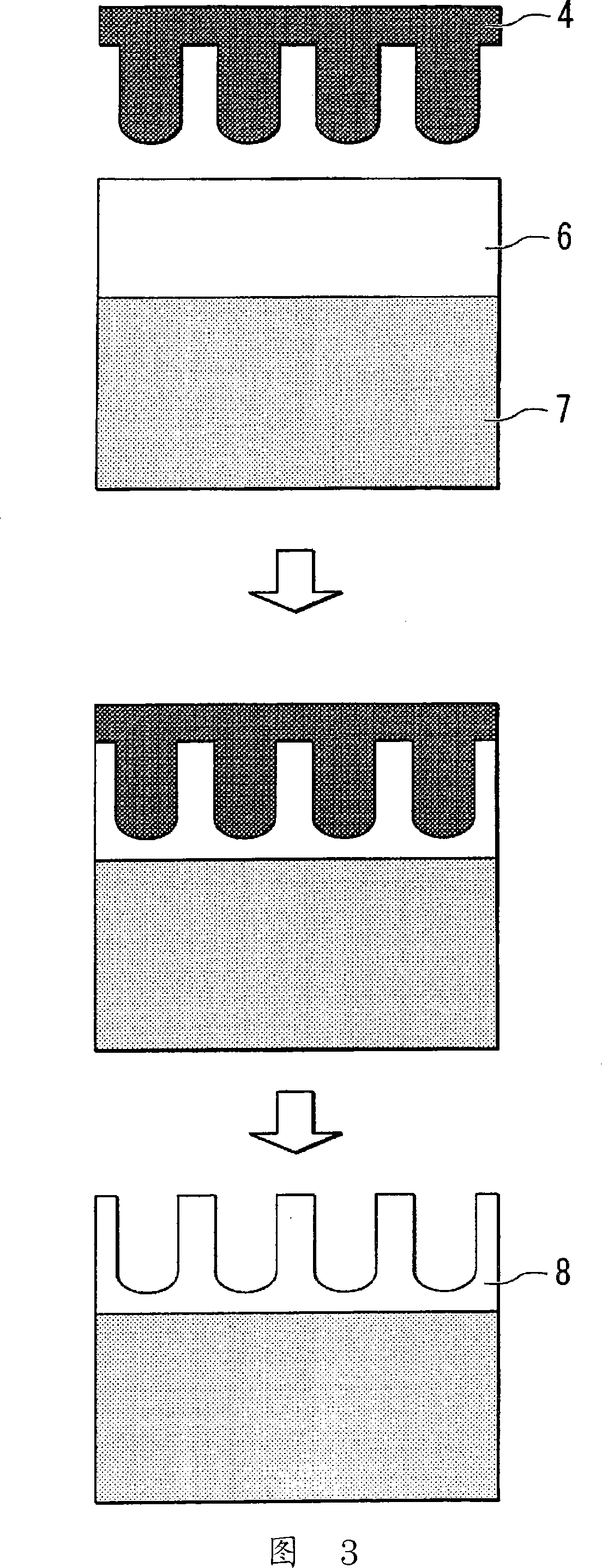

[0075] Example 3 [Manufacture of acrylic porous film by photoimprint method using a stamper with controlled protrusion shape]

[0076] Ultraviolet irradiation was performed in a state in which a Ni stamper manufactured by the same method as in Example 2 was pressed into the acrylic monomer dropped on the glass substrate. After the monomer was cured, the stamper was peeled off, thereby producing a porous acrylic resin film on the substrate. The electron micrograph (the figure observed with the electron microscope) of the surface of the produced acrylic resin porous film (porous polymer film 8) is shown in FIG. 8, and the cross-sectional electron micrograph (the figure observed with the electron microscope) is Figure 9 shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com