Separator, battery using the same, and method for manufacturing separator

A separator and battery technology, applied in the direction of organic electrolyte batteries, secondary batteries, battery pack components, etc., can solve problems such as the inability to obtain capacity, and achieve the effects of improving safety, preventing secondary defects, and reducing thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

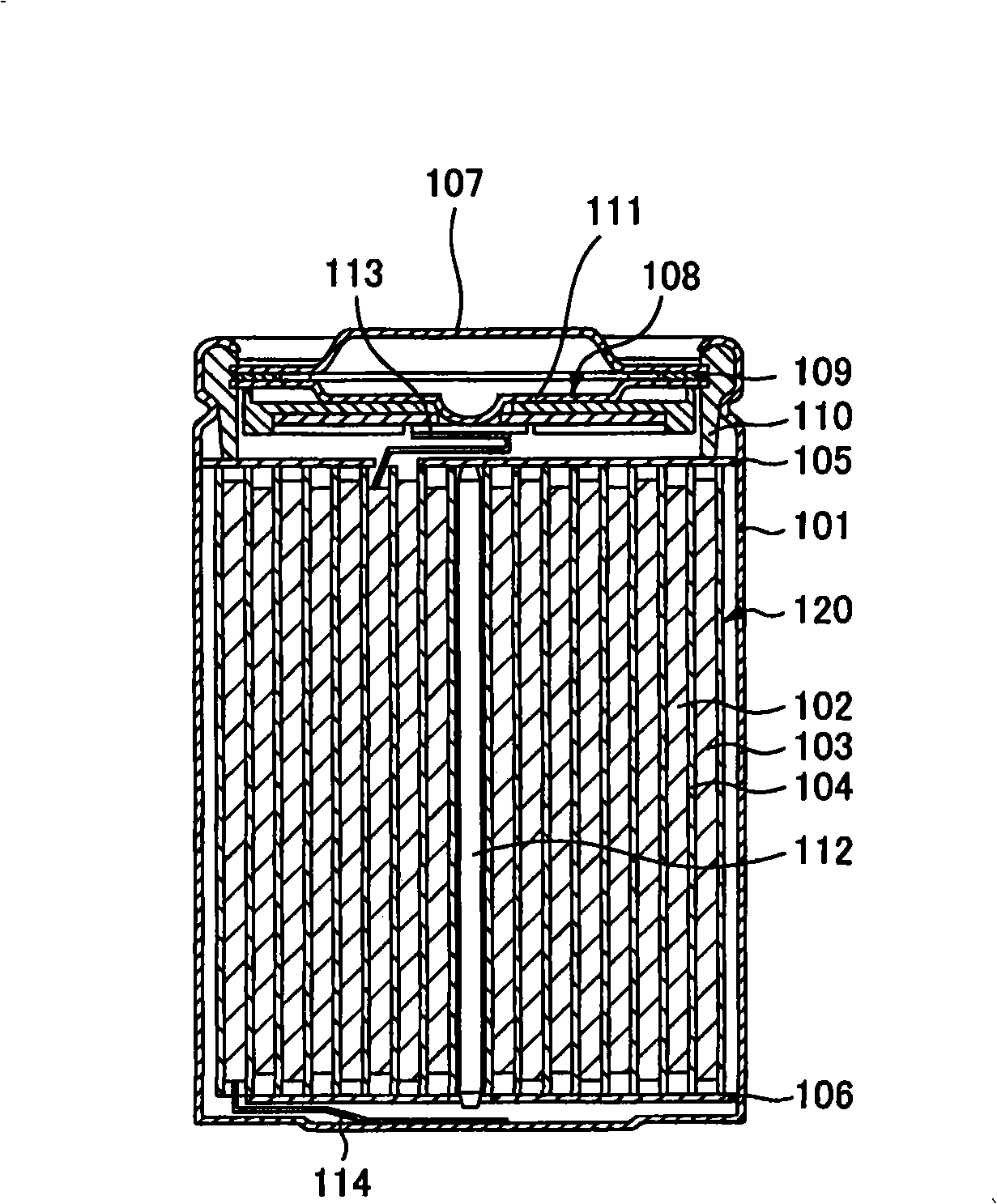

Embodiment 1

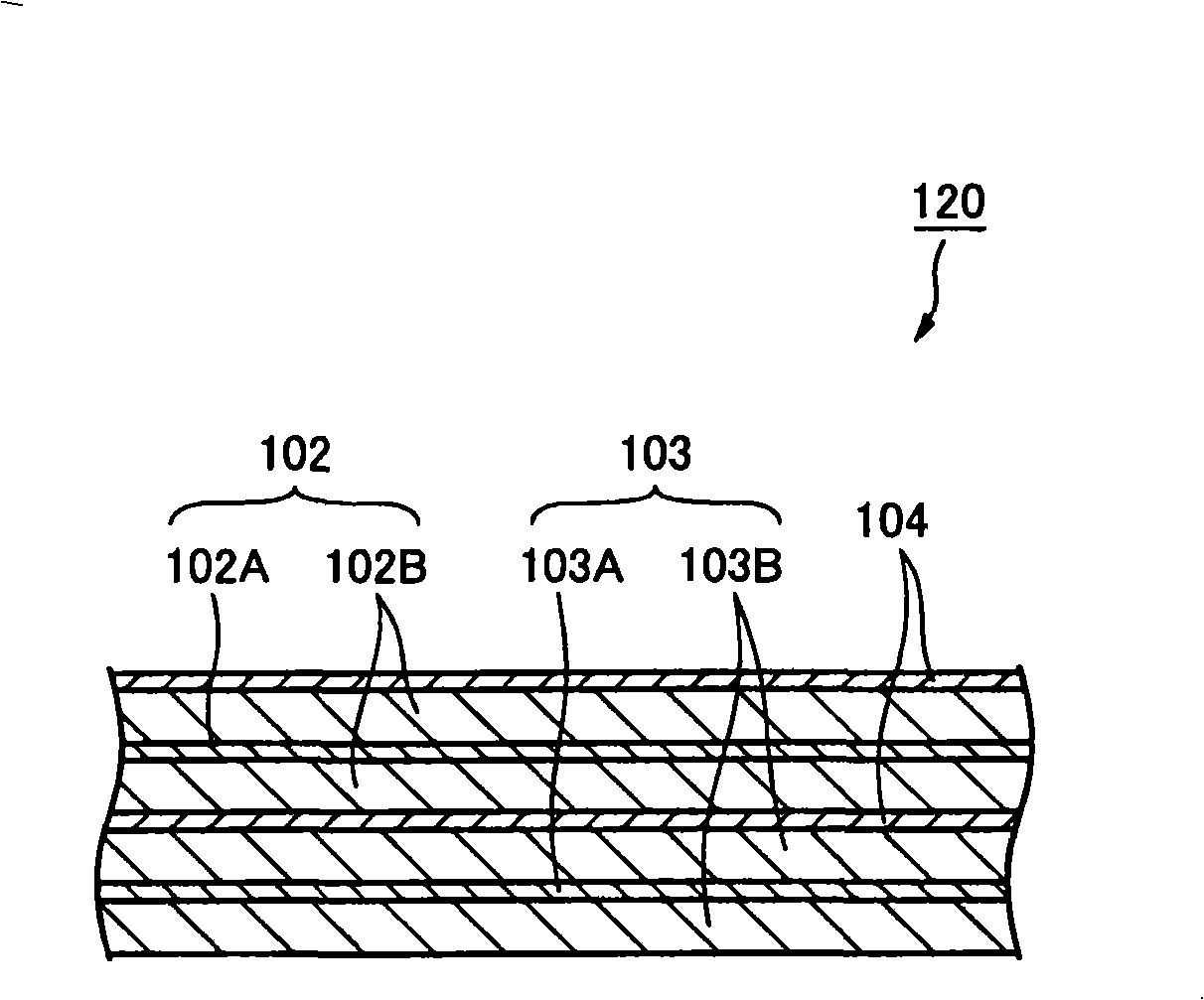

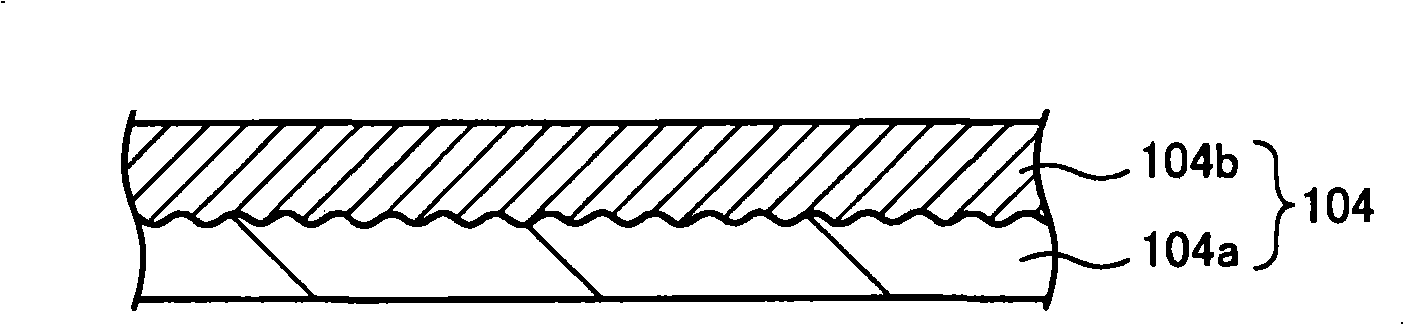

[0124] The viscous liquid product containing only the polysilazane compound was coated as a precursor onto a 16 μm thick polyethylene microporous film by a desktop coater, and then placed in a water bath. Thereafter, the resulting product was dried by hot air to form a separator 104 having an exposed layer 104a made of polyethylene and a cover layer 104b of a microframe 104c of a polyethylene microporous film coated with a glass layer 104d. In addition, the thickness of the glass layer 104d was measured with a thickness gauge, and it was 2 μm. In this regard, both "the thickness of the polyethylene microporous film" and "the thickness of the separator 104 having the exposed layer 104a and the cover layer 104b" were measured with a thickness gauge. Substituting these values into the following equation yields the thickness of the glass layer 104d.

[0125] (equation)

[0126] ("thickness of glass layer 104d")=("thickness of separator 104 having exposed layer 104a and cover l...

Embodiment 2

[0134] The battery of Example 2 was manufactured according to the same method described in Example 1, except that the amount of the viscous liquid product containing only polysilazane compounds as a precursor was adjusted so that when the separator 104 was produced, the thickness of the glass layer 104d was 0.5 μm.

Embodiment 3

[0136] The battery of Example 3 was fabricated according to the same method described in Example 1, except that the amount of the viscous liquid product containing only the polysilazane compound as a precursor was adjusted so that when the separator 104 was produced, the thickness of the glass layer 104d was 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com