Press brake die and bending machine

A bending machine and die technology, applied in the field of bending machine manufacturing, can solve the problems of complicated installation of the die, poor flattening effect, easy loosening, etc., and achieve the effect of good flattening effect, fast progress, and fast work progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

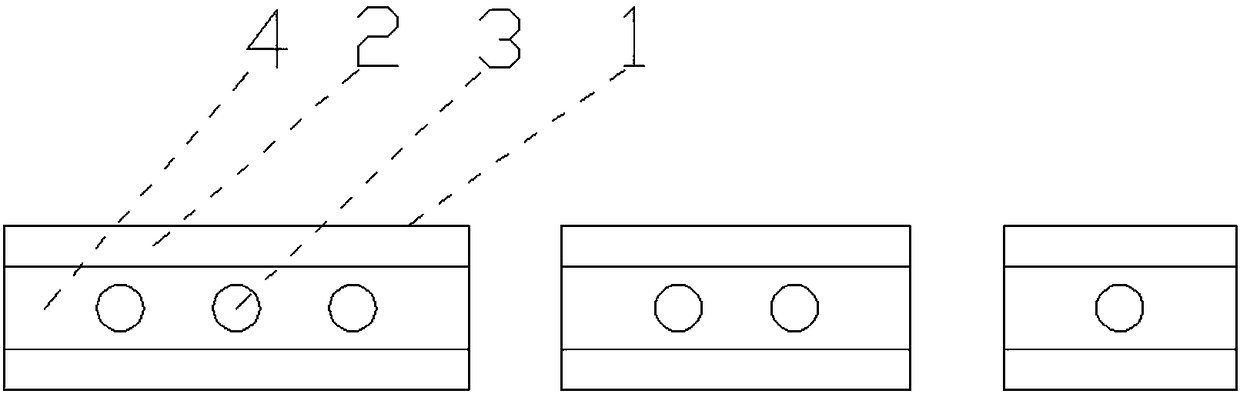

[0044] Such as figure 1 , 2 As shown, a bending machine die includes a flat die die body 1, the flat die die body 1 has a concave cross-section, the protrusions on both sides are die shoulders 2, and the inner shoulders of the die shoulders 2 are The inner corner 7 is chamfered to avoid damage caused by the collision between the die shoulder 2 and the slide block 5 during installation.

[0045]The middle concave part is the inner bottom 4 of the compression mold, and the inner bottom 4 of the compression mold is provided with a number of blind holes, and the magnets 3 which completely match the size of the blind holes are arranged in the blind holes. The flat mold compression mold body 1 is composed of several independent compression mold sections, and magnets 3 are arranged at equal intervals on each section. The magnet 3 is a neodymium-iron-boron magnet. The neodymium-iron-boron magnet is the permanent magnet with the strongest magnetic force so far. It has high cost perfo...

Embodiment 2

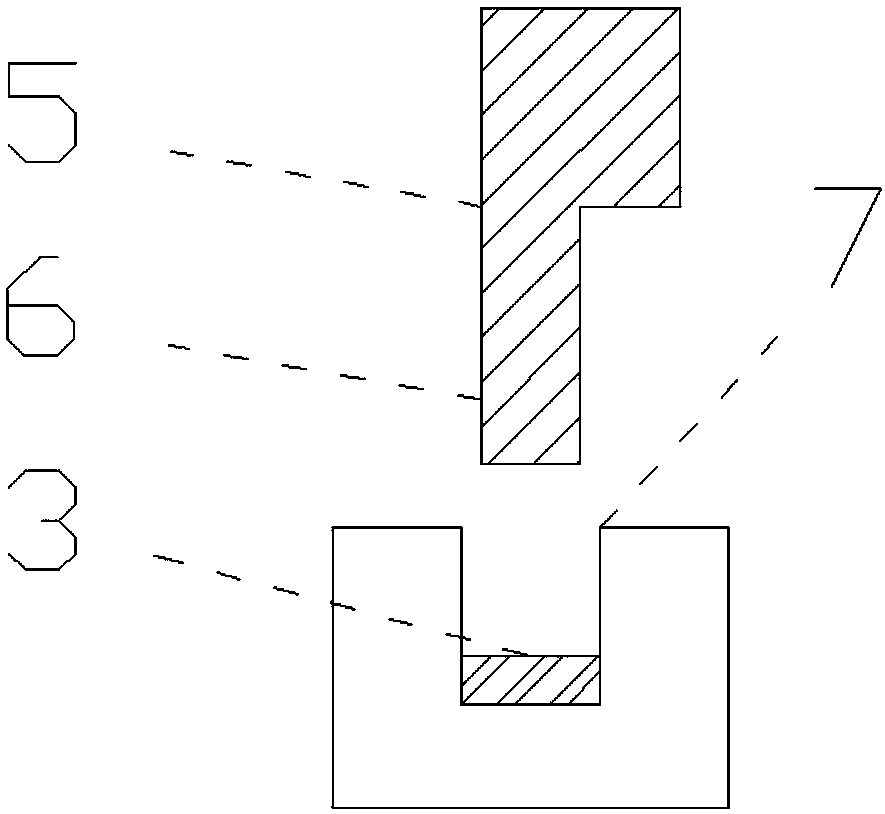

[0050] A bending machine with the pressing die of the bending machine in Embodiment 1, the width of the end 6 of the slider of the bending machine is the same as the width of the inner bottom 4 of the pressing die, the body 1 of the flat die pressing die is adsorbed to the end 6 of the sliding block, It is fixed on the end 6 of the slider, and there is no gap between the flat die body 1 and the slider 5 . For irregular parts to be flattened, the bending machine is used for flattening, and the flat die is installed with magnets. The installation is fast, the stability is good, there will be no deviation during work, and the work progress is fast. Multi-segment flat dies are used for different parts The area and length of the flattening area are flattened, the quality is good, and the progress is fast, which avoids the consequences of one-time flattening and deformation of other parts caused by independent flattening, and also overcomes the fact that the entire flat die can only ...

Embodiment 3

[0052] A method for pressing a bending machine, the steps are as follows:

[0053] A) The parts that need to be flattened in the detection need to be flattened and the size of the area. The part enters the end of the bending machine as the calculation, and the calculated flattened position corresponds to the position of the slider 5 and the flattened position of each section. The required flattening length of slider 5;

[0054] For example, if a car door panel needs to be flattened, there are five points that need to be flattened, and none of them are on a straight line. According to our calculations, point A is an area with a length of 10cm, point B is an area with a length of 5cm, and point C is an area with a length of 5cm. Point D is the area with a length of 6cm, point D is the area with a length of 10cm, point E is an area with a length of 15cm, and points A, B, and C are on a straight line, and points D and E are on a straight line, and if a single flattening machine is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com