Polyolefin microporous membrane

A technology made of microporous membranes and polyolefins, applied to secondary battery parts, structural parts, battery pack parts, etc., can solve problems such as insufficient electrical characteristics, difficulty in achieving high membrane strength, and increased thermal shrinkage problems, achieve excellent strength and low heat shrinkage, improve battery characteristics and battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

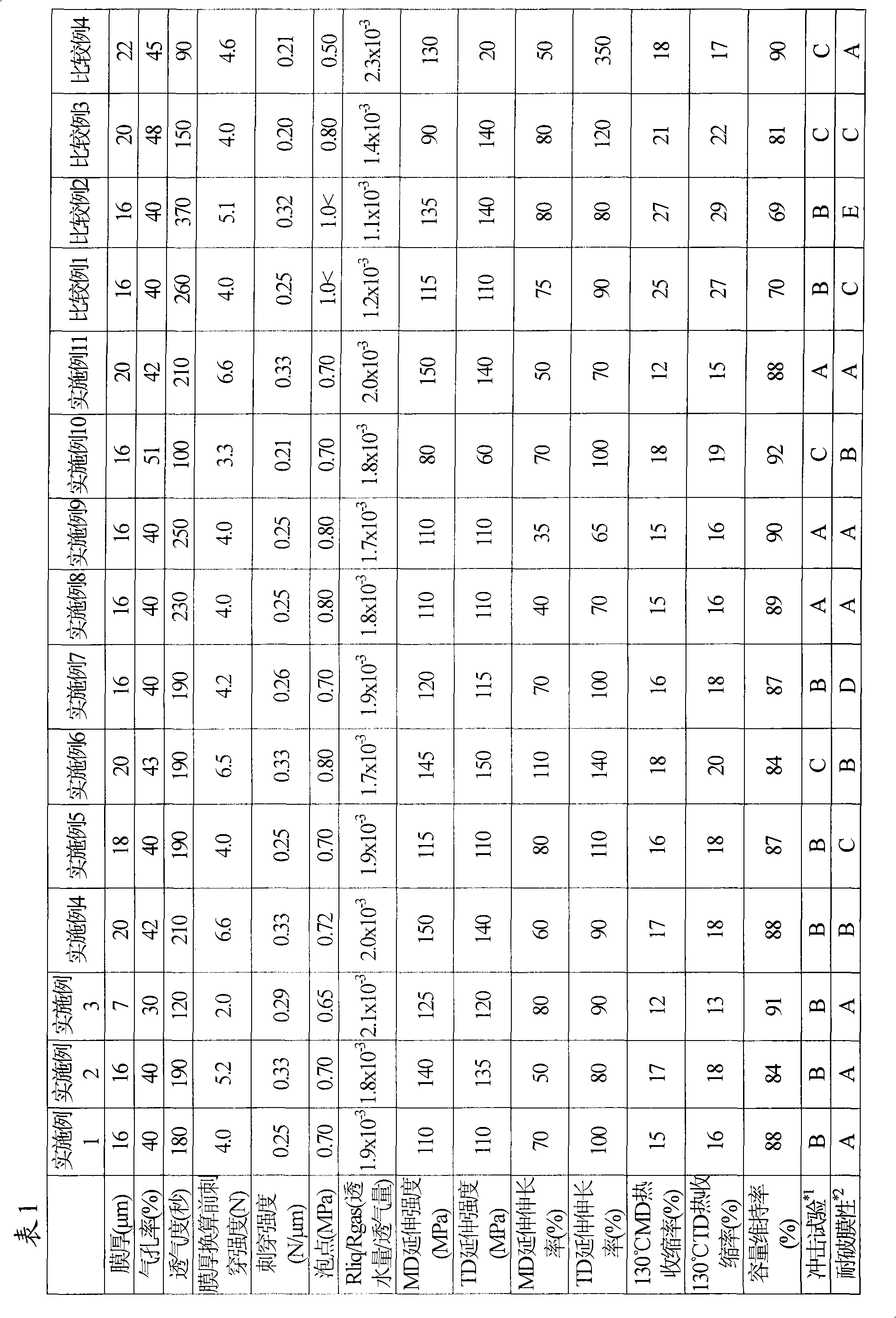

Embodiment 1

[0137] 47% by mass of Mv700,000 homopolymer polyethylene, 46% by mass of Mv300,000 homopolymer polyethylene, and 7% by mass of Mv400,000 polypropylene were dry blended using a tumble mixer. 1% by mass of pentaerythritol-tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] was added as an antioxidant to 99% by mass of the pure polymer mixture obtained, Dry blending was performed again with a drum mixer to obtain a mixture of polymers and the like. The mixture of the obtained polymer and the like was replaced with nitrogen, and then supplied to a twin-screw extruder through a feeder under a nitrogen atmosphere. In addition, liquid paraffin (dynamic viscosity at 37.78°C is 7.59×10 -5 m 2 / s) into the extruder barrel.

[0138] The feeder and the pump were adjusted so that the ratio of the amount of liquid paraffin to the entire mixture of melt kneading and extrusion was 65% by mass. The melt-kneading conditions were a set temperature of 200° C., a screw rotation speed of ...

Embodiment 2

[0145] Except that the biaxial stretching temperature was 120° C., it was carried out in the same manner as in Example 1. Table 1 shows the physical properties of the obtained polyolefin microporous membrane.

Embodiment 3

[0147] Except that the original film thickness after extrusion is 900 μm, the biaxial stretching temperature is 122°C, the stretching temperature at the time of heat setting is 130°C, and the stretching ratio is 2.0 times, and the temperature at the time of relaxation thereafter is 135°C and the relaxation rate is 0.80. Other than that, it carried out similarly to Example 1. Table 1 shows the physical properties of the obtained polyolefin microporous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com