Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about How to "Good heat shrinkability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging film or sheet

InactiveUS6416832B1Good formabilityExcellent gas barrier propertiesFlexible coversWrappersCopolymerPolymer chemistry

The invention provides a single-layer or multi-layer packaging film or sheet having at least one layer formed of a polyamide resin composition, wherein the layer formed of the polyamide resin composition is a layer (A) formed of a polyamide resin composition comprising a copolymer nylon (c) composed of an aliphatic nylon (co)polymer component (1) and an aromatic nylon (co)polymer component (2) in a proportion of at least 5 wt. %.

Owner:KUREHA KAGAKU KOGYO KK

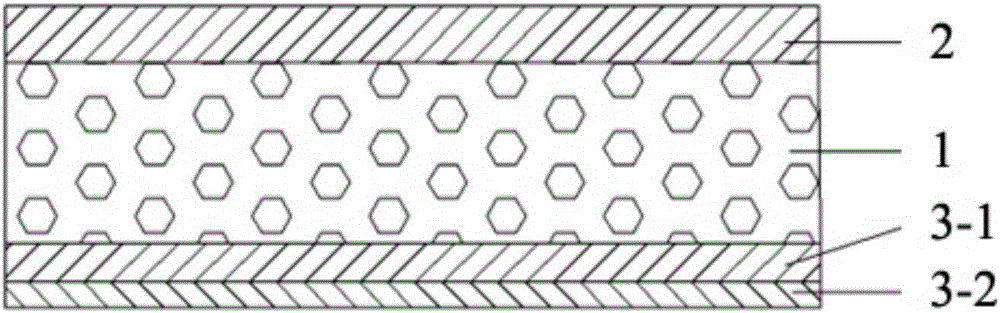

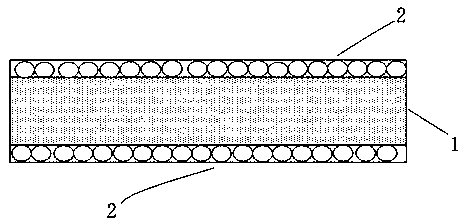

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

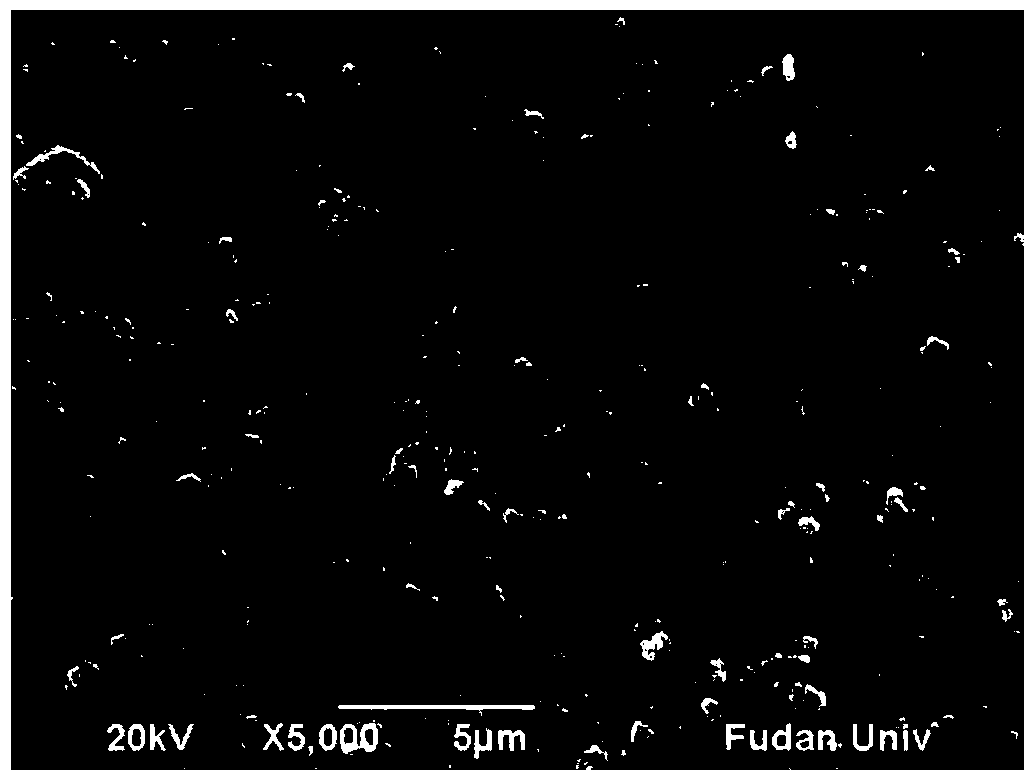

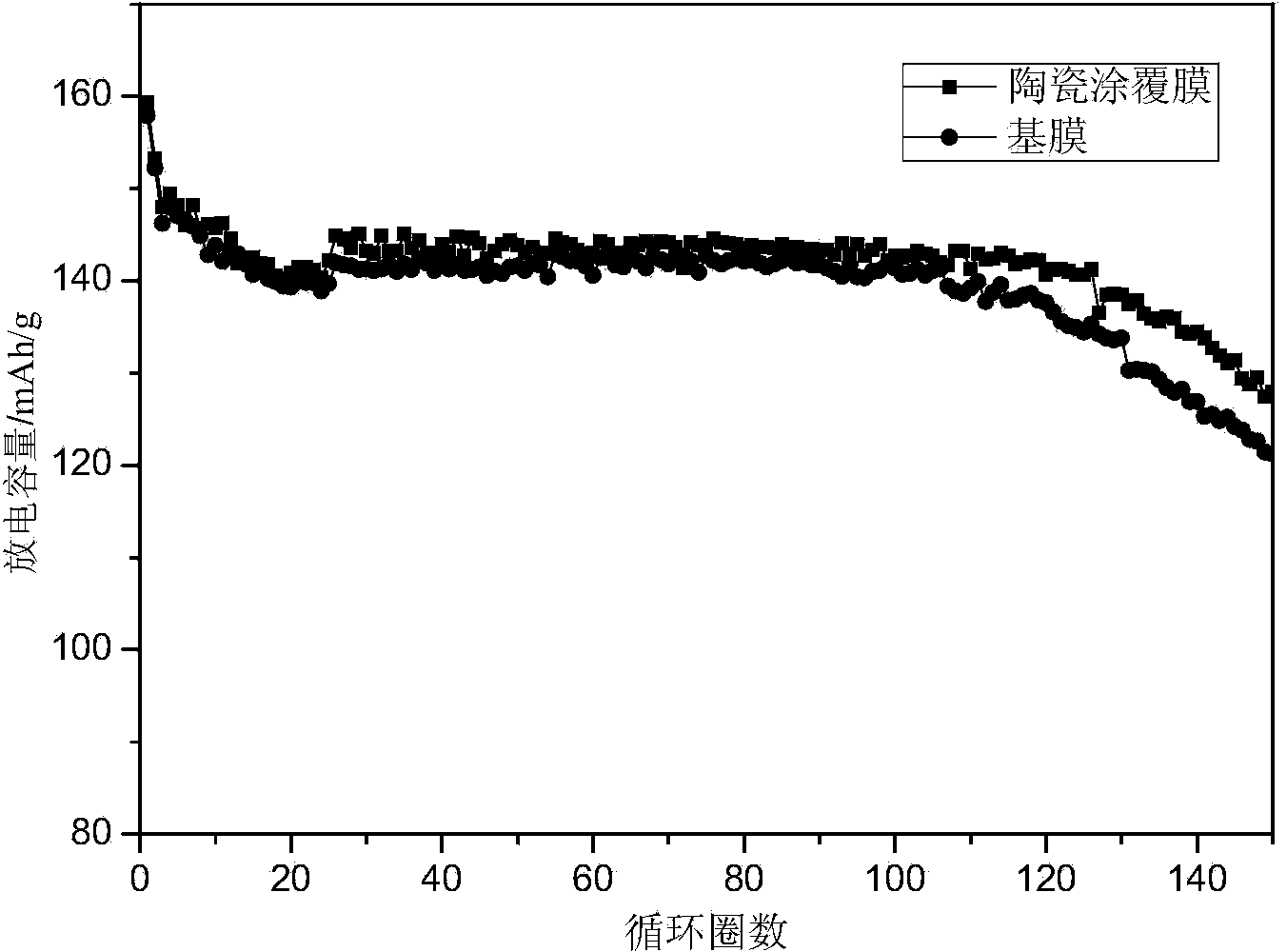

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

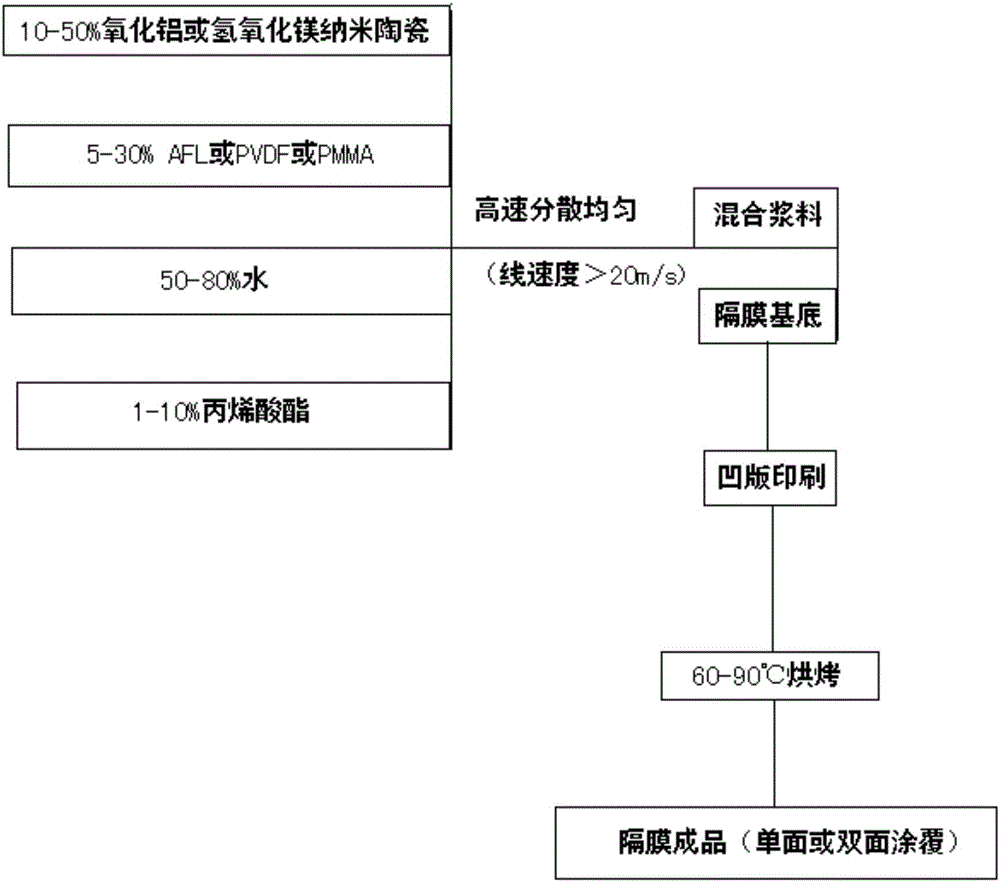

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

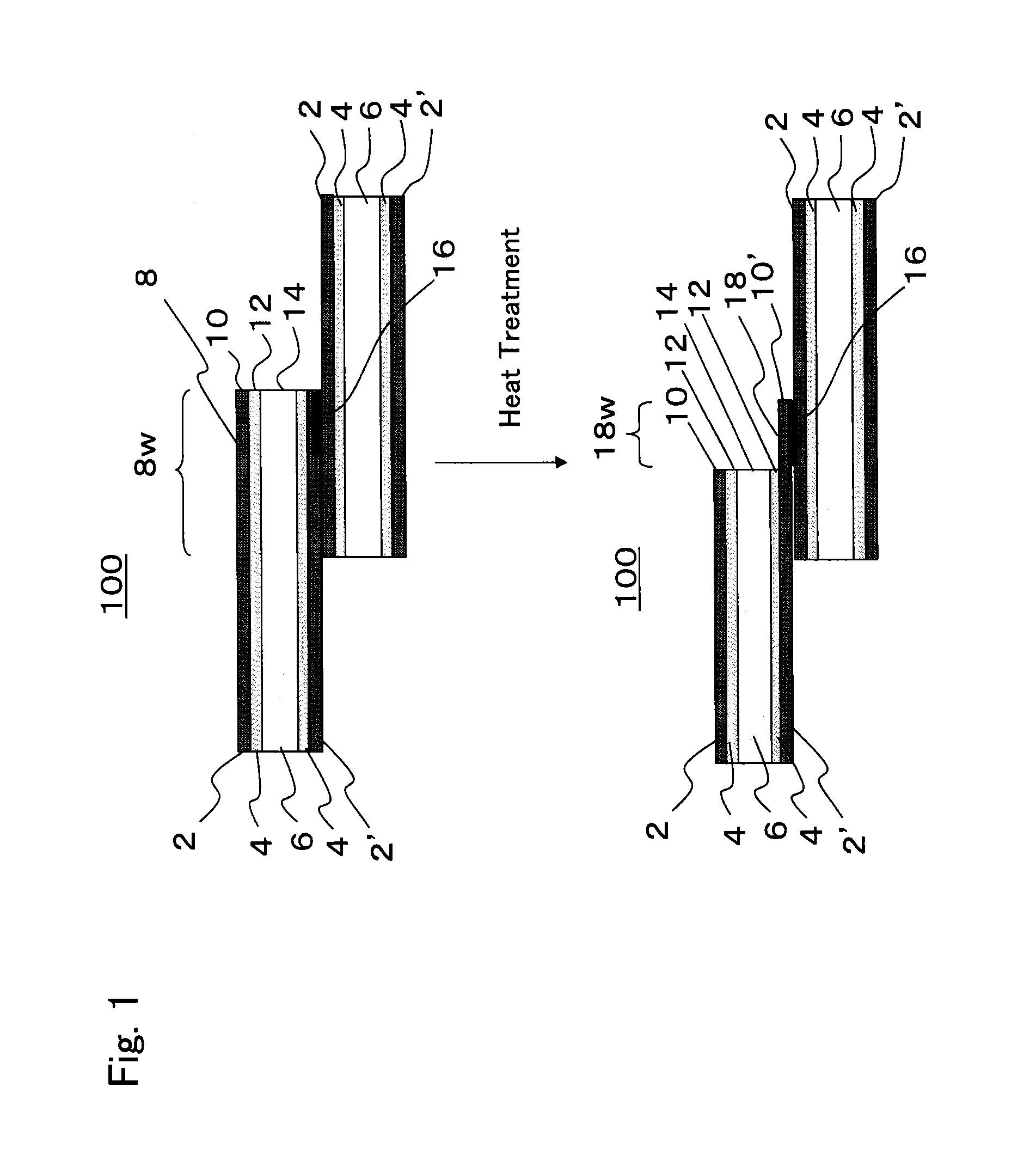

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

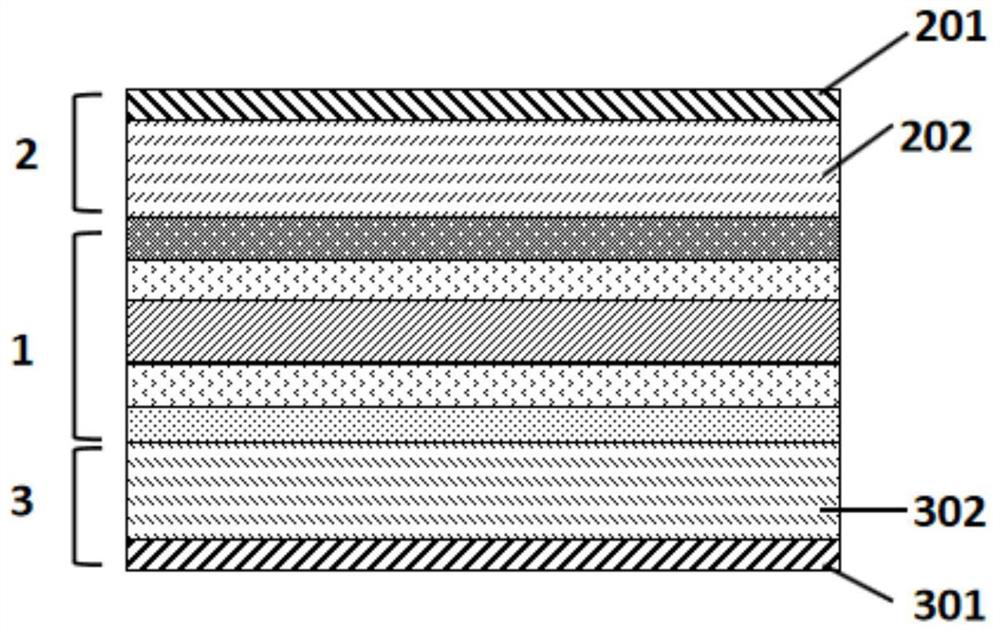

Lithium supplement composite diaphragm, preparation method and application

ActiveCN105932206AImprove temperature resistanceGood heat shrinkabilityCell seperators/membranes/diaphragms/spacersSecondary cellsTemperature resistanceLithium-ion battery

The invention discloses a lithium supplement composite diaphragm, a preparation method and application, and belongs to the technical field of a lithium secondary battery. According to the lithium supplement composite diaphragm, a ceramic layer and a ceramic-lithium supplement layer are arranged at two sides of a base diaphragm; on the one hand, the temperature resistance of the diaphragm is improved, the heat shrinkable property of the diaphragm is improved, and the occurrence of short circuit accidents is reduced; and on the other hand, the Lithium ions consumed in the charge / discharge process can be timely supplemented, the ion transport speed is improved, and the structure stability in the circulation process of the lithium battery is improved. According to the lithium supplement composite diaphragm, the preparation method and the application, the lithium supplement layer is arranged on the surface of the ceramic layer, potential safety hazards resulting from micropore blocking due to the fact that metal lithium powder directly contacts the base diaphragm can be avoided, moreover, the ceramic layer plays a role in buffering and heat dissipation, and the security of the lithium powder in the use process is improved. Netty current collectors are employed in the lithium battery, and the lithium ions can pass through an anode sheet and a cathode pole rapidly, and a high speed channel is provided to supplement the lithium ions timely.

Owner:LUOYANG LIRONG NEW ENERGY TECH

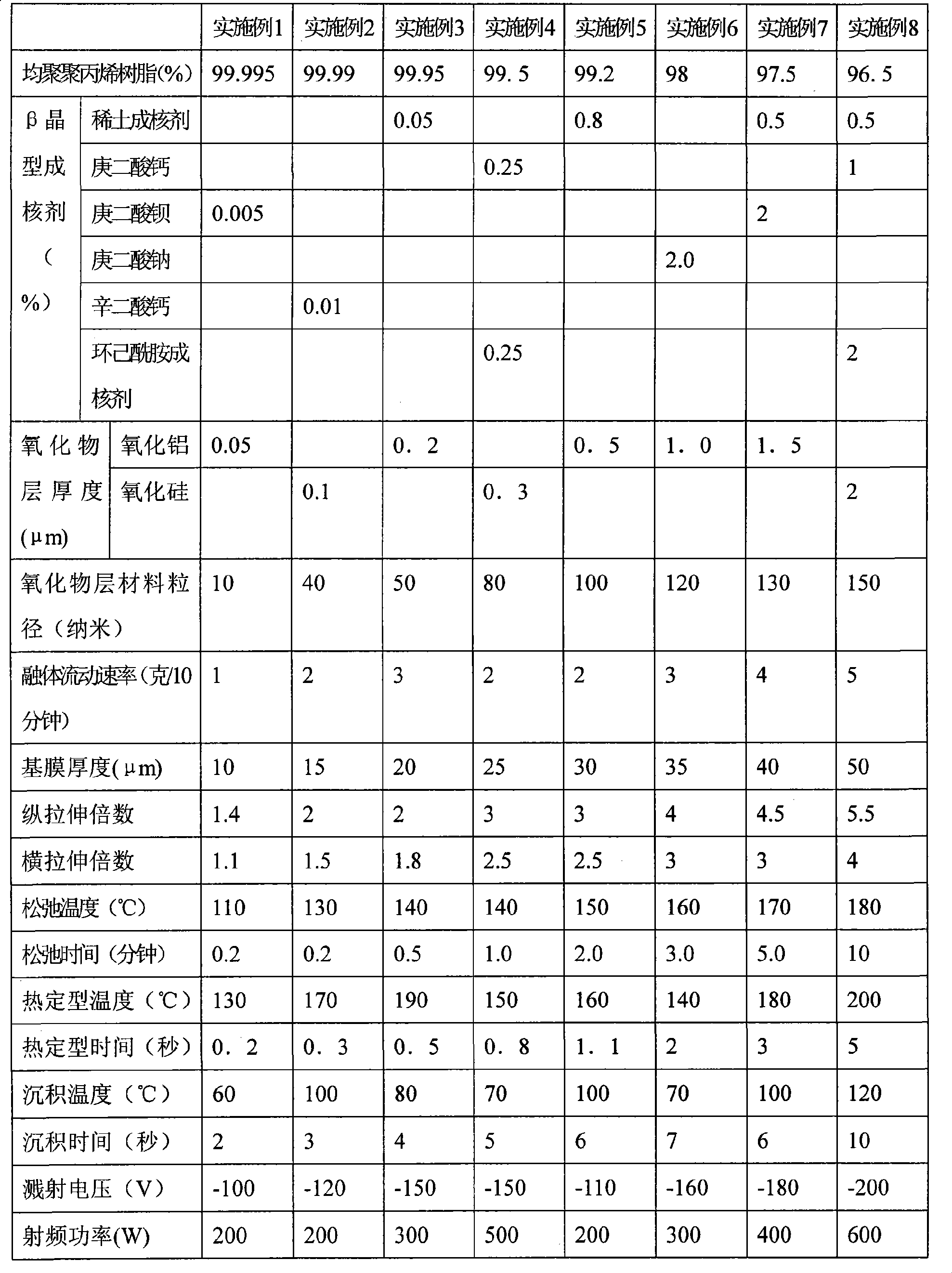

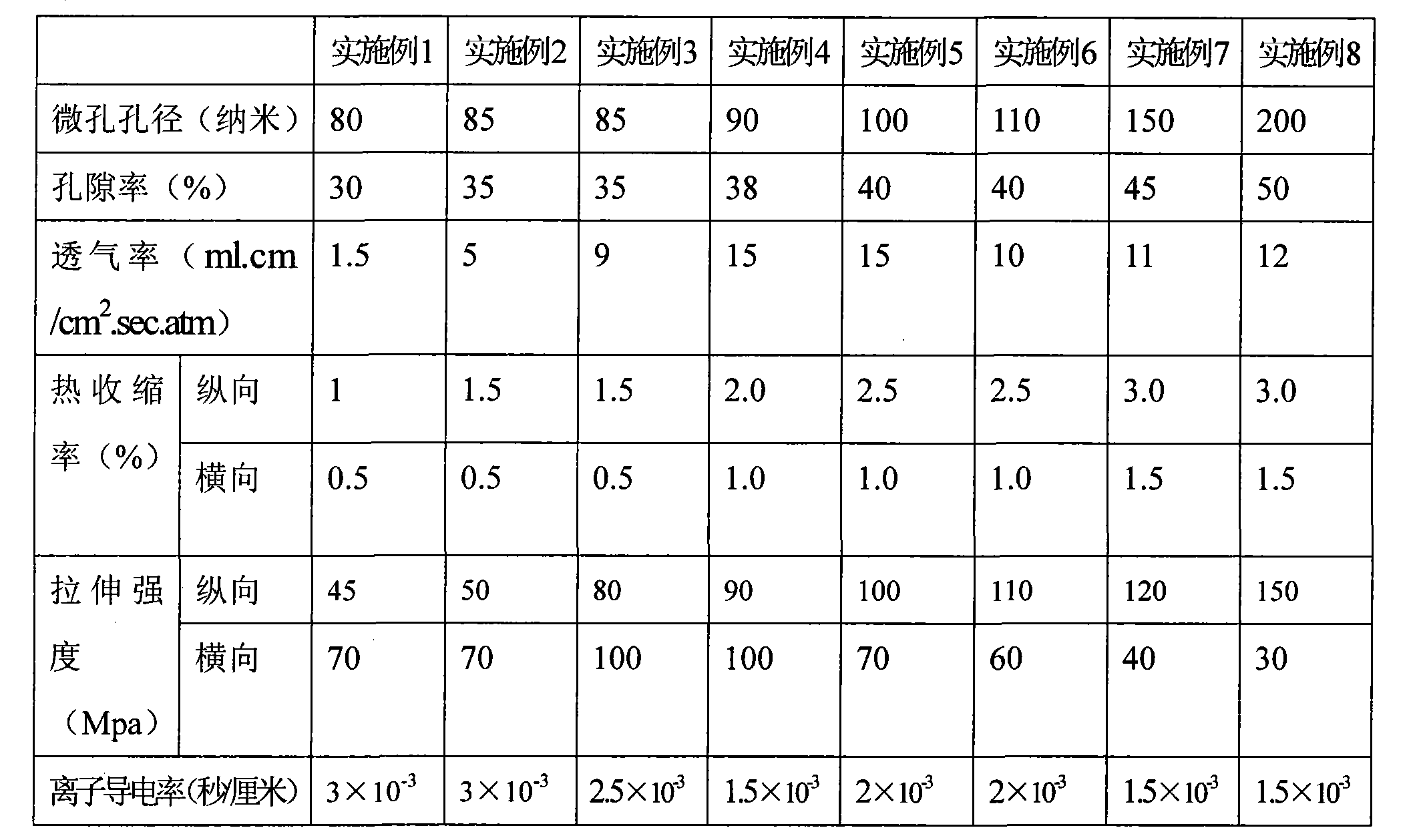

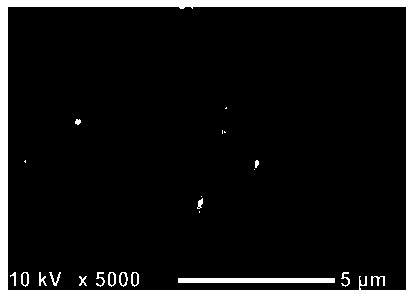

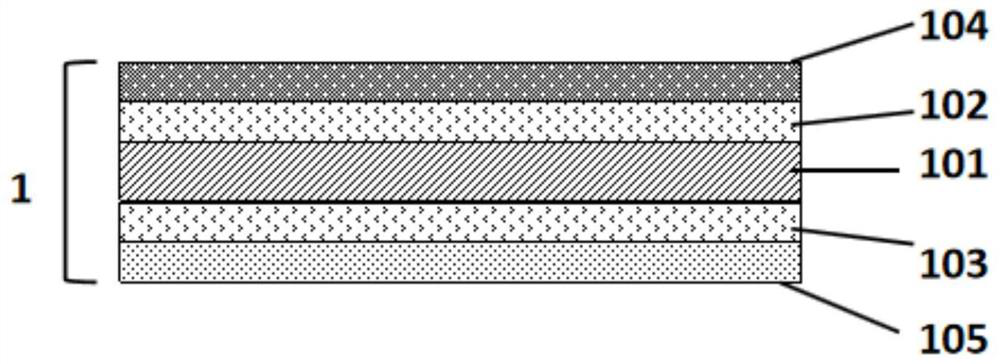

Polyolefin micropore barrier diaphragm and method for producing the same

InactiveCN101462381AImprove ionic conductivityImprove performanceSynthetic resin layered productsCell component detailsLithiumPorosity

The invention relates to a polyolefin microporous diaphragm and a manufacture method thereof, which belongs to the field of thin-film manufacture. The polyolefin microporous diaphragm consists of a polyolefin microporous basal membraneand oxide layer(s) on or / and under the polyolefin microporous basal membrane, wherein the polyolefin microporous basal membrane consists of 96.5 to 99.995 percent of homo-polypropylene resin and 0.005 to 3.5 percent of beta crystal form nucleating agent according to weight percentage; the polyolefin microporous basal membrane has the average pore size between 80 and 200 nanometers, the porosity between 30 and 50 percent and the air permeability between 1.5 and 15 ml / cm<2>.sec.atm; and the thickness of the oxide layer is between 0.05 and 2 microns. The polyolefin microporous diaphragm has the characteristics of uniform micropores, good air permeability, good thermal shrinkage properties and high ionic electrical conductivity, and can be widely applied to medical dialysis membranes, industrial water treatment membranes and lithium-ion secondary battery diaphragms.

Owner:韩伟嘉

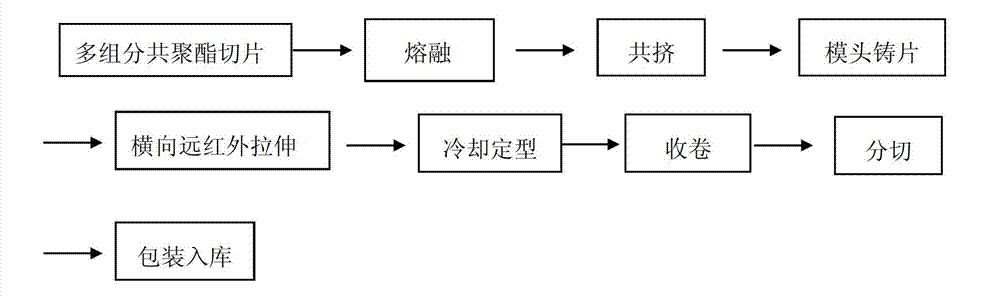

Preparation method of heat shrinkable polyester film

The invention discloses a preparation method of a heat shrinkable polyester film. The method comprises the following steps of: carrying out esterification and condensation polymerization reaction on multi-component dicarboxylic acid and multi-component dihydric alcohol in the presence of a catalyst, a stabilizing agent, an antistatic agent, a chain extender, an anti-caking agent or a modifying agent to prepare a multi-component polyester; carrying out melt extrusion, extension and pelleting on the multi-component polyester to prepare a multi-component polyester slice; and carrying out melted extrusion, die head casting, transverse far infrared drawing, cooling molding, rolling and cutting on the multi-component polyester slice to prepare the heat shrinkable polyester film. The heat shrinkable polyester film with high shrinkage percentage prepared by using the method is pretty high in strength and heat shrinkage performance, excellent in transparency, malleability, and toughness, good in glossiness, uniform in shrinkage, non-toxic, odorless, and easy to recycle, and a product of the film is suitable for labels for various containers and direct packaging of a food product, a beverage product, an electronic product, an electric product, a mechanical product, a hardware product and the like.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Low-temperature shrinkable film

InactiveUS20070122600A1Good heat shrinkabilityFlexible coversWrappersVolumetric Mass DensityCopolymer

An object of the present invention is to provide a shrinkable film excellent in dimensional stability at a temperature of 60° C. and having good shrink properties in a temperature of 100° C. and 120° C. A low-temperature shrinkable film includes a film composed of at least one layer including at least one ethylene-α-olefin copolymer (A) with a density of from 0.870 g / cm3 to 0.920 g / cm3 and at least one ethylenic copolymer (B) having a main peak below 110° C. in the 2nd fusion behavior of differential scanning calorimetry, wherein the proportion of the heat of fusion at 100° C. or below to the total heat of fusion is from 50% to 100% in the 2nd fusion behavior of differential scanning calorimetry for ethylene-α-olefin copolymer (A); the proportion of the heat of fusion at 100° C. or below to the total heat of fusion is from 60% to 100% in the 2nd fusion behavior of differential scanning calorimetry for the film; and the average value of a heat shrinkage percentage in the longitudinal direction and a heat shrinkage percentage in the lateral direction of the film is from 0 to 15% at 60° C., 50% or greater at 100° C. and 70% or greater at 120° C.

Owner:ASAHI KASEI LIFE & LIVING CORP

Preparation method for ceramic coating separator

ActiveCN104183805AOvercoming the drawbacks of effective decentralizationEnsure decentralizationCell component detailsCeramic coatingLithium-ion battery

The invention relates to a preparation method for a ceramic coating separator material used to lithium ion batteries. The preparation method comprises steps of preparation of a ceramic slurry, separator pretreatment, precise coating, drying and the like. The prepared product has the characteristics that the ceramic coating is compact, uniformly and firm in adhesion and the separator is small in thermal shrinkage, and the prepared product has obvious effect on improving safety performance of the lithium ion battery and prolonging battery service life.

Owner:ZHANGJIAGANG NENGCI MATERIAL SCI & TECHCO LTD

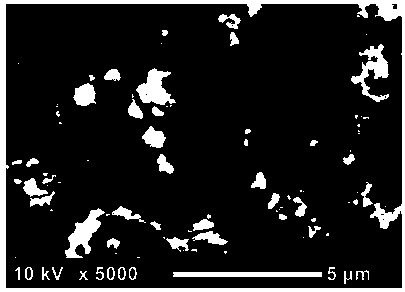

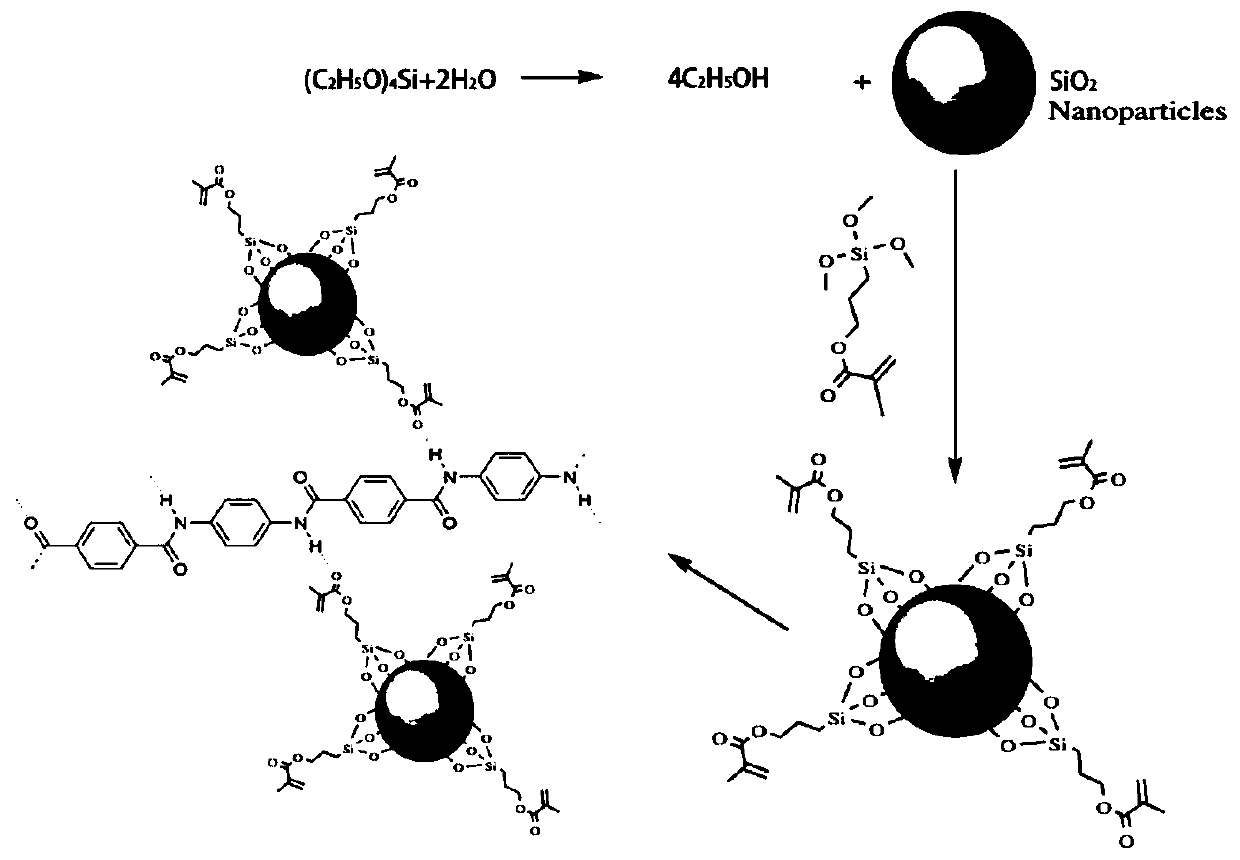

Inorganic nanoparticle-modified aramid fiber paste and aramid-coated lithium battery composite diagram

InactiveCN110048063AGood heat shrinkabilityImprove high temperature resistanceMaterial nanotechnologyCell component detailsAramidInorganic nanoparticles

The invention discloses inorganic nanoparticle-modified aramid fiber paste and an aramid-coated lithium battery composite diagram. The inorganic nanoparticle-modified aramid fiber paste comprises aramid, inorganic nanoparticle, a coupling agent and a solvent. The aramid-coated lithium battery composite diagram comprises a battery diagram and an aramid coating layer, wherein the aramid coating layer is coated at a single side or dual sides of the battery diagram, and the aramid coating layer is formed by coating the inorganic nanoparticle with modified aramid paste. The high-temperature resistant performance of the lithium battery diagram is greatly improved, and the air permeability of the lithium battery diagram is improved.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

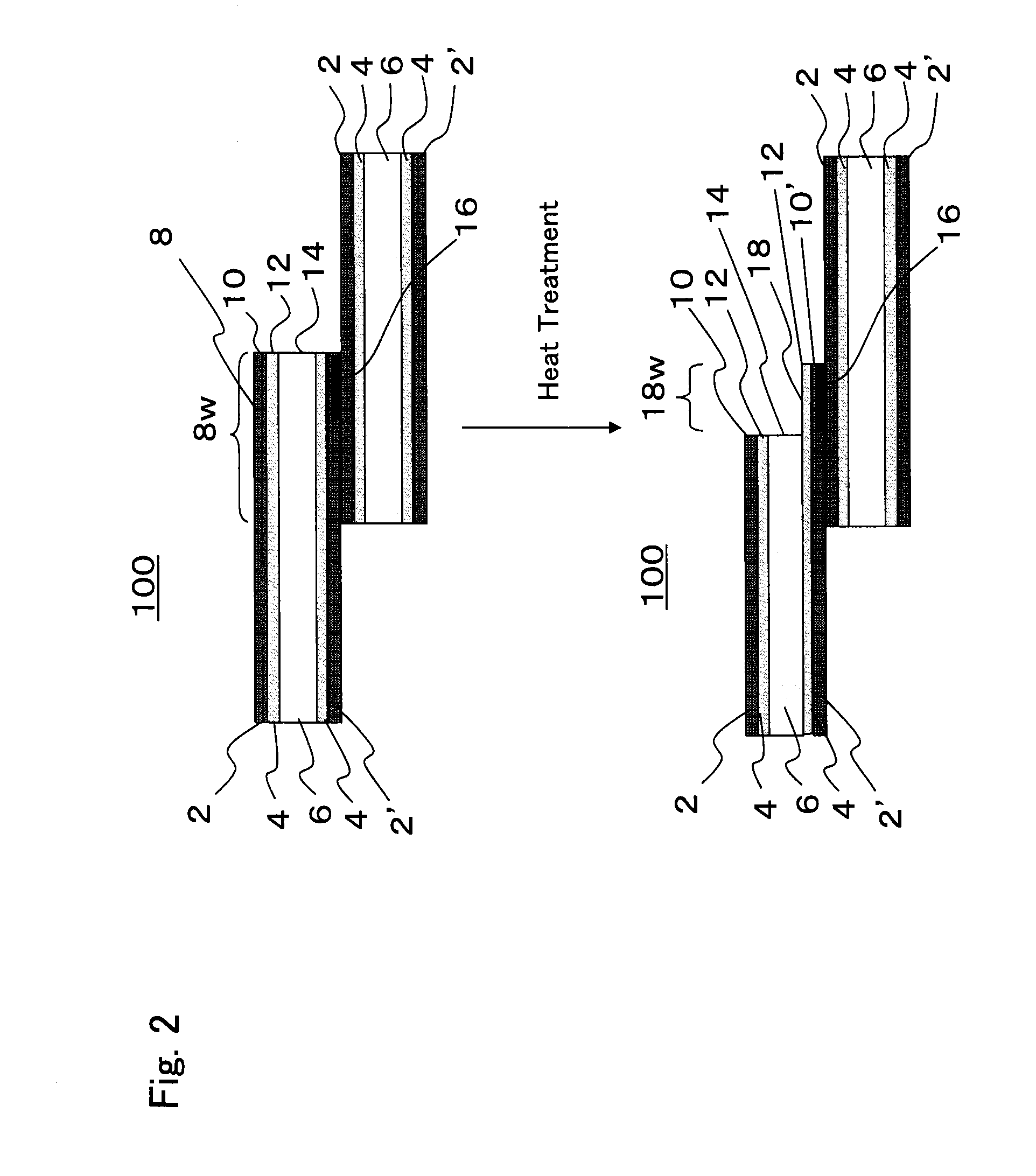

Polyolefin Series Heat-Shrinkable Film, Molded Product and Heat-Shrinkable Laminated Label Employing the Film, and Container

ActiveUS20080311320A1Good heat shrinkabilityLow naturalWrappers shrinkageShrinkage connectionsPolymer sciencePolyolefin

The present invention provides a polyolefin series heat-shrinkable film comprising a mixed resin mainly containing a polyolefin series resin (A), polylactic acid series resin (B), and a resin (C) facilitating compatibility with the resin (A) and the resin (B), or comprising at least one layer made of the mixed resin, wherein mass ratio of the resin (A) to the resin (B) is (A) / (B)=99 / 1 to 70 / 30; heat shrinkage ratio of the film at least in one direction when dipped in hot water at 80° C. for 10 seconds is 20% or more; and natural shrinkage ratio of the film when stored at 40° C. under 50% RH environment for 7 days is less than 10%. This polyolefin series heat-shrinkable film exhibits excellent heat-shrinkable property and shrink finishing quality, and inhibits natural shrinkage. This invention also provides a polyolefin series heat-shrinkable label and container on which the heat-shrinkable label is fitted.

Owner:MITSUBISHI CHEM CORP

Battery separator and preparation method thereof

InactiveCN103441229AImprove electrochemical performanceImprove thermal stabilitySecondary cellsCell component detailsCross-linkPolyolefin

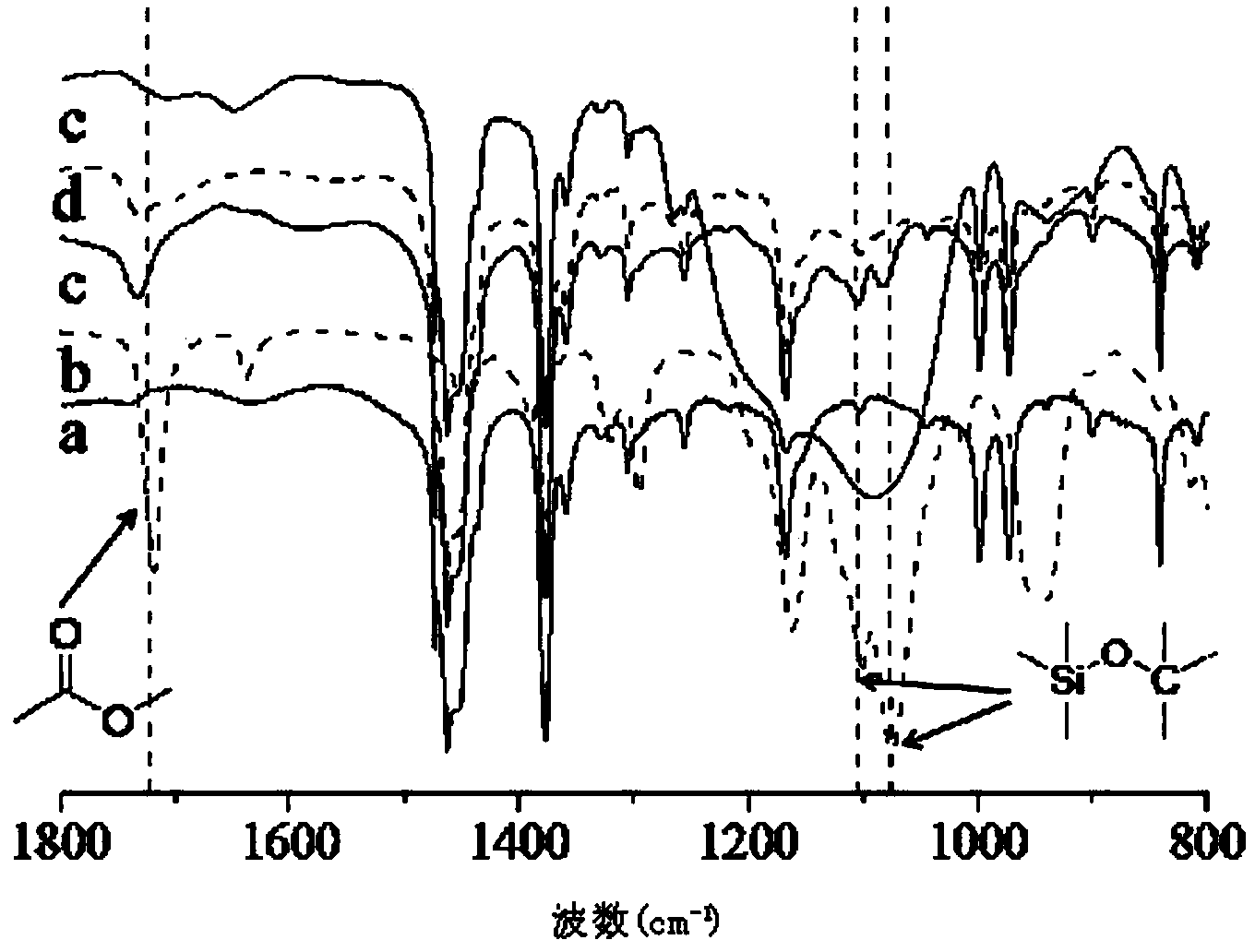

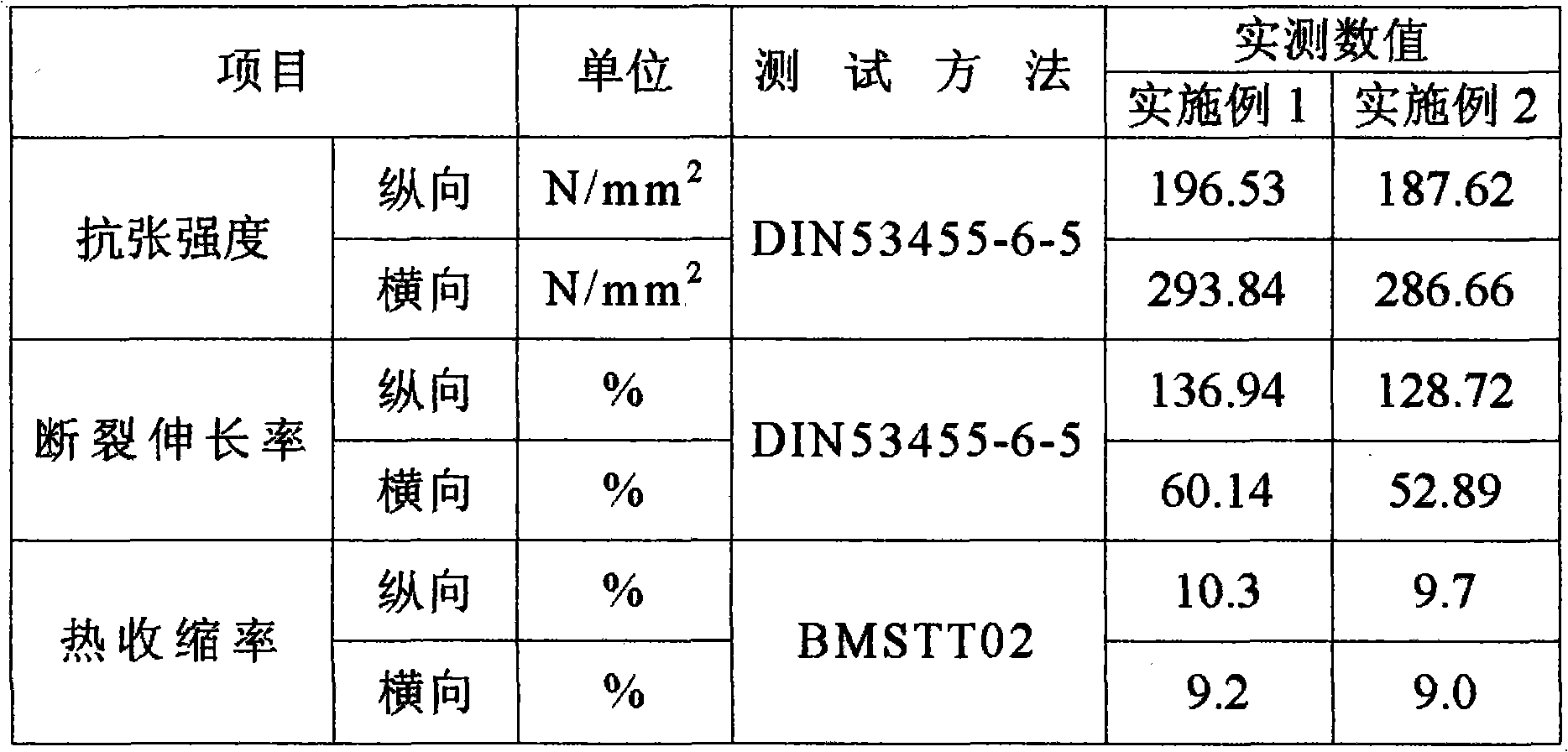

The invention relates to a preparation method of a battery separator. The preparation method comprises: providing a polyolefin porous membrane; adhering an oxidizing agent to the surface of the polyolefin porous membrane; providing a liquid-phase medium containing an organic silicon oxide, wherein the organic silicon oxide contains a methacryloxy group or at least two alkoxy groups, and the alkoxy groups and the methacryloxy group are respectively connected with silicon atoms; heating the polyolefin porous membrane with the surface adsorbed the oxidizing agent in the liquid-phase medium to polymerize the organic silicon oxide and grafting the polymerized organic silicon oxide with the polyolefin porous membrane; and providing an acidic environment or an alkali environment, placing the grafted polyolefin porous membrane in the acidic environment or the alkali environment, to perform a condensation reaction on silicon and oxide groups to form a silicon-oxide cross-linked network structure which is grafted with the polyolefin porous membrane. The invention also relates to the battery separator.

Owner:TSINGHUA UNIV

BOPP thin film of hard-box cigarette package special for super-high speed cigarette packer

ActiveCN102079155AWear-resistantGood optical performanceFlexible coversWrappersEngineeringEthylene Homopolymers

The invention discloses a biaxially-oriented polypropylene (BOPP) thin film of a hard-box cigarette package special for a super-high speed cigarette packer. The thin film adopts a way of directly co-extruding and compositing a three-layer structure, wherein the upper surface structure of the thin film is mainly made from polypropylene copolymer; the core structure of the thin film is mainly made from polypropylene homopolymer; and the lower surface structure of the thin film is mainly made from polypropylene copolymer. In the BOPP thin film disclosed by the invention, excellent optical performance, smoothness and thermal shrinkage are kept; the stiffness is good; the elastic modulus is high; the thickness is uniform; the surface of the film has certain wear resisting property; and the film can be applicable to a super-high speed cigarette packer set and effectively solves the technical problem that an ordinary hard-box cigarette package thin film cannot be matched with the packer set to be used.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

Lithium-ion battery separator, and preparation method and application thereof

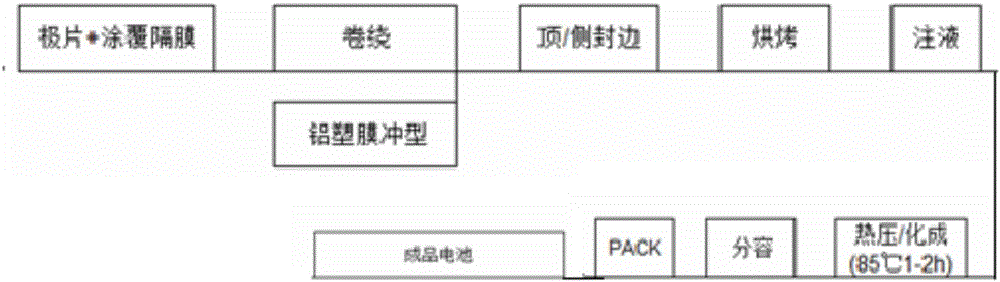

ActiveCN106207059AImprove securityHeat shrinkable area expandsFinal product manufactureSecondary cellsCyclic processSafety testing

The invention provides a lithium-ion battery separator, and a preparation method and application thereof. The lithium-ion battery separator comprises a separator substrate and an aqueous function layer composited on the surface of the separator substrate. The aqueous function layer is equipped with multiple micropores. The aqueous function layer has viscidity. When the separator provided by the embodiment of the invention is applied to a polymer lithium-ion battery, a partial lithium separation phenomenon will not occurs in a cycle process and deformation or a relatively high expansion phenomenon will not occur in a battery pole group, thereby facilitating stability of cycle life. Moreover, the heat contractility of the separator is improved. The separator and an electrode are adhered together well with the combination of effects such as the viscidity of the aqueous function layer. In a safety test process or when the battery is abused such as the fact that the battery is punctured, extruded, twisted and bended, or when the battery is used in a high temperature environment for a long time, the safety performance of the battery can be greatly improved.

Owner:LENOVO (BEIJING) CO LTD

Preparation method of porous composite isolating membrane

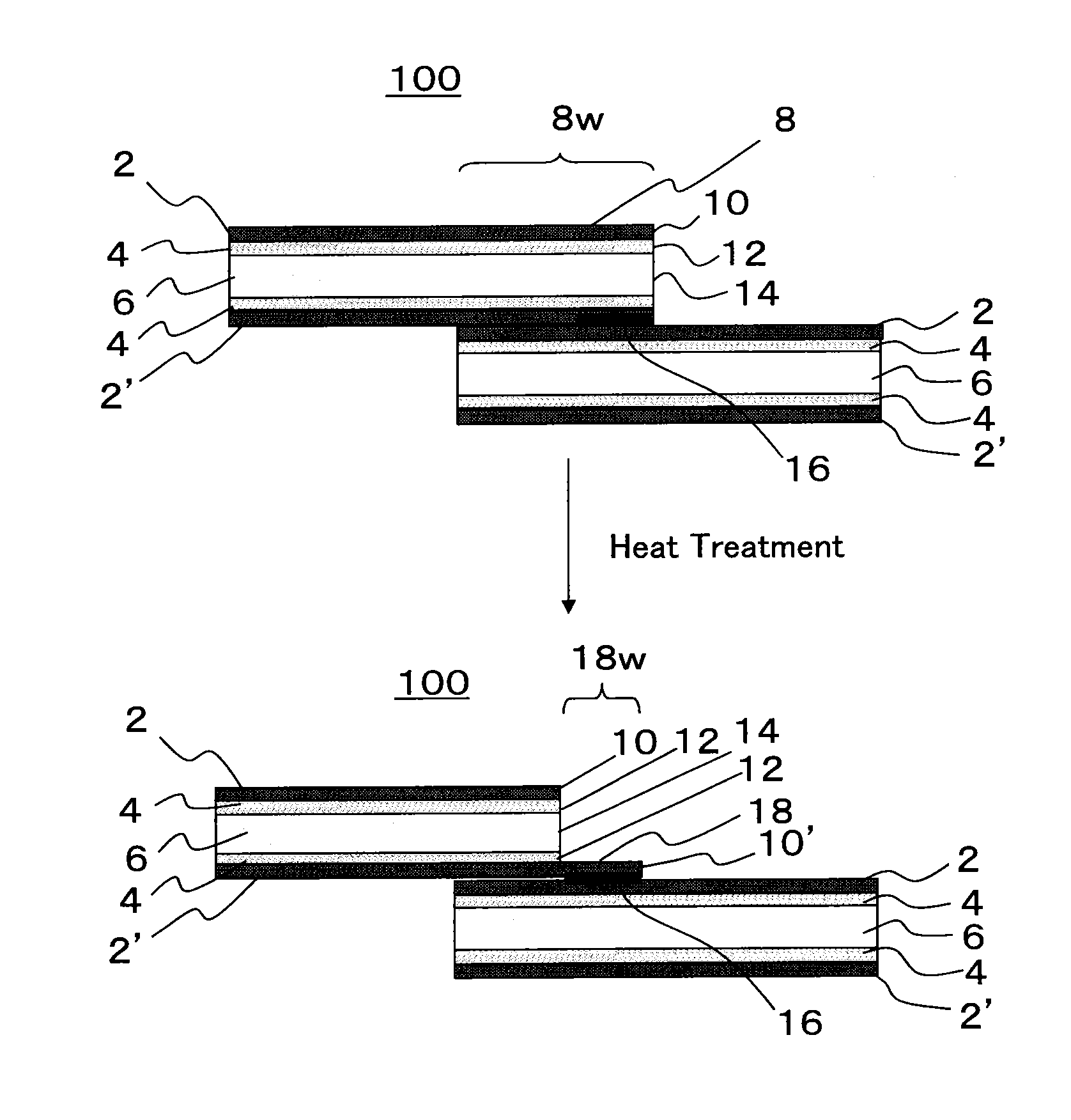

ActiveCN104262674AIncrease productivityReduce manufacturing costFibre typesSecondary cellsThermal stabilityThermal treatment

The invention provides a preparation method of a porous composite isolating membrane. The preparation method comprises the following steps: (1) moulding technology of the porous composite isolating membrane: preparing a porous isolating membrane basic material from organic particles; (2) coating technology of a functional material coating: coating a functional material on at least one surface of the porous isolating membrane basic material so as to obtain a porous isolating membrane basic material with a functional material coating; (3) thermal treatment technology: drying the functional material coating, ad carrying out a thermal treatment on the porous isolating membrane basic material and the functional material coating so as to obtain the porous composite isolating membrane. The provided preparation method can prepare a porous composite isolating membrane with an excellent performance, and has the advantages of high efficiency and low cost. The prepared porous composite isolating membrane has the advantages of high pore rate, good breathability, high binding performance, high mechanical strength, and high thermal stability.

Owner:DONGGUAN AMPEREX TECH +1

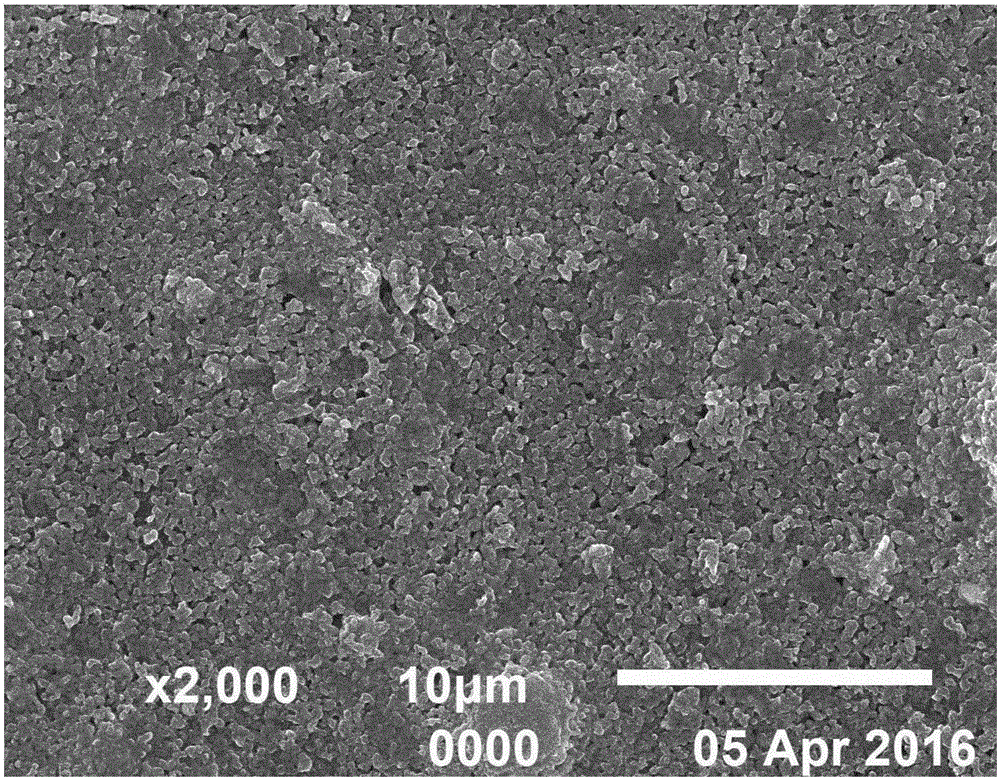

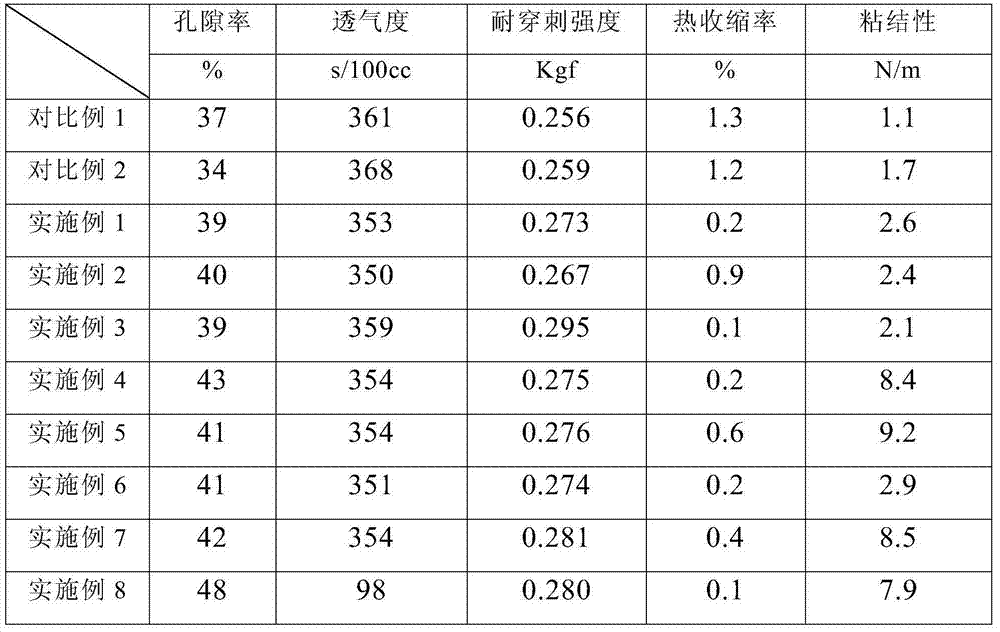

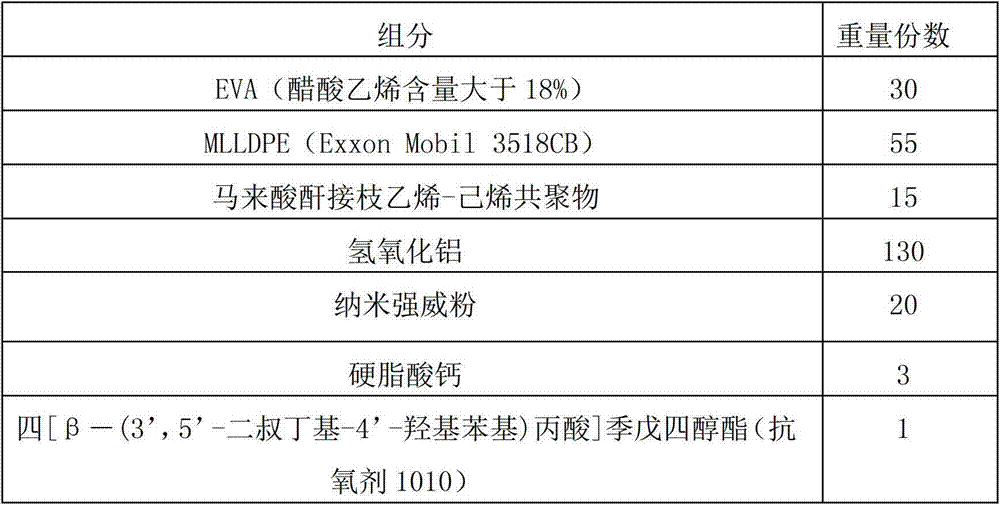

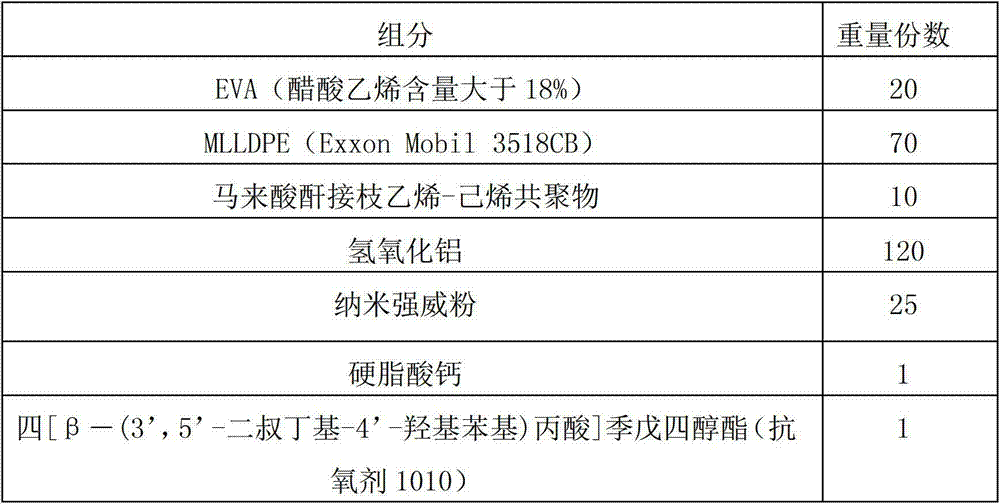

Nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and preparation thereof

ActiveCN103205053AImprove toughnessHold powder wellPlastic/resin/waxes insulatorsInsulated cablesPolyolefinAntioxidant

The invention relates to a cable material, and in particular relates to a nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and a preparation method thereof. The polyolefin cable material comprises the following components: EVA (Ethylene Vinyl-acetate Copolymer), MLLDPE (Linear Low-Density Polyethylene), an interfacial compatibilizer, aluminum hydroxide, nanometer strong micropowder, an antioxidant and a lubricant. The preparation method comprises the following steps of: evenly stirring the EVA and the MLLDPE as basic materials, the interfacial compatibilizer, the aluminum hydroxide, the nanometer strong micropowder, the antioxidant and the lubricant in a high-speed mixer; performing banburying in a banbury mixer at the temperature between 120 and 150 DEG C; extruding by using double screw rods; granulating by grinding and hot-cutting; conveying materials by using a cyclone separator; and screening by using a vibrating screen and packaging, thereby obtaining the finished nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material product. Compared with the common low-smoke halogen-free and flame-retardant polyolefin cable material, the polyolefin cable material provided by the invention has the effects that the thermal aging resistance is enhanced; the shrinkage performance of the product is improved greatly; and the problem that the low-smoke halogen-free polyolefin cable material is easy to shrink at the high temperature is solved.

Owner:JIANGSU LINRY NEW MSTAR TECH

Heat-shrinkable tube having tearability

ActiveUS20140255633A1Good heat shrinkabilityEasy to operateWrappers shrinkageShrinkage connectionsPolymer sciencePolymer chemistry

An object of the present invention is to provide a tube which can be easily torn and has a large heat-shrinkability at a low temperature. The tube of the present invention is a heat-shrinkable tube having tearability, including a mixture of a fluorine resin and a different kind of resin from the fluorine resin, in which an amount of change in loss energy, ΔE loss, with change in temperature from 175° C. to 185° C. is a positive value.

Owner:JUNKOSHA

Polyolefin series heat-shrinkable film, molded product and heat-shrinkable laminated label employing the film, and container

ActiveUS8137773B2Good heat shrinkabilityLow naturalWrappers shrinkageSynthetic resin layered productsPolyolefinThermal water

The present invention provides a polyolefin series heat-shrinkable film comprising a mixed resin mainly containing a polyolefin series resin (A), polylactic acid series resin (B), and a resin (C) facilitating compatibility with the resin (A) and the resin (B), or comprising at least one layer made of the mixed resin, wherein mass ratio of the resin (A) to the resin (B) is (A) / (B)=99 / 1 to 70 / 30; heat shrinkage ratio of the film at least in one direction when dipped in hot water at 80° C. for 10 seconds is 20% or more; and natural shrinkage ratio of the film when stored at 40° C. under 50% RH environment for 7 days is less than 10%. This polyolefin series heat-shrinkable film exhibits excellent heat-shrinkable property and shrink finishing quality, and inhibits natural shrinkage. This invention also provides a polyolefin series heat-shrinkable label and container on which the heat-shrinkable label is fitted.

Owner:MITSUBISHI CHEM CORP

Thermal contracting polyester film and method for preparing same

The present invention reveals one kind of heat shrinking polyester film prepared with one kind of modified copolyester. The modified copolyester is polymer of one composition comprising terephthalic acid, ethylene glycol, and one first modifier for destroying crystallinity. The modified copolyester has glass transition temperature within 40-85 deg.c. The first modifier is 1, 3-dihydroxy-2-methyl propane, 1, 3- dihydroxy-2- methyl propane alkoxy ester and / or 2, 5-dimethyl-2, 5-hexadiol. The present invention also reveals process of preparing the heat shrinking polyester film with sheet of the modified copolyester and through stretching, cooling and curing.

Owner:FAR EASTERN NEW CENTURY COPRRATION

Polyolefin microporous membrane

ActiveCN101568575AExcellent strength and low heat shrinkageImprove battery characteristics and battery safetyLi-accumulatorsCell component detailsLarge porePolyolefin

Disclosed is a polyolefin microporous membrane having a bubble point of not more than 1 MPa, a tensile strength in the longitudinal direction of not less than 50 MPa, a tensile strength in the width direction of not less than 50 MPa, and a thermal shrinkage in the width direction at 130 DEG C of not more than 20%. This polyolefin microporous membrane is excellent in strength and low thermal shrinkage property, while having a large pore diameter.

Owner:ASAHI KASEI KK

Modified polyolefin membrane coated with silicon dioxide layer and preparation method thereof

InactiveCN106328864ANo pollution in the processReduce pollutionCell seperators/membranes/diaphragms/spacersLi-accumulatorsPolyolefinAlcohol

The invention relates to a modified polyolefin membrane coated with a silicon dioxide layer and a preparation method thereof. The method comprises the following steps of: uniformly mixing ammonium hydroxide, water, ethyl alcohol and Tween 80; adding tetraethoxysilane; uniformly stirring; adding a polyolefin membrane; soaking for a period of time, and then taking out, cleaning and drying, thereby acquiring the product. According to the method provided by the invention, the technique is simple and convenient, the modified polyolefin membrane has no or less pollution to environment, the energy consumption is low, the application scope is wide and the performance is excellent when the prepared modified membrane is applied to a lithium sulfur battery.

Owner:珠海泰坦储能科技有限公司

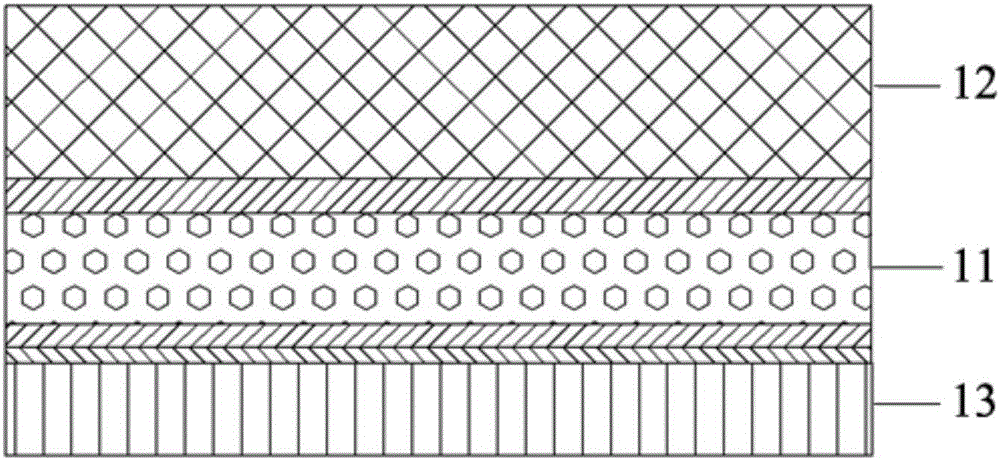

Composite diaphragm with lithium supplementing effect, and preparation method thereof and lithium ion battery

PendingCN112599928AImprove electrochemical performanceGood chemical propertiesElectrolyte/reactants regenerationCell component detailsHigh diaphragmCeramic coating

The invention provides a composite diaphragm with a lithium supplementing effect. The composite diaphragm comprises a base membrane, a first ceramic coating and a second ceramic coating which are respectively positioned on the upper surface and the lower surface of the base membrane, a lithium supplementing gel coating positioned on the upper surface of the first ceramic coating, and a gel coatingpositioned on the lower surface of the second ceramic coating. According to the invention, with the ceramic coating in the diaphragm, the temperature resistance of the diaphragm is improved, the thermal shrinkage of the diaphragm is improved, explosion caused by short circuit due to direct contact between a positive electrode and a negative electrode due to diaphragm deformation caused by thermalcontraction of the diaphragm at a high temperature is prevented, the lithium supplementing gel coating can realize uniform and accurate lithium supplementing of a silicon-carbon negative electrode sheet, a silicon-carbon negative electrode is prevented from being excessively lithiated to cause lithium precipitation, after lithium supplementing is finished, the gel coating and the electrode sheethave higher bonding force under the action of hot-pressing shaping, and the lithium ion good conductor powder remained in the lithium supplementing coating has good ionic conductivity, so that the conduction of lithium ions is promoted.

Owner:TIANJIN ENERGIES

Heat-shrinkable film, moldings and heat-shrinkable labels made by using the film, and containers made by using the moldings or fitted with the labels

ActiveCN101175797AExcellent thermal shrinkage propertiesGood heat shrinkabilityBio-packagingSynthetic resin layered productsMeth-Polymer science

The aim of the present invention is to obtain a heat-shrinkable film which is excellent in mechanical characteristics such as heat shrinkage characteristics, impact resistance, and transparency and in the finish of shrinkage and which is suitable for shrink packaging, shrink bundling, shrinkable labels, and so on. A film which is made from a mixed resin comprising as the main components either a polylactic acid resin (A) and a (meth)acrylic resin (B) or a polylactic acid resin (A) and a silicone / acrylic composite rubber (D) or has at least one layer made from the mixed resin and which exhibits a heat shrinkage percentage of 20% or above in the main shrinkage direction when dipped in water at 80 C for 10 seconds.

Owner:MITSUBISHI CHEM CORP

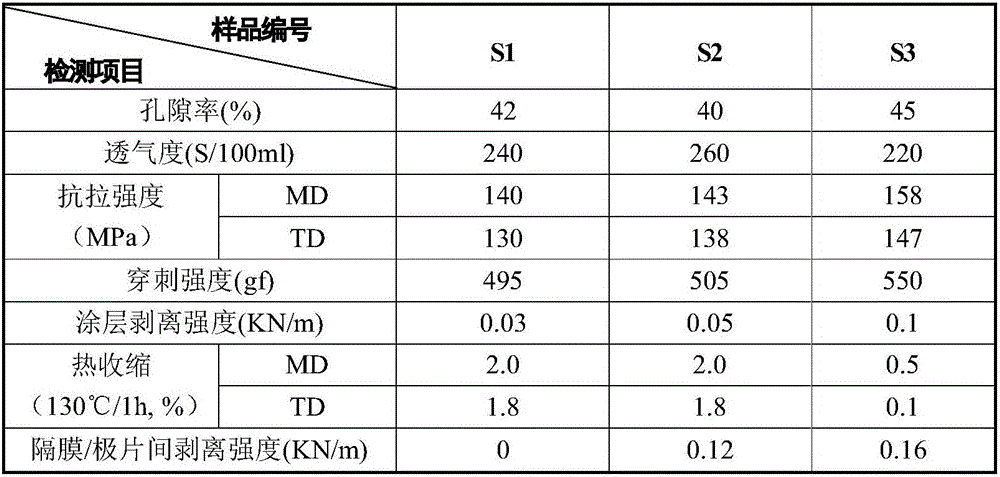

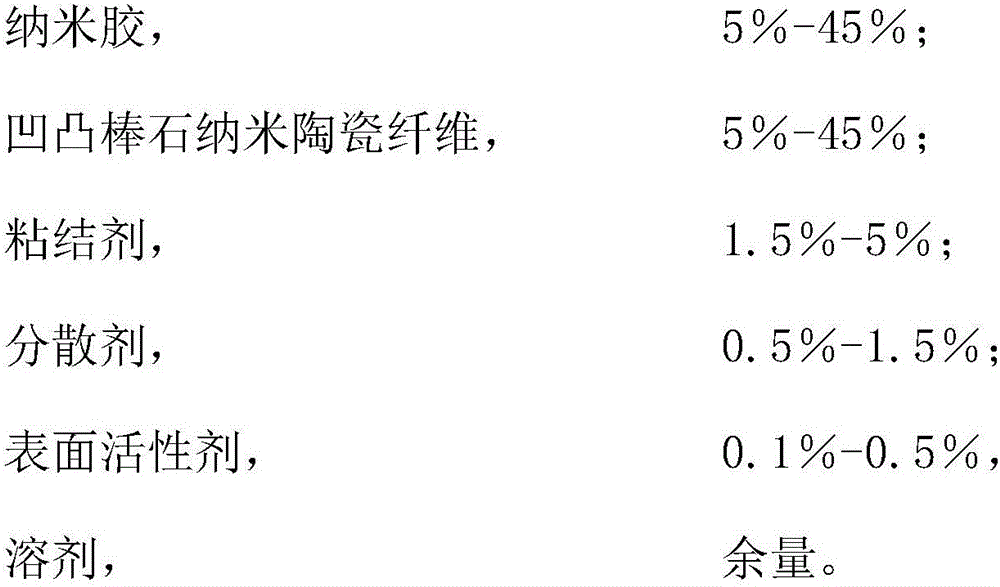

Mixed slurry for preparing composite diaphragm and preparation method of composite diaphragm

ActiveCN107528038AImprove coating peel strengthHigh tensile strengthMaterial nanotechnologyCell component detailsFiberNanoceramic

The invention discloses mixed slurry for preparing a composite diaphragm. The mixed slurry is prepared from components in percentage by mass as follows: 5%-45% of nano-glue, 5%-45% of attapulgite nano-ceramic fiber, 1.5%-5% of a binder, 0.5%-1.5% of a dispersant, 0.1%-0.5% of a surfactant and the balance of a solvent. The invention further discloses a preparation method of the composite diaphragm.

Owner:JIANGSU QINGTAO ENERGY TECH

Heat shrinkable polyester film and preparation method thereof

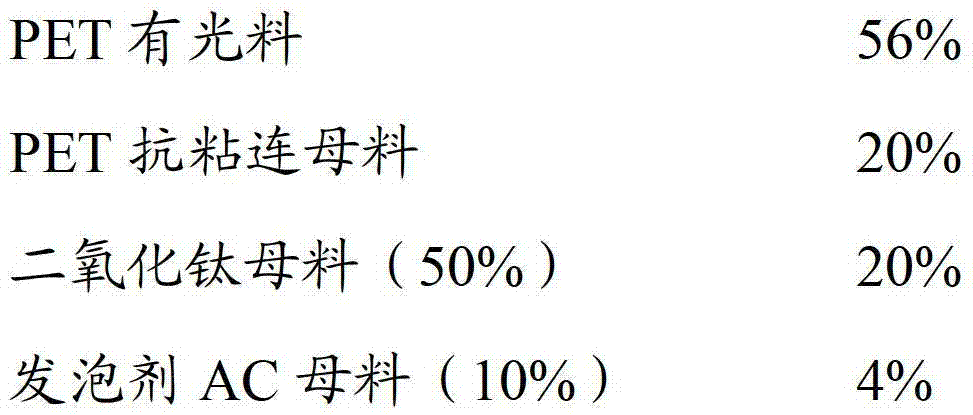

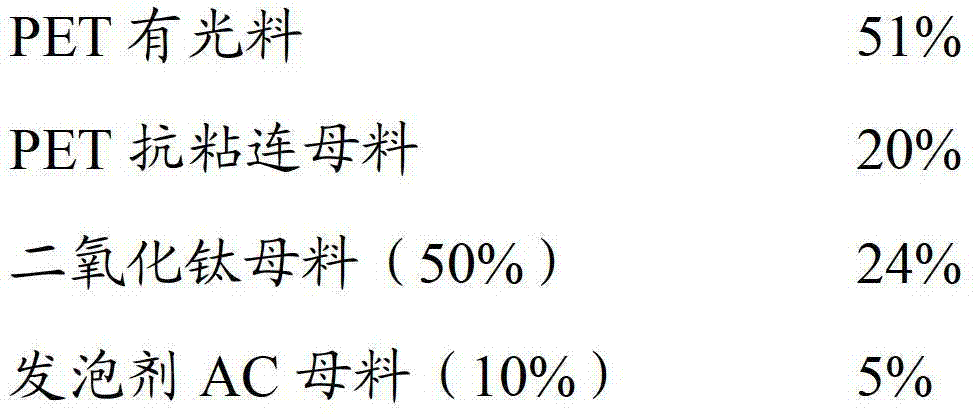

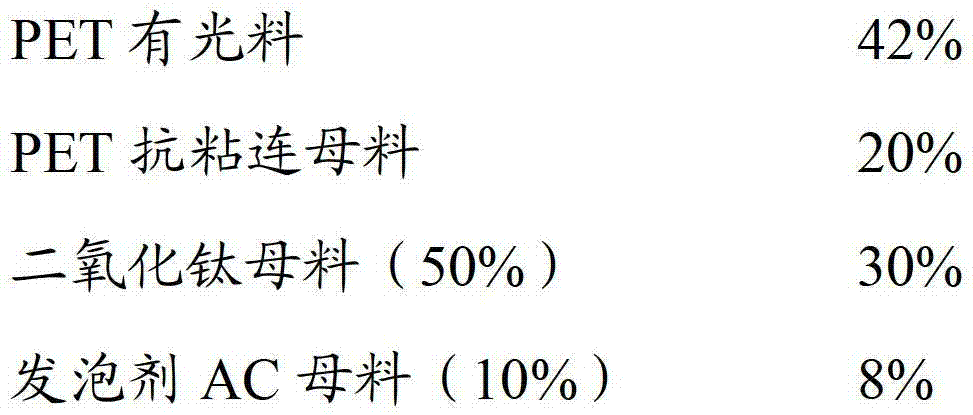

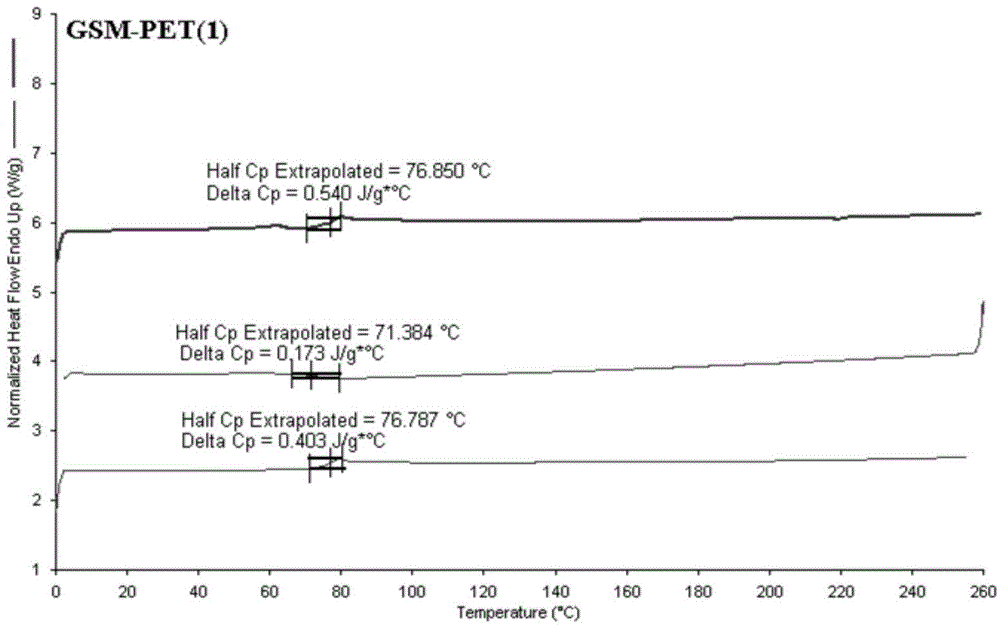

ActiveCN103113724ARaw materials are easy to getCraft is easy to getChemical industryMasterbatchPolyester

The invention relates to the technical field of a heat shrinkable polyester film, and particularly relates to a heat shrinkable polyester film and a preparation method thereof. The invention provides a heat shrinkable polyester film and a preparation method thereof, so as to solve the defect of poor performance of the existing heat shrinkable polyester film (a heat shrinkable for short) and the defects that the PVC (polyvinyl chloride) heat shrinkable film pollutes the environment, and is difficult to recover. The heat shrinkable polyester film is prepared from the following raw materials in percentage by weight: 20-59% of polyester material. 20-30% of anti-blocking master batch, 20-40% of filler particle master batch, and 1-10% of foaming agent master batch; the content of filler particles in the filler particle master batch is 30-50wt%; the content of a foaming agent in the foaming agent master batch is 10-20wt%; and the density of the polyester film is 0.8-1.3g / cm<3>. The raw materials of the polyester film are easy to obtain, the preparation method is simple and the polyester film is excellent in performance.

Owner:NINGBO CHANGYANG TECH

Method for producing two-way stretching polypropylene film for cigarette by pipe soaking method

The production process of polypropylene film includes the following steps: mixing polypropylene resin and functional mother material in certain ratio, co-extruding in extruder to form initial tubular film; fast cooling of the initial tubuler film; preheating at 260-400 deg.c in a stove; transverse blowing to expand for 5.0-8.0 times at 300-510 deg.c in a stove; longitudinal stretching for 6.5-8.0 times at 135-150 deg.c; wind cooling, winding, cutting rewinding and re-cutting. Compared with available plain drawing process, the present invention has the advantages of small covered area, less investment and high heat shrinkage of the product.

Owner:海南日新酒店管理有限公司

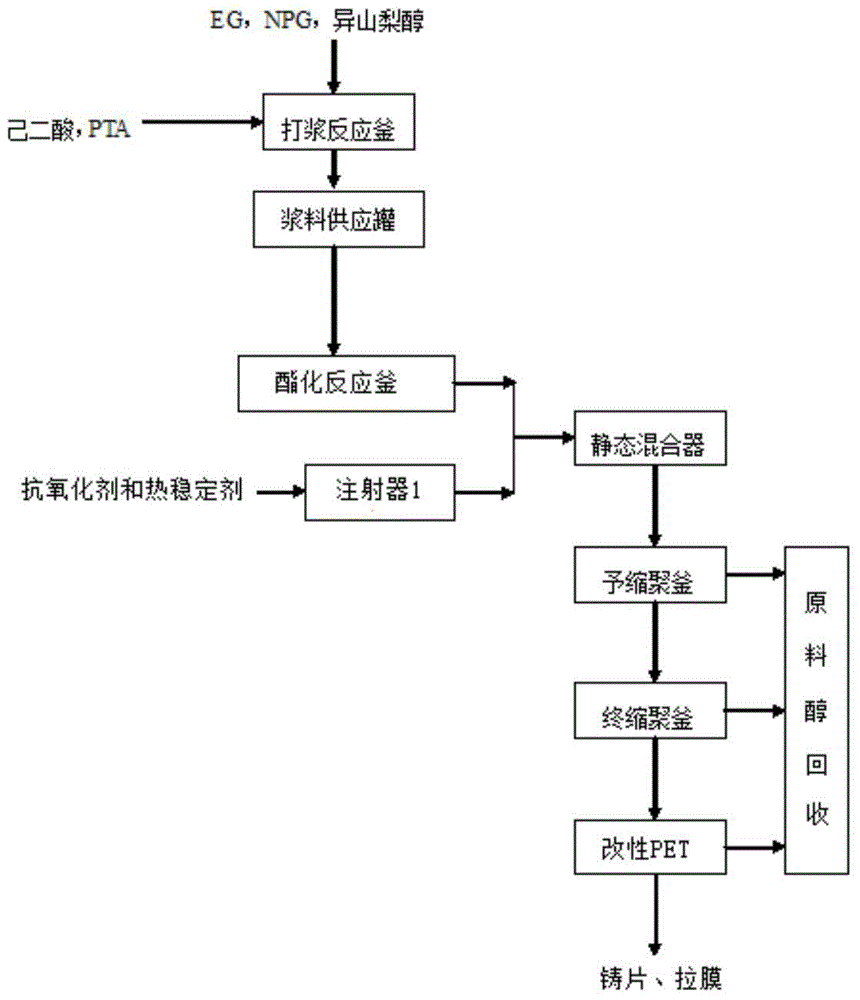

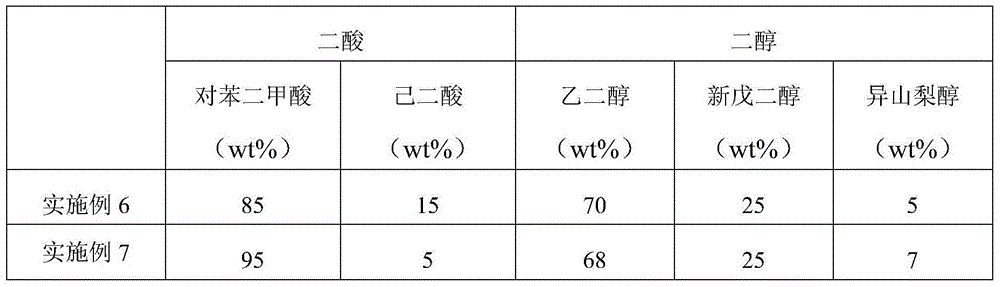

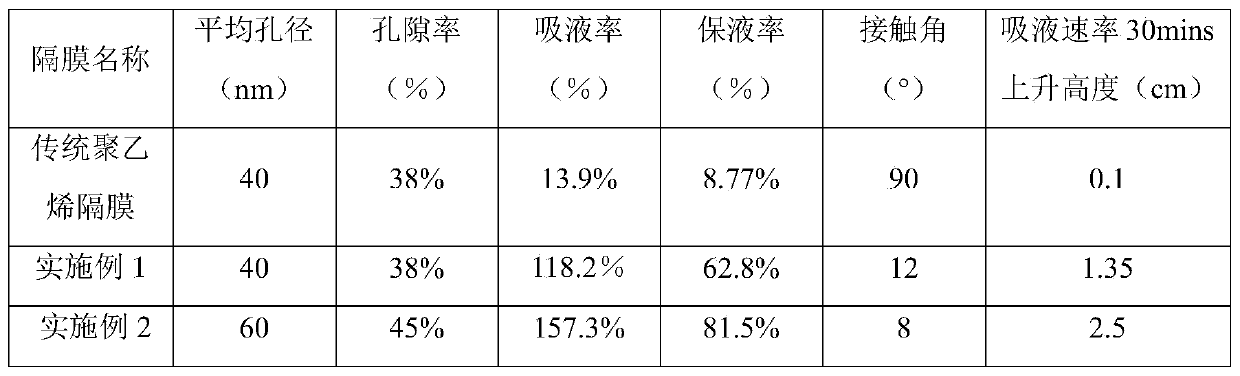

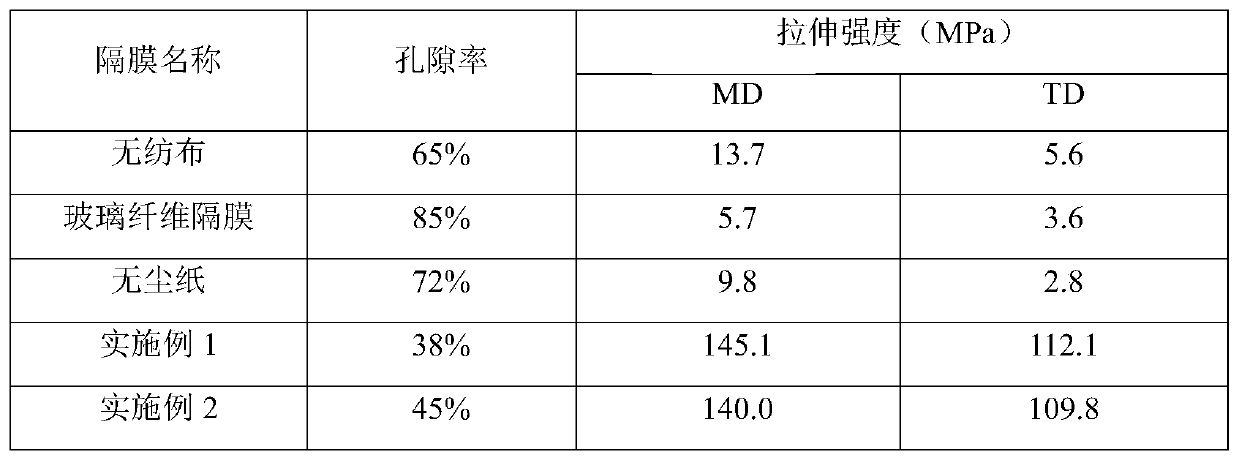

Modified PET (polyethylene terephthalate) copolymer for high-toughness heat-shrinkable film and preparation method of modified PET copolymer

ActiveCN104804177AQuality improvementAvoiding discrepancies in performance metricsPolymer sciencePolyethylene terephthalate glycol

The invention relates to the field of polyester, particularly to a modified PET (polyethylene terephthalate) copolymer for a high-toughness heat-shrinkable film, a preparation method of the modified PET copolymer as well as the heat-shrinkable film prepared from the copolymer. The modified PET copolymer is formed by copolymerizing five monomers, namely, terephthalic acid, adipic acid, ethylene glycol, neopentyl glycol and isosorbide. According to the preparation method of the modified PET copolymer, continuous polymerization is performed on the basis of adoption of three-kettle short-process polyester continuous polymerization equipment. The modified copolymer obviously solves the problem of embrittlement of the PET heat-shrinkable film in another direction and improves the toughness of the heat-shrinkable film; the glass transition temperature of the prepared film is up to 76 DEG C, and the film has the higher heat resistance and meets requirements of some occasions with usage temperatures higher than 70 DEG C.

Owner:CHINESE TEXTILE ACAD

Solid electrolyte multilayer membranefor lithium ion battery and preparation method thereof

InactiveCN110400965AIncrease transfer rateImproved magnification performanceSolid electrolytesSecondary cellsSolid state electrolytePolyolefin

The invention discloses a solid electrolyte multilayer membrane for a lithium ion battery. The solid electrolyte multilayer membrane comprises a solid electrolyte layer and an organic polymer layer, wherein the upper and lower sides of the solid electrolyte layer are respectively provided with organic polymer layers. The solid electrolyte multilayer membrane replaces a traditional polyolefin-basedseparator to improve the lithium ion transmission rate and improve the rate performance of the lithium battery; the solid electrolyte membrane has the excellent heat shrinkage performance at a high temperature, and improves the safety performance of the battery; compared with the conventional composite solid electrolyte membrane, the ratio of solid electrolyte is increased, the electrical conductivity is increased, and the rate performance of the battery is improved; the organic polymer materials on both sides of the three-layer composite structure solid-state electrode membrane can bond theanode and the cathode in the lithium battery, so that the battery core is more firm, and the safety of the battery cores in the transportation and use process is improved.

Owner:苏州顺创新能源科技有限公司

Water-based metal ion secondary battery diaphragm, and preparation method and application thereof

InactiveCN110364664AImprove wettabilityImprove liquid retention capacitySecondary cellsCell component detailsWater basedPolymer

The invention discloses a water-based metal ion secondary battery diaphragm, and a preparation method and application thereof, and belongs to the technical field of lithium battery diaphragms. The water-based metal ion secondary battery diaphragm comprises a porous base membrane; the surface of the porous base membrane is coated with a hydrophobic coating; the surface of the hydrophobic coating isgrafted with a hydrophilic coating; the hydrophilic coating is grafted on the surface of the hydrophobic coating through a laser radiation surface grafting method; the wavelength of a light beam forradiation is 9.1-10.6 [mu]m; and the radiation duration is 100-500 ns, preferably 100-200 ns. By adopting the technical scheme provided by the invention, the wettability and the liquid retention of the diaphragm can be effectively improved on the basis of keeping the original excellent physical properties, conductivity and cycle performance of the polymer diaphragm, so that the use requirements ofthe water-based metal ion secondary battery diaphragm are met.

Owner:安徽金力新能源有限公司

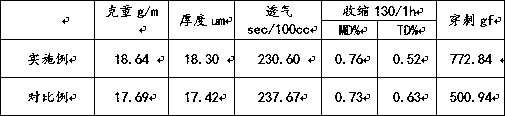

High-safety ceramic diaphragm for lithium ion battery and preparation method

InactiveCN109411678AGood heat shrinkabilityImprove puncture strengthCell component detailsCoatingsAdhesiveGram

The invention provides a high-safety ceramic diaphragm for a lithium ion battery. The high-safety ceramic diaphragm comprises a base membrane and ceramic slurry which is coated on the surface of the base membrane, wherein the ceramic slurry is prepared from the following components in parts by weight: 1 part of aluminum oxide, 0.0125 part of a dispersant, 0.3 to 0.4 part of a thickening agent, 0.1to 0.2 part of a waterborne adhesive and a wetting agent, wherein the mass part ratio of the wetting agent to a mixed solution containing the aluminum oxide, the dispersant, the thickening agent andthe waterborne adhesive is 0.001 to 1. The high-safety ceramic diaphragm has the advantages that the gram weight is enhanced, the thermal shrinkage performance of the diaphragm is improved, the puncture strength of the diaphragm is enhanced and the diaphragm is not easy to damage.

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

Polyethylene thermal shrinkage film

ActiveCN107458059APerformance coordinationGood heat shrinkabilitySynthetic resin layered productsPolyolefinPolymer science

The invention relates to a polyethylene thermal shrinkage film, and belongs to the technical field of polyolefin films. The polyethylene thermal shrinkage film is characterized in that the thickness of the thermal shrinkage film is 50-60[mu]m; the thermal shrinkage film comprises an inner layer, a middle layer and an outer layer; in the inner layer and the outer layer, the mass ratio of metallocene polyethylene resin is 1 / 2-1 / 3, and the mass ratio of each of low-density polyethylene and high-density polyethylene is 1 / 4-1 / 3; in the middle layer, the mass ratio of the metallocene polyethylene resin is 1 / 2-4 / 5, and the mass ratio of the low-density polyethylene and / or the high-density polyethylene is 1 / 4-1 / 5; and the metallocene polyethylene resin is a copolymer of ethylene and alpha-olefin, the density is 0.930-0.940g / cm<3>, and the melt mass flow rate is 0.3-1.0g / 10min. By adding the specific metallocene polyethylene resin, the shrinkage performance of each layer is more coordinated; and the shrinkage performance and mechanical properties of the polyethylene thermal shrinkage film are ensured at a lower thickness.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com