Water-based metal ion secondary battery diaphragm, and preparation method and application thereof

A metal ion and secondary battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as poor lyophilicity, instability, diaphragm gas permeability, strength and other physical properties that are difficult to meet the use requirements, etc. Achieve the effects of improving liquid retention, ensuring performance, and wide heat resistance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the aqueous metal ion secondary battery diaphragm of the present invention comprises the following steps:

[0043] Step 1. Coating a hydrophobic coating on one or both sides of the porous base membrane by spray coating, dimple coating, dip coating or other methods;

[0044] Step 2. Conduct CO on the surface of the coated base film 2 For pulse laser radiation treatment, the radiation beam wavelength is 9.1 μm to 10.6 μm, and the radiation duration is 100 to 500 ns, preferably 100 to 200 ns.

[0045] Step 3, cleaning and vacuum-drying the basement membrane after radiation treatment to constant weight treatment; specifically, first placing the basement membrane in acetone for rinsing, and then putting it into distilled water to wash away excess acetone; then extracting the basement membrane The film is placed in a vacuum environment and dried at 30-65 degrees Celsius for 0.5-1.5 hours;

[0046] Step 4. Put the base film after drying and constant...

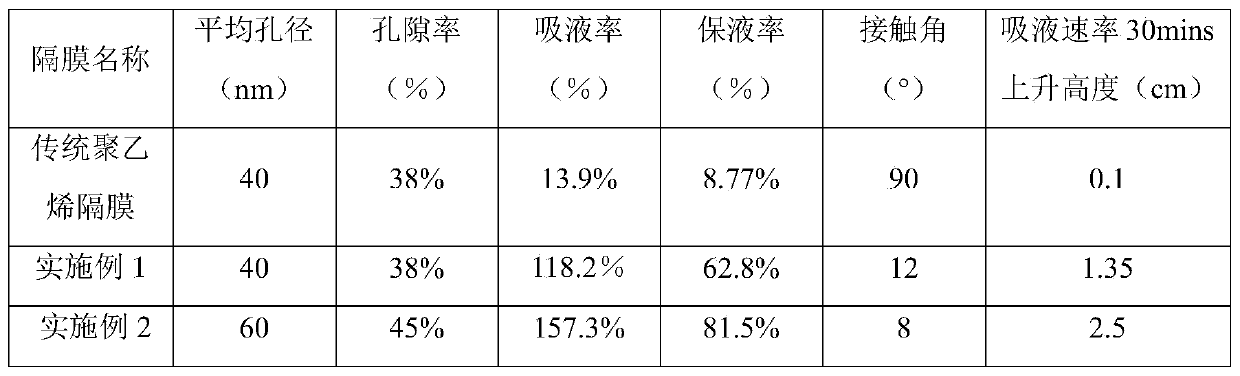

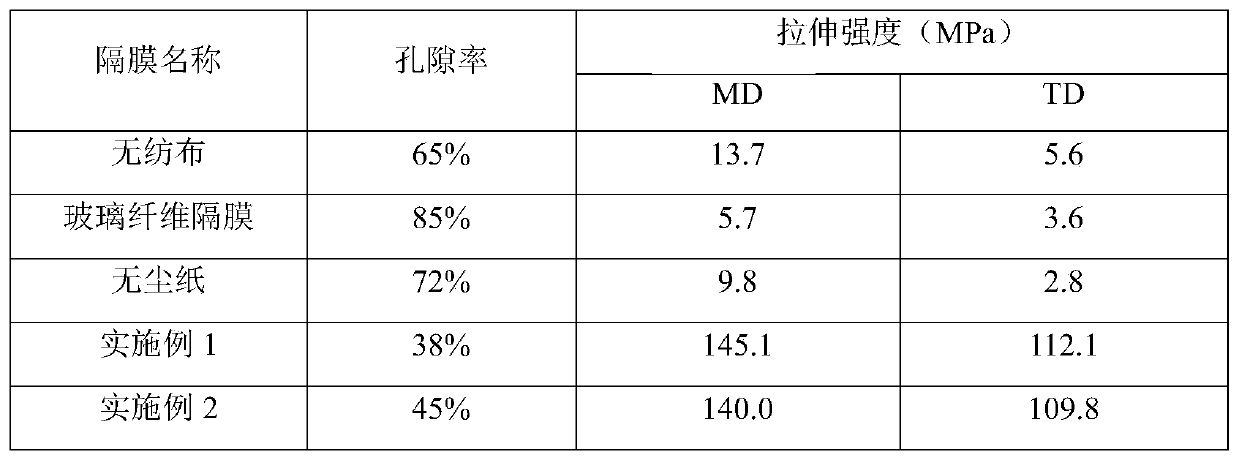

Embodiment 1

[0049] A water-based metal ion secondary battery separator of the present embodiment includes a polyethylene porous base film (polyethylene is melt-extruded and then stretched according to thermally induced phase separation (TIPS)), and the polyethylene porous base film The surface is coated with a hydrophobic coating, and the surface of the hydrophobic coating is grafted with a hydrophilic coating. The hydrophobic substance used in the hydrophobic coating is carboxymethyl cellulose, and the thickness of the hydrophobic coating is 1 μm. The coating of the hydrophilic coating includes a solvent and a hydrophilic substance, wherein the hydrophilic substance is selected from acrylic acid monomer, the solvent is ethanol, and the ratio of the solvent to the hydrophilic substance is 3:1.

[0050] The preparation method of the aqueous metal ion secondary battery diaphragm of the present embodiment comprises the following steps:

[0051] Step 1. Coating a hydrophobic coating on one s...

Embodiment 2

[0056] A water-based metal ion secondary battery separator in this embodiment includes a polyethylene porous base film, the surface of the polyethylene porous base film is coated with a hydrophobic coating, and the surface of the hydrophobic coating is grafted with hydrophilic Water-based coating. The hydrophobic substance used in the hydrophobic coating is selected from cyclomethicone, and the thickness of the hydrophobic coating is 2 μm. The coating of the hydrophilic coating includes a solvent and a hydrophilic substance, wherein the hydrophilic substance is selected from acrylic acid-sodium acrylate copolymer, the solvent is methanol, and the ratio of the solvent to the hydrophilic substance is 5:1.

[0057] The preparation method of the aqueous metal ion secondary battery diaphragm of the present embodiment comprises the following steps:

[0058] Step 1, coating the hydrophobic coating on both sides of the porous base membrane by means of dip coating;

[0059] Step 2. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com