Lithium supplement composite diaphragm, preparation method and application

A composite diaphragm, lithium replenishment technology, applied in the direction of separator/film/diaphragm/spacer element, electrical component, electrochemical generator, etc., can solve the problem of low lithium ion transmission rate, insufficient lithium ion supply, and deterioration of electrochemical performance. and other problems, to achieve the effect of increasing ion transmission rate, improving heat shrinkage and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

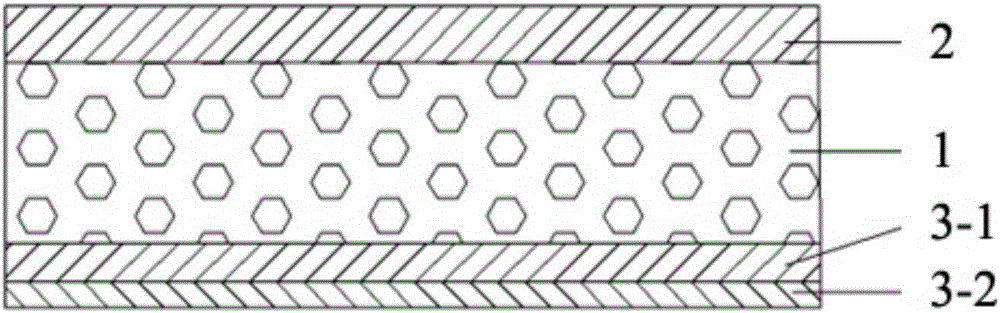

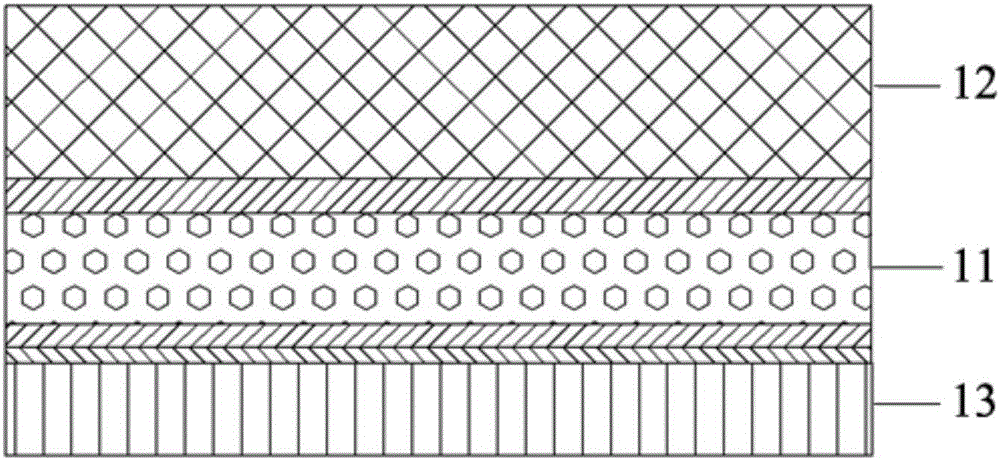

[0039] like figure 1 , 2 As shown, the lithium-replenishing composite diaphragm 11 includes: a base film 1 (commercially available Celgard film, PP film, model 2400, thickness 21 μm), and a 3 μm thick ceramic layer 2 and a ceramic-lithium supplementing layer are respectively arranged on both sides of the base film The ceramic-replenishing lithium layer is composed of a 2 μm thick ceramic layer 3-1 and a 1 μm thick lithium supplementing layer 3-2, and the ceramic layer 3-1 and the lithium supplementing layer 3-2 are sequentially arranged outward along the surface of the base film 1 .

[0040] The ceramic layer is composed of the following components in mass percentage: 54.5% of aluminum oxide powder (particle size 5 μm), 18.2% of polymethyl methacrylate (molecular weight 20,000, purchased from Shanghai Lizhe Chemical Co., Ltd.), nitrile Rubber (45% acrylonitrile content) 27.3%; the lithium replenishing layer is composed of the following components in mass percentage: metal li...

Embodiment 2

[0049] Lithium-supplemented composite separator, including: base film (PP film, SD214, thickness 20μm, purchased from Shenzhen Xingyuan Material Technology Co., Ltd.), with a 4.5μm-thick ceramic layer and a ceramic-lithium-replenishing layer on both sides of the base film. ; The ceramic-lithium-supplementing layer is composed of a 3 μm-thick ceramic layer and a 1.5 μm-thick lithium-replenishing layer, and the ceramic layer and the lithium-replenishing layer are sequentially arranged outward along the surface of the base film; wherein the ceramic layer is composed of the following mass percentage components : Al2O3 powder (particle size 10μm) 30%, polymethyl methacrylate (molecular weight 20,000) 30%, nitrile rubber (acrylonitrile content 35%) 40%; Component composition: metal lithium powder (particle size 200 μm) 50%, nitrile rubber (acrylonitrile content 35%) 50%.

[0050] The preparation method of the lithium-supplemented composite diaphragm comprises the following steps:

...

Embodiment 3

[0058] Lithium-replenishing composite separator, including: base film (PE film, SW309, thickness 25μm, purchased from Shenzhen Xingyuan Material Technology Co., Ltd.), and 6μm-thick ceramic layers and ceramic-lithium-replenishing layers are respectively provided on both sides of the base film; The ceramic-lithium supplementation layer is composed of a 4 μm thick ceramic layer and a 2 μm thick lithium supplementary layer, and the ceramic layer and the lithium supplementary layer are sequentially arranged outward along the surface of the base film; wherein the ceramic layer is composed of the following components in mass percentage: three Alumina powder (particle size 50μm) 90%, poly(isobutyl methacrylate) (molecular weight 50,000, purchased from Shanghai Lizhe Chemical Co., Ltd.) 5%, nitrile rubber (acrylonitrile content 20%) 5% %; the lithium supplement layer is composed of the following components by mass percentage: 80% of metallic lithium powder (particle size of 200 μm), 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com