Composite diaphragm with lithium supplementing effect, and preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and composite diaphragms, applied in the field of lithium supplementation for lithium batteries, which can solve the problems of cumbersome procedures, the effect needs to be improved, and the difficulty in realizing accurate lithium supplementation of the negative electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

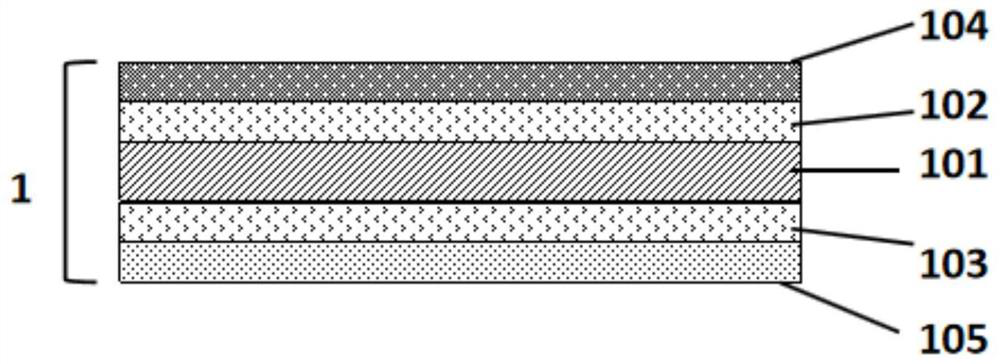

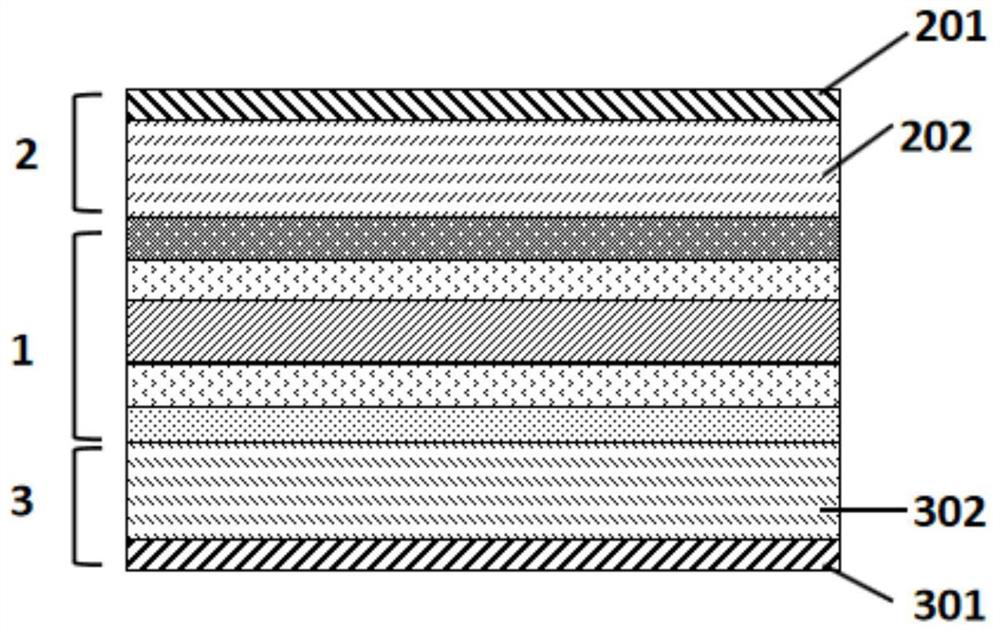

[0034] (1) According to the ratio of 95% of ceramic powder and 5% of binder, weigh alumina powder and polyvinylidene fluoride powder and disperse them in NMP to prepare ceramic slurry, and obtain a ceramic slurry with a solid content of 75%. , use a gravure coater to evenly coat the ceramic slurry on both surfaces of the 10 μm PE base film, and obtain a ceramic separator with a thickness of 16 μm after drying, wherein the thickness of the ceramic coating on each surface is 3 μm,

[0035] (2) Negative active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 90% of the irreversible capacity of the silicon-carbon negative electrode, and the surface density of the pole piece ρ 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated according...

Embodiment 2

[0038] (1) According to the ratio of 95% of ceramic powder and 5% of binder, weigh alumina powder and polyvinylidene fluoride powder and disperse them in NMP to prepare ceramic slurry, and obtain a ceramic slurry with a solid content of 75%. , use a gravure coater to evenly coat the ceramic slurry on both surfaces of the 10 μm PE base film, and obtain a ceramic separator with a thickness of 16 μm after drying, wherein the thickness of the ceramic coating on each surface is 3 μm,

[0039] (2) Negative active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 100% of the irreversible capacity of the silicon carbon negative electrode, and the surface density ρ of the pole piece 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated accordin...

Embodiment 4

[0045] (1) According to the ratio of 95% of ceramic powder and 5% of binder, weigh alumina powder and polyvinylidene fluoride powder and disperse them in NMP to prepare ceramic slurry, and obtain a ceramic slurry with a solid content of 75%. , use a gravure coater to evenly coat the ceramic slurry on both surfaces of the 10 μm PE base film, and obtain a ceramic separator with a thickness of 16 μm after drying, wherein the thickness of the ceramic coating on each surface is 3 μm,

[0046] (2) Negative active material (a mixture of graphite and silicon, capacity C 负 =500mAh g -1 , first coulombic efficiency ICE=80%), pre-lithiated design capacity C 设 It is 100% of the irreversible capacity of the silicon carbon negative electrode, and the surface density ρ of the pole piece 负面 = 20 mg cm -2 , pole piece area S 负面 =82cm 2 , the specific capacity of metal lithium powder is C Li =3600mAh g -1 , the mass M of lithium metal powder required can be accurately calculated accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com