Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

A ceramic coating and lithium battery technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problem of high specific surface energy of ultrafine alumina powder, low powder shedding and uniformity, uneven coating thickness, etc. problems, to achieve the effect of strong absorption and retention of electrolyte, good air permeability and high peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Its preparation method comprises the following steps:

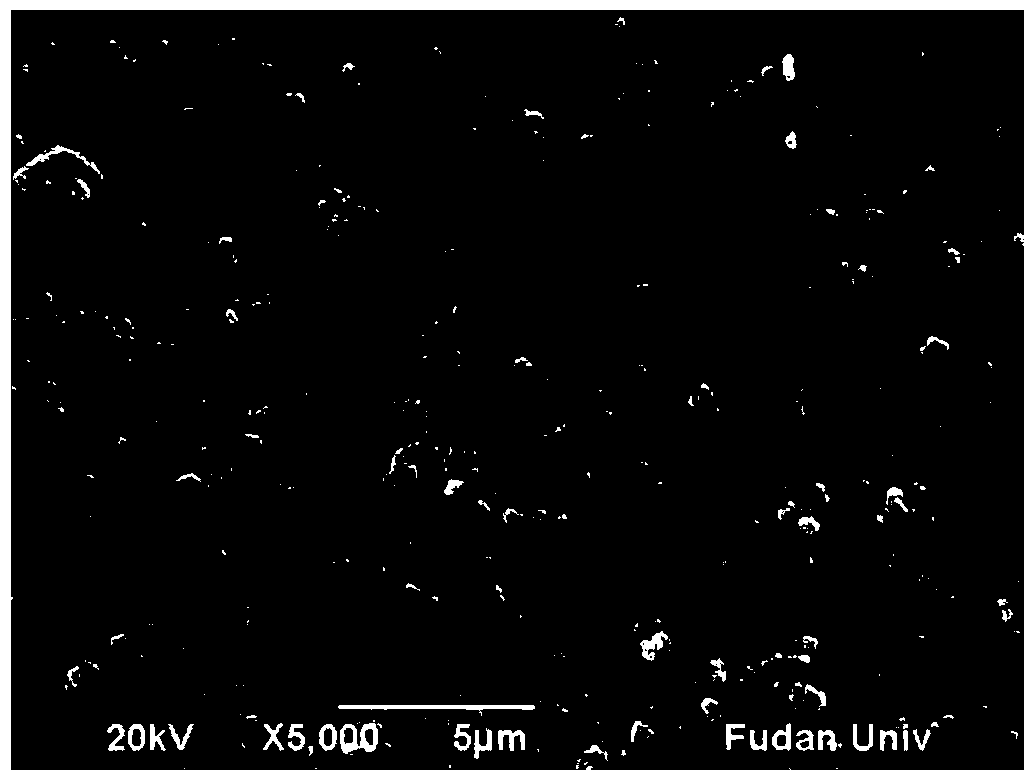

[0037] Step 1, take the particle size ratio D 1 / D 2 Nano-alumina powder of 0.10-0.20 is dispersed in deionized water to prepare a nano-alumina aqueous dispersion;

[0038] Step 2, mix the nano-alumina aqueous dispersion with adhesives, additives, additives to reduce the surface tension of the slurry and eliminate micro-bubbles, and configure the ceramic coating slurry, wherein the mass ratio of alumina: adhesive 5~20:1;

[0039] Step 3, uniformly coating the ceramic coating slurry on the surface of the substrate separator to obtain a ceramic coated separator for lithium batteries.

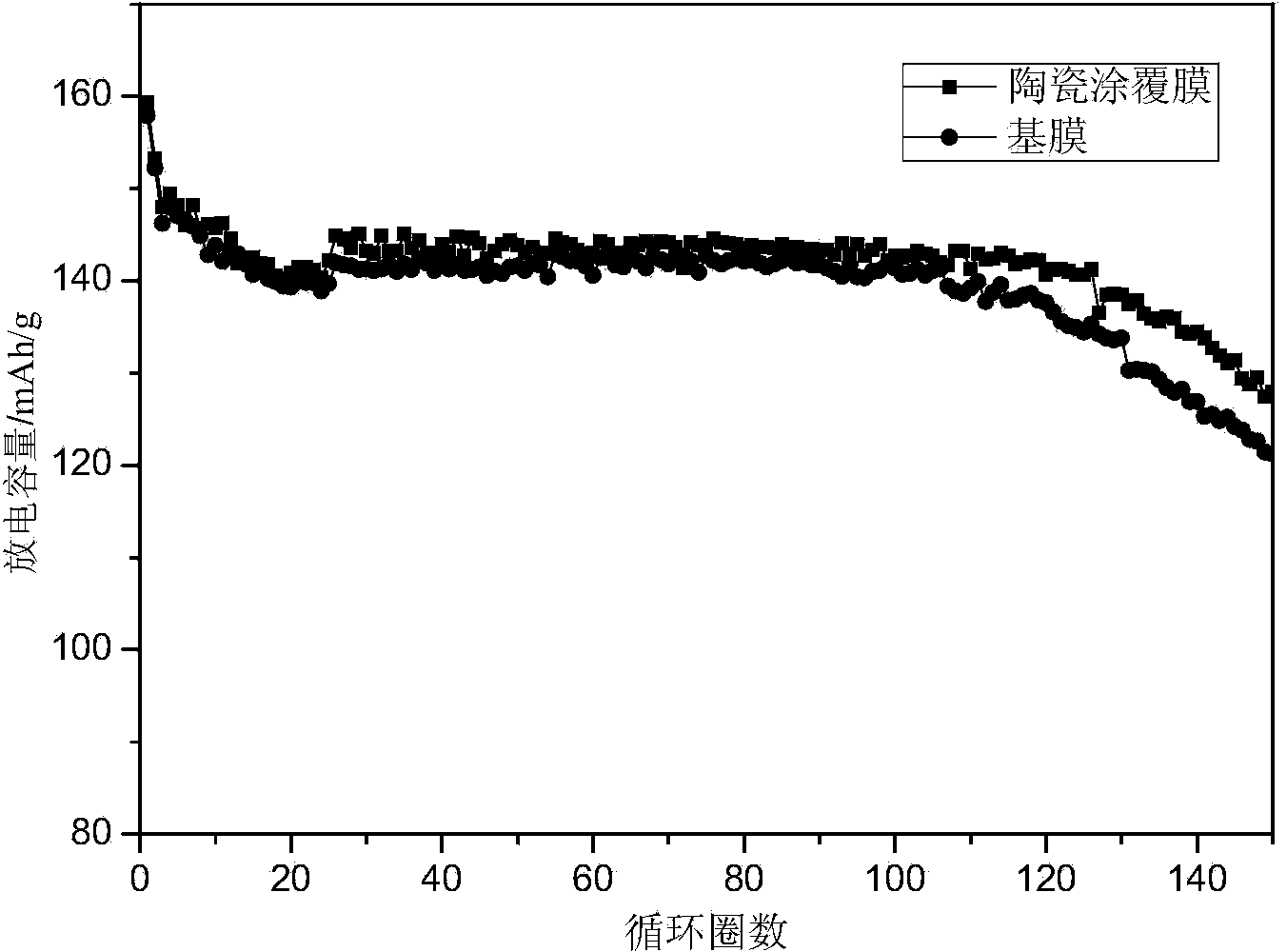

[0040] The embodiment of the present invention has good air permeability, high peeling force, strong ability to absorb and retain electrolyte, and heat shrinkage performance, which is beneficial to the improvement of the capacity retention rate of the battery and improves the cycle life of the battery.

[0041] In the embodiment of...

Embodiment 1

[0044] A preparation method for a ceramic-coated diaphragm for an energy storage lithium battery, comprising the following steps;

[0045]Step 1. Take 2g of alumina with D1 of 50nm and 8g of alumina with D2 of 400nm, add them to 40g of deionized water, first stir at high speed for 30min, and then ultrasonically disperse for 30min to obtain a pre-dispersion of nano-alumina. The dispersant with a mass fraction of 0.5% is added to the pre-dispersion liquid, including: sodium dodecylbenzenesulfonate 0.125g, octylphenol polyoxyethylene 0.063g and polyacrylic acid 0.063g, the amount ratio of the three is 2:1 :1. Stir the pre-dispersion at high speed for 30 minutes, then add a small amount of dilute hydrochloric acid solution and dilute sodium hydroxide solution to adjust the pH value of the dispersion to 4-5;

[0046] The above-mentioned pre-dispersion liquid was ball-milled in a ball mill for 2 hours to obtain a uniform and stable nano-alumina aqueous dispersion.

[0047] Step 2,...

Embodiment 2

[0056] A ceramic-coated diaphragm for an energy storage lithium battery and a preparation method thereof, comprising the following steps;

[0057] Step 1: Take 4g of alumina with D1 of 80nm and 6g of alumina with D2 of 500nm, add them to 30g of deionized water, first stir at high speed for 30min, and then ultrasonically disperse for 30min to obtain a pre-dispersion of nano-alumina. The dispersant with a mass fraction of 1.0% is added to the pre-dispersion liquid, including: 0.20 g of sodium dodecylbenzenesulfonate, 0.10 g of octylphenol polyoxyethylene and 0.10 g of polyacrylic acid, and the ratio of the three is 2:1 :1. Stir the pre-dispersion at high speed for 30 minutes, then add a small amount of dilute hydrochloric acid solution and dilute sodium hydroxide solution to adjust the pH value of the dispersion to 4-5;

[0058] The above-mentioned pre-dispersion liquid was ball-milled in a ball mill for 2 hours to obtain a uniform and stable nano-alumina aqueous dispersion.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com