Polymer composite membrane as well as preparation method and lithium ion battery with same

A polymer and composite film technology, applied in the field of lithium-ion batteries, can solve the problems of poor high temperature resistance, poor mechanical strength of materials, and high cost, to ensure high temperature resistance safety performance, avoid contact between positive and negative electrodes, improve The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

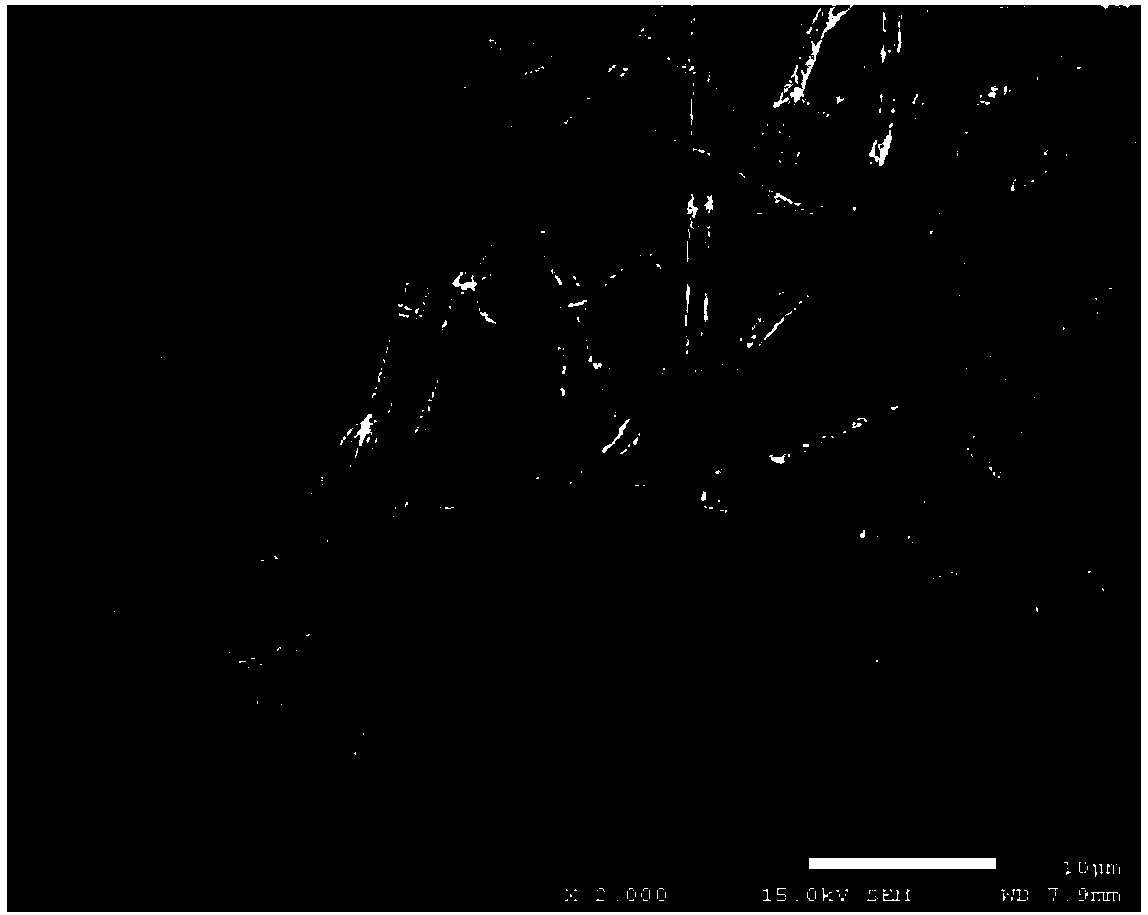

Image

Examples

preparation example Construction

[0039] The preparation method of the ceramic diaphragm provided by the present invention realizes optimal dispersion of ceramic particles by controlling the amount of each component in the ceramic layer slurry, the number average molecular weight of the dispersant, and the rotational speed of the ceramic layer slurry, thereby controlling the packing density between the ceramic particles To control the surface density of the ceramic layer at a unit thickness (1μm) to 1.8mg / cm 2 2 In this way, the high temperature heat shrinkability of the ceramic diaphragm can be improved on the basis of basically not reducing the gas permeability, so that the heat resistance temperature can reach above 160°C, that is, the thermal stability can be improved without increasing the thickness of the ceramic layer, so that Does not affect the energy density of the battery.

[0040] According to the polymer composite membrane of the present invention, preferably, in the ceramic layer, relative to 100...

Embodiment approach

[0050] According to the polymer composite film of the present invention, the acrylate cross-linked polymer refers to a polymer obtained by cross-linking polymerization of reactive acrylate monomers. The cross-linking degree of the acrylate cross-linked polymer may be 2-30%, preferably 5-20%. In the present invention, the degree of crosslinking refers to the percentage of the weight of the crosslinked polymer to the total weight of the polymer. In addition, the glass transition temperature of the acrylate crosslinked polymer is preferably -20°C to 60°C, more preferably -12°C to 54°C. According to a preferred embodiment of the present invention, the acrylate crosslinked polymer is the second acrylate crosslinked polymer, the third acrylate crosslinked polymer, or the first acrylate crosslinked polymer A mixture with the second acrylate crosslinked polymer and / or the third acrylate crosslinked polymer; wherein, the first acrylate crosslinked polymer contains 70 to 80% by weight ...

Embodiment 1

[0149] Embodiment 1 (preparation of the polymer composite film of PE base film-heat-resistant fiber layer two-layer structure)

[0150] This example is used to illustrate the polymer composite membrane provided by the present invention and its preparation method.

[0151] (1) Form a heat-resistant fiber layer on the PE base film:

[0152] Polyetherimide (ultem 1000 commercially available from SABIC Innovative Plastics (Shanghai) Co., Ltd., with a melting point of 370-410°C and a glass transition temperature of 215°C, the same below) and polyvinylidene fluoride-hexafluoropropylene (commercially purchased from Akema Investment Co., Ltd., the weight average molecular weight is 450000g / mol, the melting point is 152°C, the glass transition temperature is -40°C, and the liquid absorption rate in the electrolyte solution at 25°C is 45%, the same below ) according to the weight ratio of 1:1, the blending method adopts mechanical stirring to stir the two polymers evenly, the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com