Composite membrane for lithium ion secondary battery, manufacturing method of composite membrane and electrochemical device containing membrane

A technology for secondary batteries and composite diaphragms, which is applied in the field of composite diaphragms for lithium-ion secondary batteries and electrochemical devices. It can solve problems such as fire, thermal shrinkage of the diaphragm, and thermal runaway of the battery. It achieves simple operation, excellent safety performance, and excellent performance. The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

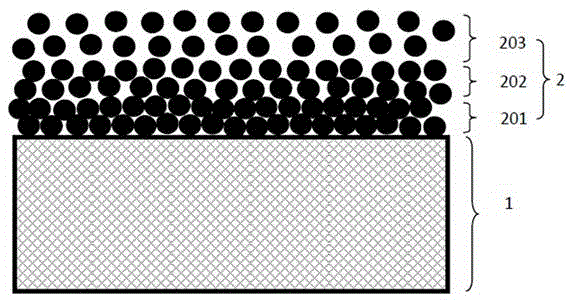

[0038] A preparation method for a composite diaphragm for a lithium ion secondary battery, comprising the following steps:

[0039] a) Dissolve the binder in a solvent to form a binder solution, add inorganic particles to the binder solution corresponding to different porous insulating layers, and mix evenly to prepare a slurry for each layer of porous insulating layer; the solvent is tetrahydrofuran , methyl ethyl ketone, dimethyl formamide, dimethyl acetamide, tetramethyl urea, tetramethyl phosphate, acetone, dichloromethane, chloroform, dimethylamide, N-methylpyrrolidone, cyclohexane, water , any one or a combination of several alcohols;

[0040] b) Add different amounts of pore-forming agents to the slurries corresponding to different porous insulating layers to form the final slurry of each layer of porous insulating layer; the final slurry formed by binder, inorganic particles and pore-forming agent The mass percent concentration of the mixture is 20-70wt%, preferably 3...

Embodiment 1

[0058] The preparation method of the positive and negative electrodes is the same as that of Comparative Example 1, and will not be described below.

[0059] Porous diaphragm: A polyethylene microporous film with a thickness of 9 μm is used as the porous diaphragm.

[0060]Preparation of porous insulating layer 1: first add 40wt% polyacrylate emulsion (the content in aqueous solution is 40wt%) to deionized water and stir for 1 hour, then add 55wt% Al 2 o 3 Particles (average particle size is 0.5 μm, particle size distribution is 0.1 ~ 3.5um) are stirred for 2 hours, and then ground in a ball mill for 1 hour, and then 5 wt % ammonium bicarbonate is added to the ground slurry, and stirring is continued for 1 hour to prepare a slurry. The solid content is 30wt%. Then use gravure coating to uniformly cover the prepared slurry on one surface of a 9 μm polyethylene microporous film with a coating thickness of 4 μm, and set aside.

[0061] Preparation of porous insulating layer 2:...

Embodiment 2

[0065] Porous diaphragm: A polyethylene microporous film with a thickness of 9 μm is used as the porous diaphragm.

[0066] Preparation of porous insulating layer 1: first add 15wt% polyacrylate emulsion (40wt% in aqueous solution) to deionized water and stir for 1 hour, then add 75wt% Al 2 o 3 After the particles (average particle size is 0.5 μm, particle size distribution is 0.1~3.5um) are stirred for 2 hours, they are ground in a ball mill for 1 hour, and then 10 wt% of ammonium bicarbonate is added to the ground slurry, and the stirring is continued for 1 hour to prepare a slurry. The solid content is 30wt%. Then use gravure coating to uniformly cover the prepared slurry on one surface of a 9 μm polyethylene microporous film with a coating thickness of 1 μm, and set aside.

[0067] Preparation of porous insulating layer 2: first add 15wt% polyacrylate emulsion (40wt% in aqueous solution) to deionized water and stir for 1 hour, then add 60wt% Al 2 o 3 After the particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com