Copolyamide industrial yarn and preparation method thereof

A technology of copolyamide and industrial yarn, which is applied in the direction of single-component polyamide rayon, rayon manufacturing, filament/thread forming, etc., which can solve the problem of low wear resistance and chemical resistance of polyester industrial yarn and increase production Cost, complex production process and other issues, to achieve low heat shrinkage performance, improve breaking strength, increase the effect of drafting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

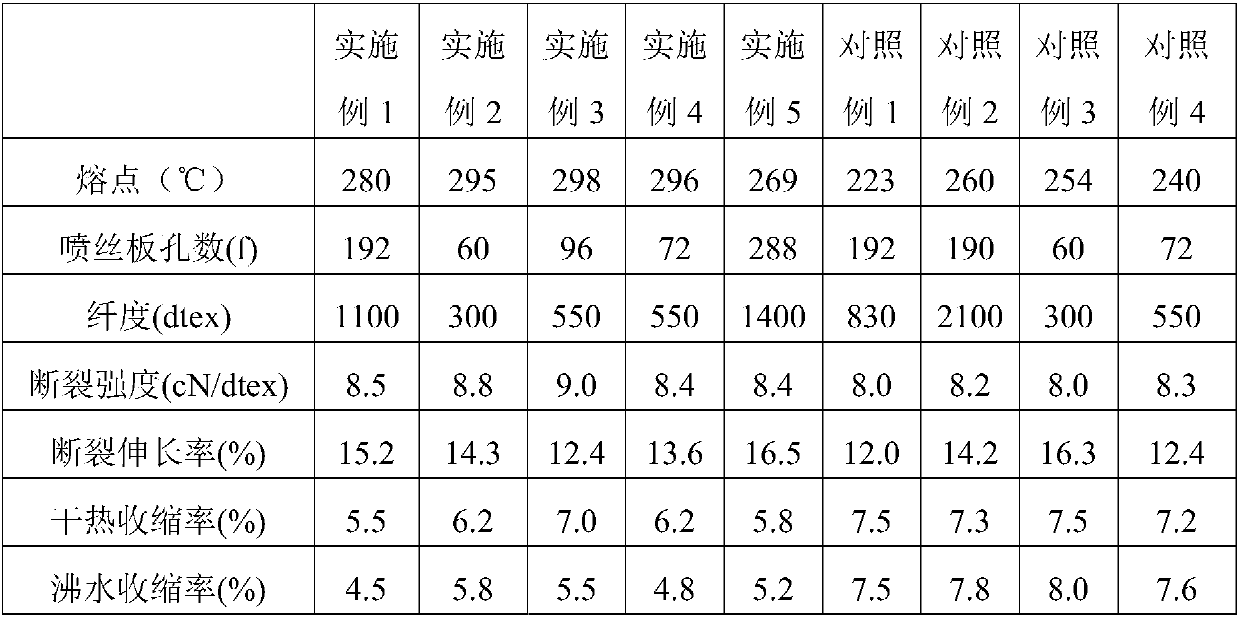

Examples

Embodiment 1

[0073] The copolyamide industrial yarn in this example is obtained by polymerizing raw materials including monomers and additives, wherein the monomers are composed of 1,5-pentanediamine, terephthalic acid and adipic acid, and 1,5-pentanediamine in the monomers The mass content of diamine is 40%, the mass content of terephthalic acid is 25%, and the mass content of adipic acid is 35%; the additive is antioxidant 1010.

[0074] The preparation method of the copolyamide industrial yarn of the present embodiment comprises the steps:

[0075] 1. Prepare mixed solution

[0076] Under nitrogen conditions, mix 1.32kg 1,5-pentamethylenediamine, 0.817kg terephthalic acid, 1.16kg adipic acid, 3.3kg water and antioxidant 1010 in a polymerization kettle, adjust with a small amount of pentamethylenediamine The pH value was 8.0, and a mixed solution was obtained; wherein, the total concentration of monomers in the mixed solution was 50wt%, and the content of antioxidant 1010 was 50ppm.

...

Embodiment 2

[0088] The copolyamide industrial yarn in this example is obtained by polymerizing raw materials including monomers and additives, wherein the monomers are composed of 1,5-pentanediamine, terephthalic acid and adipic acid, and 1,5-pentanediamine in the monomers The mass content of diamine is 40%, the mass content of terephthalic acid is 31%, and the mass content of adipic acid is 29%; the additive is copper acetate.

[0089] The preparation method of the copolyamide industrial yarn of the present embodiment comprises the steps:

[0090] 1. Prepare mixed solution

[0091] Under nitrogen, mix 1.31kg 1,5-pentanediamine, 1.02kg terephthalic acid, 0.971kg adipic acid, 3.3kg water and copper acetate in a polymerization kettle, and use a small amount of pentamethylenediamine to adjust the pH value is 8.0, and a mixed solution is obtained; wherein, the total concentration of monomers in the mixed solution is 50wt%, and the content of copper acetate is 0.5%.

[0092] 2. Preparation o...

Embodiment 3

[0103] The copolyamide industrial yarn in this example is obtained by polymerizing raw materials including monomers and additives, wherein the monomers are composed of 1,5-pentanediamine, terephthalic acid and dodecanedibasic acid, and 1 , The mass content of 5-pentanediamine is 35%, the mass content of terephthalic acid is 37%, and the mass content of dodecanedibasic acid is 28%; the additive is sodium hypophosphite.

[0104] The preparation method of the copolyamide industrial yarn of the present embodiment comprises the steps:

[0105] 1. Prepare mixed solution

[0106] Under nitrogen, mix 1.4kg of 1,5-pentanediamine, 1.47kg of terephthalic acid, 1.09kg of dodecanedibasic acid, 2.64kg of water and sodium hypophosphite in a polymerization kettle, and use a small amount of pentamethylenediamine The amine adjusted the pH value to 7.8 to obtain a mixed solution; wherein, the total concentration of monomers in the mixed solution was 60wt%, and the content of sodium hypophosphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com