Industrialized polyimide fiber drafting method

A technology of polyimide fiber and polyimide filament, applied in textiles and papermaking, etc., can solve the problems of uneven internal stress of fibers, adverse effects of fiber properties, and impact thermal load of fibers, and achieve physical-mechanical properties. Improvement, reduction in the probability of fluff, and less impact heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

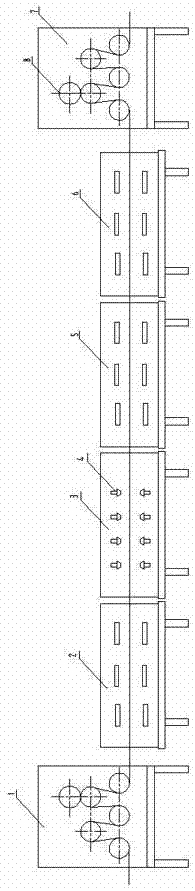

[0026] An industrialized polyimide fiber drawing method is to place polyimide filaments with a certain denier and uniform tension in a four-stage hot box environment, and after being clamped by rubber rollers, the filaments are stretched at 30m / min At the highest feeding speed, 3 times drafting can be achieved through the speed difference between the front drafting machine and the rear drafting machine. The four-stage heat box is a combination of a preheating section heat box, a superheated steam humidification section heat box, a high-temperature drafting heat box, and an air setting heat box.

[0027] The length of the hot box in the preheating section is 1m, the preheating temperature is 180°C, the temperature control accuracy of the box is 2°C, and the temperature uniformity is ±5°C. The length of the superheated steam humidification section is 1.5m, the temperature of the inner cavity of the box is maintained at 180°C, the temperature control accuracy of the box is 2°C, a...

specific Embodiment 2

[0030] An industrial polyimide fiber drawing method is to place a polyimide filament sheet with a certain denier and uniform tension in a four-stage hot box environment, and after being clamped by rubber rollers, the filament sheet is stretched at 50m / min 2.5 times of drafting can be realized through the speed difference between the front drafting machine and the rear drafting machine at a certain feeding speed. The four-stage heating box is a combination of a preheating section heating box, a superheated steam humidifying section heating box, a high temperature drawing heating box, and a hot roller tension setting heating box.

[0031] The length of the hot box in the preheating section is 1m, the preheating temperature is 200°C, the temperature control accuracy of the box is 2°C, and the temperature uniformity is ±5°C. The length of the superheated steam humidification section is 2m, the temperature of the inner cavity of the box is maintained at 220°C, the temperature contr...

specific Embodiment 3

[0034] An industrial polyimide fiber drawing method is to place polyimide filaments with a certain denier and uniform tension in a four-stage hot box environment, and after being clamped by rubber rollers, the filaments are fed into the Under the speed, the drafting of a certain multiple is realized by the speed difference between the front drafting machine and the rear drafting machine, the feeding speed of the polyimide filament sheet is 10m / min, and the drafting ratio is 1.5;

[0035] The four-stage heat box is a combination of a preheating section heat box, a superheated steam humidification section heat box, a high-temperature drawing heat box and a shaping heat box.

[0036] The length of the hot box in the preheating section is 0.5m, the preheating temperature is 50°C, the temperature control accuracy of the box is 2°C, and the temperature uniformity is ±5°C;

[0037] The length of the hot box in the superheated steam humidification section is 0.5m, the preheating tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com