Highly-transparent polyethylene composition and preparation method thereof

A technology of polyethylene and composition, applied in the field of high-transparency polyethylene composition and preparation thereof, can solve the problems of insufficient heat aging resistance, tear resistance and anti-drop impact strength, etc., and achieve excellent mechanical properties and optical properties. performance, overcoming metallocene processing difficulties, and the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

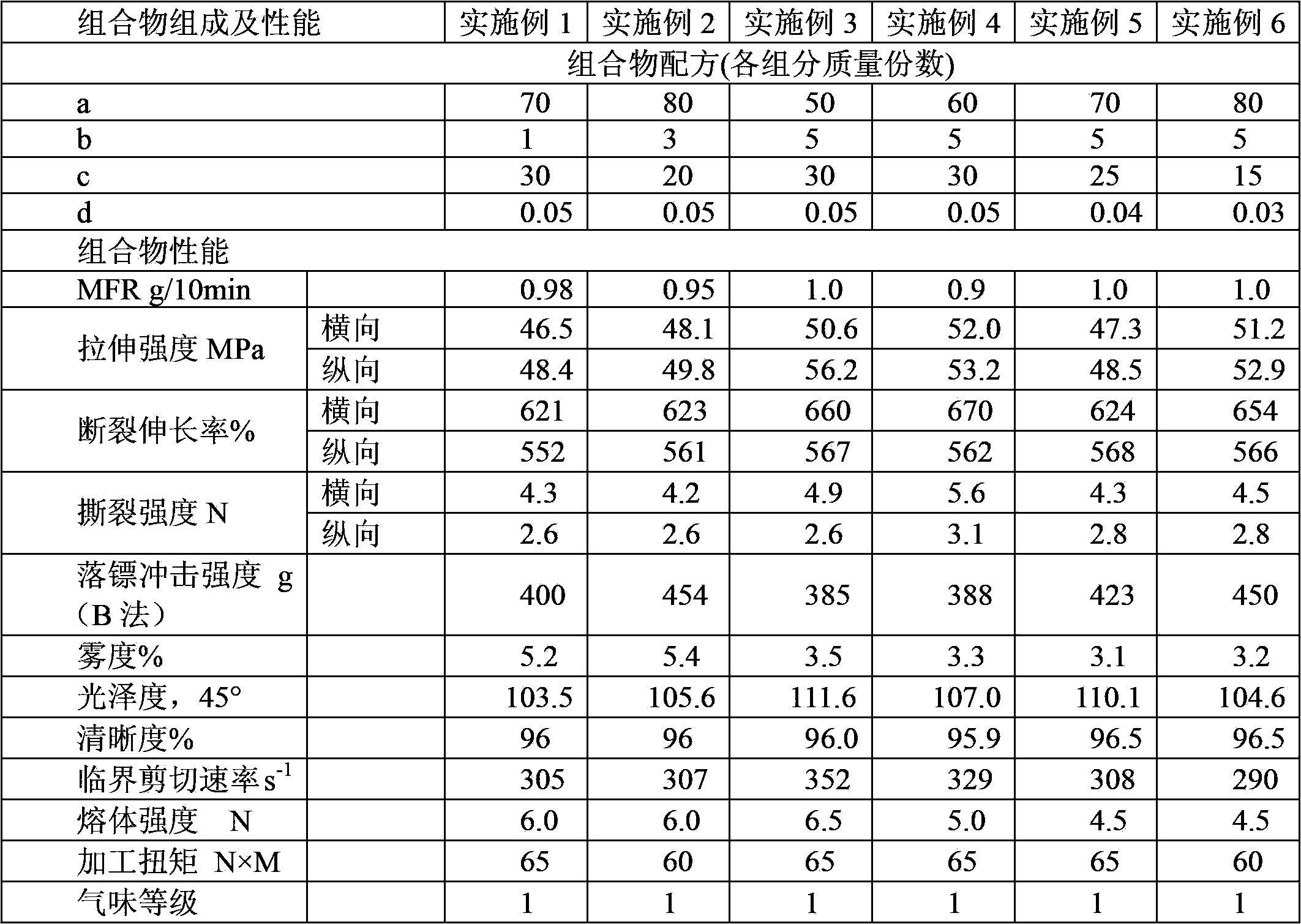

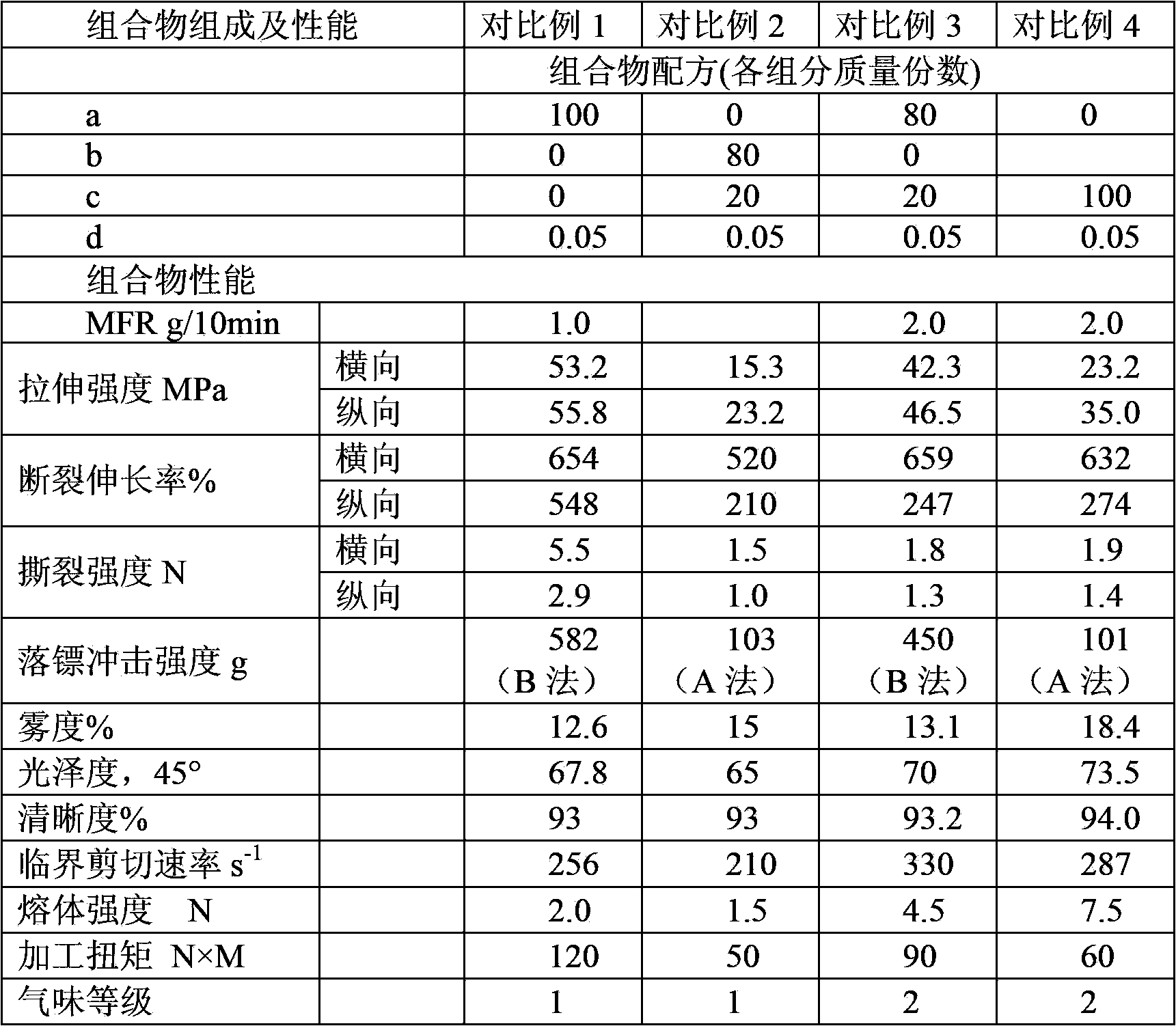

Examples

Embodiment 1、2、5、6

[0043] Component a: hexene copolymerized linear low density polyethylene prepared by metallocene catalyst, melt mass flow rate (190°C, 2.16Kg) 1.0g / 10min, density 0.9200g / cm 3 , the comonomer mole percentage is 2.53%, the degree of branching is 111.4 / 10000C, the terminal methyl group is 128.3 / 10000C, the molecular weight distribution breadth index is 3.08, and the weight average molecular weight is 123,500.

[0044] Component b: hexene copolymerized linear low density polyethylene prepared by metallocene catalyst, melt mass flow rate (190°C, 2.16Kg) 10g / 10min, density 0.9122g / cm 3 , the comonomer mole percentage is 3.25%, the branching degree is 21.1 / 10000C, the terminal methyl group is 133.8 / 10000C, the resin melting temperature is 101.3°C and 113.4°C, the weight average molecular weight is 110,000, and the molecular weight distribution width index is 3.8.

[0045] Component c: Qilu company product 2102TN00, density 0.919g / cm 3 , Melt mass flow rate (190°C, 2.16Kg) 2.0g / 10mi...

Embodiment 3

[0048] Component a: Metallocene linear low density polyethylene 1018CA (ExxonMobil Chemical Co., Ltd.), density 0.918g / cm 3 , Melt mass flow rate (190°C, 2.16Kg) 1.0g / 10min.

[0049] Component b: hexene copolymerized linear low density polyethylene prepared by metallocene catalyst, melt mass flow rate (190°C, 2.16Kg) 10g / 10min, density 0.9122g / cm 3 , the comonomer mole percentage is 3.25%, the branching degree is 21.1 / 10000C, the terminal methyl group is 133.8 / 10000C, the resin melting temperature is 101.3°C and 113.4°C, the weight average molecular weight is 110,000, and the molecular weight distribution width index is 3.8.

[0050] Component c: Qilu company product 7042, density 0.920g / cm 3 , Melt mass flow rate (190°C, 2.16Kg) 2.0g / 10min, weight average molecular weight 100,000, molecular weight distribution breadth index 4.5.

[0051] Component d: Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester is used as antioxidant, the dosage is 0.03 par...

Embodiment 4

[0053] Component a: hexene copolymerized linear low density polyethylene prepared by metallocene catalyst, melt mass flow rate (190°C, 2.16Kg) 1.0g / 10min, density 0.9201g / cm 3 , the comonomer mole percentage is 2.53%, the degree of branching is 111.4 / 10000C, the terminal methyl group is 128.3 / 10000C, the molecular weight distribution breadth index is 3.08, and the weight average molecular weight is 123,500.

[0054] Component b: hexene copolymerized linear low density polyethylene prepared by metallocene catalyst, melt mass flow rate (190°C, 2.16Kg) 10g / 10min, density 0.9122g / cm 3 , the comonomer mole percentage is 3.25%, the branching degree is 21.1 / 10000C, the terminal methyl group is 133.8 / 10000C, the resin melting temperature is 101.3°C and 113.4°C, the weight average molecular weight is 110,000, and the molecular weight distribution width index is 3.8.

[0055] Component c: 2102TN26, the product of Qilu Company, with a density of 0.918g / cm 3 , Melt mass flow rate (190°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com