Aramid dissolved solution and preparation method of aramid dissolved solution as well as aramid membrane coating solution and production method of aramid membrane coating solution, and membrane

A technology of dissolving solution and coating solution, which is applied in the direction of coating, polyamide coating, electrical components, etc., can solve the problems of large thermal shrinkage and affecting service life, and achieve the effect of improving thermal shrinkage rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] An embodiment of the present invention provides a method for preparing an aramid fiber solution, including:

[0028] S1. Dissolving the auxiliary solvent in the organic solvent to obtain the first solution.

[0029] Further, the organic solvent is selected from the group consisting of dimethylacetamide (DMAC), N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF) or dimethyl phthalate (DMP) Any kind.

[0030] Dimethylacetamide, molecular formula CH 3 CON(CH 3 ) 2 , Colorless transparent liquid, low toxicity, flammable. It can be mixed with organic solvents such as water, alcohol, ether, ester, benzene, chloroform and aromatic compounds.

[0031] Methylpyrrolidone, a colorless transparent oily liquid with a slight amine odor. Low volatility, good thermal and chemical stability, and can evaporate with water vapor. It is hygroscopic. Sensitive to light. It is easily soluble in water, ethanol, ether, acetone, ethyl acetate, chloroform and benzene, and can dissolve most organi...

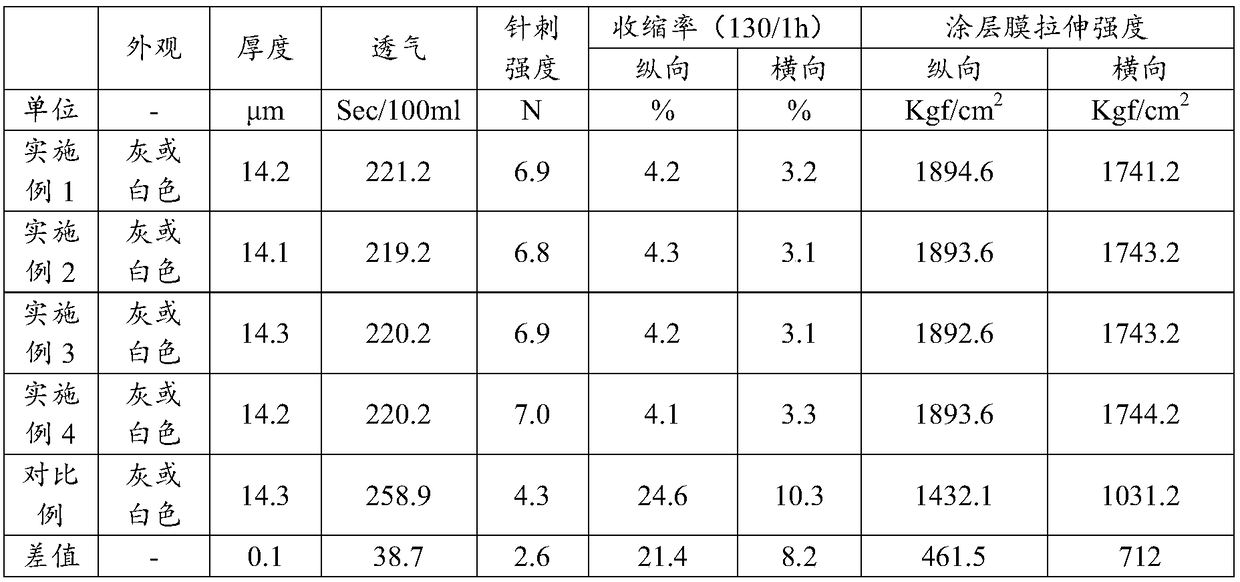

Embodiment 1

[0071] This embodiment provides an aramid diaphragm coating liquid, which is prepared as follows:

[0072] CaCl 2 Dissolved in DMAC solvent, among them, CaCl 2 The mass of the meta-aramid is 1wt% of the DMAC solvent; then the meta-aramid is dissolved in the DMAC solvent, and the mass of the meta-aramid is 7wt% of the DMAC solvent. Heat and stir in a water bath for 4 hours until the aramid fiber is completely dissolved, isolate the air, and place it to room temperature to prepare an aramid solution.

[0073] Add the pore former to the aramid dissolving liquid, where the mass of the pore former is 4% of the aramid dissolving liquid, fully agitate it, and put it into the alumina particle slurry dispersed in the DMAC solvent, where the alumina particles account for 20wt% of the total mass of DMAC solvent. Stir evenly, filter out the material, and finish the coating slurry of aramid membrane.

Embodiment 2

[0075] This embodiment provides an aramid diaphragm coating liquid, which is prepared as follows:

[0076] Dissolve LiCl in NMP solvent, where the mass of LiCl is 4wt% of NMP solvent; then dissolve meta-aramid in NMP solvent, and the mass of meta-aramid is 15wt% of NMP solvent. Heat and stir in a water bath for 7 hours until the aramid fiber is completely dissolved, isolate the air, and place it to room temperature to prepare an aramid solution.

[0077] The pore former is added to the aramid dissolving solution, where the mass of the pore former is 6% of the aramid dissolving solution, fully agitated, and then put into the alumina particle slurry dispersed in NMP solvent, in which alumina particles account for 30wt% of the total mass of NMP solvent. Stir evenly, filter out the material, and finish the coating slurry of the aramid membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com