Polyamide 5X short fiber as well as preparation method and application thereof

A polyamide and staple fiber technology, applied in the field of polyamide 5X staple fiber and its preparation, can solve the problems such as poor mechanical properties of sewing thread, achieve excellent performance, low elongation, and reduce the effect of greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

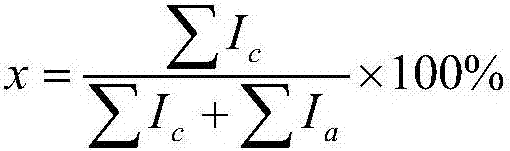

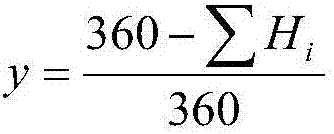

Method used

Image

Examples

preparation example Construction

[0108] A preparation method of polyamide 5X short fiber, it may further comprise the steps:

[0109] (1) Polymerizing 1,5 pentamethylenediamine and dicarboxylic acid to form a polyamide 5X melt; or, heating polyamide 5X (polyamide 5X resin) to a molten state to form a polyamide 5X melt;

[0110] (2), the polyamide 5X melt is spun to form spun silk;

[0111] (3) Polyamide 5X staple fibers are obtained after the as-spun silk is processed.

[0112] Wherein, in the step (1), the polyamide 5X resin is a polyamide 5X resin chip.

[0113] The relative viscosity of polyamide 5X resin chip can be 3.1-3.6.

[0114] Because polyamide 5X resin has strong water absorption, it can be dried before it is heated and melted. The drying temperature is 100-150°C and the drying time is 10-30h. The moisture content of polyamide 5X after drying is 50-1500ppm, preferably 200-800ppm, more preferably 300-700ppm, even more preferably 400-600ppm.

[0115] The spinning in step (2) includes the followi...

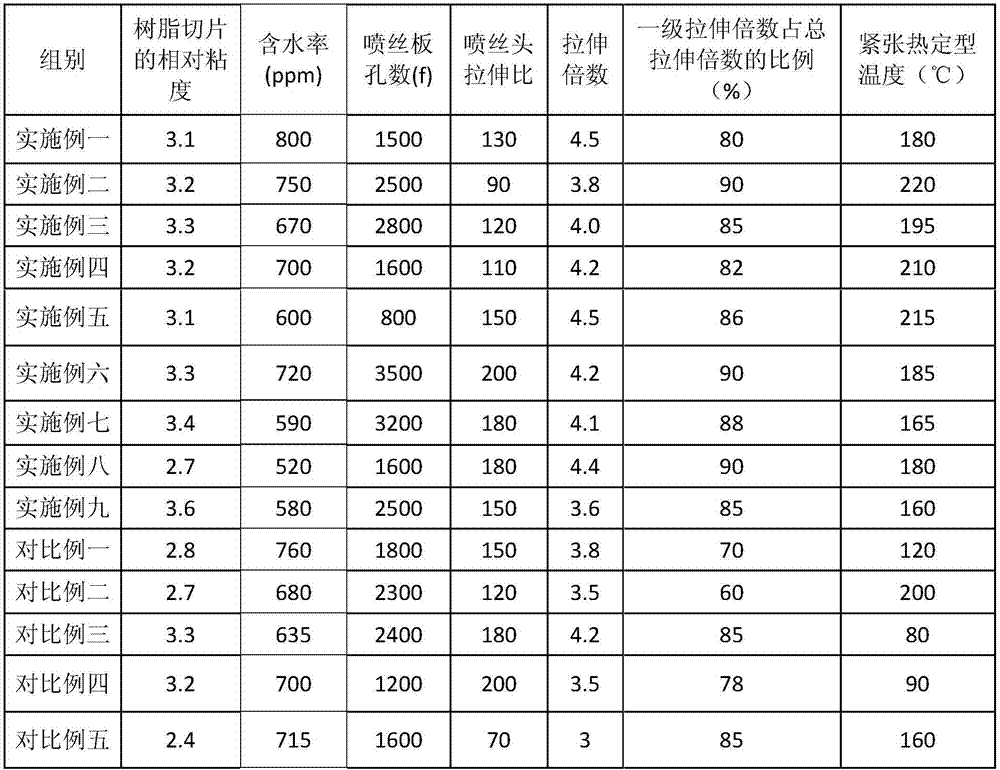

Embodiment 1

[0151] The present embodiment provides a kind of preparation method of polyamide 56 short fiber, it comprises the steps:

[0152] (1) Select polyamide 56 slices with a relative viscosity of 3.1, and dry them under nitrogen protection. The drying temperature is 135°C and the drying time is 20 hours. After drying, the polyamide 56 slices enter the single-screw machine through a closed nitrogen protection hopper Carry out heating and melting, obtain polyamide 56 melt;

[0153] (2), polyamide 56 melt is sprayed out by the spinneret that number of holes is 1500f, and the draw ratio of spinneret is 130, and after polyamide 56 melt sprays out spinneret hole, cools by ring air blowing, and wind temperature is 25°C, wind speed 0.5m / s, to get as-spun silk;

[0154] (3), as-spun silk is fed into the silk barrel by feeding rollers to obtain raw silk, and the raw silk is stretched in three stages by cluster frame, and the total draw ratio is 4.5 times, wherein, the first-order draw ratio ...

Embodiment 2

[0157] The present embodiment provides a kind of preparation method of polyamide 56 short fiber, it comprises the steps:

[0158] (1) Select polyamide 56 slices with a relative viscosity of 3.2, and dry them under nitrogen protection. The drying temperature is 135°C, and the drying time is 20 hours. After drying, the polyamide 56 slices enter the single-screw machine through a closed nitrogen protection silo. Carry out heating and melting, obtain polyamide 56 melt;

[0159] (2), polyamide 56 melt is sprayed out by the spinneret that number of holes is 2500f, and the draw ratio of spinneret is 90, and after polyamide 56 melt sprays out spinneret hole, cools by ring air blowing, and wind temperature is 25°C, wind speed 0.6m / s, to get spun silk;

[0160] (3), as-spun silk is fed into the silk barrel by feeding rollers to obtain raw silk, and the raw silk is stretched in three stages by cluster frame, and the total stretching ratio is 3.8 times, wherein, the primary stretching ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com