Polylactic acid membrane and preparation method of polylactic acid membrane

A polylactic acid and film technology, applied in the field of polymers, can solve the problems of lack of technical means, strength reduction, slow crystallization speed of polylactic acid film, etc., and achieve the effect of good continuity, simple process, and excellent transverse tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

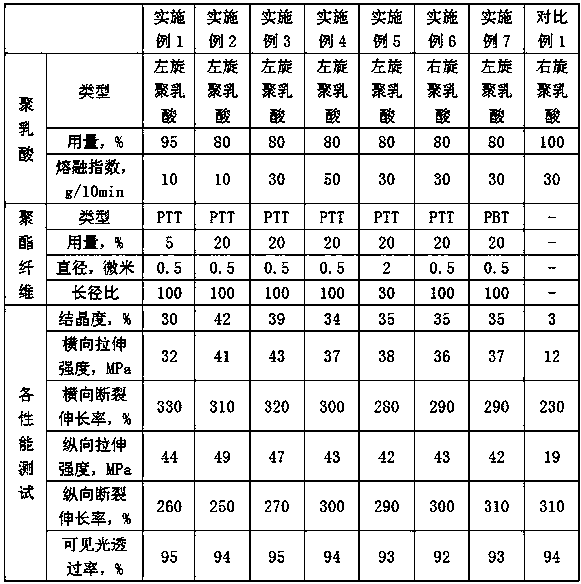

Examples

Embodiment 8

[0042] After drying the right-handed polylactic acid resin with a melt index of 30g / 10min, and 15% mass fraction of PTT fibers (diameter 0.9μm, aspect ratio 70) were pelletized with a twin-screw extruder, and then extruded by a single screw cast film. In the melt stretching stage, the distance from the die head to the casting roll is 15cm, the temperature of the die head is 175°C, and the cooling air volume is 100m 3 / min, the casting roll temperature is 70°C. During extrusion, in the melt stretching stage, the ratio of the melt extrusion speed to the casting roll line speed is 1:120, and the polylactic acid film can be obtained by winding.

Embodiment 9

[0044] After drying the right-handed polylactic acid resin with a melt index of 30g / 10min, and 15% mass fraction of PTT fibers (diameter 0.9μm, aspect ratio 70) were pelletized with a twin-screw extruder, and then extruded by a single screw cast film. In the melt stretching stage, the distance from the die head to the casting roll is 15cm, the temperature of the die head is 210°C, and the cooling air volume is 100m 3 / min, the casting roll temperature is 70°C. During extrusion, in the melt stretching stage, the ratio of the melt extrusion speed to the casting roll line speed is 1:120, and the polylactic acid film can be obtained by winding.

Embodiment 10

[0046] After drying the right-handed polylactic acid resin with a melt index of 30g / 10min, and 15% mass fraction of PTT fibers (diameter 0.9μm, aspect ratio 70) were pelletized with a twin-screw extruder, and then extruded by a single screw cast film. In the melt stretching stage, the distance from the die head to the casting roll is 15cm, the temperature of the die head is 225°C, and the cooling air volume is 100m 3 / min, the casting roll temperature is 70°C. During extrusion, in the melt stretching stage, the ratio of the melt extrusion speed to the casting roll line speed is 1:120, and the polylactic acid film can be obtained by winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com