Automatic spraying line for golf club head

An automatic spraying, golf head technology, applied in spray booths, spraying devices, etc., can solve problems such as harm to workers' health, long transfer routes, easy leakage of oil and gas, etc., to achieve practicability and adaptability, consistent spraying surface , spray the effect of fast tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

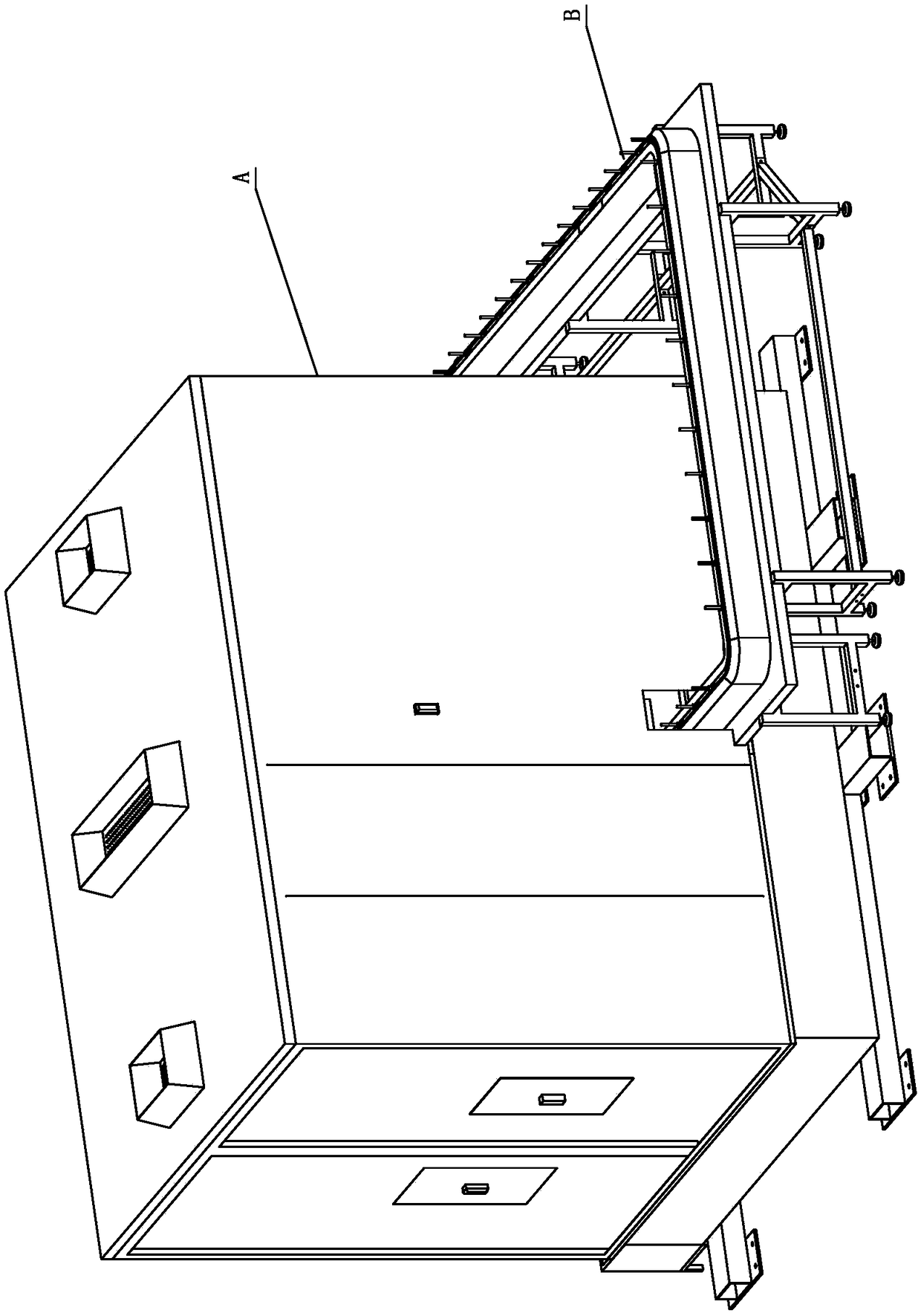

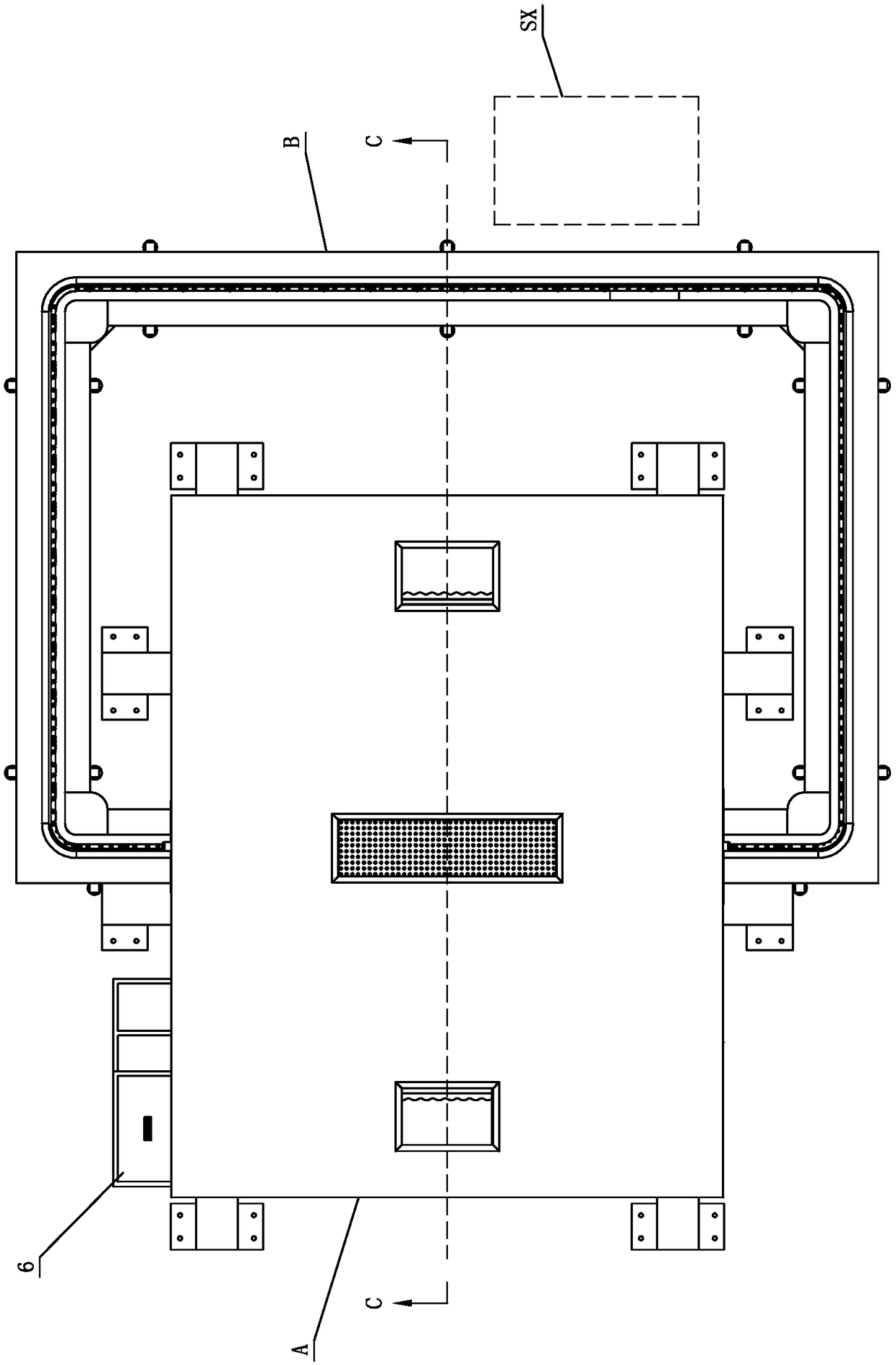

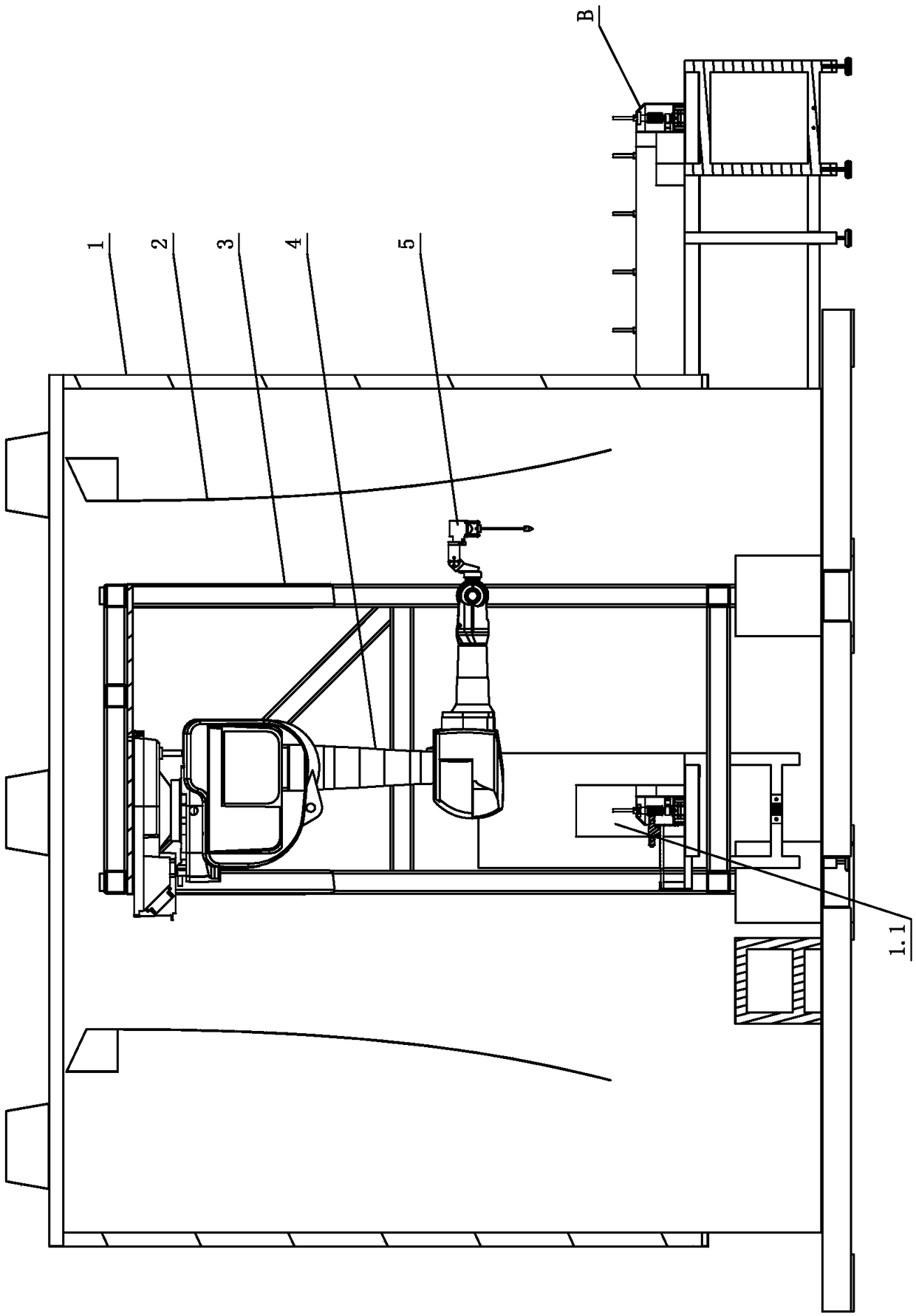

[0034] see Figure 1-Figure 8 , the golf head automatic spraying line, including spraying equipment A for spraying workpieces and conveying equipment B for transporting workpieces, the workpieces to be sprayed are golf heads; one spraying equipment A is set along the conveying equipment B; The conveying equipment B is arranged in a ring and runs through the spraying equipment A; the spraying equipment A includes a water curtain cabinet 1, a support gantry 3 and a multi-axis robot 4 (the multi-axis robot 4 in this embodiment is a six-axis robot), and the water curtain cabinet 1 Closed covering support gantry 3 and multi-axis robot 4, multi-axis robot 4 is mounted upside down on the top of support gantry 3, multi-axis robot 4 is provided with a spray gun 5, by controlling the movement of the spray gun 5 to achieve comprehensive spraying of the workpiece; The conveying equipment B includes a conveying mechanism and several ball head tooling assemblies. The conveying mechanism inc...

no. 2 example

[0047] see Figure 9 , this golf head automatic spraying line is different from the first embodiment in that: there are three spraying equipment A, and they are respectively arranged along the conveying direction of the conveying equipment B, and the conveying equipment B runs through the three spraying equipment A in sequence; For example, it can meet the workpiece with three spraying processes.

[0048] It can be seen that this spraying line can also be expanded according to the workpiece process; if the workpiece requires two spraying processes, then two spraying equipment A can be spliced to the conveying equipment B to automatically perform multi-process spraying.

[0049] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com