Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Not prone to vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

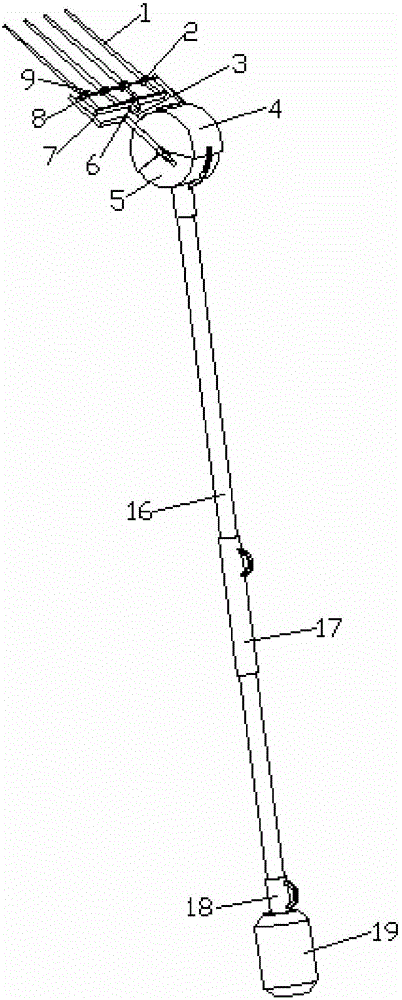

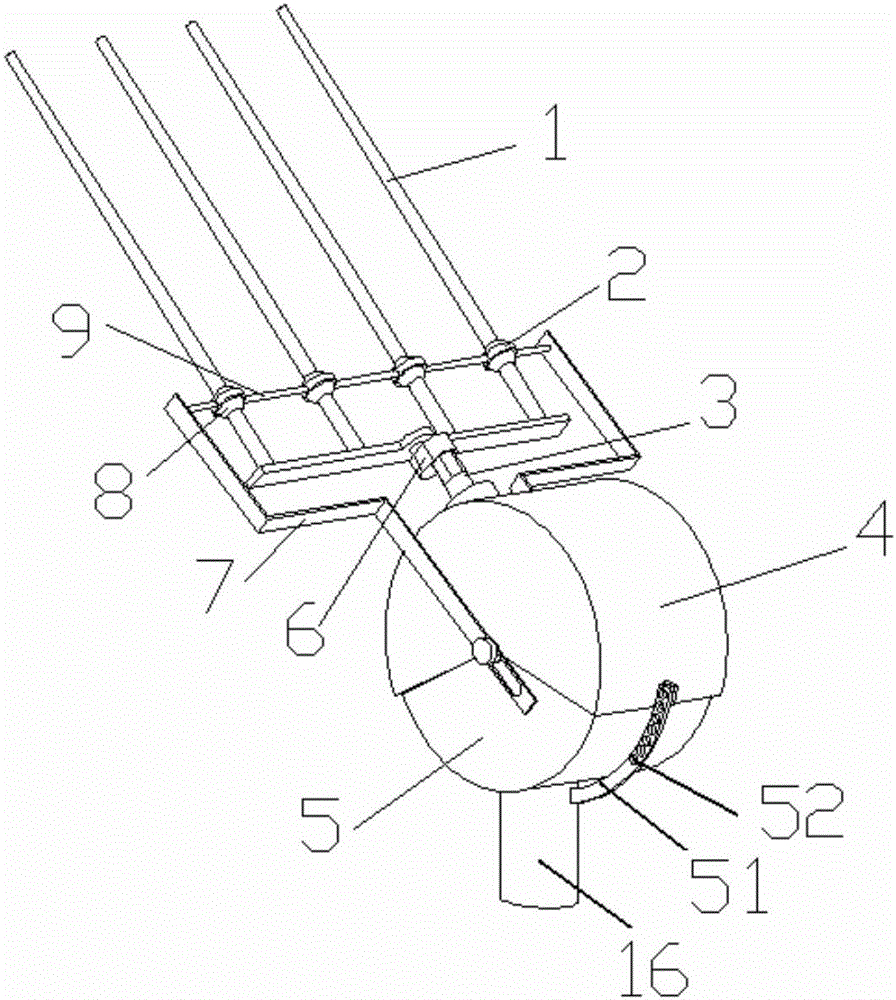

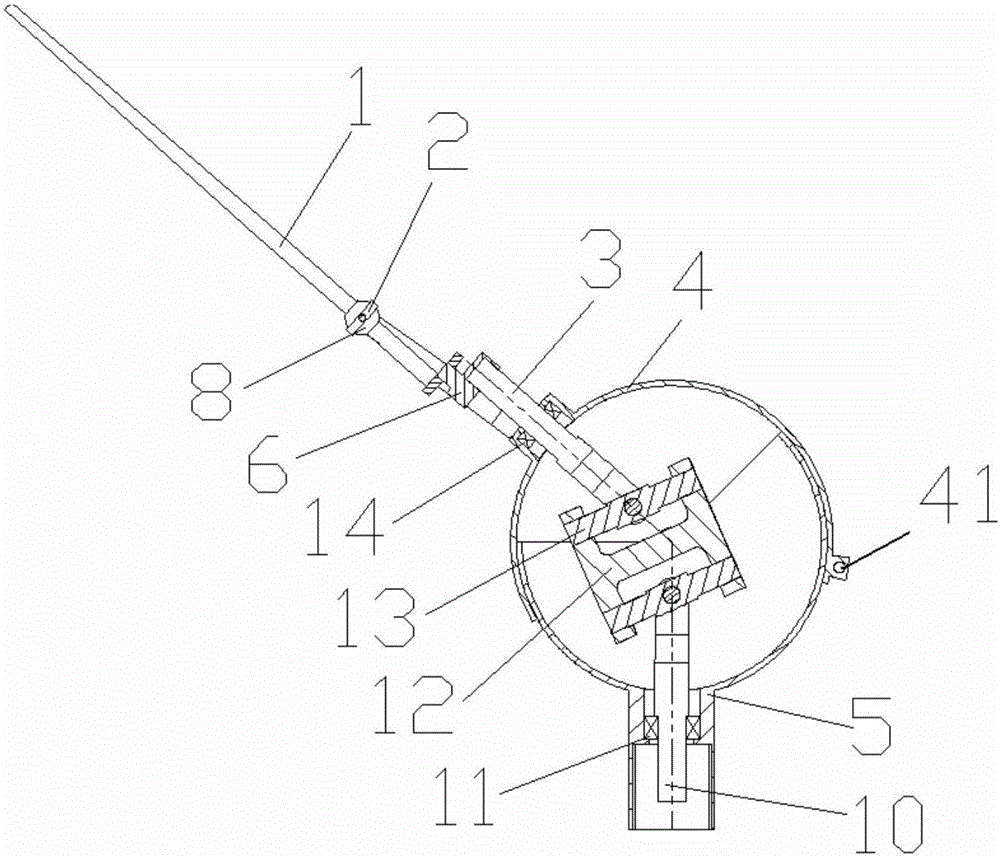

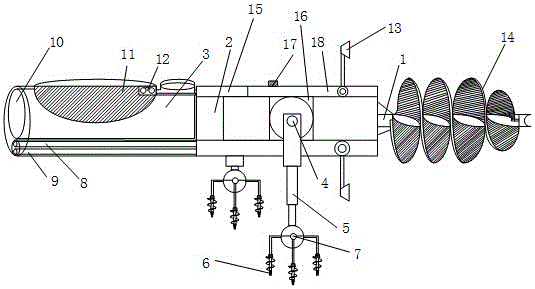

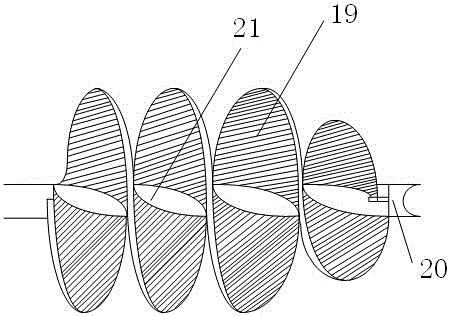

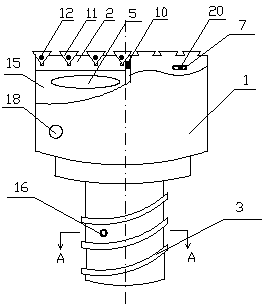

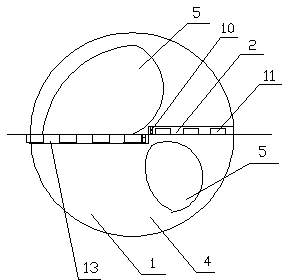

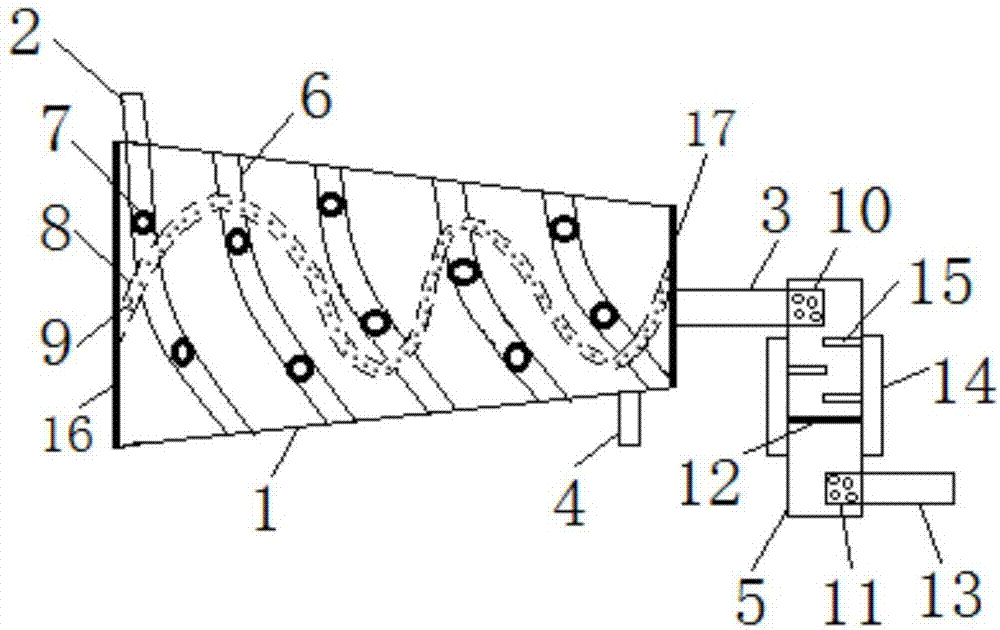

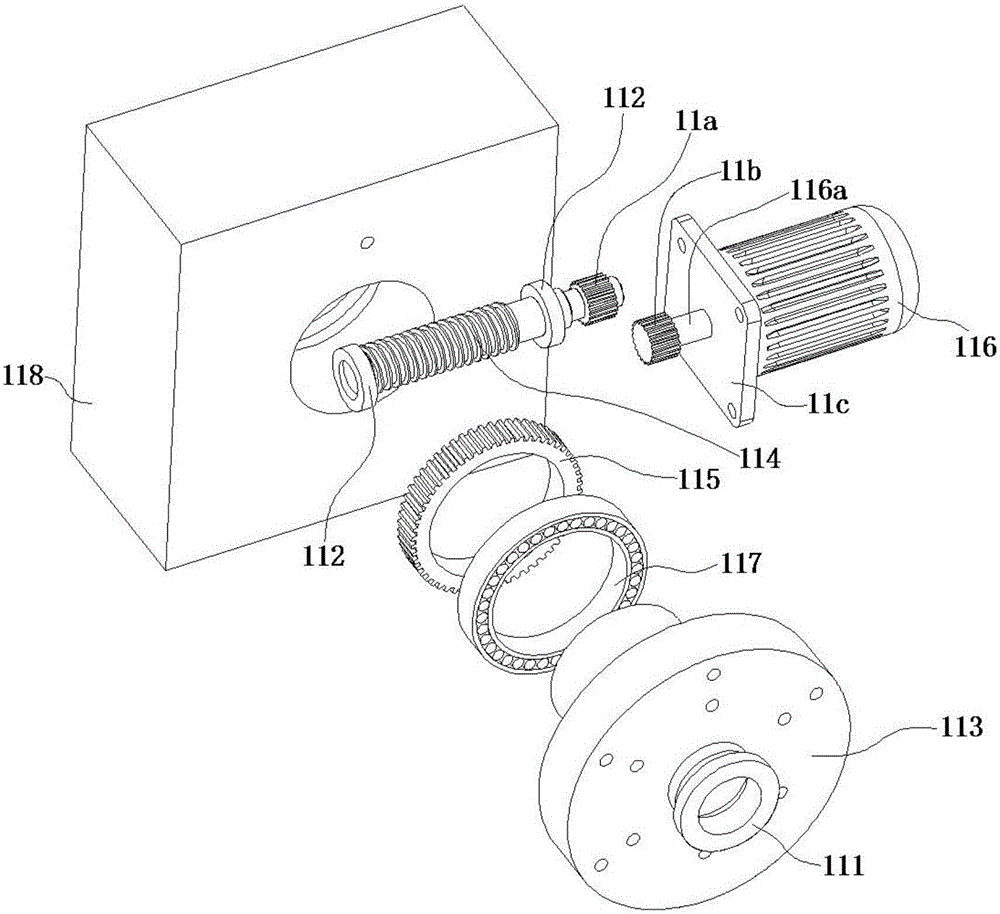

Forest fruit picking equipment adjustable in vibration amplitude and elevation angle

ActiveCN105850372APitch angle is easy to adjustReduce labor intensityPicking devicesVibration amplitudeElevation angle

The invention provides forest fruit picking equipment adjustable in vibration amplitude and elevation angle. The forest fruit picking equipment comprises a power device and a working head, an output shaft of the power device outputs rotating motion and is connected with the working head, the working head comprises a picking head and a picking hand, the picking head comprises a rack, two rotating shafts are arranged on the rack, one of the rotating shafts is connected with the power device while another one is connected with the picking hand, the rotating shafts are connected through a dual Cardan joint, and a picking head output shaft is connected with the picking hand, can rotate around the rack by a set angle and is arranged in a positionable manner to form a picking hand pitching angle adjusting device; the picking hand comprises a comb-tooth-shaped picking member, a fulcrum frame and a vibration amplitude adjusting device, and the fulcrum frame is adjustable in position on a picking rod to adjust vibration amplitude of the picking rod. The forest fruit picking equipment is adjustable in vibration amplitude and elevation angle, thereby being capable of conveniently and efficiently picking forest fruits and being popularized in the public.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

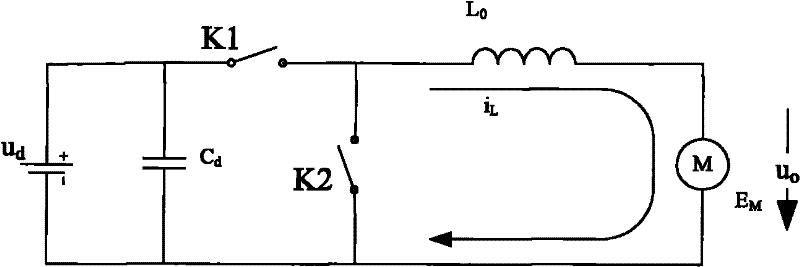

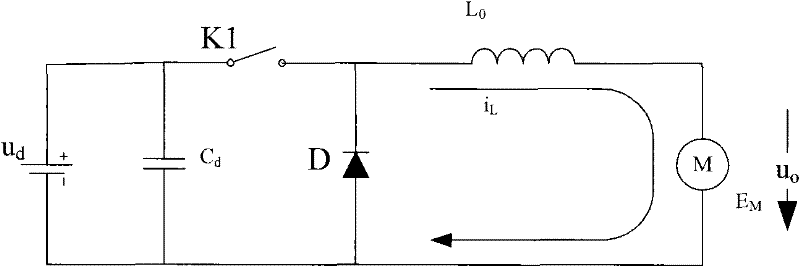

an AC chopper

An AC chopper is connected between an AC power supply and a load circuit, comprising: a switch group, a voltage polarity detector and a switch control logic unit. Among them, the voltage polarity detector is connected to both ends of the AC power supply, and is used to detect the voltage polarity of the chopper input AC power supply when the switch is switched; the switch control logic unit receives the voltage polarity sent by the voltage polarity detector Signal, and send different control signals to the switch group according to the voltage polarity signal to control the state switching sequence of the switch group, and finally make the circuit switch between the freewheeling mode and the active mode. Because the switching method of the present invention is only when the circuit freewheeling mode and the active mode are converted, the state of the switch group is related to the input AC power voltage polarity signal, so the safety and reliability of the system are high; and, due to the method's The voltage polarity signal is fed back to the switch control logic unit discontinuously, so the system is not easy to generate oscillation.

Owner:SHANGHAI WEIMAN ELECTRICAL TECH DEVCO

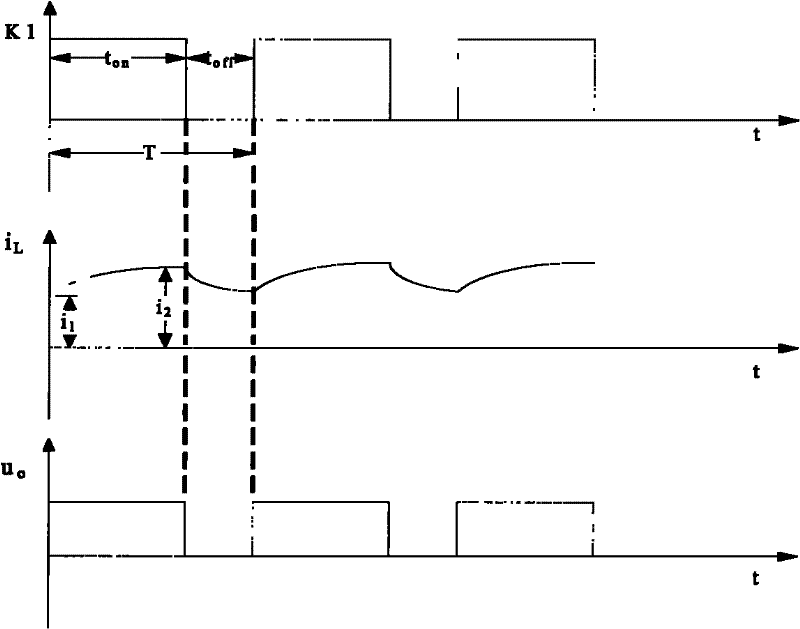

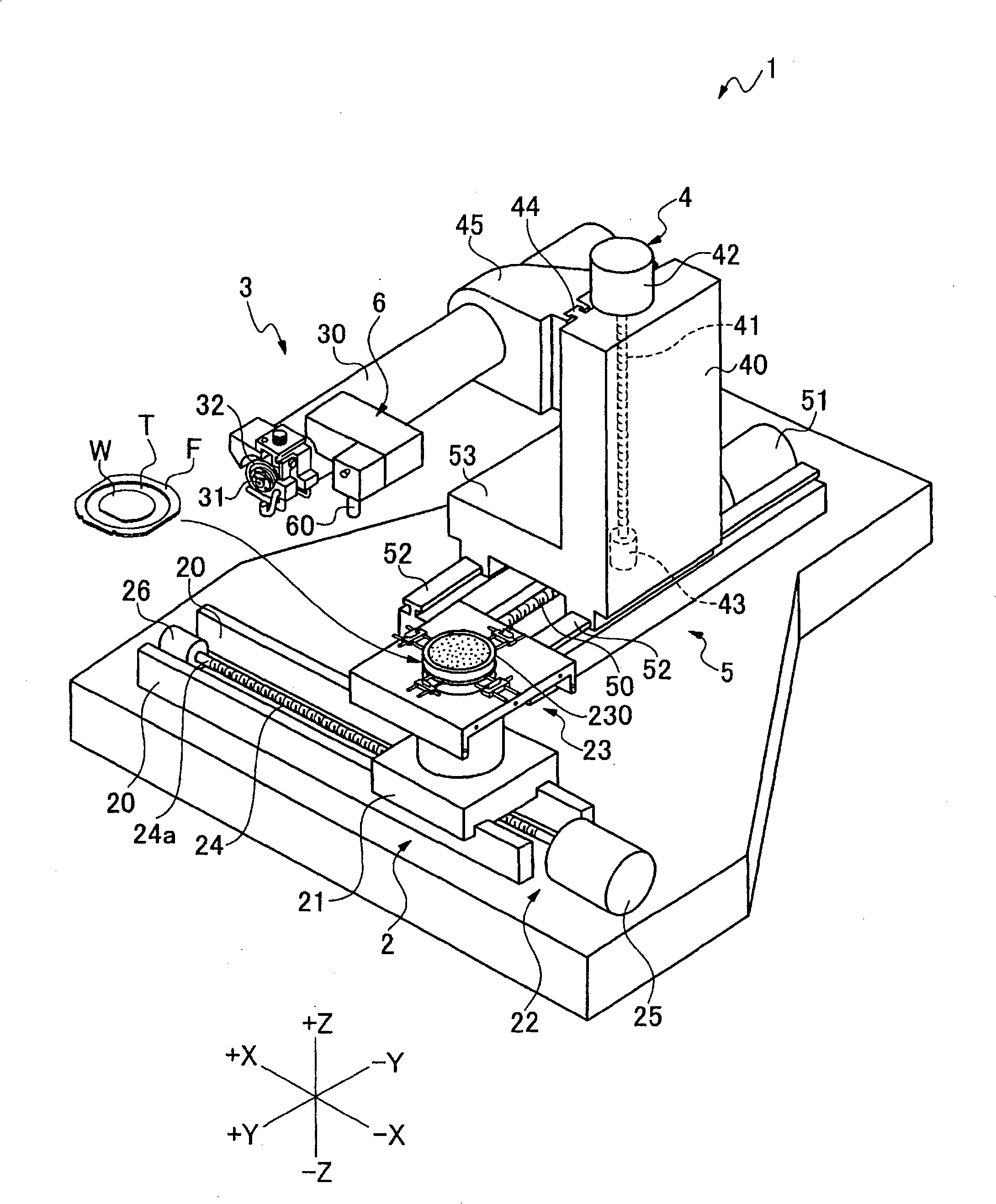

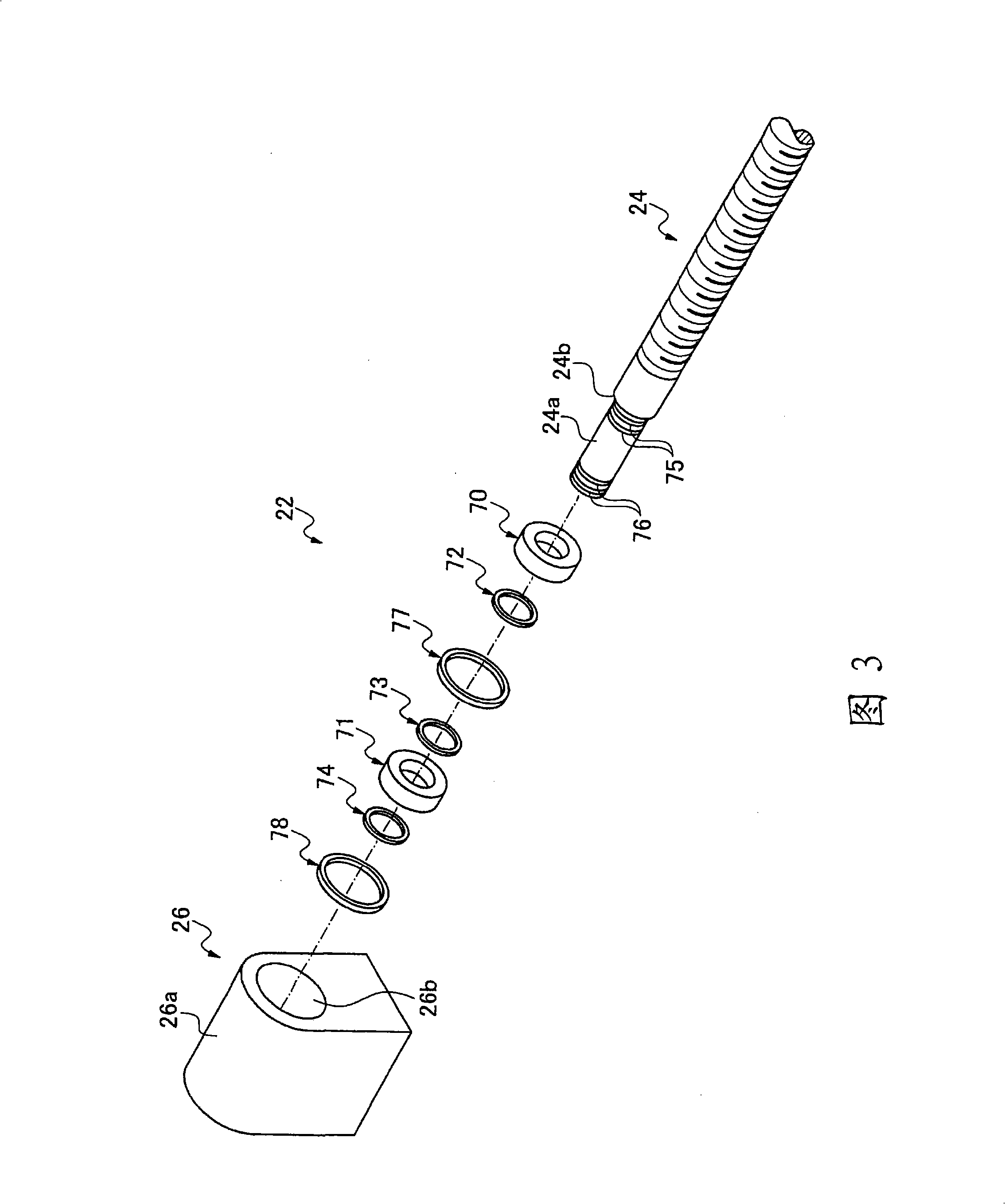

Driving mechanism and cutting apparatus

InactiveCN101256979AReduce vibrationReduce slidingRolling contact bearingsSemiconductor/solid-state device manufacturingBall bearingEngineering

The invention provides a driving mechanism and a cutting device, wherein one end of the feed screw shaft of the driving mechanism is connected with a driving source, while the other end is supported rotatably, moving with a plurality of slide bodies connected with the feed screw screwed on the feed screw shaft, which prevents the vibration of the feed screw shaft in such a driving mechanism with the structure. A driving mechanism having a driving unit in which a drive source is connected to a feed screw shaft and a feed nut is in screw engagement with the feed screw shaft and connected to an active element through a sliding body, wherein the active element is moved by being driven by the driving unit. An inner ring of a bail bearing for supporting the feed screw shaft is fixed to the outer periphery of a free end portion of the feed screw shaft, and an outer ring elastic body which supports an outer ring of the ball bearing slidably in the axial direction of the feed screw shaft and which absorbs vibration of the feed screw shaft is disposed at the inner periphery of a tubular portion for containing the ball, bearing at a terminal support portion.

Owner:DISCO CORP

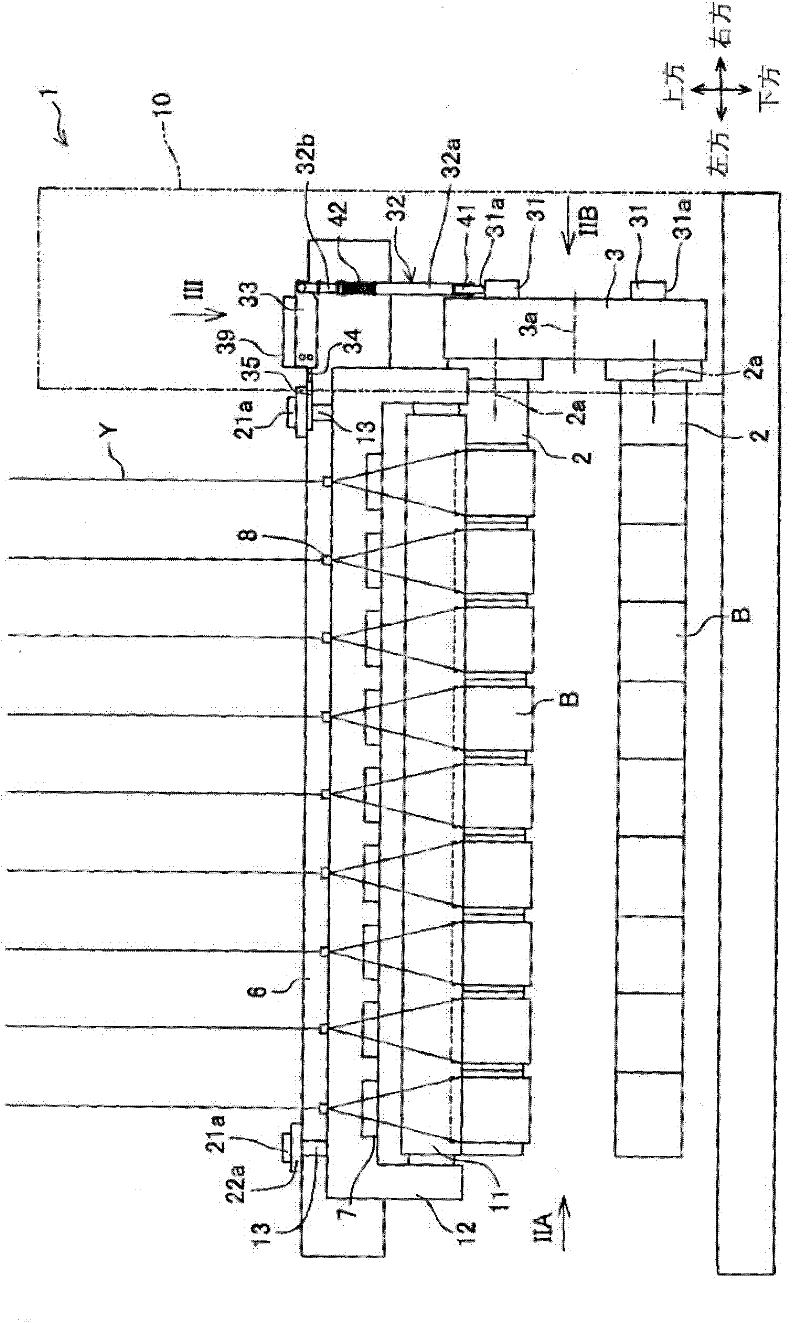

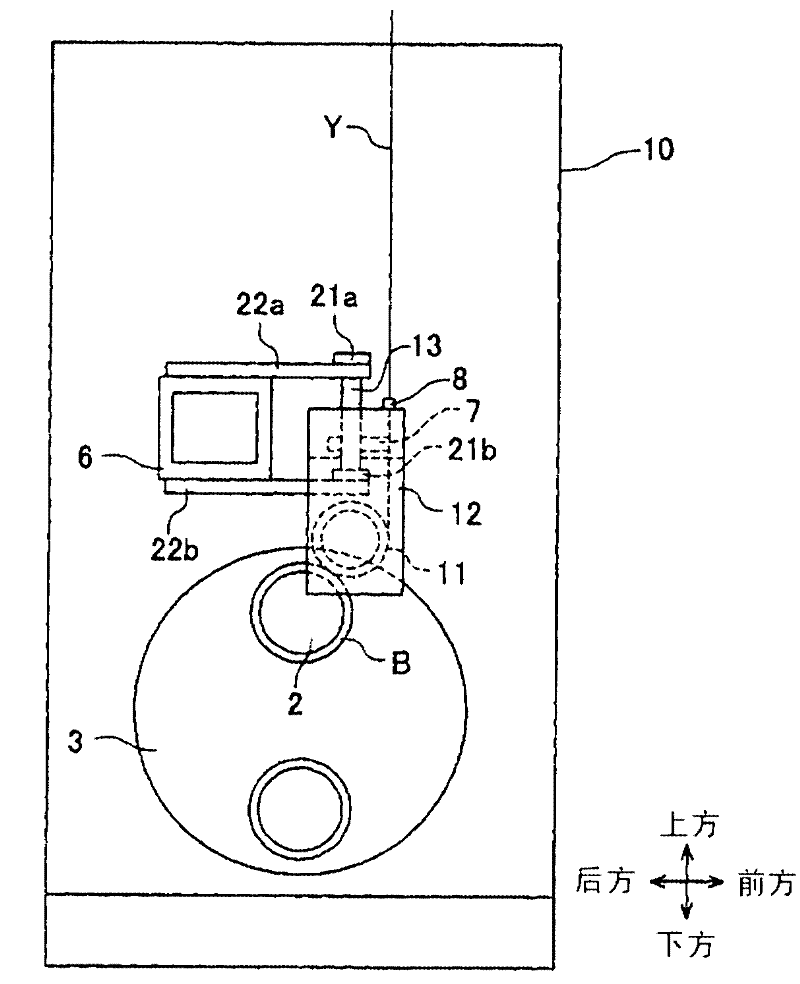

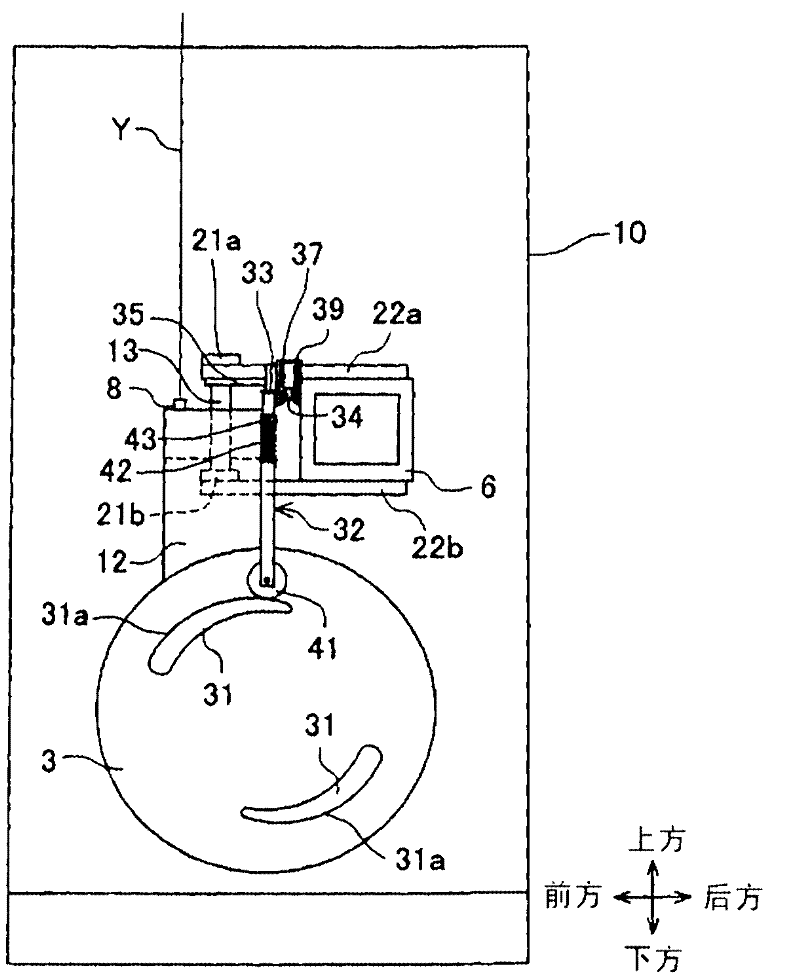

Winding machine

An object of the present invention is to provide a winder in which improper winding of yarns and the breakdown of portions around the contact roller hardly occur even if a tilt unit by which the contact roller is tilted is broken. In a winder 1, as an amount of yarns Y wound onto bobbins B increases, a turret table 3 rotates in the direction in which a bobbin holder 2 moves away from a contact roller 11. A tilt mechanism 5 transfers, by a cam 31, a cam rod 32, a force multiplying arm 33, a tie rod 34, and a tilt arm 35, the rotation of the turret table 3 to a guide shaft 13 elevatably supports a supporting member 12, so as to tilt the guide shaft 13. As a result, as the amount of the yarns Y wound onto the bobbins B attached to the bobbin holder 2 is increased and the bobbin holder 2 is warped, the contact roller 11 supported by the supporting member 12 is tilted.

Owner:TMT MACHINERY INC

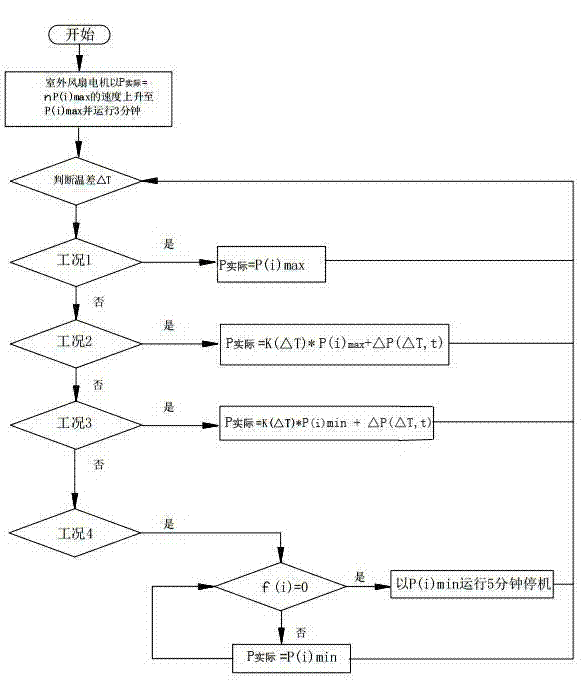

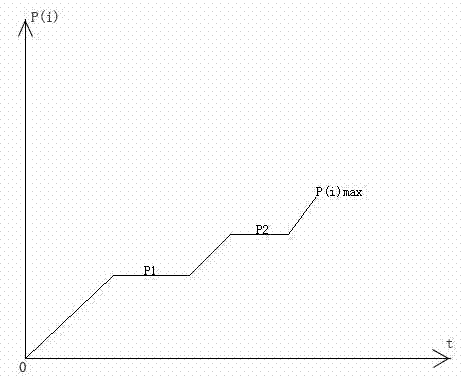

Air-conditioner outdoor motor control method

InactiveCN103115416ASteady increase in speedImprove use comfort performanceSpace heating and ventilation safety systemsLighting and heating apparatusMotor controlStart up

The invention relates to the technical field of air-conditioners in electrical equipment, in particular to an air-conditioner outdoor motor control method, and aims at reducing noise and vibration production in the process of starting to a high rotation speed of an overall unit. The air-conditioner outdoor motor control method includes the following steps: S1, starting up: the rotation speed of an outdoor fan motor is improved to P (i) max from an actual rotation speed P (actual), and then the outdoor fan motor operates for 3minutes, wherein the P (actual) is equal to n P (i) max; and S2, the difference value delta T between temperature of indoor environment and set temperature of an indoor unit is judged. According to the air-conditioner outdoor motor control method, the rotation speed of the starting stage of the outdoor motor is set to be from low to high, and therefore the noise and the vibration are not easily produced in the process of the starting to the high rotation speed of the overall unit, and use comfortable sensation of users is improved.

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

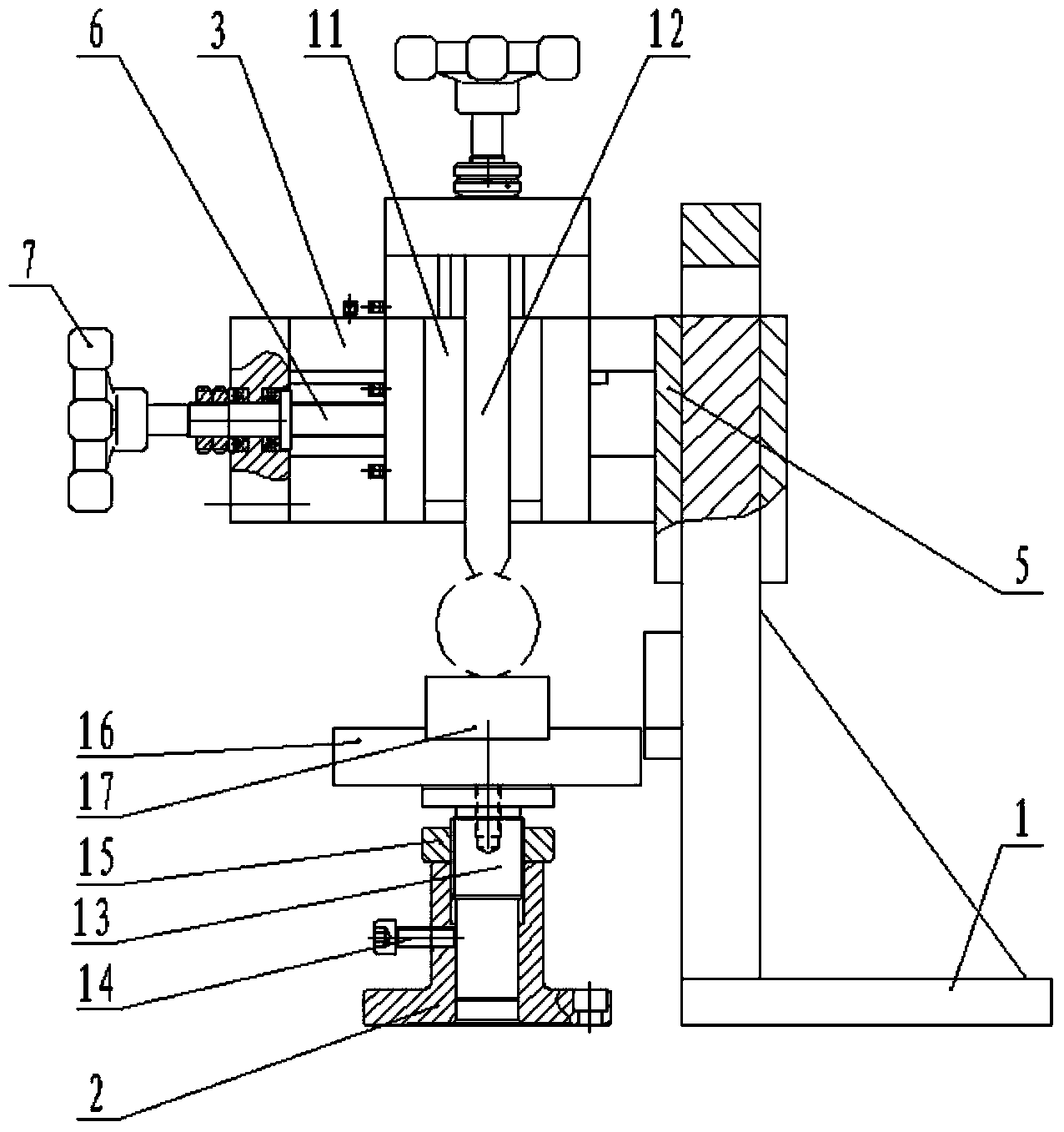

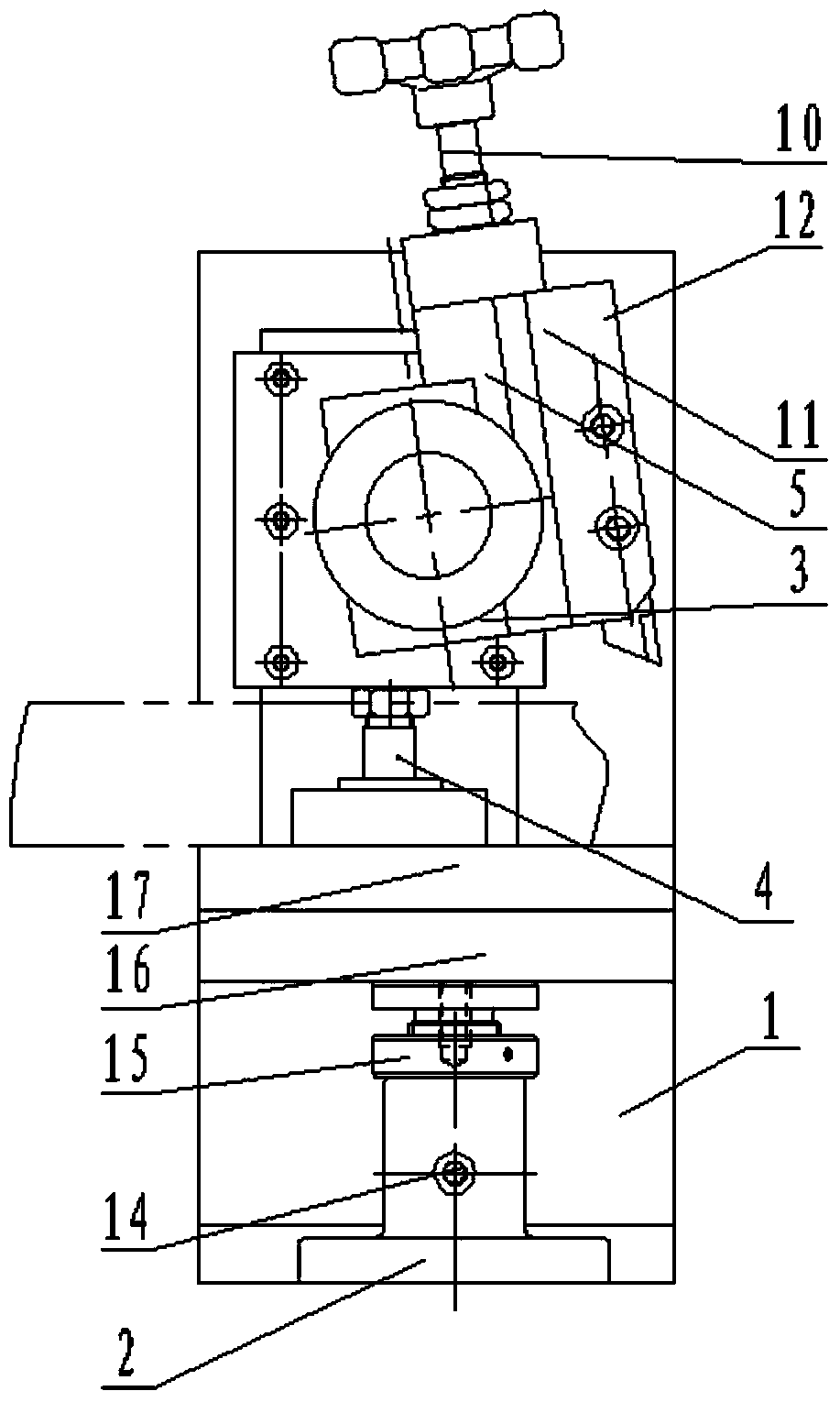

Scraper device for welded joint of welded tube

InactiveCN104227115AReduce wearGood removal effectWelding/cutting auxillary devicesPlaning/slotting machinesEngineeringWeld seam

The invention discloses a scraper device for a welded joint of a welded tube, which has a good using effect and long service life. The scraper device comprises a tool holder and a supporting seat, wherein a cross arm capable of moving vertically and a cylinder capable of driving the cross arm to move are arranged on the tool holder, a sliding seat capable of moving horizontally is arranged on the cross arm, a carriage capable of being vertically adjusted is arranged on the sliding seat, a planer tool, which is at an angle of 60-85 degrees to the top surface of the welded tube, is arranged on the carriage, the supporting seat is arranged under the planer tool, the supporting seat can be vertically adjusted, and a supporting plate is arranged at the top of the supporting seat.

Owner:JIANGSU LONGYUAN METAL TECH

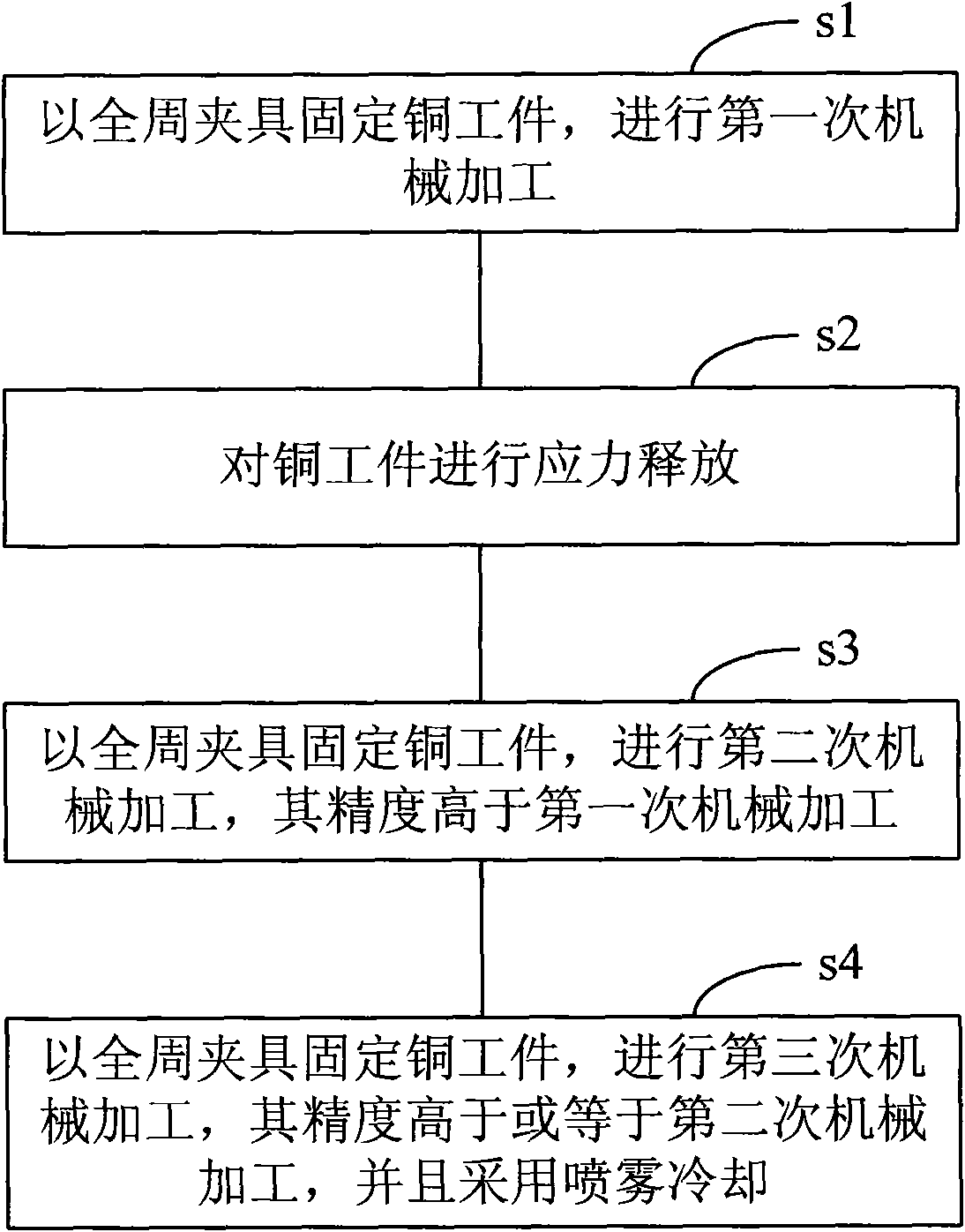

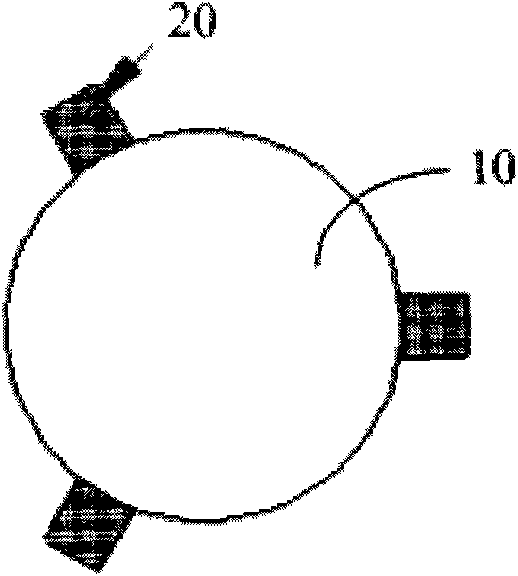

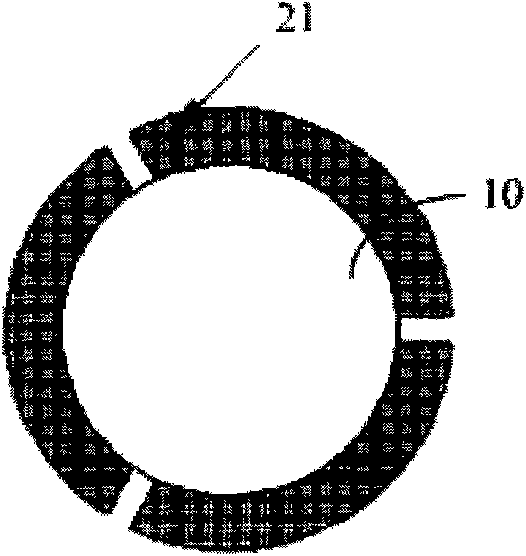

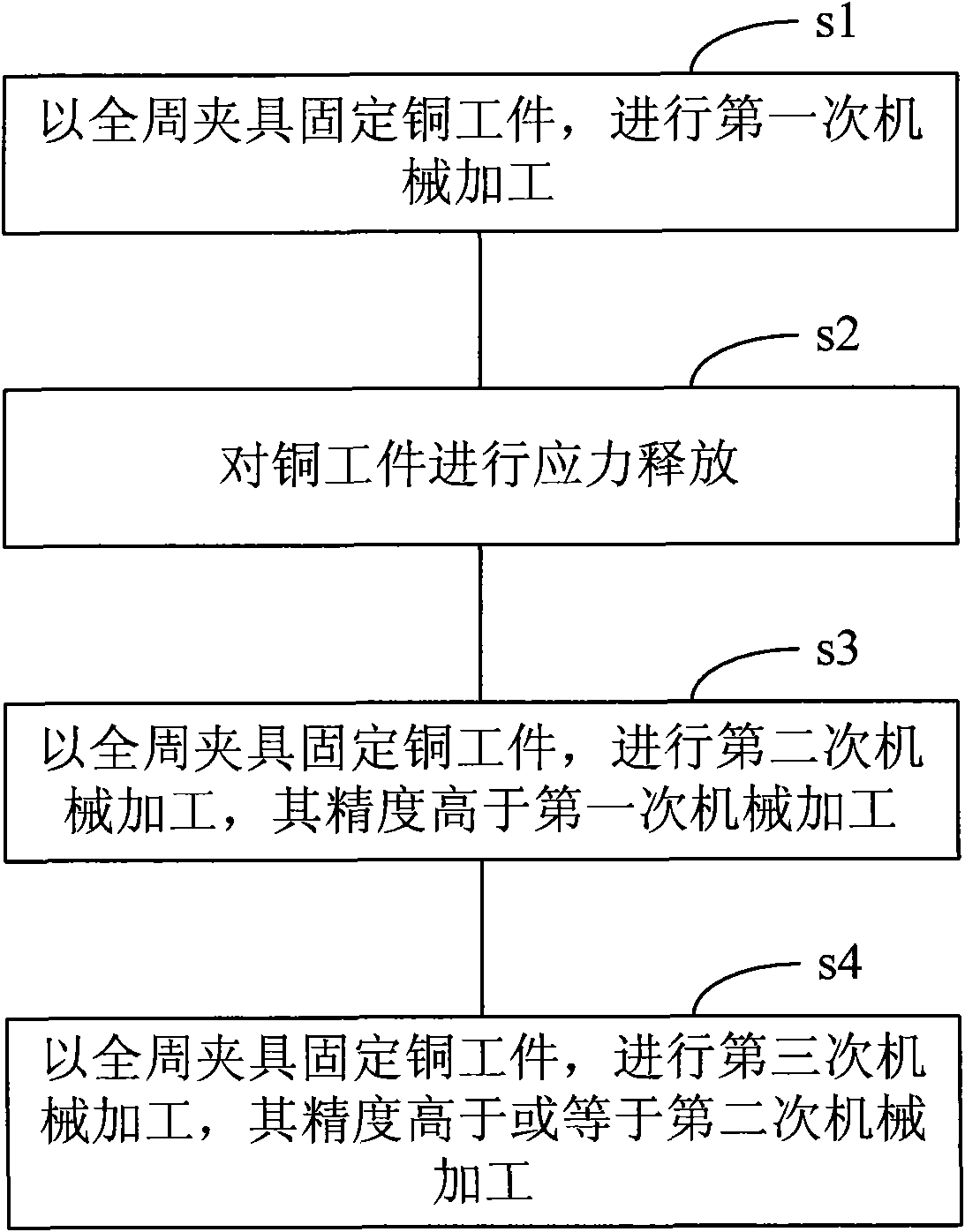

Processing method for copper target material

ActiveCN101619430ALess scratchesReduce wearVacuum evaporation coatingSputtering coatingCopperSpray cooling

The invention provides a processing method for copper target materials, comprising the following steps: mechanical processing is carried out on a copper workpiece for three times with gradually increasing accuracy, wherein spray cooling is adopted during the third mechanical processing, a full-wave clamp is adopted for fixing the copper workpiece in three times of mechanical processing processes, and stress release is carried out on the copper workpiece at least between the first mechanical processing and the second mechanical processing. The processing method for the copper target materials can prevent oxidation of copper in a mechanical processing process, and enable the copper target materials to obtain better consistency of surface grains and lower surface roughness.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Processing method for copper target material

ActiveCN101619429AReduce distortionLess scratchesVacuum evaporation coatingSputtering coatingCopperFull wave

The invention provides a processing method for copper target materials, comprising the following steps: a copper workpiece is processed through mechanical processing with gradually increasing accuracy for three times, wherein the copper workpiece is fixed by a full-wave clamp in three times of mechanical processing processes, and stress release is carried out on the copper workpiece at least between the first mechanical processing and the second mechanical processing. The copper target materials obtained through the processing method for the copper target materials has better consistency of surface grains and lower surface roughness.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

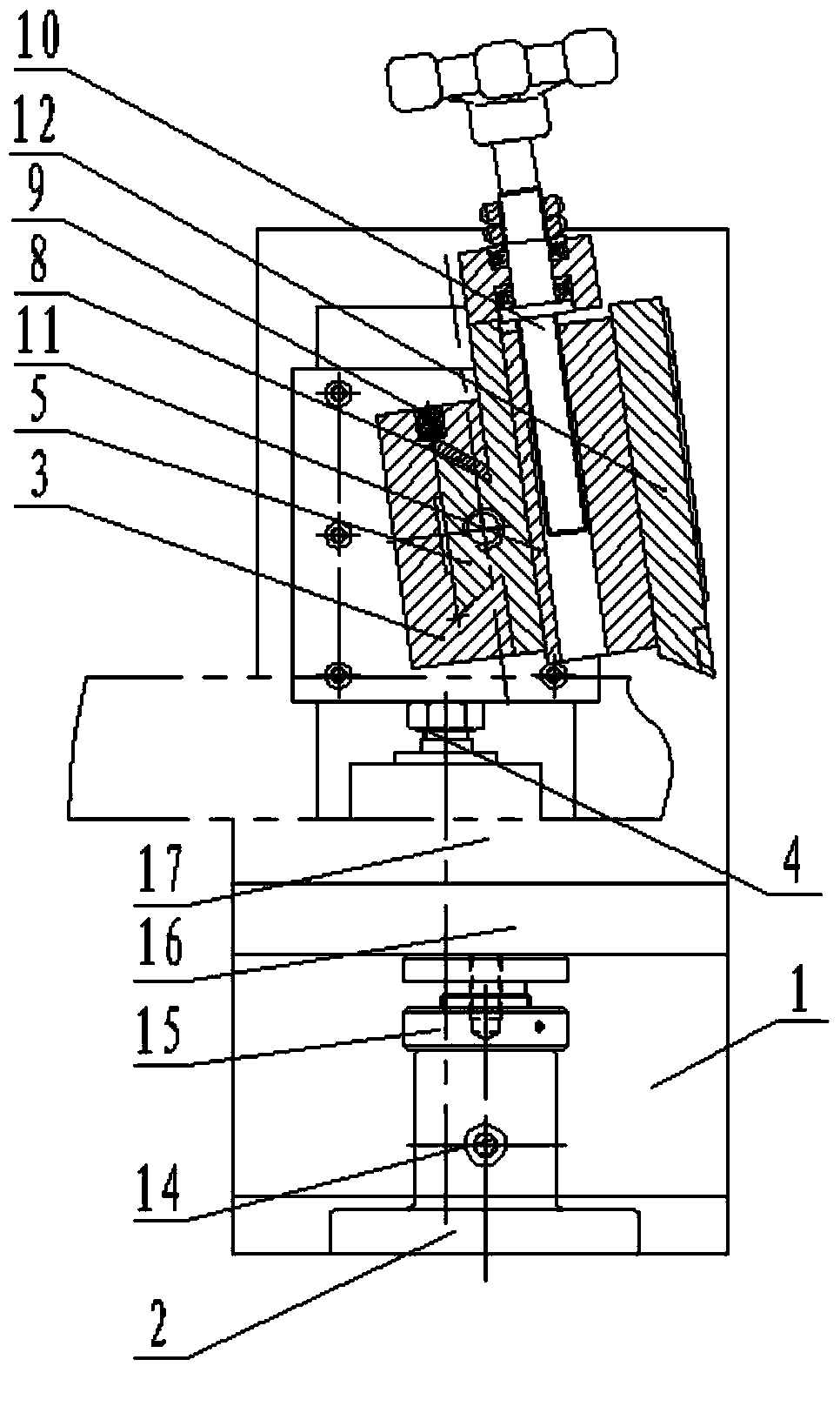

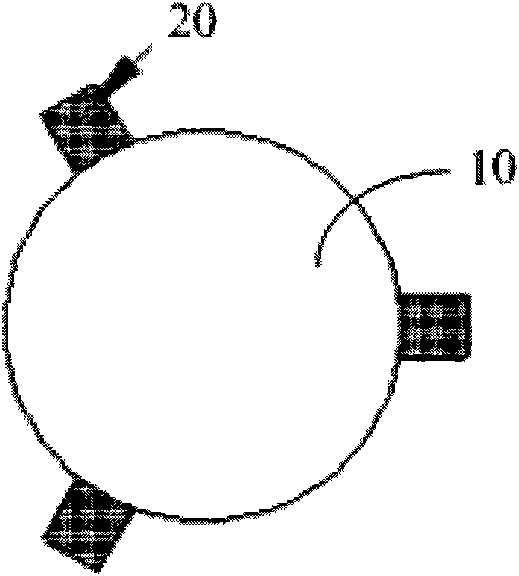

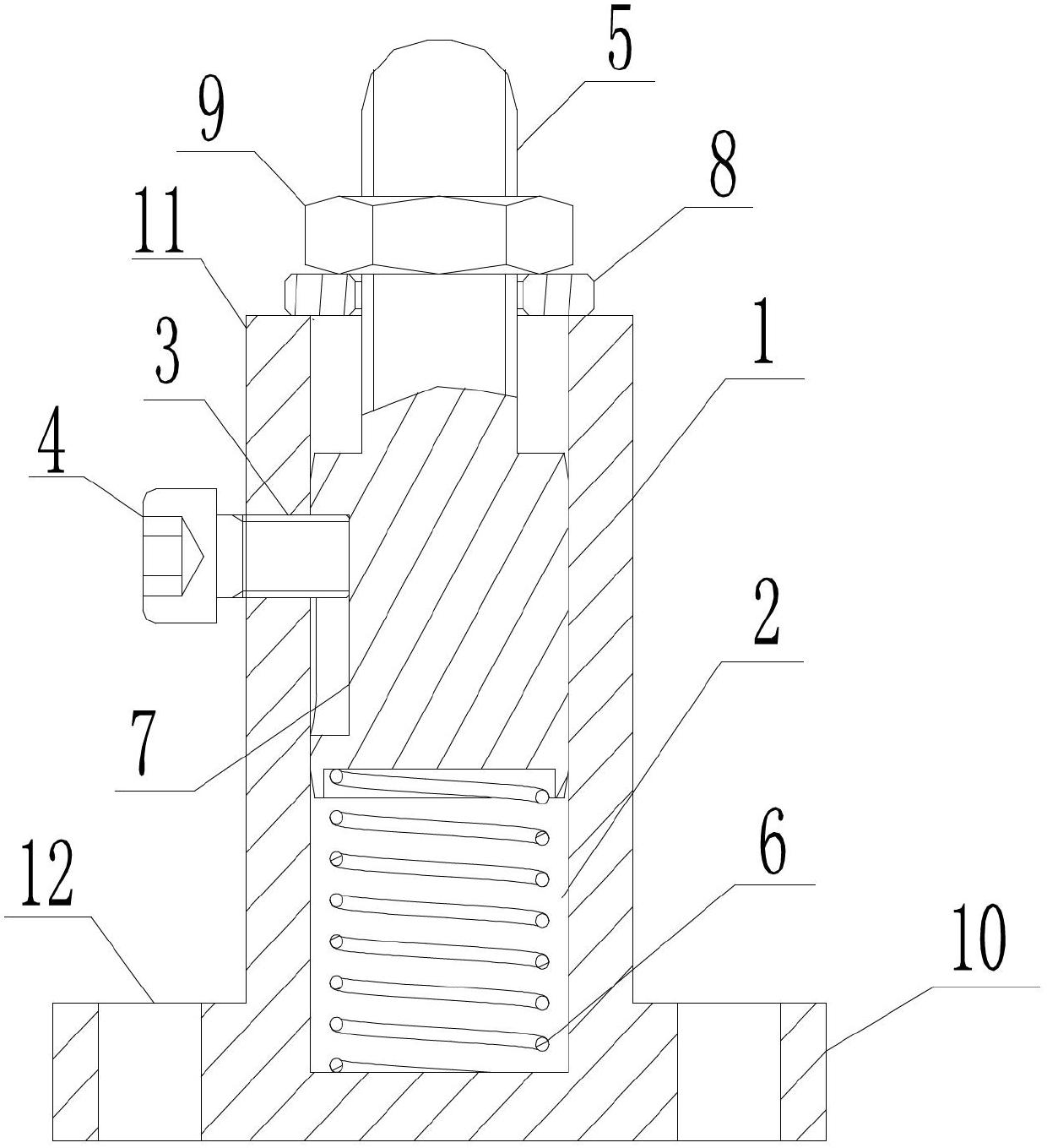

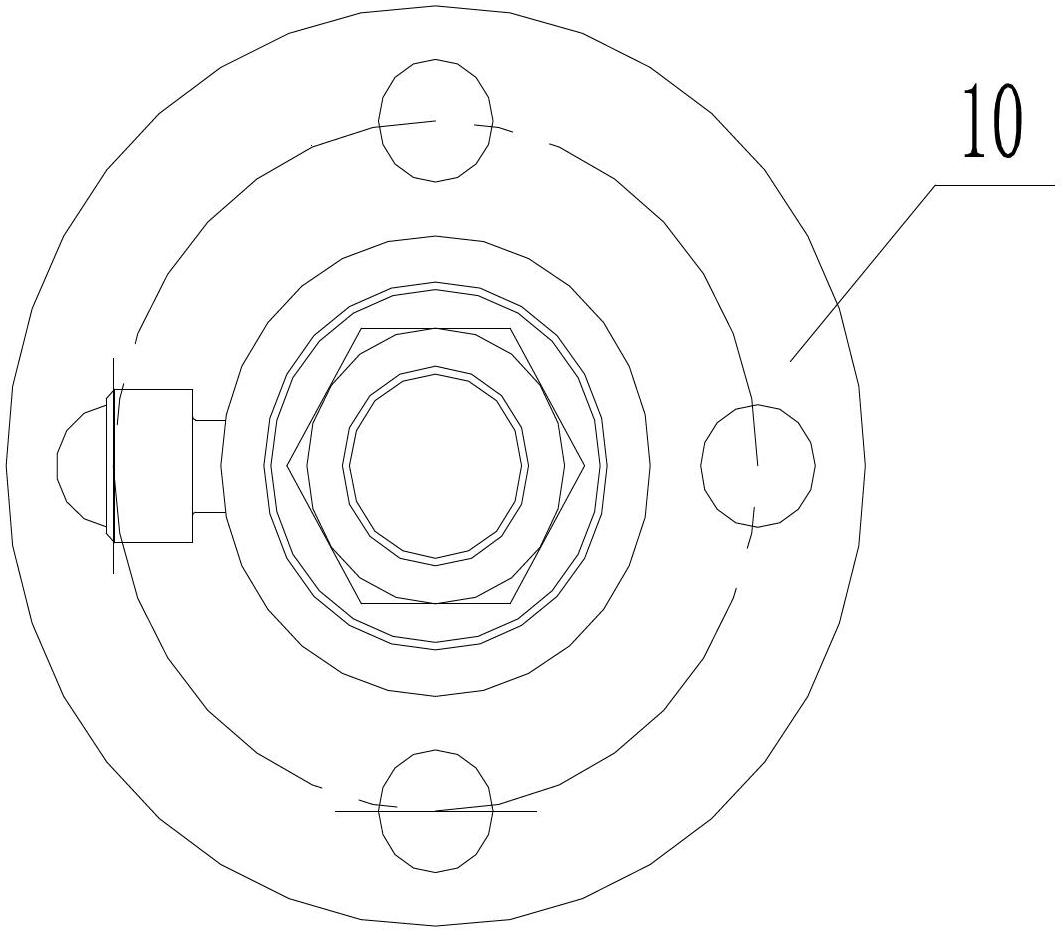

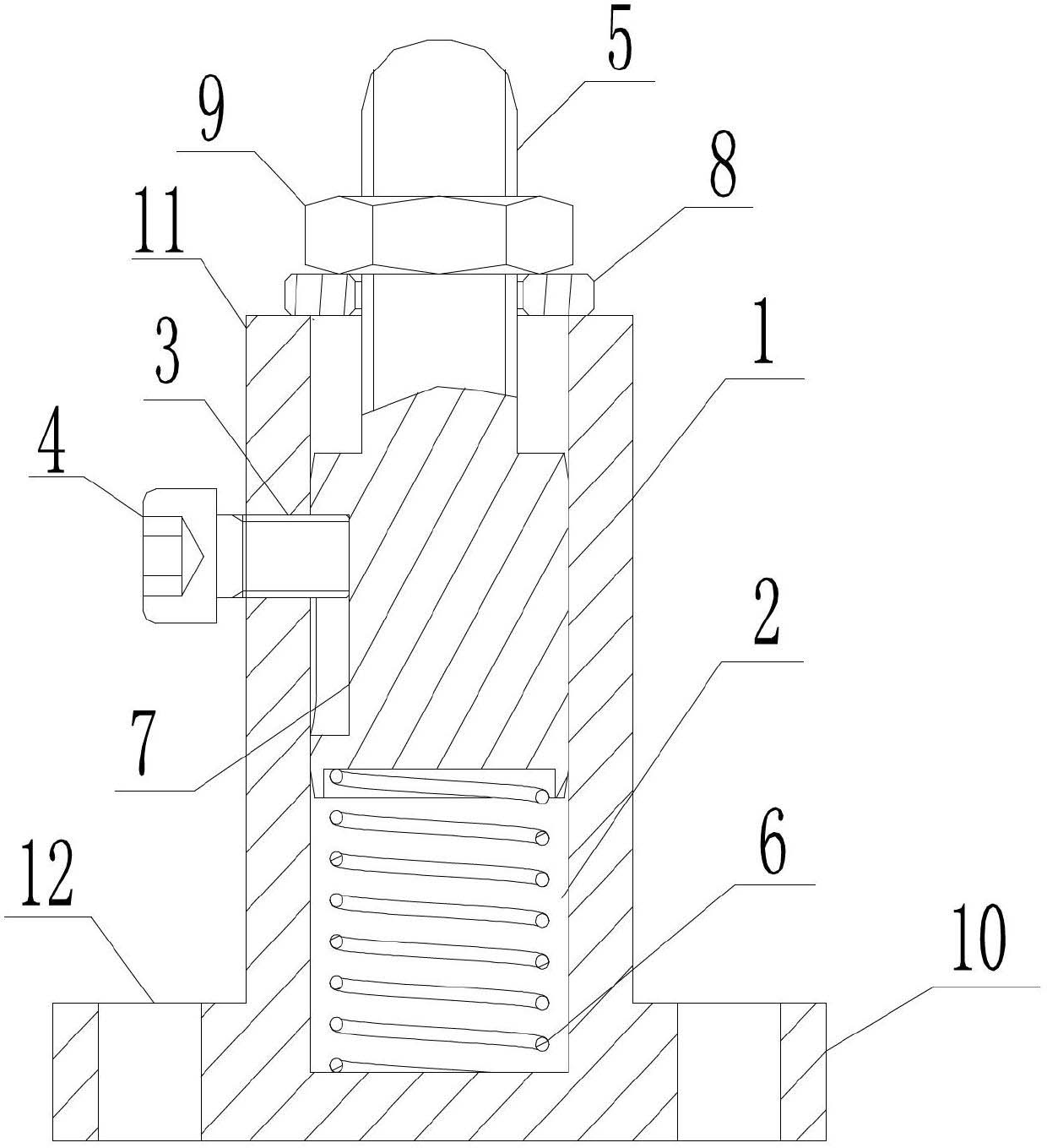

Spring auxiliary support

InactiveCN102672499ANot prone to vibrationNo chattering phenomenonPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to a spring auxiliary support which comprises a base. A shaft hole is arranged in the middle of the base, a screw hole is arranged on the lateral face of the base, and an inner hexagon screw is arranged in the screw hole. A supporting shaft is movably arranged in the shaft hole, a spring is arranged between the bottom of the shaft hole and the supporting shaft, a key groove is arranged on the lateral face of the supporting shaft, and a flat gasket and a hexagon thin nut are arranged at the upper portion of the supporting shaft. The spring auxiliary support is stable in force control and does not easily generate vibration when parts are machined, and vibration lines on the machining surfaces are avoided.

Owner:鹰普机械(宜兴)有限公司

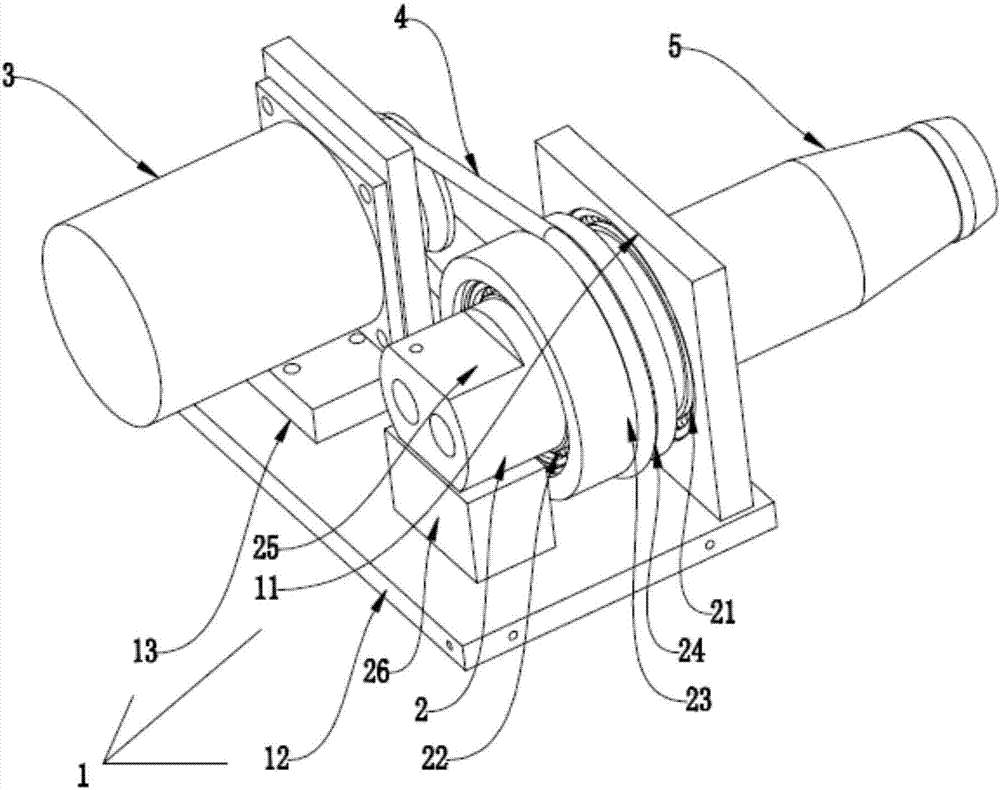

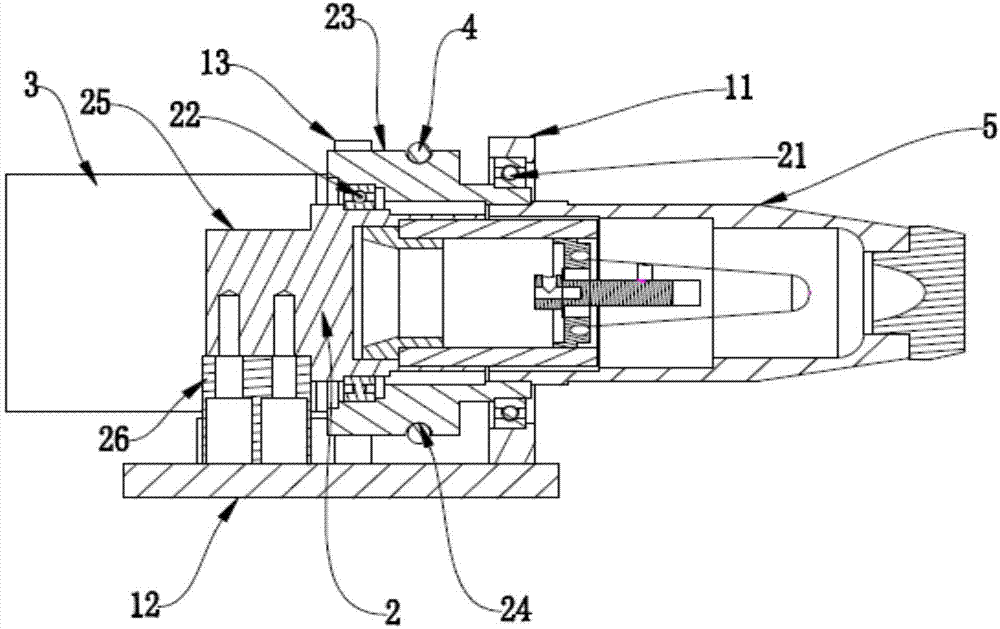

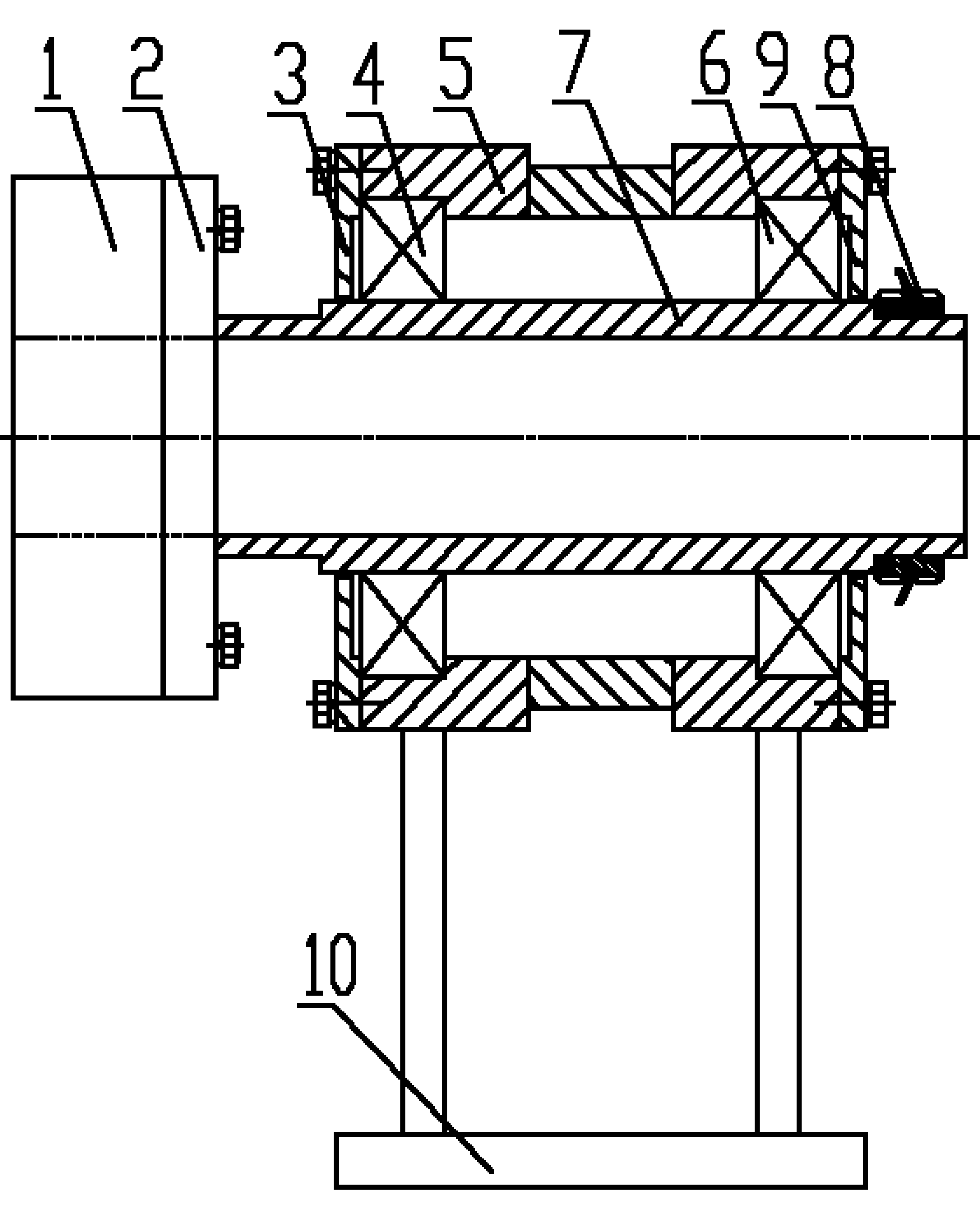

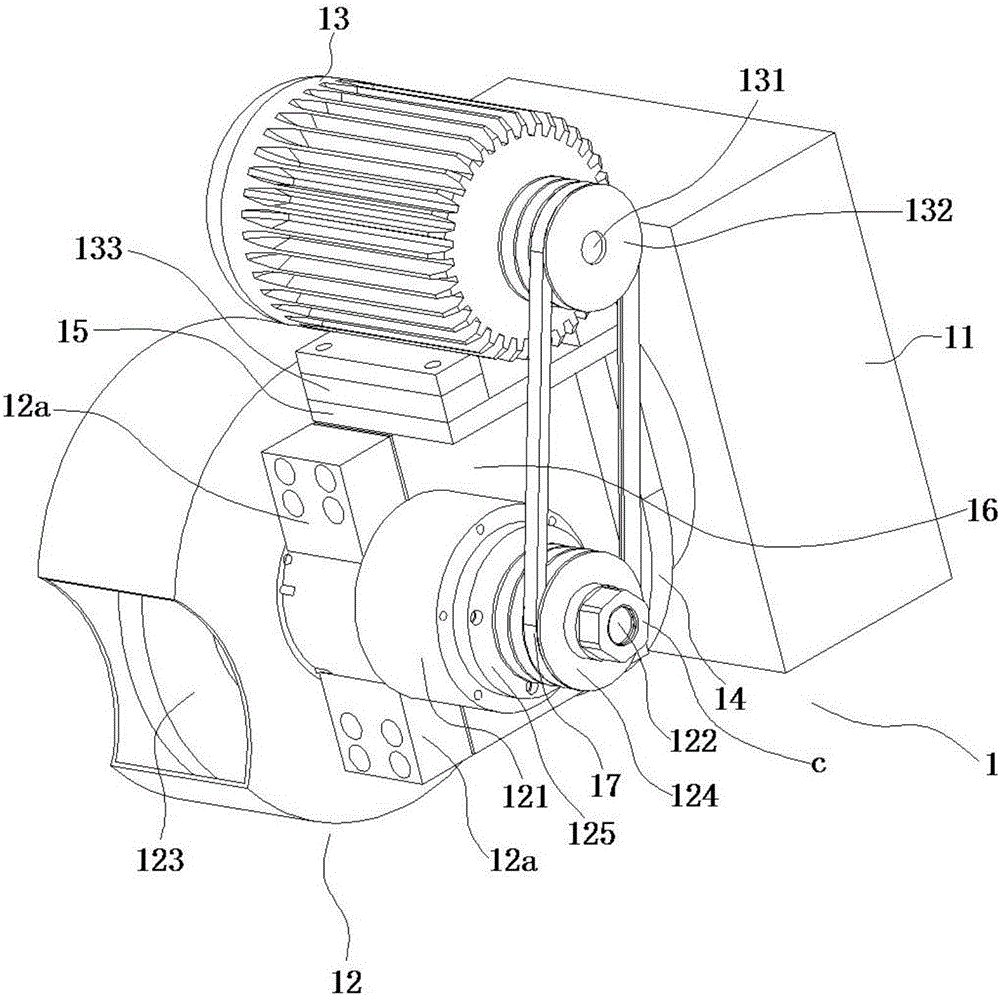

Plasma gun rotating device

InactiveCN103796410ANot prone to vibrationExpand the spraying rangePlasma techniqueMotor driveEngineering

A plasma gun rotating device comprises a rack, a motor, a conveyor belt, a plasma gun and a shaft core. The motor is fixed on the rack. The motor drives, through the conveyor belt, the shaft core to rotate. The plasma gun is arranged at the tail end of the shaft core. A bearing is arranged on the middle back portion of the shaft core. The shaft core is provided with a rotating shell. The bearing is arranged between the shaft core and the rotating shell. A spray head of the plasma gun is arranged in an inclined mode. The motor drives, through the conveyor belt, the plasma gun to rotate. The plasma gun rotating device expands the spraying range, improves spraying efficiency, reinforces the stability of the plasma gun in the spraying process, and realizes a better spray effect.

Owner:广东韦达尔传媒有限公司

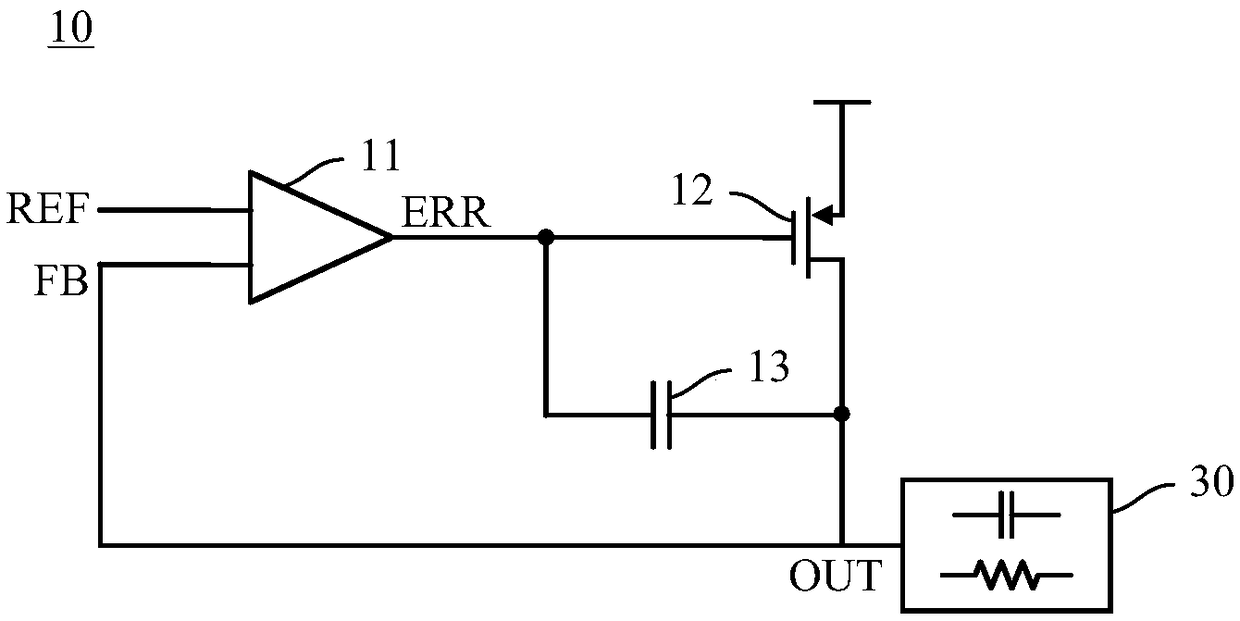

Low-pressure difference voltage stabilizer and flash memory

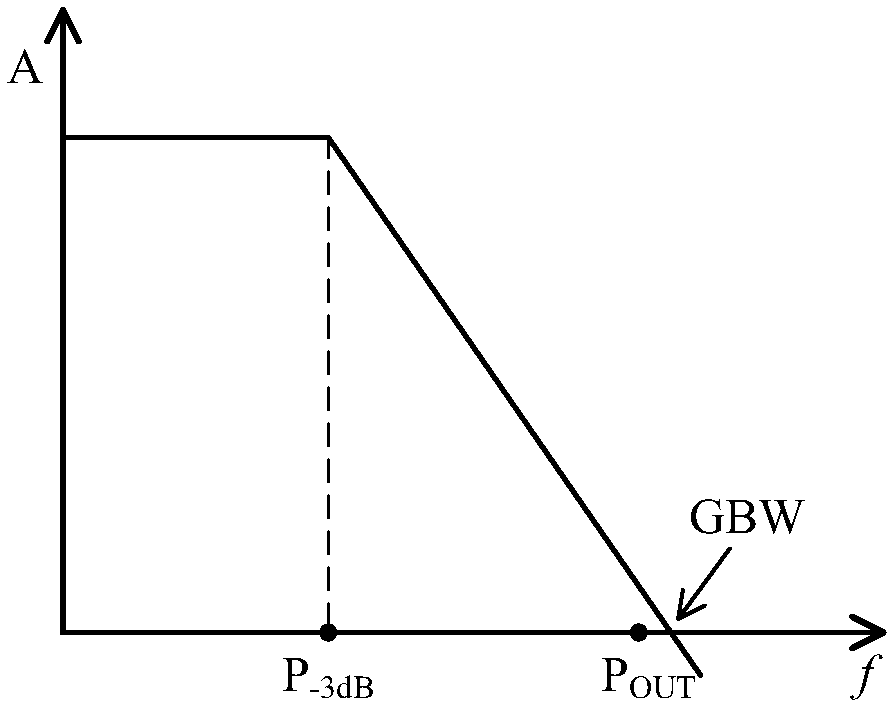

PendingCN108491020ANot easy to vibrateNot prone to vibrationRead-only memoriesElectric variable regulationCurrent loadControl signal

The invention provides a low-pressure difference voltage stabilizer and a flash memory. The low-pressure difference voltage stabilizer comprises a first-grade error amplifier, a power tube, a first Miller capacitor and a load detection circuit, wherein the power tube is connected with the first-grade error amplifier and suitable for outputting an adjusted output signal applied on load; the first Miller capacitor is arranged between an output end of the first-grade error amplifier and an output end of the power tube; the load detection circuit is suitable for generating a control signal according to a current load situation of the load; the first-grade error amplifier comprises a gain adjusting unit used for positively adjusting the gain of the first-grade error amplifier according to the control signal. The low-pressure difference voltage stabilizer has good stability when being no-load or light-load.

Owner:YANGTZE MEMORY TECH CO LTD

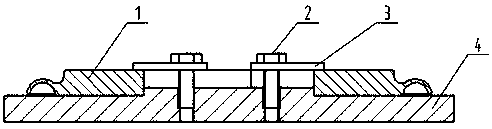

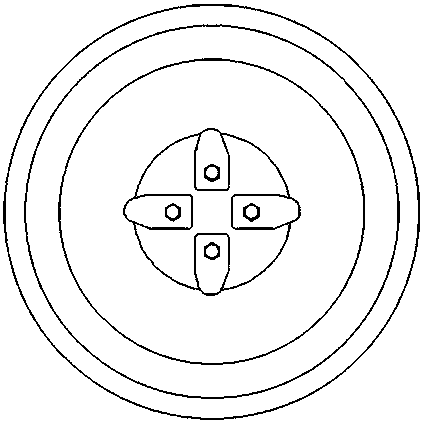

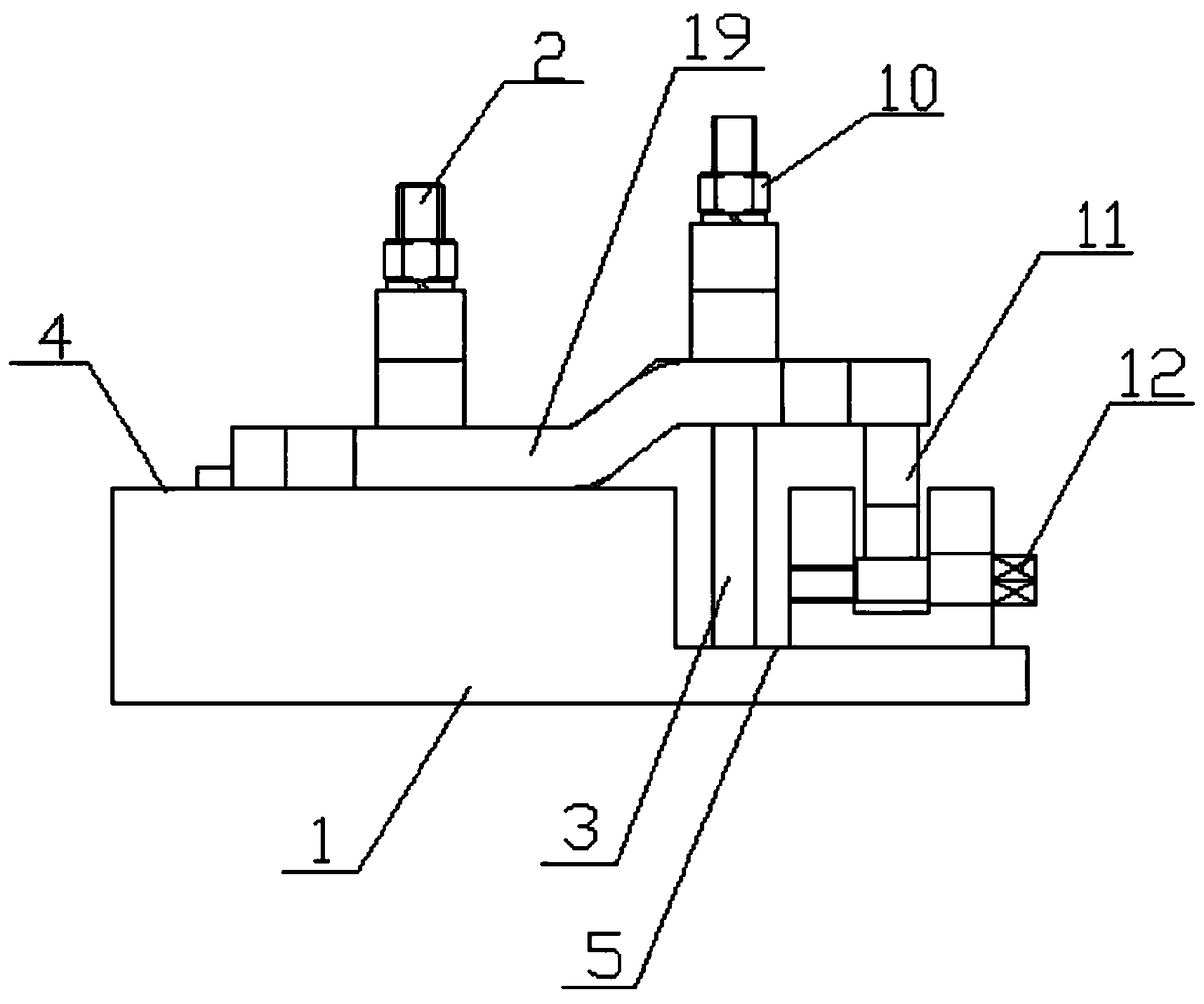

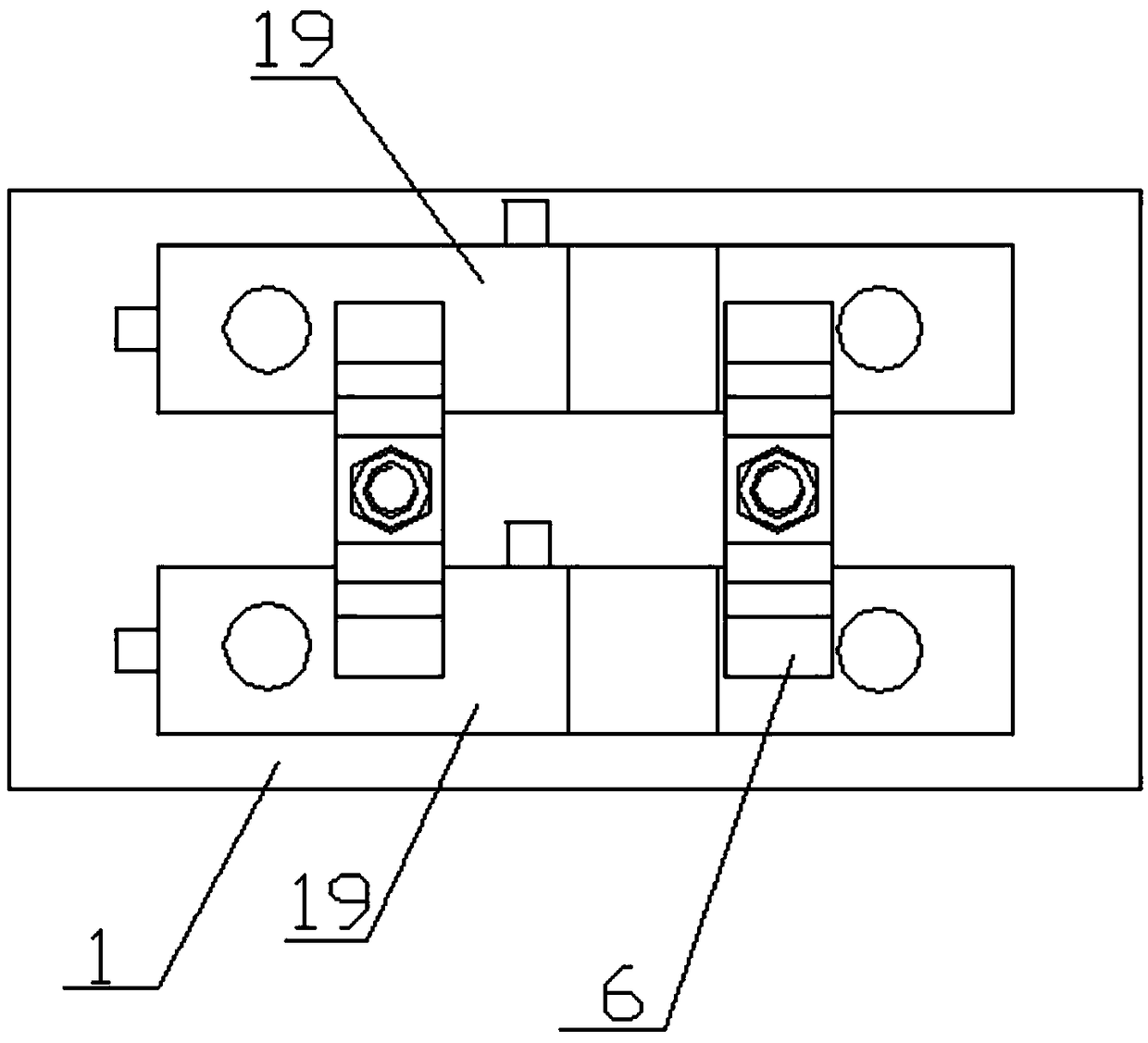

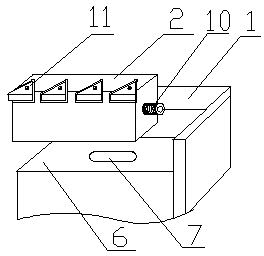

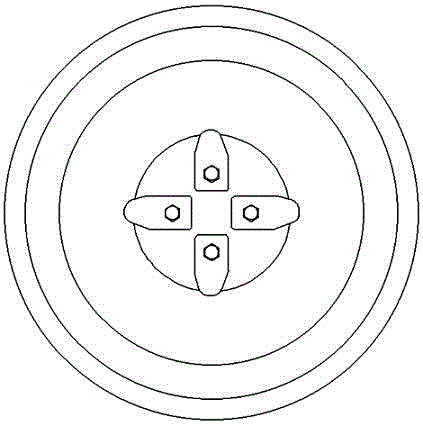

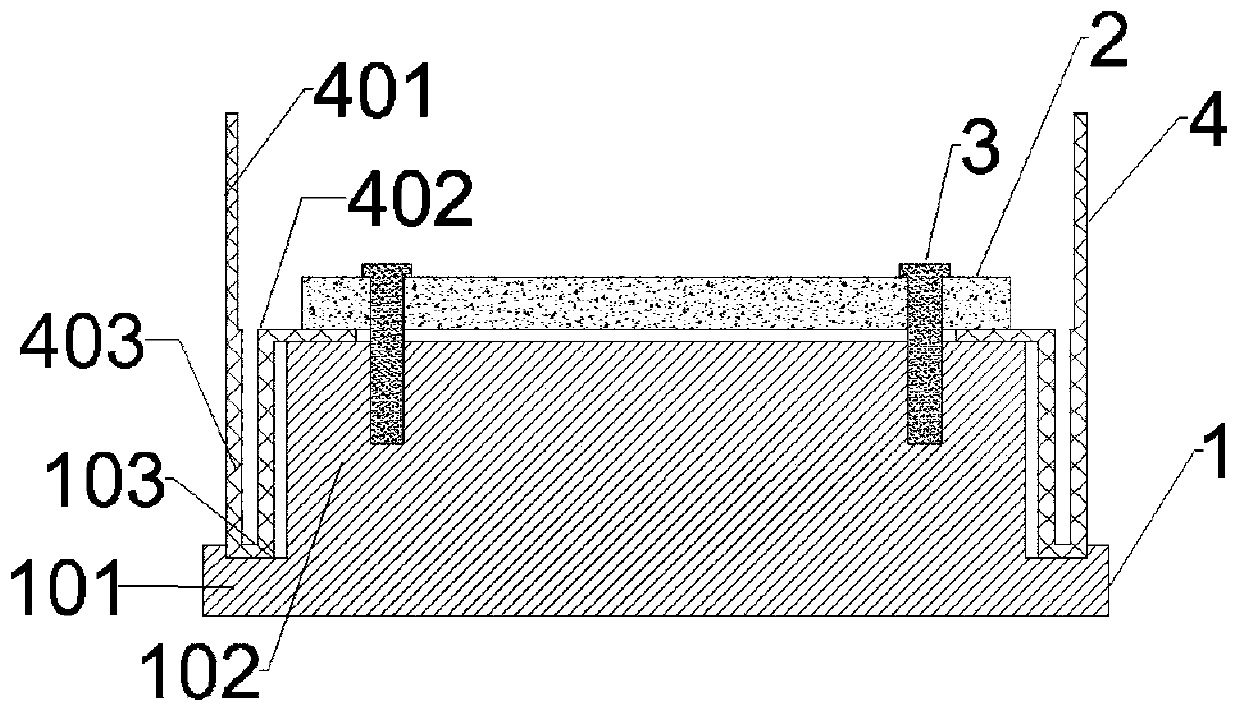

Specialized process mold for machining pi-ring sealing washer and manufacturing and use method

InactiveCN108453522ASmall amount of deformationNot prone to vibrationPositioning apparatusMetal-working holdersProduction rateSheet steel

The invention provides a specialized process mold for machining a pi-ring sealing washer and a manufacturing and use method, wherein the mold and the method belong to the field of heat exchanger sealing inner member processing. The process mold ensures processing precision of the pi-ring sealing washer. The specialized process mold comprises a two-step frustum, bolts and a pressure plate. The thickness of the base plate of the two-step frustum is not less than 60mm. The outer diameter of the base plate of the two-step frustum is larger than the designed diameter of the pi-ring sealing washer.The height of a boss is 7mm. The diameter of the boss is smaller than the actual dimension of the inner diameter of the pi-ring sealing washer by 3-15 [mu]m. Four bolt holes are uniformly distributedon the boss. The pressure plate is rectangular. The pressure feed end is a slope-shaped fillet. The pressure plate is internally provided with a hole. The mold is made of a steel plate. In machining of the pi-ring sealing washer, rough machining is performed on two planes, an inner circle and an external circle; then the pi-ring sealing gasket 1 is embedded into the process mold and is fixed by compressing screws 2 and the pressure plate 3; Semi-fine machining or fine machining is performed on the inner part and the outer part of the pi-ring. The specialized process mold and the manufacturingand use method have advantages of realizing simple manufacture and easy operation, ensuring machining of the qualified pi-ring sealing washer, effectively shortening production period and improving productivity.

Owner:LANZHOU LS HEAVY EQUIP

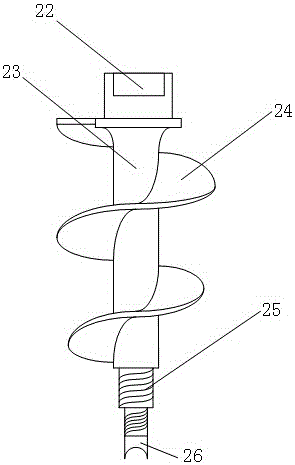

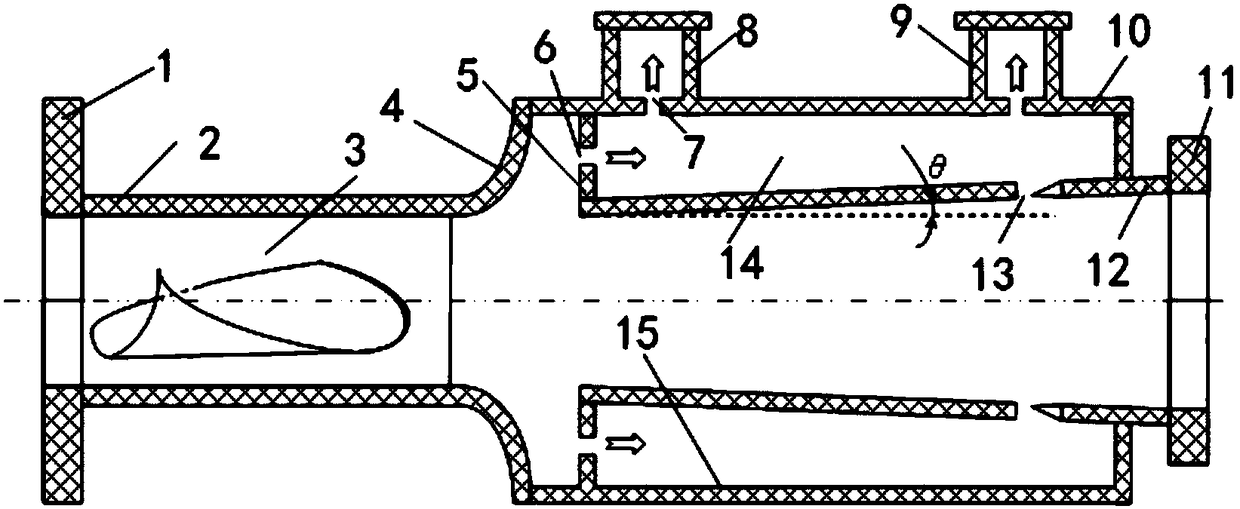

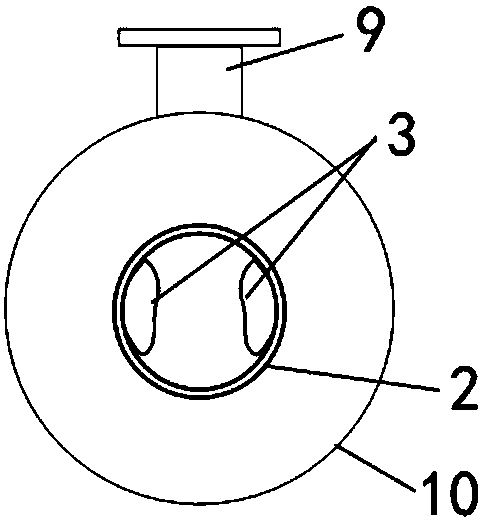

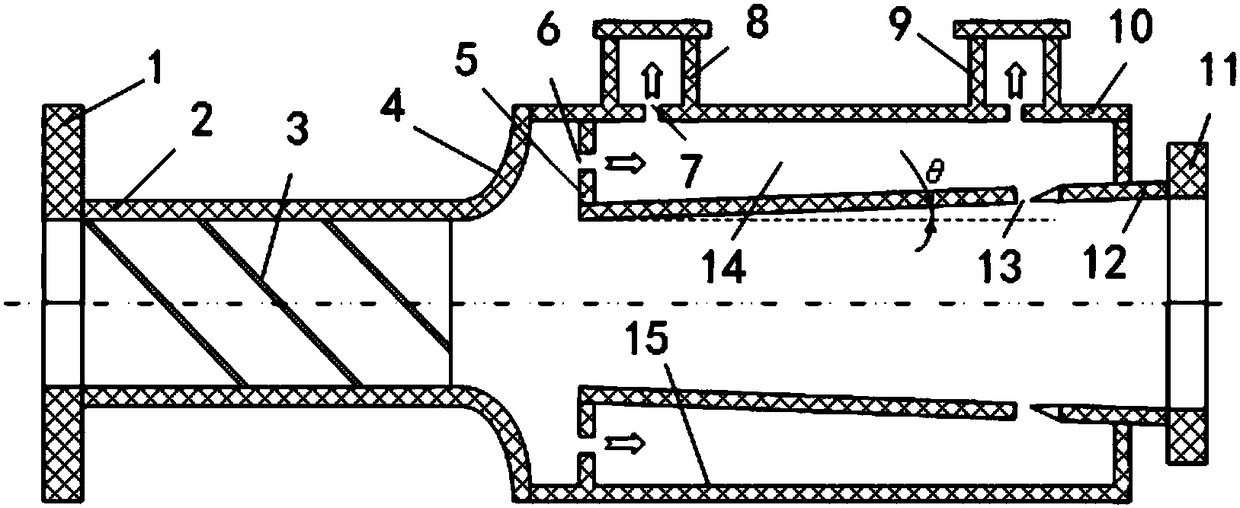

Mine tunnel water gushing-out advance rescue real-time embedded control device

ActiveCN106020025ANot easy to skewNot prone to vibrationProgramme controlMining devicesSound sourcesWater source

The invention relates to a mine tunnel water gushing-out advance rescue real-time embedded control device, and belongs to the technical field of real-time embedded detection control. The device is composed of device front part, a device middle part and a device rear part. The device front part comprises a device front part spiral bit. The device middle part is composed of a rotary joint, a telescopic rod, a claw part spiral bit, a forward driving claw, an external sound source receiving device, a communication module, a circulating moving plate, an LED light source and a three-dimensional imaging device. The device rear part comprises a cable data wire I, a power supply line I, an air channel, a rescue goods bin and a sound transmit-receive device. The mine tunnel water gushing-out advance rescue real-time embedded control device is capable of entering a rescue point to contact trapped persons in time after a water gushing-out accident of a mine tunnel and before a life channel is available, determining the trapped position and the surrounding environment, and providing bases and guidance for the next search and rescue decision; in addition, the device is internally provided with the rescue goods bin and the air channel, thereby providing the basic water source, food, drugs and fresh air to the trapped persons.

Owner:KUNMING UNIV OF SCI & TECH

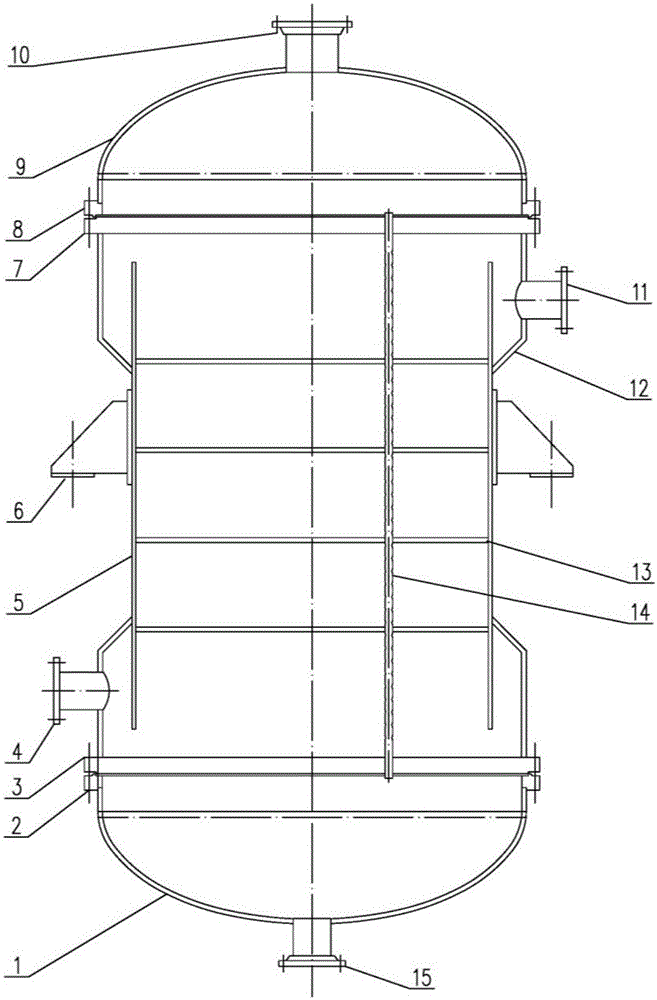

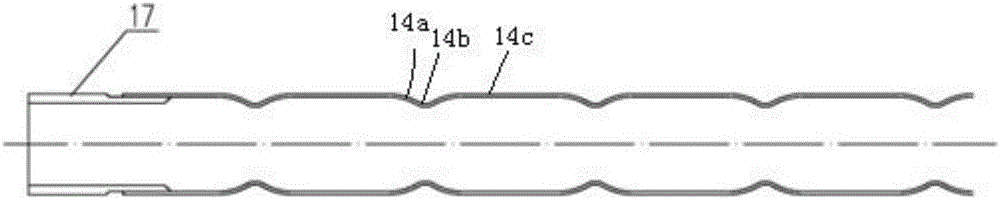

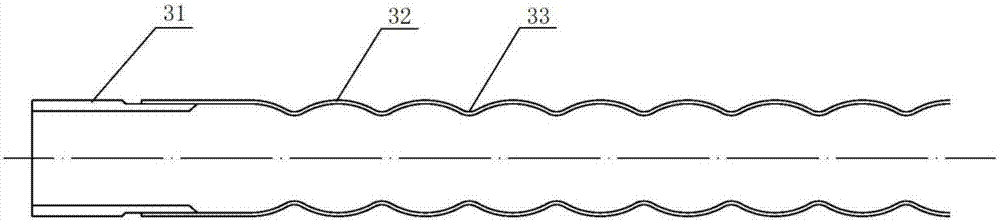

Corrugated straight pipe heat exchanger and heat exchange method

InactiveCN105841523AIncreased turbulenceImprove heat transfer efficiencyStationary tubular conduit assembliesHeat transfer modificationStraight tubeEngineering

The invention relates to a corrugated straight tube heat exchanger and a heat exchange method thereof. The corrugated straight tube heat exchanger is composed of an upper tube box, a shell-side cylinder and a lower tube box. The upper tube box is provided with a tube-side medium inlet. The lower tube box is provided with a tube-side medium outlet, and the two sides of the shell-side cylinder are respectively provided with a shell-side medium inlet and a shell-side medium outlet; A plurality of corrugated straight tubes are vertically arranged in the cylinder body as heat exchange tubes. The main body of the corrugated straight tubes is a structure of corrugated tube sections plus straight tube sections, that is, a cycle of waveform includes crest-straight-line segment-peak-trough; both ends of the corrugated straight tube A smooth straight tube is used for fixed connection with the upper and lower tube sheets, and the shell-side cylinder is provided with a plurality of square-hole jet plates along the height direction. The invention effectively improves the heat exchange efficiency, suppresses the formation of dirt, and solves the wear problem between the heat exchange tube and the baffle plate. In addition, it also has the advantages of convenient disassembly of the heat exchange tube, small equipment volume, and low cost.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Cranked plate hole-boring clamp

ActiveCN108381235AGuaranteed pressing forceImprove vibrationWork clamping meansPositioning apparatusEngineeringSelf positioning

The invention discloses a cranked plate hole-boring clamp. The cranked plate hole-boring clamp comprises a base, a first threaded rod, a second threaded rod, a floating self-positioning device and twofloating pressing devices. The base is provided with a first workpiece supporting surface and a second workpiece supporting surface, and the height of the second workpiece supporting surface is lessthan that of the first workpiece supporting surface. Each floating pressing device comprises a floating pressing plate and a pressing cushion block. The two sides of the lower end surface of each floating pressing plate are provided with pressing plate supporting parts correspondingly. The upper end faces of the floating pressing plates are provided with arc surface protrusions. The lower end faces of the pressing cushion blocks are provided with positioning grooves matched with the arc surface protrusions. The lower end of the first threaded rod sequentially penetrates through a locking nut,the corresponding pressing cushion block and the corresponding floating pressing plate and then is connected to the first workpiece supporting surface. The lower end of the second threaded rod sequentially penetrates through a locking nut, the corresponding pressing cushion block and the corresponding floating pressing plate and then is connected to the second workpiece supporting surface. The cranked plate hole-boring clam can clamp two to-be-machined workpieces at a time, and the machining precision of the workpieces can be improved.

Owner:ANHUI HUANGSHAN HENGJIU CHAIN TRANSMISSION CO LTD

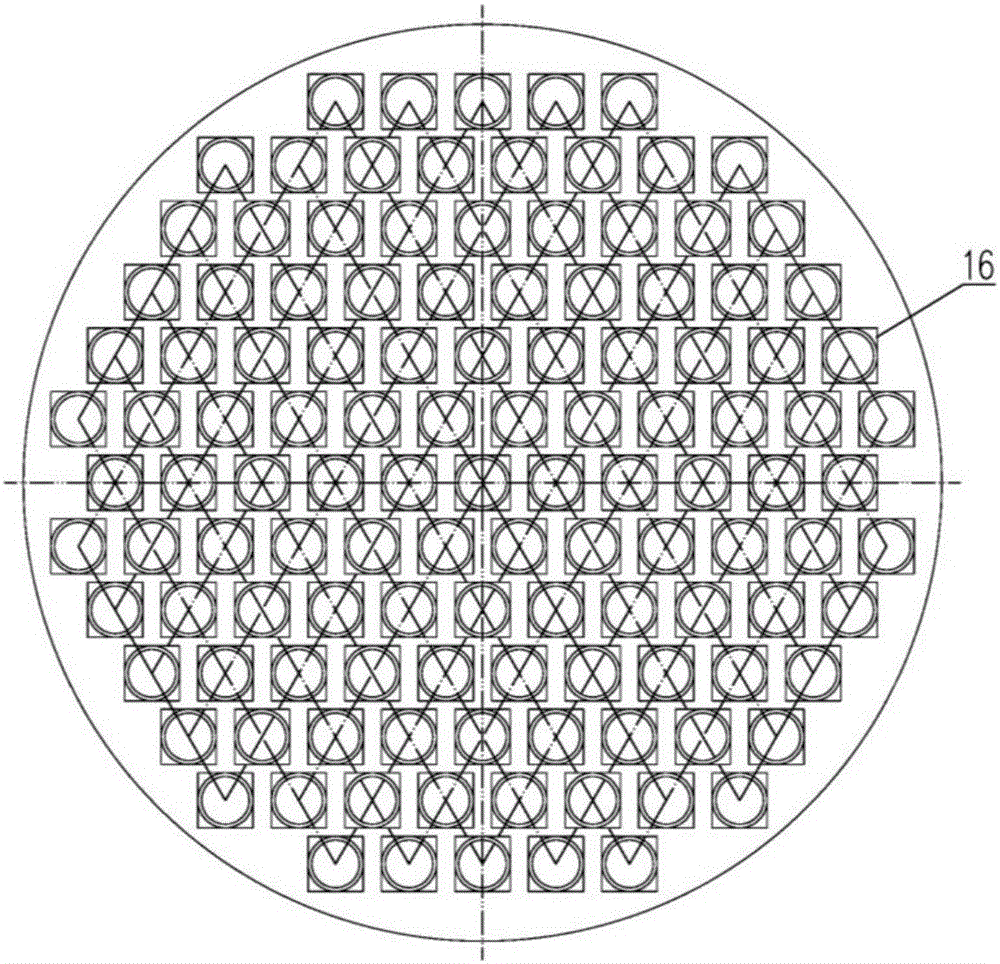

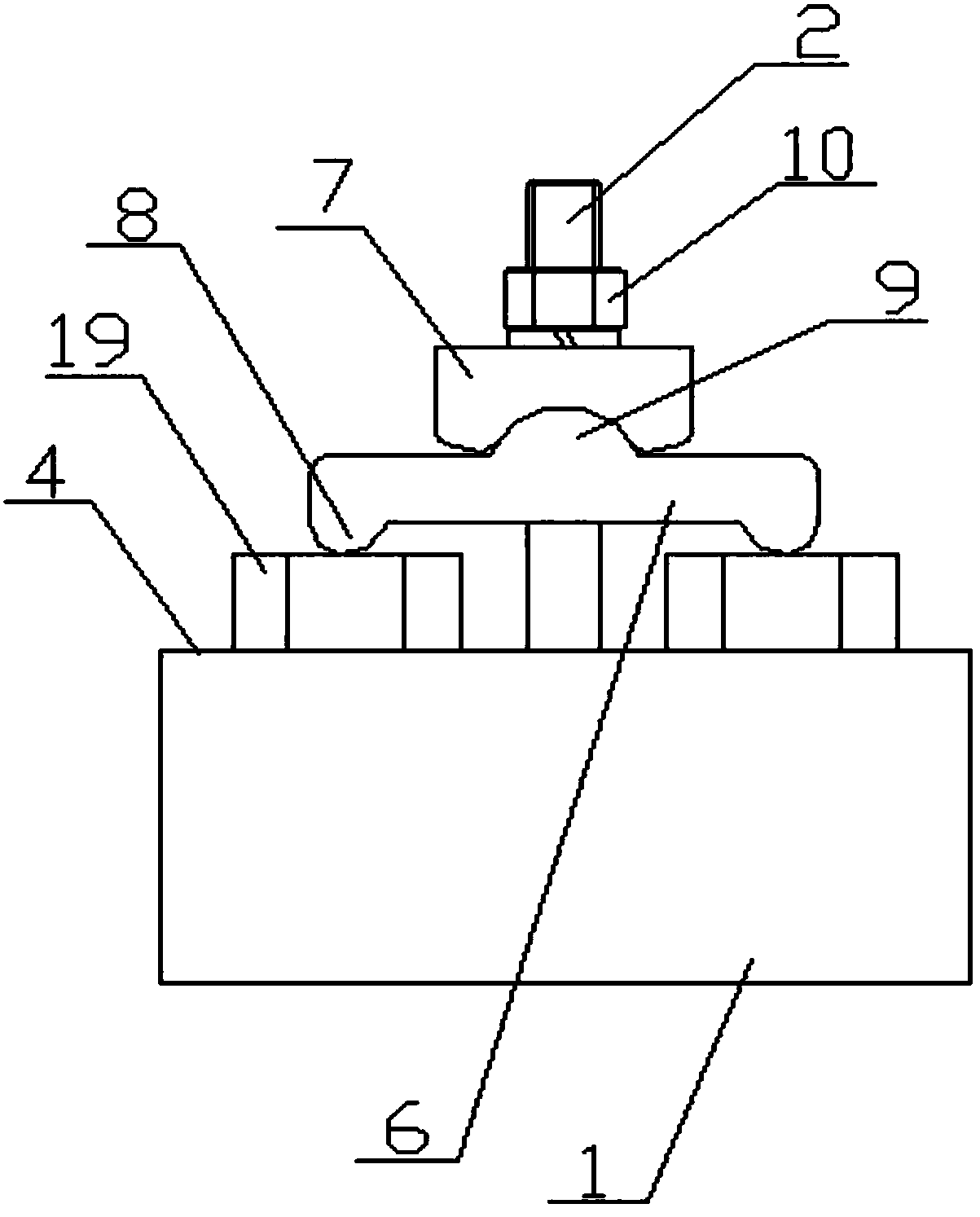

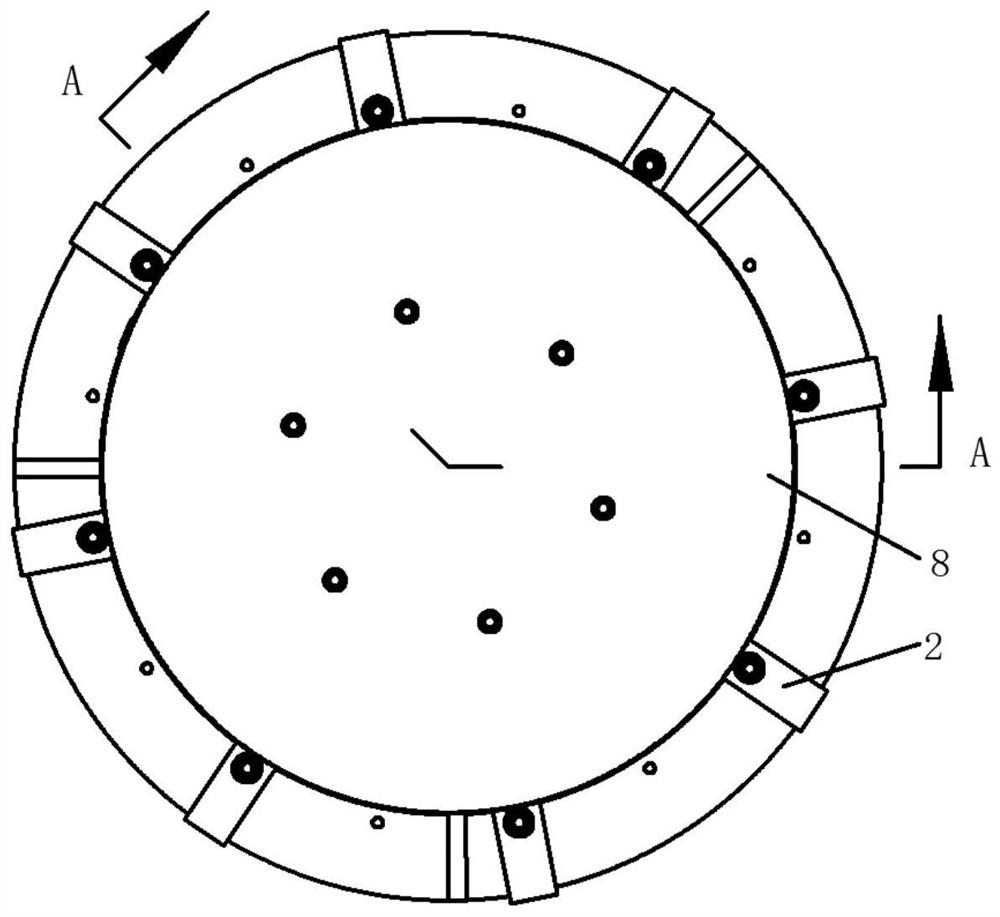

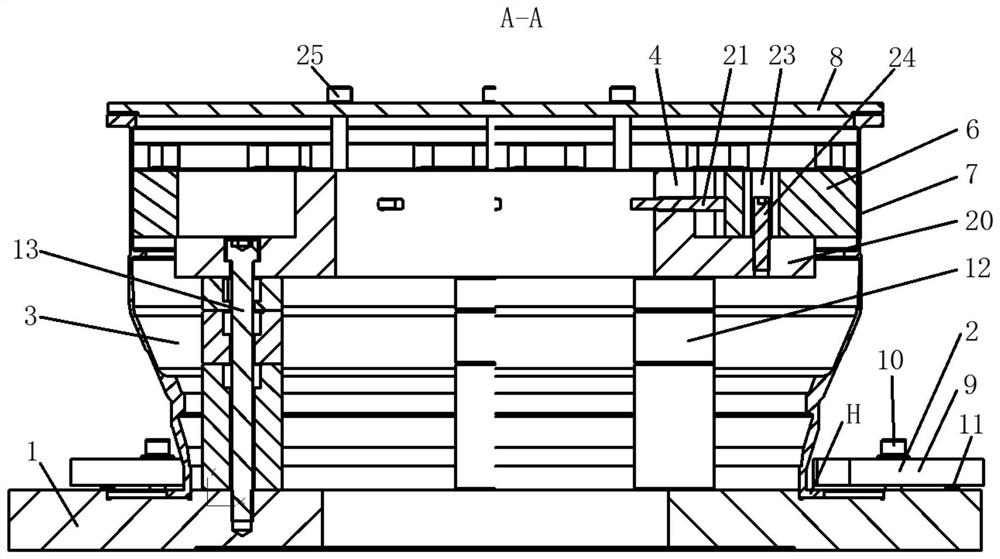

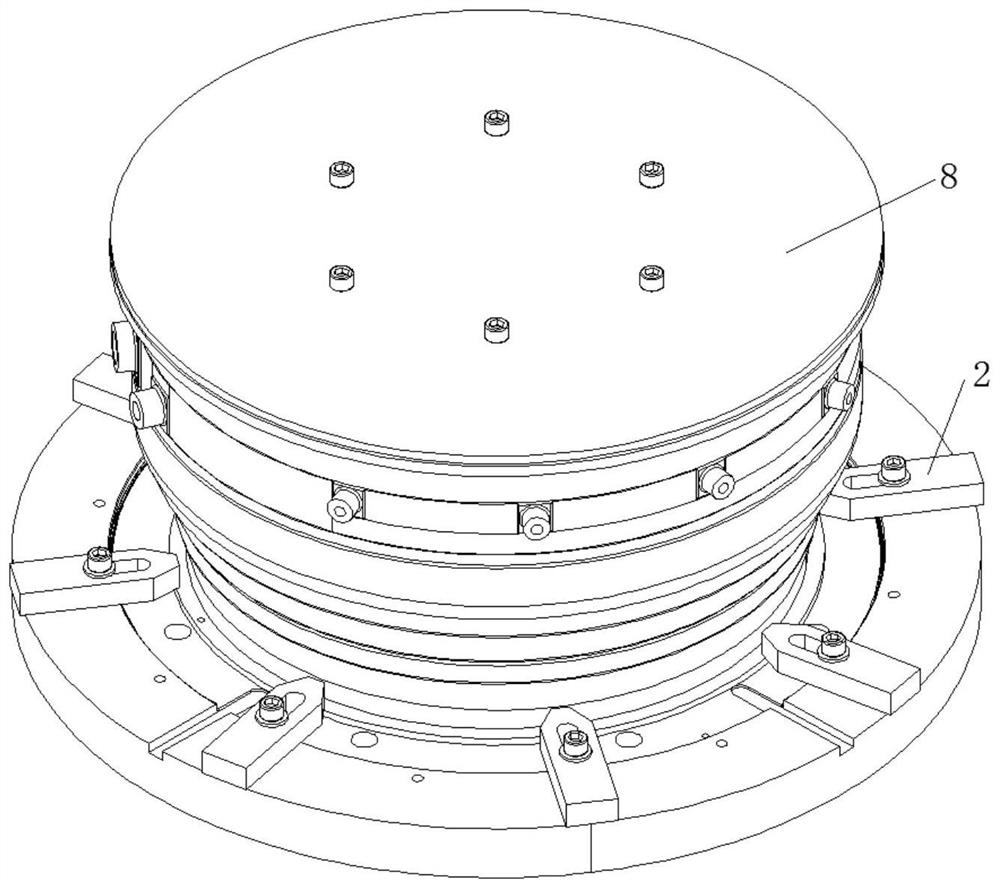

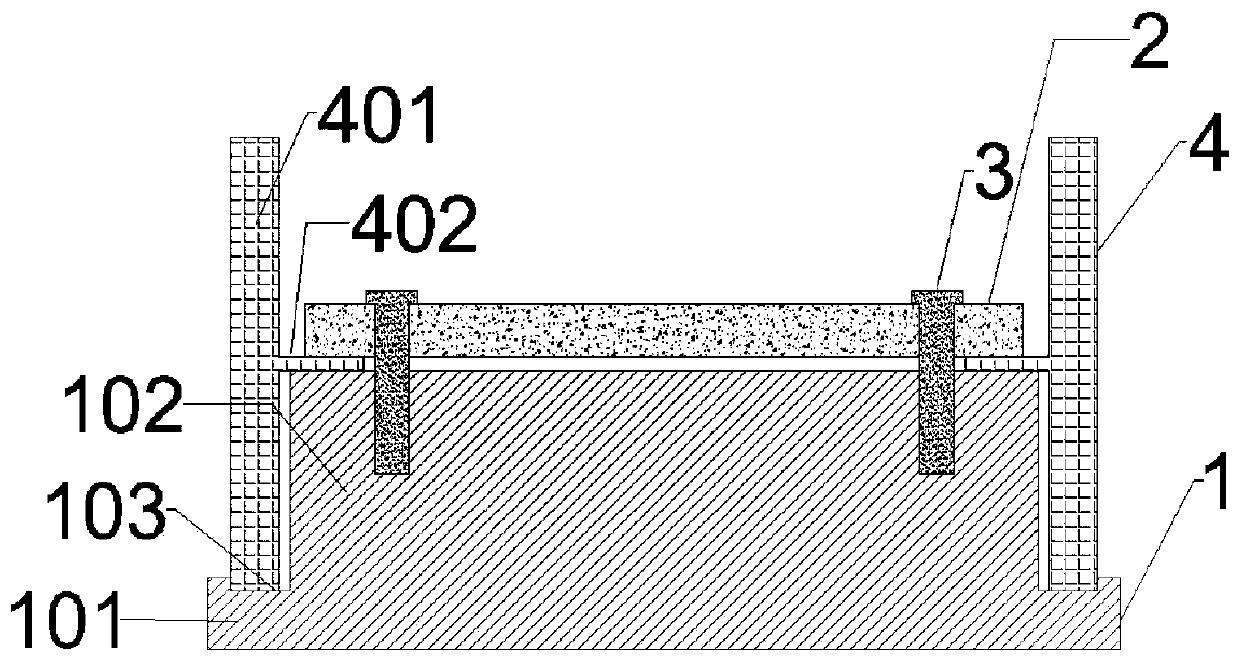

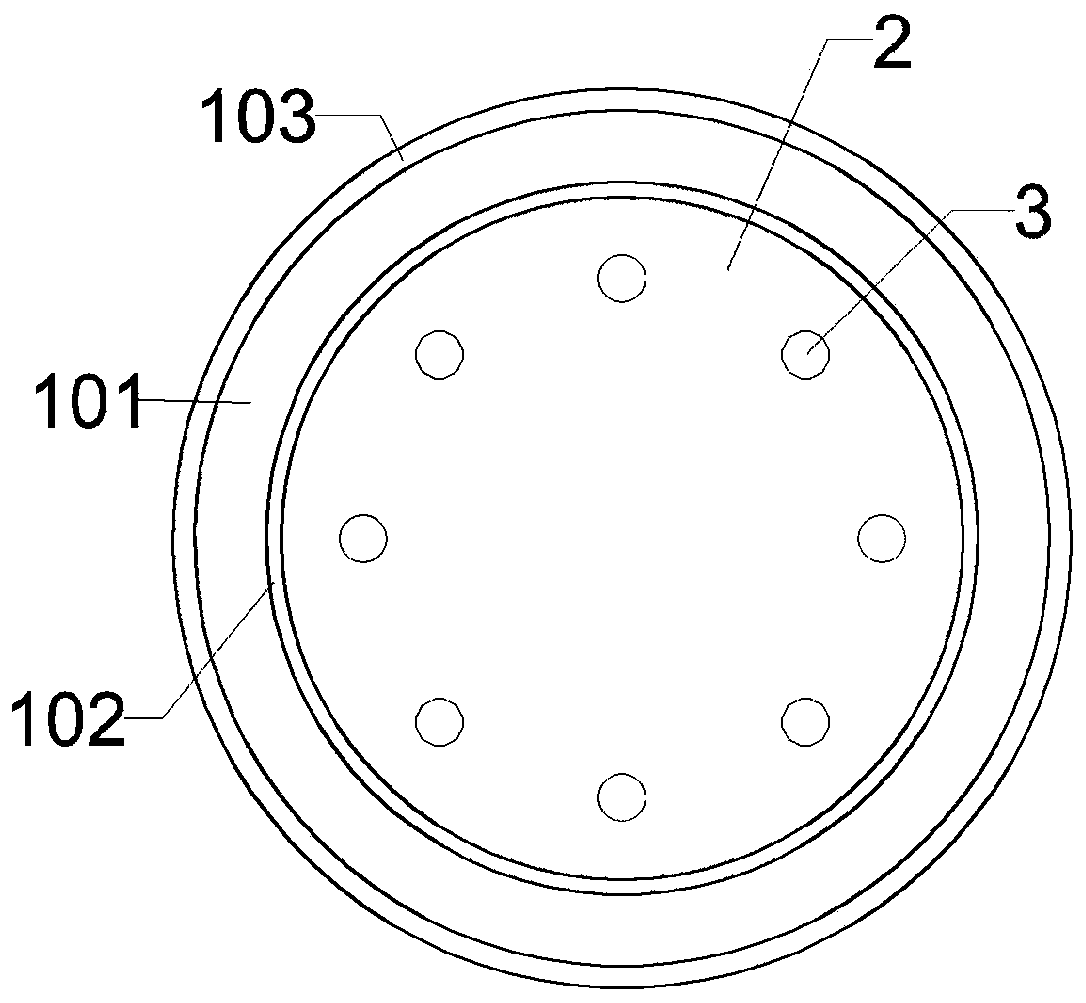

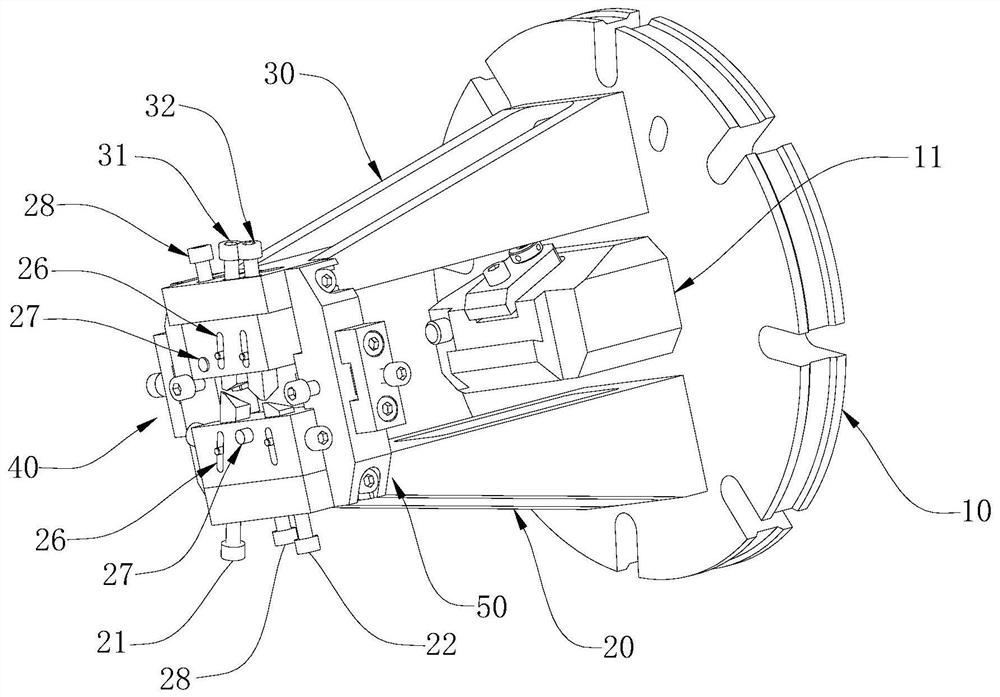

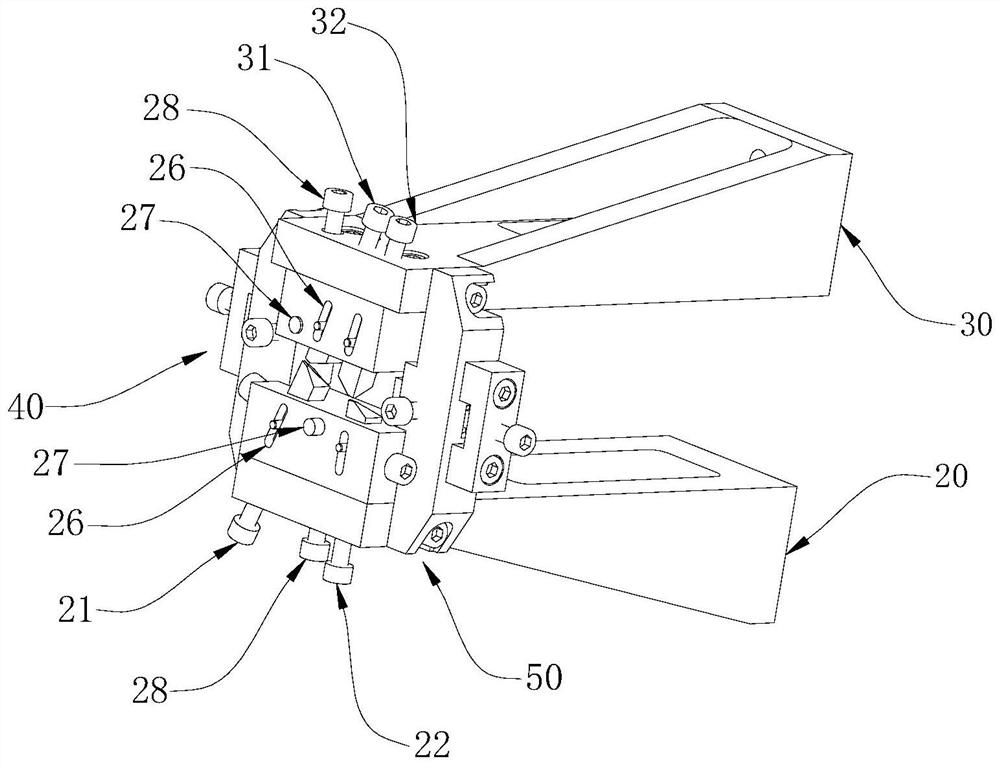

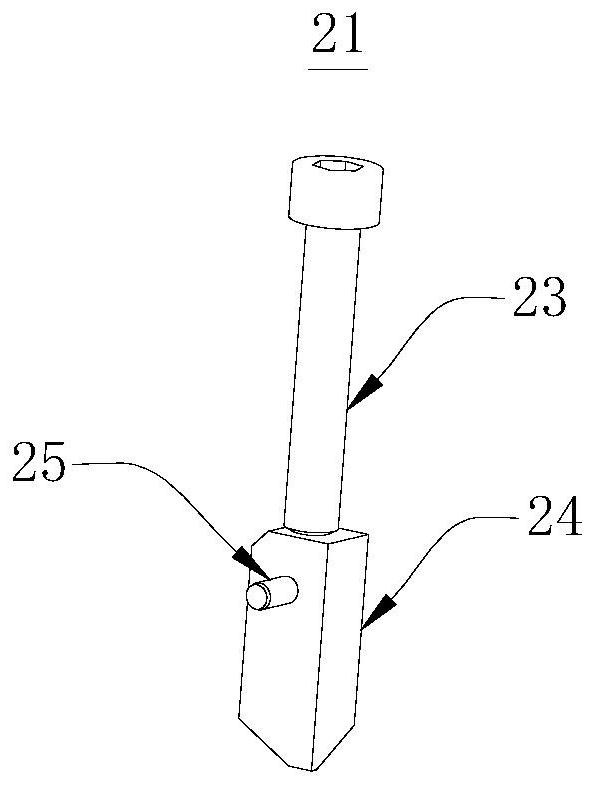

Clamp for machining annular casing of aero-engine with large length-diameter ratio

PendingCN111975406AReduce vibrationClamp firmlyWork clamping meansPositioning apparatusStructural engineeringMachining process

The invention relates to a clamp for machining an annular casing of an aero-engine with a large length-diameter ratio. The clamp comprises a chassis, wherein a pressing device is arranged at the top end of the chassis and can press and fix an annular plate at the bottom end of the annular casing at the top end of the chassis; an inner supporting assembly is detachably and fixedly connected above the chassis and comprises a plurality of supporting blocks which are arranged in the circumferential direction; the outer side surfaces of the supporting blocks can be pressed and attached to the innerwall of the top of the annular casing; a cover plate is detachably and fixedly connected above the inner supporting assembly; and the bottom surface of the cover plate can be pressed and attached tothe top surface of the annular casing. According to the clamp, the annular casing with the large length-diameter ratio is clamped on a five-axis linkage turning and milling composite machining centerat a time, so that the machining of the inner surface and the outer surface of the annular casing can be completed, the vibration of a workpiece is small in the machining process, and the thin wall ofthe annular casing is not easy to deform.

Owner:杭州天扬机械有限公司

Deep hole machining ejector drill

ActiveCN103737071AIngenious structureReliable chip breakingTransportation and packagingTrepanning drillsScrapCurrent limiting

The invention discloses a deep hole machining ejector drill. The deep hole machining ejector drill comprises a drill body, two tool chucks and a hollow connecting thread, and is skilful in structure. Tool bits are overlapped in a staggered way along the central line of a lower end face, two tool chuck mounting grooves are unequal in lengths, and the length of a longer tool chuck mounting groove is 0.5-1 millimeter larger than the radius of the drill body. During working, cutting edges cover an entire machining surface, and the machining surface is flat. Since a plurality of cutting edges are adopted for cutting, reliable chip breaking is ensured, and scrap iron is fine and easy to discharge and is prevented from blocking. Acting force produced in a cutting process is shared by a plurality of tool bits, thereby prolonging the service lives of the tool bits. The aim of controlling the water current is fulfilled by using a current limiting plate, cutting edges can be cooled fully, and the service lives of the tool bits are prolonged. Since cutting edges of the drill bits are replaced by easily-replaceable parts such as tool chucks and tool bits, fittings can be replaced, tool bodies are protected, and the production cost is reduced. Since drill body is provided with two vanes which are uniformly distributed around the central axis of the drill body, radial force acting on two symmetrical cutting edges in a machining process is counteracted, the drill body is prevented from vibrating, the surface accuracy of machined holes is increased, and the quality of a machined product is enhanced.

Owner:NINGBO RONGKE MAITE NC TOOLS

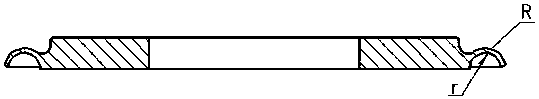

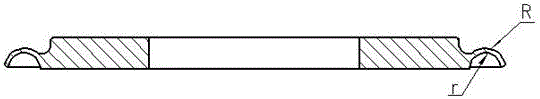

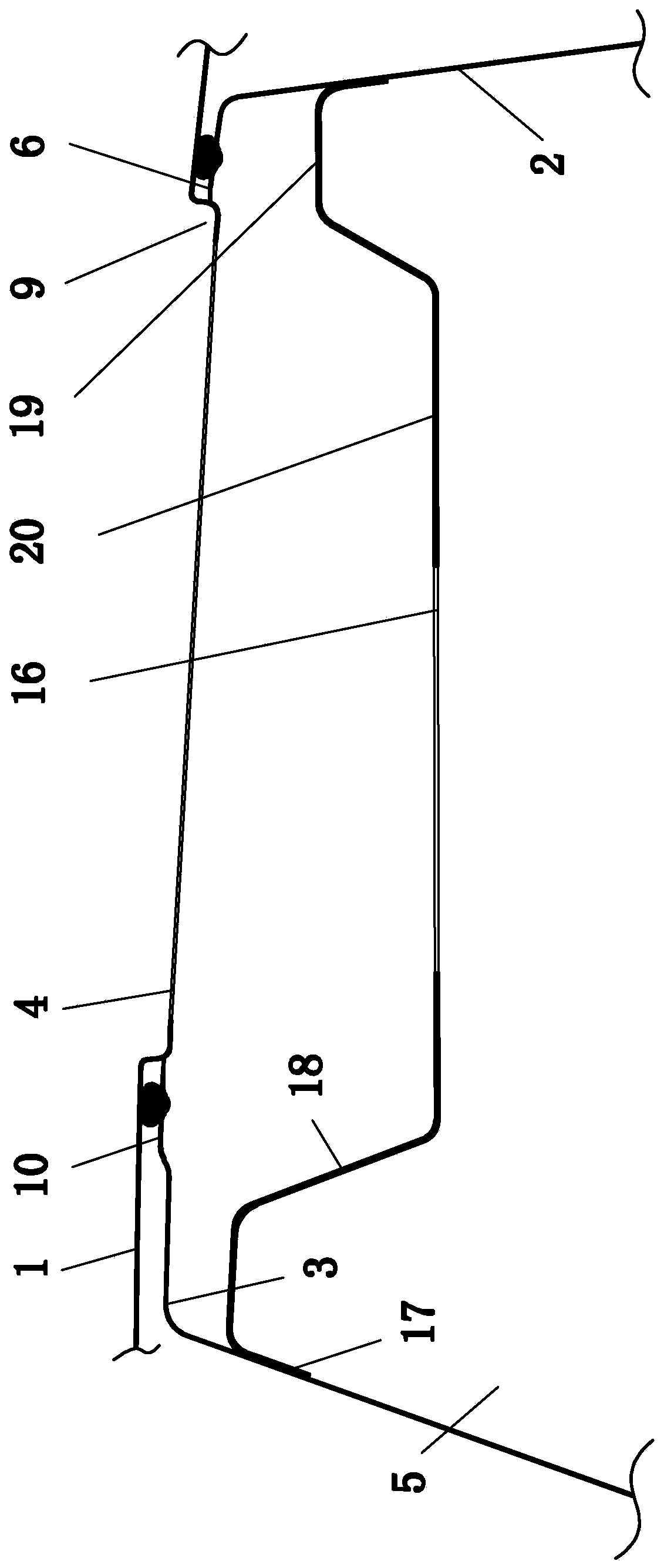

Machining method for omega-shaped ring sealing washer

InactiveCN106583755ASmall amount of deformationNot prone to vibrationProduction rateMachining process

The invention discloses a machining method for an omega-shaped ring sealing washer, and belongs to the field of heat exchanger sealing internals. By adoption of the machining method, the problems of deformation and poor precision in the machining process are solved. The machining method comprises the following steps that a special process mould invented by the company and used for machining the omega-shaped ring sealing washer is adopted; the two planes, the inner circle and the outer circle of the omega-shaped ring sealing washer are subjected to rough turning at first; the omega-shaped ring sealing washer 1 is embedded into the special process mould 4 during semi-finish turning and finish turning and fixed through compression bolts 2 and pressing plates 3, and the outer circle plane and the R part are machined; the workpiece is turned, and then the inner circle plane and the r part of the omega-shaped ring are machined, wherein the cut depth is 0.5-1 mm, the amount of feed is 0.5 mm / r, and the cutting speed is 40 m / min; and cooling liquid is continuously fed in the machining process, so that the temperature of the workpiece is not greater than 40 DEG C. According to the machining method for the omega-shaped ring sealing washer, vibration is not prone to occurring during machining of the omega-shaped ring sealing washer, operation is easy, it is guaranteed that the qualified workpiece can be machined, the production period is effectively shortened, and the productivity is increased.

Owner:LANZHOU LS HEAVY EQUIP

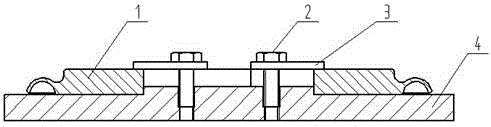

Clamping structure of thin-walled piece, clamping method of thin-walled piece and application of clamping structure of thin-walled piece

PendingCN110774030ARealize clampingGuaranteed flatnessPositioning apparatusMetal-working holdersEngineeringMachining process

The invention provides a clamping structure of a thin-walled piece. The clamping structure is provided with a base platform and a cover plate. The base platform comprises a base and a boss protrudingupwards from the center of the base. The boss is fixed to the cover plate through a fixing device penetrating through the cover plate to extend into the boss. Clamping of the thin-walled piece is achieved in a vertical clamping manner, the thin-walled piece cannot vibrate in the machining process, and therefore the flatness of the machined thin-walled piece can be guaranteed. By the adoption of the clamping method of the clamping structure of the thin-walled piece, the thin-walled piece is arranged between the boss and the cover plate, rapid clamping can be achieved, the thin-walled piece canbe effectively prevented from twisting and deforming in the machining process, and machining requirements of semiconductor parts can be better met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

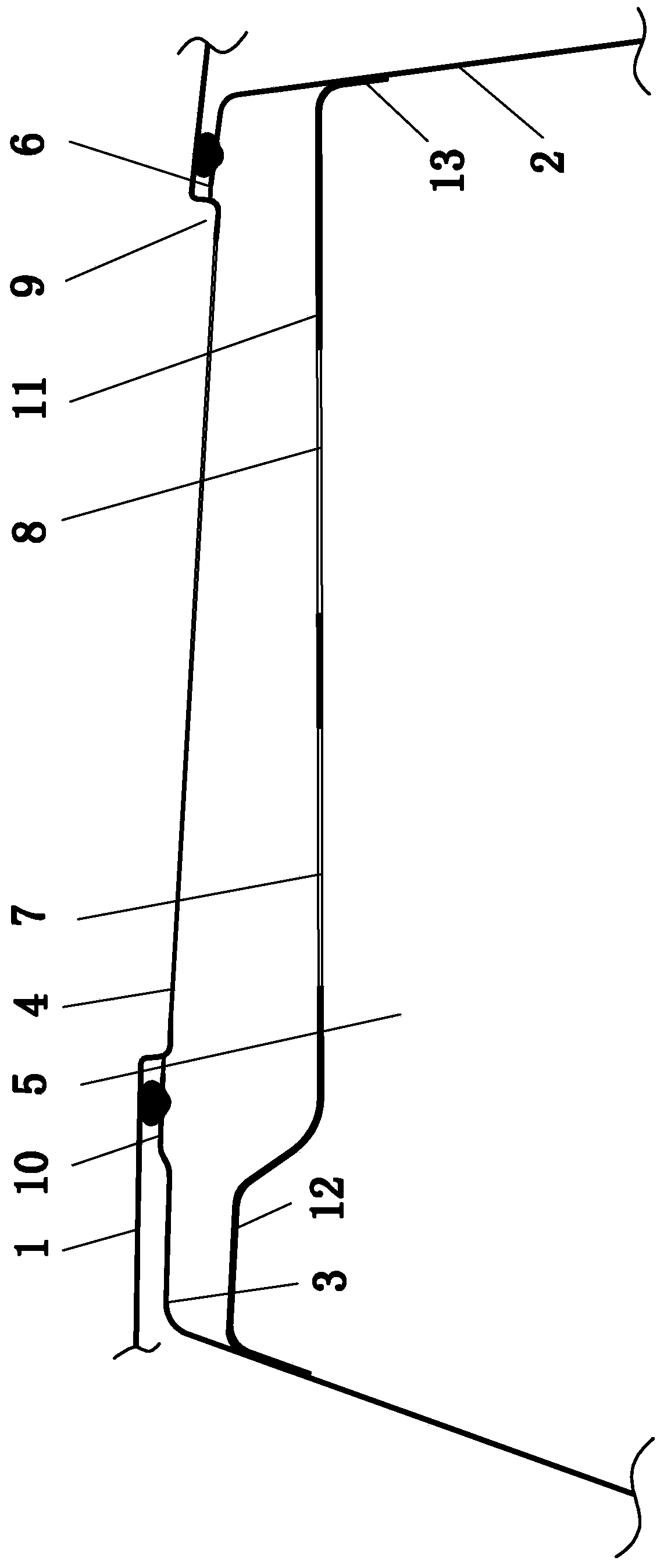

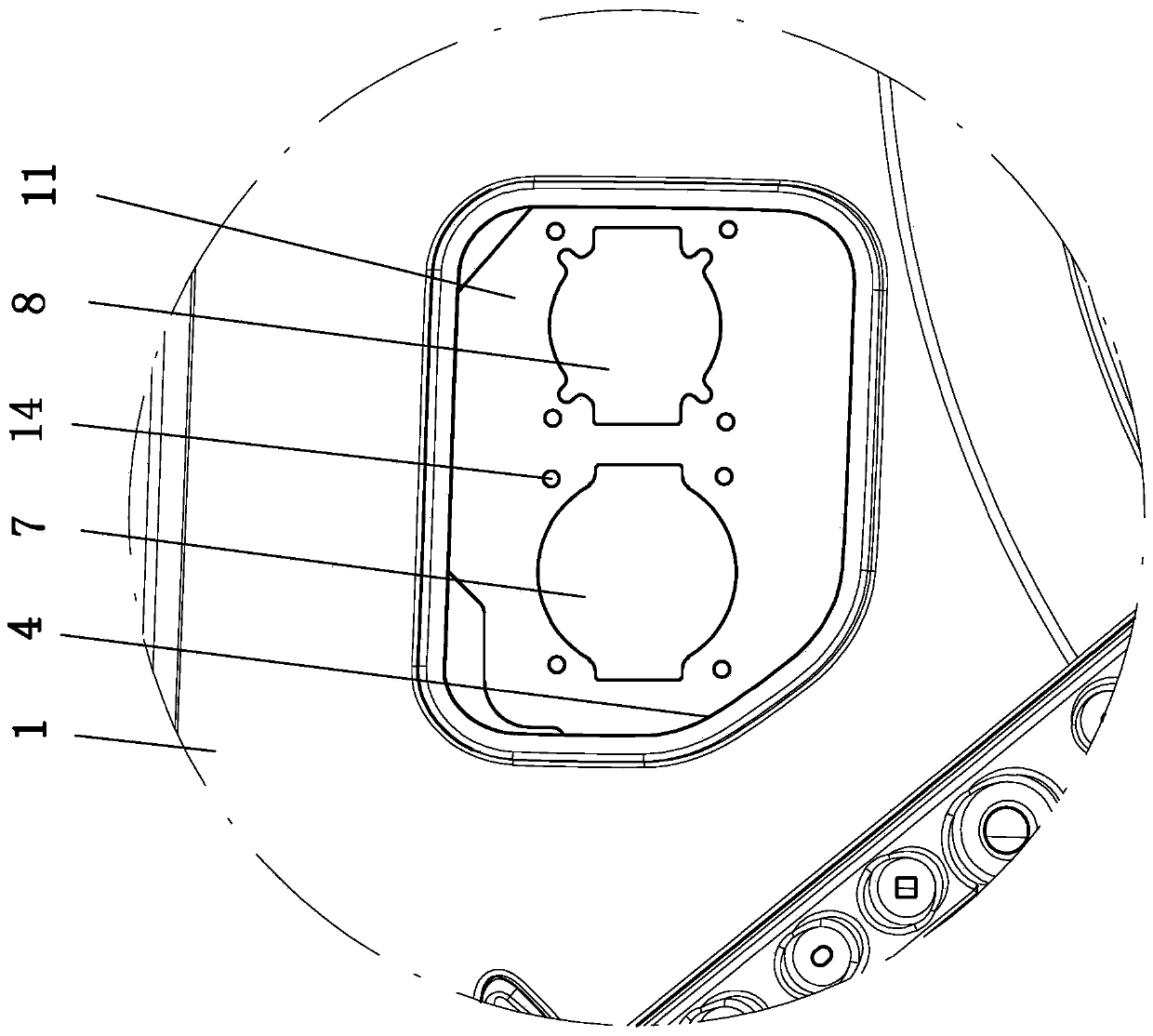

Electric vehicle charging socket mounting structure

InactiveCN109980465ALow costSmall footprintVehicle connectorsCharging stationsFast chargingElectric vehicle

The invention relates to an electric vehicle charging socket mounting structure, comprising a side wall outer plate, a wheel cover outer plate, a boss disposed on the outer end of the wheel cover outer plate and connected to the inner end of the side wall outer plate, an outer through hole disposed on the side wall outer plate, a counterbore disposed on the inner end of the boss, an inner throughhole disposed on the bottom surface of the counterbore and opposite to the outer through hole, a charging socket bracket having a fast charging socket hole and a slow charging socket hole, and an integrated socket bracket having integrated socket jacks, wherein the charging socket bracket is connected to the inner side wall of the counterbore, or the integrated socket bracket is connected to the inner side wall of the counterbore. The fast charging socket and the slow charging socket of the electric vehicle charging socket mounting structure are arranged on the same side of the side wall so asto achieve low mold cost, small occupied space, and convenient charging operation. Further, the electric vehicle charging socket mounting structure can be used for mounting a European standard integrated socket. The side wall outer plate and the wheel cover outer plate has high connection strength and are less likely to vibrate.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Titanium automobile exhaust pipe

InactiveCN107575293AIncrease contact areaIncreased turbulenceExhaust apparatusSilencing apparatusActivated carbonCooling chamber

The invention discloses a titanium automobile exhaust pipe. The inner wall of a conical pipe body is provided with a spiral gas groove, and one end, with a large caliber, of the conical pipe body is provided with an intake pipe which communicates with the gas groove, and the gas groove is internally provided with a plurality of purification bulges evenly; the conical pipe body is internally provided with purification elbow pipes made of titanium materials axially, and the purification elbow pipes are hollow pipes with porous structures, and are filled with activated carbon; a second cover bodyis provided with a connecting pipe which communicates with the upper end of the side wall of a cooling chamber, and the lower end of the side wall of the cooling chamber is provided with an exhaust pipe; the cooling chamber is internally provided with a filter screen transversely, and a plurality of flow baffles are arranged above the inner side wall of the cooling chamber and the filter screen evenly; and the outer wall of the cooling chamber is provided with elastic heat-absorbing layers in a sleeving manner. According to the titanium automobile exhaust pipe disclosed by the invention, automobile exhaust comes into full contact with the purification bulges and the purification elbow pipes separately, and the purification effect is good; the exhaust pipe is not liable to vibration, and the service lives of the exhaust pipe and fixing parts thereof are prolonged.

Owner:宝鸡钛产业研究院有限公司

Fixture for machining shroud of engine blade and machining method of engine blade

ActiveCN112091657AGood milling rigidityGuarantee processing qualityWork clamping meansMilling equipment detailsStructural engineeringMachining

The invention discloses a fixture for machining a shroud of an engine blade and a machining method of the engine blade, and belongs to the technical field of aero-engines. The fixture for machining the shroud of the engine blade comprises a first supporting block and a second supporting block which are oppositely arranged, wherein the first supporting block and the second supporting block jointlylimit the position, close to the blade shroud, of a blade body. According to the fixture, an original tip is replaced with a fake tip to clamp and fix the blade, the distance between the shroud and the fake tip is small, the milling rigidity of the blade shroud is good, and the influence brought by cutter relieving and vibration is reduced; meanwhile, the problems that the blade is extruded when the blade shroud is axially located through the tip, and consequently a part deforms and deviates from a locating surface are solved; and the blade shroud has consistency in machining and measuring technical objectives, so that the detection precision is improved, and the machining quality of the blade shroud is reversely ensured.

Owner:AECC AERO SCI & TECH CO LTD

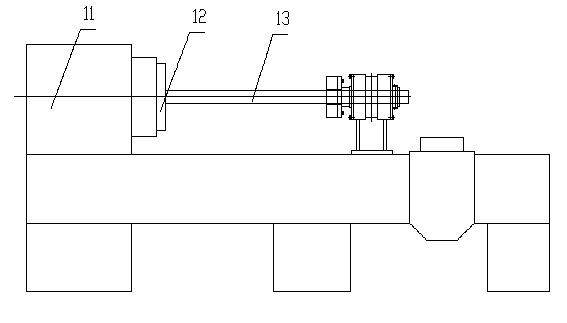

Building hoist stand column port cutting fixture and machining method of stand column port

InactiveCN102975036ASolve the technical problem of low cutting precisionNot easy to bend and deformPositioning apparatusTurning machinesEngineeringMachining

Provided is a building hoist stand column port cutting fixture and a machining method of a stand column port. The cutting fixture is arranged on a guide track of a body of a lathe. The cutting fixture is provided with a fixture seat (10) which is matched with the guide track of the lathe, a shaft sleeve (5) which is fixedly connected with the fixture seat (10), a first bearing (4), a second bearing (6), hollow rotating shafts (7) which are arranged inside the first bearing (4) and the second bearing (6), flange plates (2) which are fixedly connected with one ends of the hollow rotating shafts (7), and self-centering chucks (1) which are connected with the flange plates (2) and are coaxial with a chuck of the lathe. The first bearing (4) and the second bearing (6) are arranged at two end portions of the shaft sleeve (5). The machining method includes the following steps: mounting the cutting fixture on the guide track of the body of the lathe; enabling a stand column to penetrate through the hollow rotating shafts of the cutting fixture, clamping and fixing one end of the stand column through the chuck of the lathe, clamping and fixing the portion close to a cutting tool through the self-centering chucks; and cutting the stand column port.

Owner:湖南孟卿工程机械有限公司

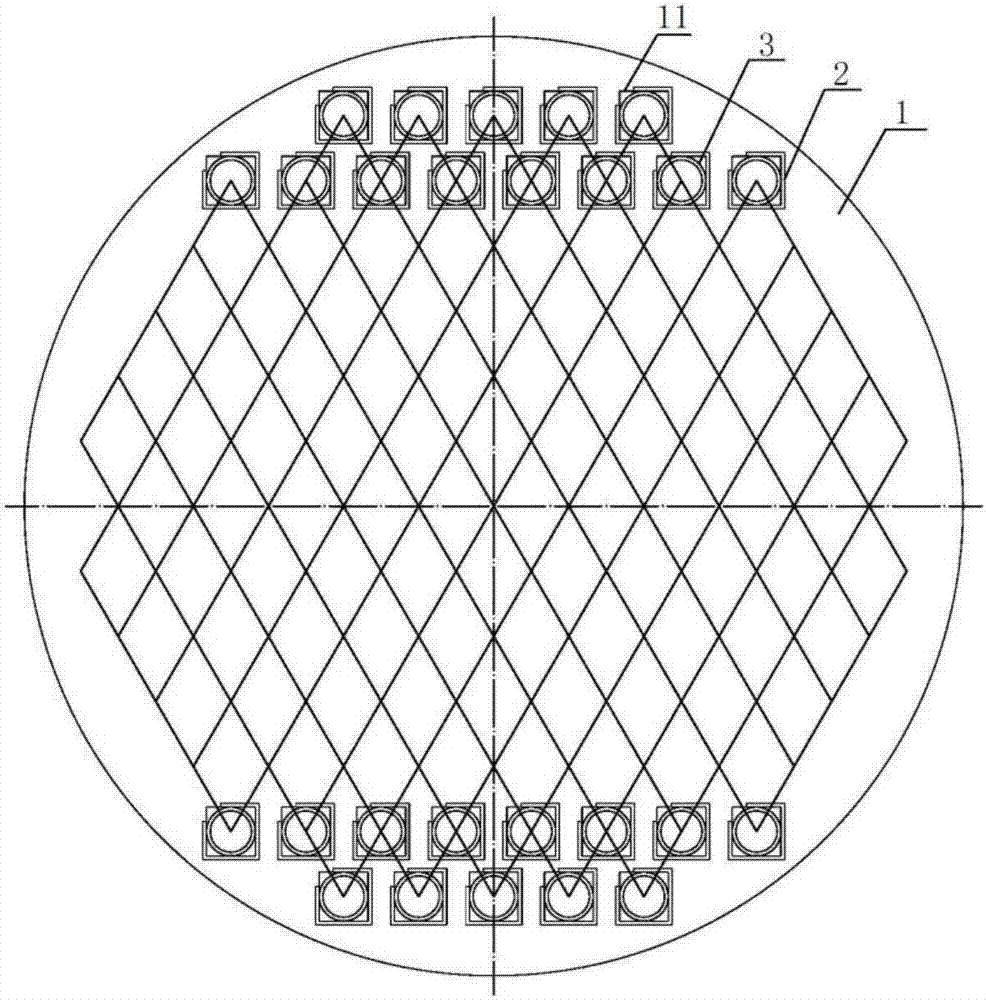

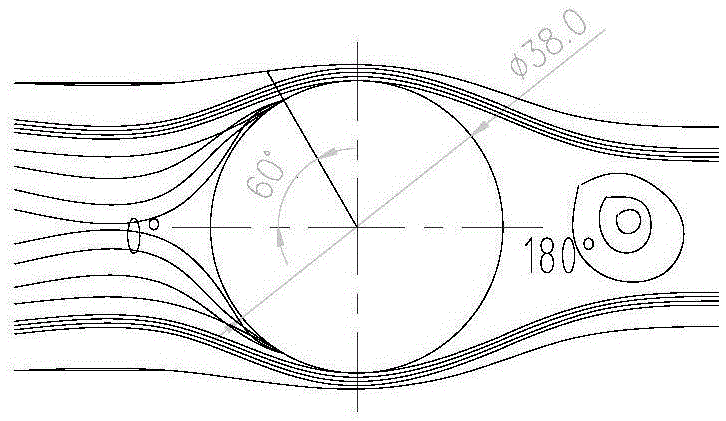

Baffling element of pipe shell type heat exchanger and working method thereof

The invention relates to a baffling element of a pipe shell type heat exchanger and a working method thereof. The baffling element of the pipe shell type heat exchanger comprises a square hole baffle and a casing pipe fixing plate. The square hole baffle is transversely arranged in a shell of the pipe shell type heat exchanger and used for fixing a corrugated pipe. The square hole baffle is a circular hole plate matched with the inner diameter of the shell, and is uniformly provided with a plurality of square through holes. The casing pipe fixing plate is embedded into the square through holes, and the inner side of the casing pipe fixing plate is tangent to the wave crest portion of the corrugated pipe. By adopting the square hole baffle, the casing pipe fixing plate is arranged in the square through holes for fixing the corrugated pipe, the heat exchange effect of the heat exchanger shell pass can be effectively improved, the fluid turbulent degree is enhanced, vibration of the heat exchanger is reduced, and the problem of abrasion caused between a corrugated pipe bundle and a baffle plate is solved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Outer discharging type pressure regulating device for circulating water pump

InactiveCN108331788AReduce resistanceAchieve the purpose of separationPump componentsPumpsCycloneExhaust valve

The invention discloses an outer discharging type pressure regulating device for a circulating water pump. The device is a hollow cylindrical barrel body, wherein the hollow cylindrical barrel body comprises a cyclone pipe, and a pressure regulating pipe which is connected to the cyclone pipe; the inside diameter of the cyclone pipe is less than that of the pressure regulating pipe; a separating part for separating air and water is arranged in the cyclone pipe, and the separating part is a spiral flow guide blade which is fixedly connected to the inner wall of the cyclone pipe. According to the device, the separating part for separating air and water is arranged in the cyclone pipe and is capable of forcibly forming spiral flow through water stream, and the purpose of separating air and water is achieved through the centrifugal force; and meanwhile, when the separated air enters the pressure regulating pipe, the air enters a suction hole and then enters a through hole and finally is exhausted through an exhaust valve at the front end or the exhaust valve at the tail end; the device is simple in structure, hard to vibrate, low in noise, and small in fluid conveying resistance.

Owner:DONGGUAN UNIV OF TECH +1

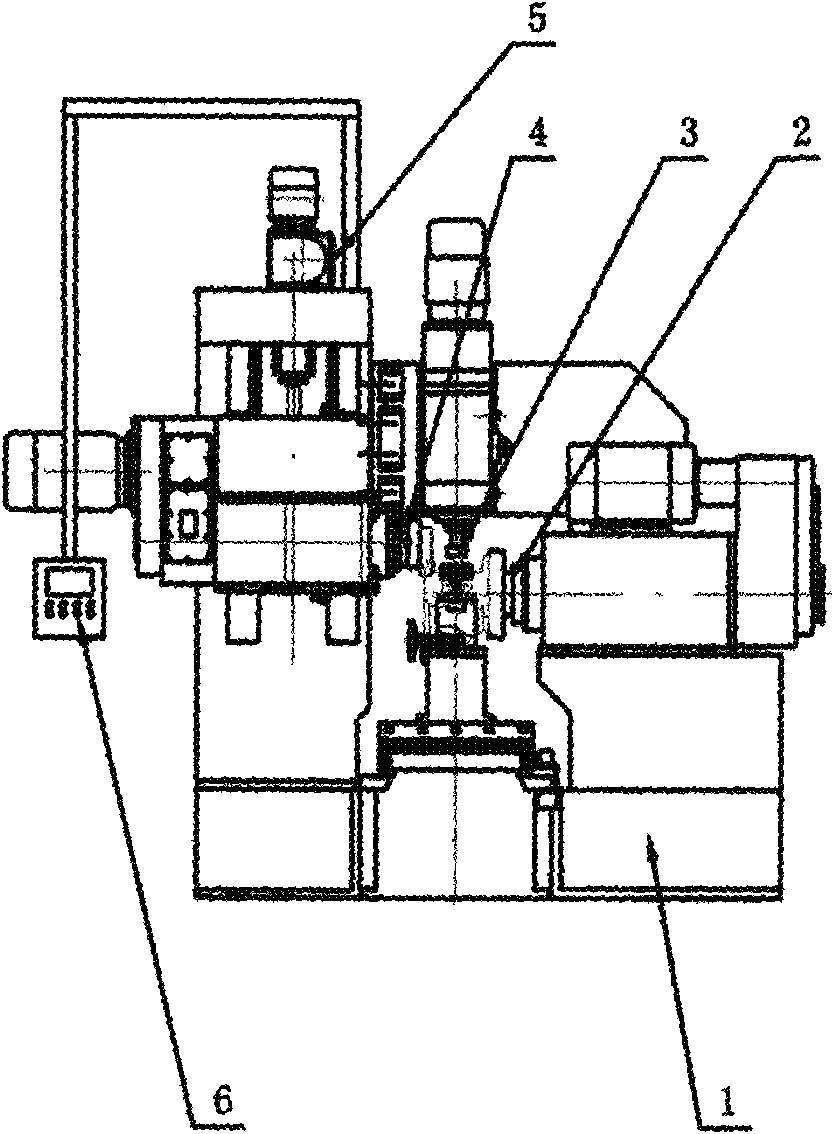

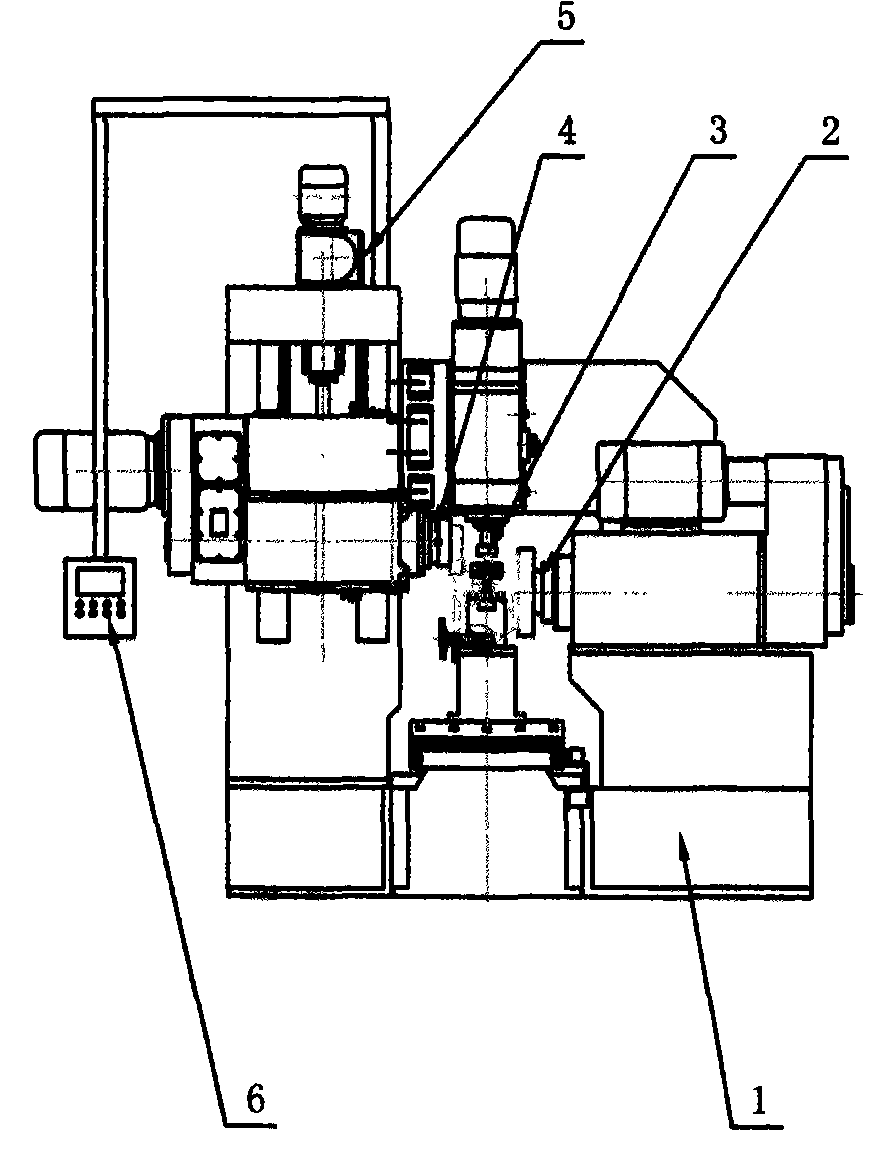

Special milling NC (numerical control) fixture machine tool of ledge

InactiveCN101987374AImprove machining accuracyNot prone to vibrationMilling equipment detailsPositioning apparatusNumerical controlHuman–machine interface

The invention discloses a special milling NC (numerical control) fixture machine tool of a ledge, which comprises a tool body, a right longitudinal milling head, a top milling head, a left longitudinal milling head, a numerical control feed box, a numerical control operation box, a guide-rail control box, a mast base, a left hydraulic fixture, an operating platform, a ledge workpiece and a right hydraulic fixture. The invention is characterized in that all mechanical processing procedures of a ledge are programmed into a computer by adopting a closed-loop control technique so as to realize the on-line monitoring and digital control of a human-machine interface; the machine tool disclosed by the invention has the function of error-correction alarm identification, and a floating supporting / adjusting mechanism is adopted in the left hydraulic fixture and the right hydraulic fixture, so that supporting points of the ledge workpiece are leveled off in the process of arranging the fixtures, the ledge is not easy to generate vibration phenomenon in the process of milling, and the three milling heads are milled simultaneously and conveniently; and because the left hydraulic fixture and the right hydraulic fixture are controlled to automatically clamp the ledge workpiece by a hydraulic system, and the ledge is clamped rapidly without moving, the machining precision of the ledge can be ensured.

Owner:YANCHENG CHAOYUE COMBINED MACHINE TOOL

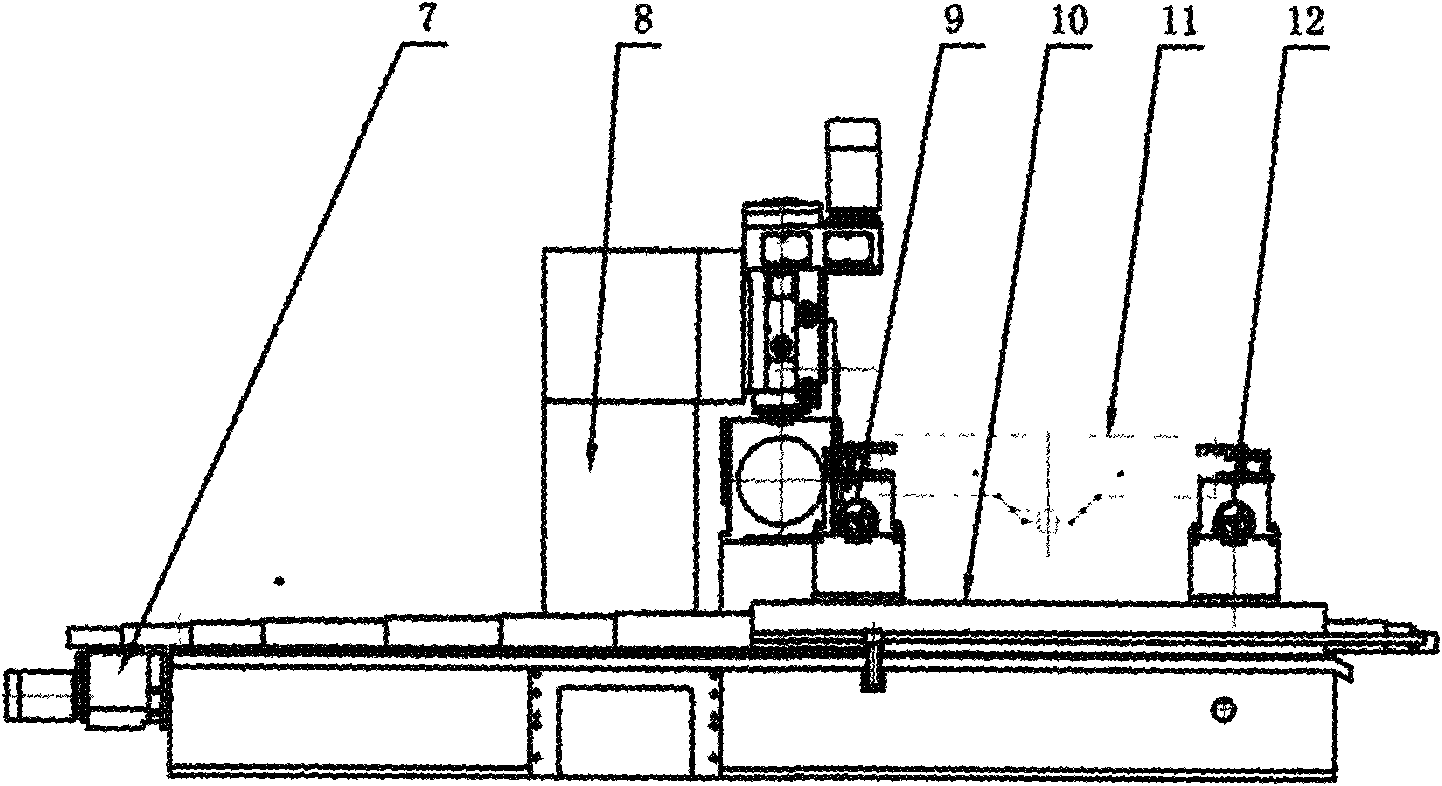

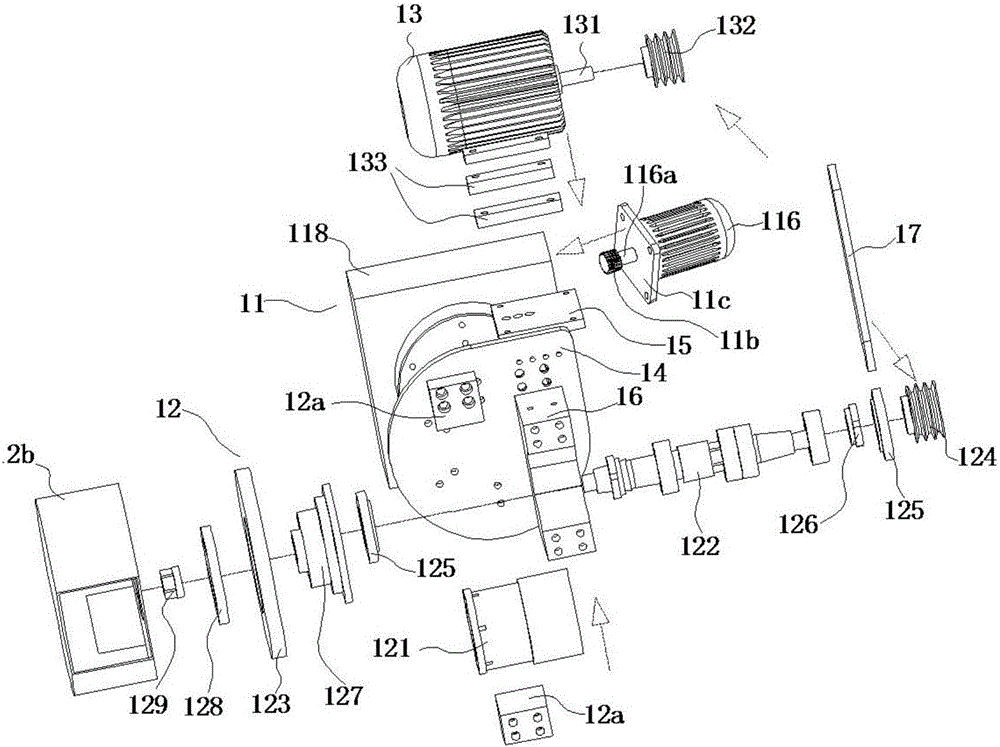

Forward and reverse tooth grinding device and full-automatic numerical control screw tooth grinding machine using same

InactiveCN105033366AIncrease usageGuaranteed cyclic operationThread cutting machinesNumerical controlMachine utilization

The invention discloses a forward and reverse tooth grinding device. The device comprises a numerical control index head, a grinding mechanism and a grinding motor. The numerical control index head is connected with the grinding mechanism through a turning-connection fixing plate. The turning-connection fixing plate is provided with a motor fixing plate. The grinding motor is installed on the motor fixing plate. The grinding motor is in transmission connection with the grinding mechanism. The invention further discloses a full-automatic numerical control screw tooth grinding machine. The full-automatic numerical control screw tooth grinding machine comprises a lathe body, the tooth grinding device and a chuck, wherein the lathe body is provided with a middle tray and a guide rail. The tooth grinding device is the forward and reverse tooth grinding device. The tooth grinding device is arranged at one end of the middle tray, and the other end of the middle tray is further provided with a follow-rest preventing workpieces from vibrating. The tooth grinding device and the tooth grinding machine can easily achieve precise angle adjustment, forward and reverse grinding is conducted, speed regulation is convenient, the device and the machine are suitable for machining of various screw tooth types, and machining precision is greatly improved. The screw tooth grinding machine can achieve automatic compensation according to the abrasion degree of a grinding tool, the machine utilization rate is greatly increased, cyclic work of machines is guaranteed, and production efficiency is improved.

Owner:东莞杰宇机械有限公司

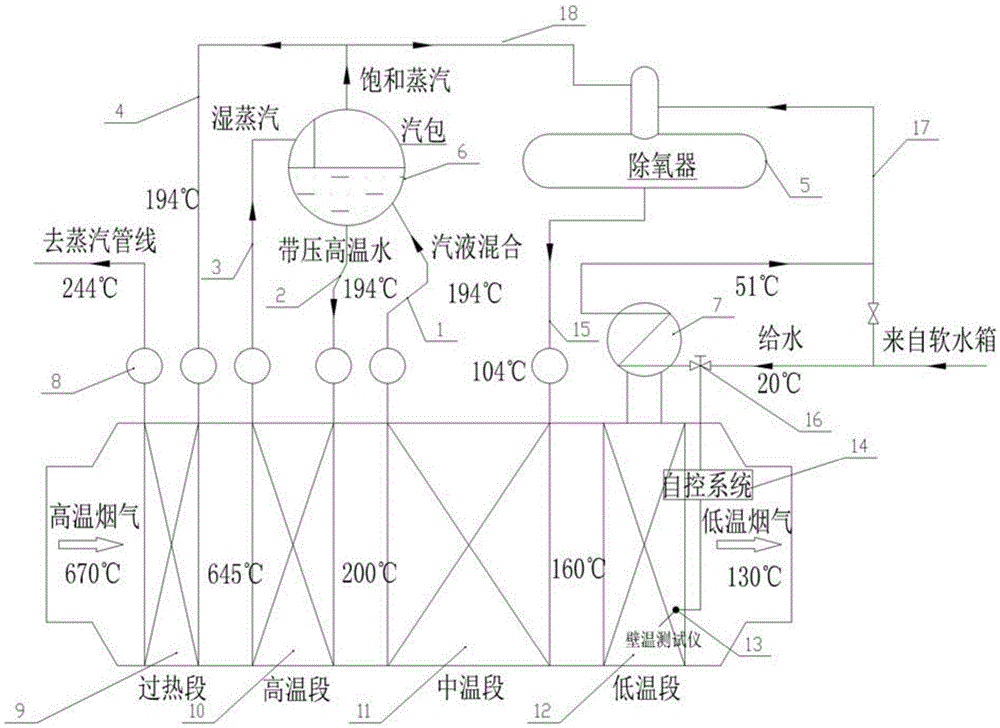

Flue gas waste heat recycling boiler with variable space and variable flow fields

ActiveCN105588095AAchieve energy saving and emission reductionGuaranteed flow rateLiquid degasificationWater heatersFlue gasDew

The invention discloses a flue gas waste heat recycling boiler with a variable space and variable flow fields. The flue gas waste heat recycling boiler adopts four heat absorption sections, wherein a low-temperature heat absorption section adopts a low-temperature near-dew-point anti-corrosion flue gas high-efficiency recycling and energy-saving heat exchange YHSP device, so that the inlet water temperature of a medium-temperature heat absorption section is increased by the low-temperature heat absorption section, and the device does not generate acid dew corrosion under the working condition that boiler load continuously changes. Besides, the heat exchange equipment of the boiler adopts SP high-efficiency heat exchange tubes, so that the good strengthened heat transfer effect is achieved, pressure drop is reduced when gas flow velocity is guaranteed, vibration does not likely occur, and scale inhibition and tube explosion prevention are relatively high. Compared with a conventional waste heat recycling device, the volume of the boiler is reduced by 20-30%, and the weight of the boiler is reduced by 30-40%, so that the low-temperature waste heat recycling, energy conservation and emission reduction of the flue gas are realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

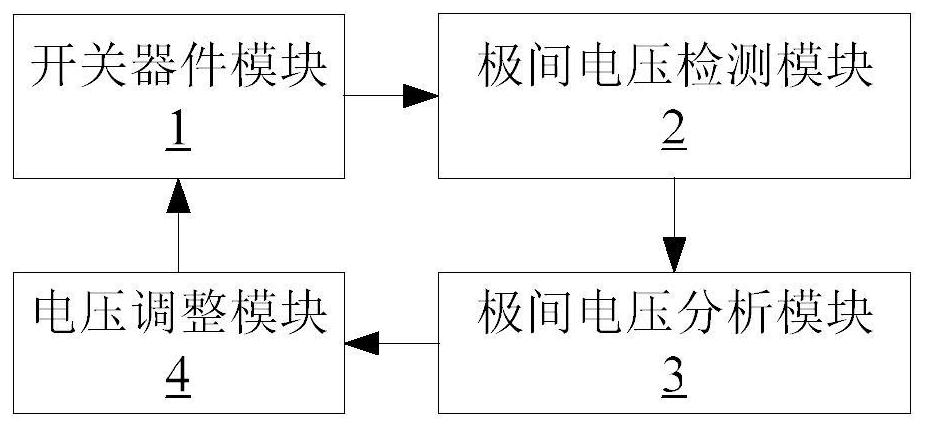

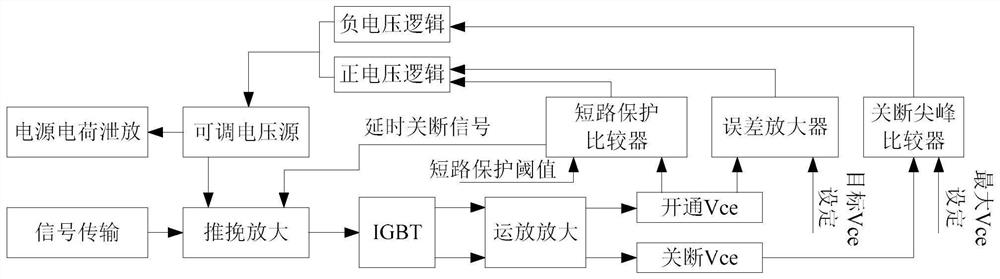

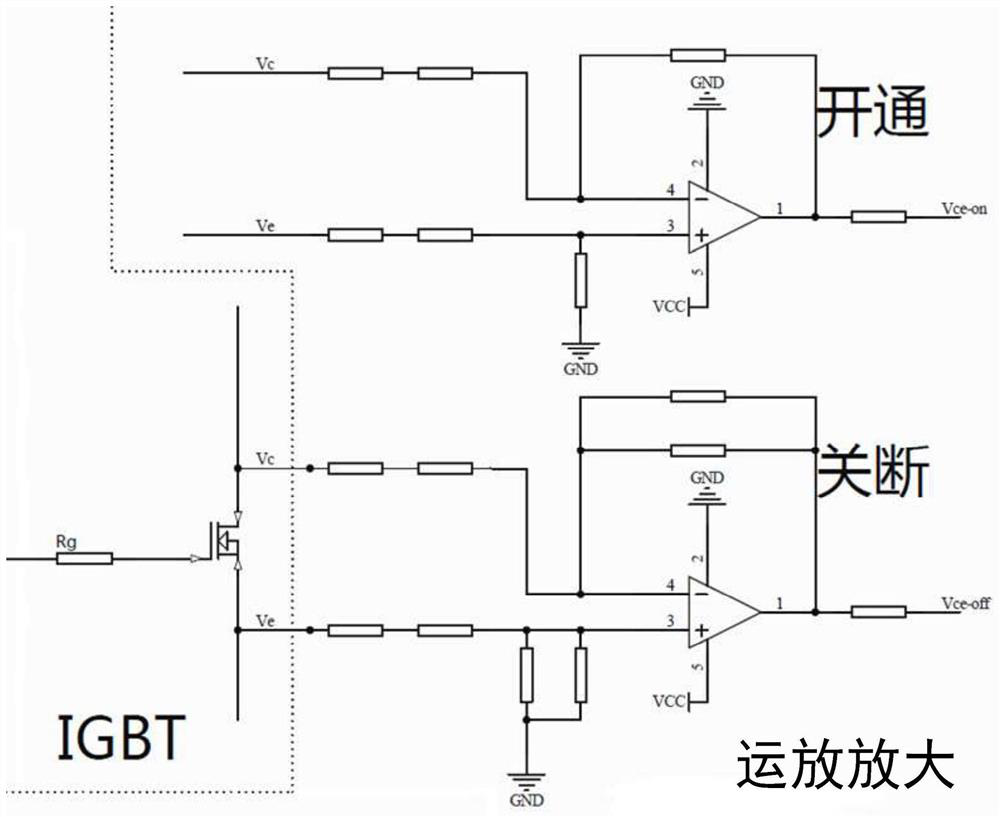

Driving system and method for dynamically adjusting gate voltage

ActiveCN112290920AReduce on-state lossNot prone to vibrationThyristorElectronic switchingControl theoryGate voltage

The invention provides a driving system and method for dynamically adjusting gate pole voltage. The driving system for dynamically adjusting the gate pole voltage comprises a switching device module;an inter-electrode voltage detection module connected with the switching device module and used for detecting the inter-electrode voltage of a switching device in the switching device module; an interelectrode voltage analysis module connected with the interelectrode voltage detection module and used for analyzing the interelectrode voltage to generate an adjustment signal; and a voltage adjustingmodule respectively connected with the inter-electrode voltage analysis module and the switching device module, and used for dynamically adjusting the gate voltage of the switching device according to the adjusting signal. By detecting the Vce, the gate voltage can be adjusted in real time, so that the on-state loss of the switching device during normal operation is reduced.

Owner:RUKING EMERSON CLIMATE TECH SHANGHAI CO LTD

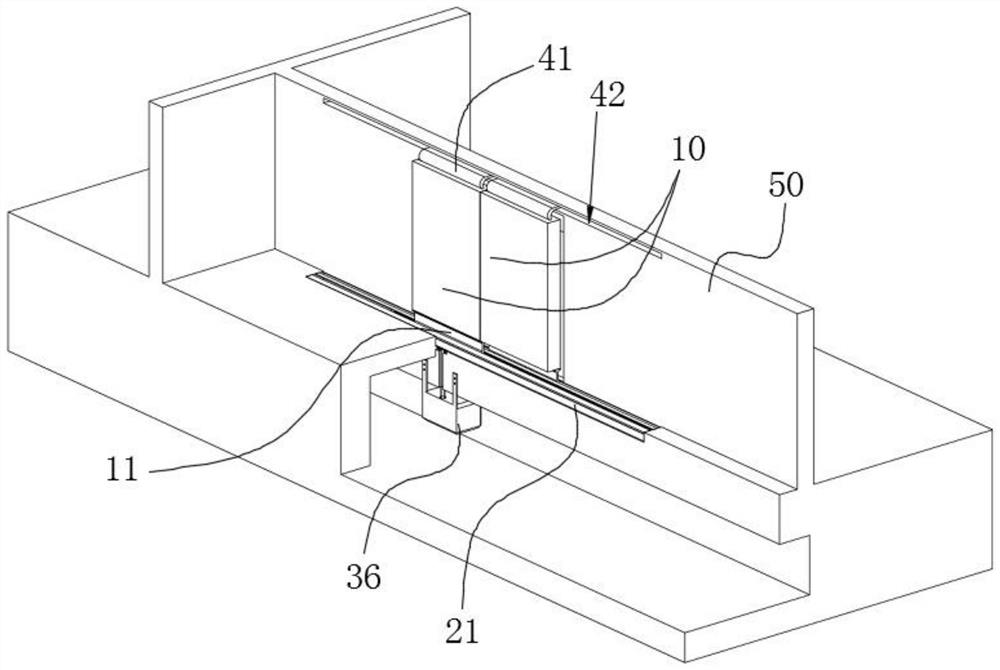

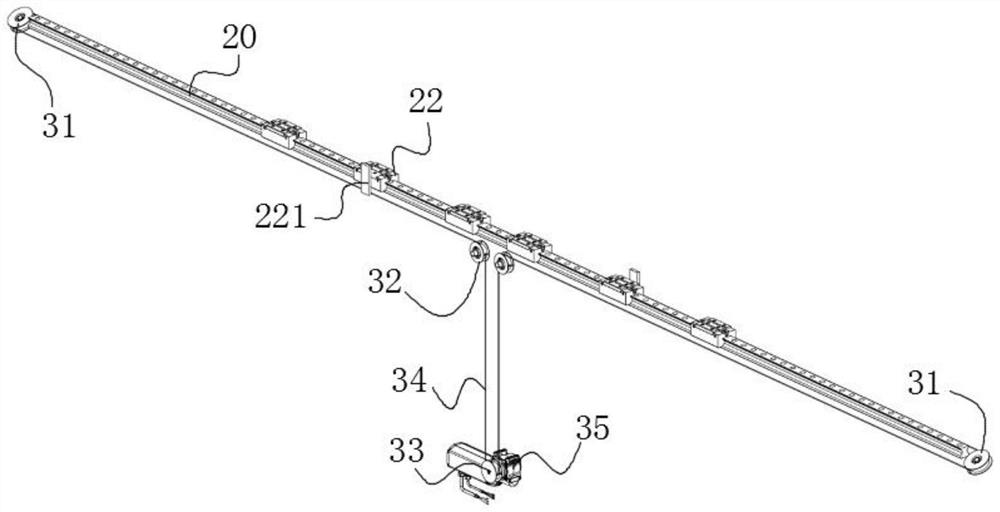

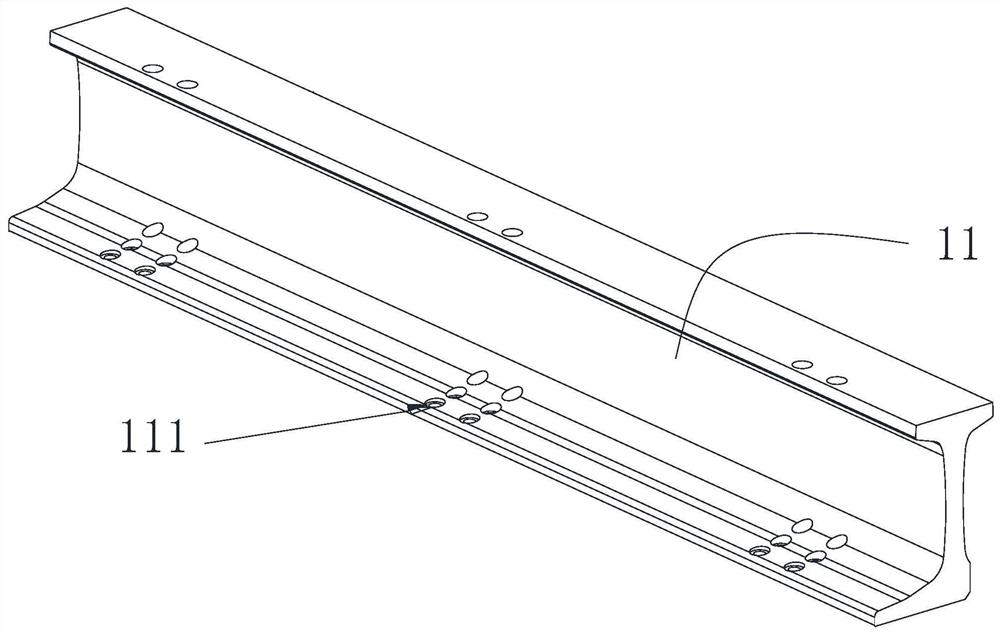

Single-rail double-opening shielding door

PendingCN113635922ASmooth slidingNot prone to vibrationRailway componentsPower-operated mechanismDoors

The invention relates to the technical field of shielding doors, in particular to a single-rail double-opening shielding door which comprises a fixed door body, a guide rail, two movable door bodies, a guide assembly and a driving assembly. The fixed door body is provided with a passing area for people to pass through; the guide rail is arranged on one side of the fixed door body and located at the bottom end of the passing area; the two movable door bodies are respectively arranged on the guide rails in a sliding manner; the guide assembly comprises a first guide part and a second guide part in sliding fit with the first guide part, the first guide part is arranged at the top end of the movable door body, and the second guide part is arranged on one side of the fixed door body and is parallel to the guide rail; and the driving assembly is used for driving the two movable door bodies to be close to or away from each other. The guide rail and the guide assembly are arranged at the bottom end and the top end of the movable door body respectively and used for guiding the movable door body to slide, and the movable door body slides more stably.

Owner:FANGDA INTELLIGENT INNOVATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com