Processing method for copper target material

A processing method and technology for copper targets, which are applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of reduced performance of copper targets, inability to meet target requirements, rust, etc. Scratching, deformation reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

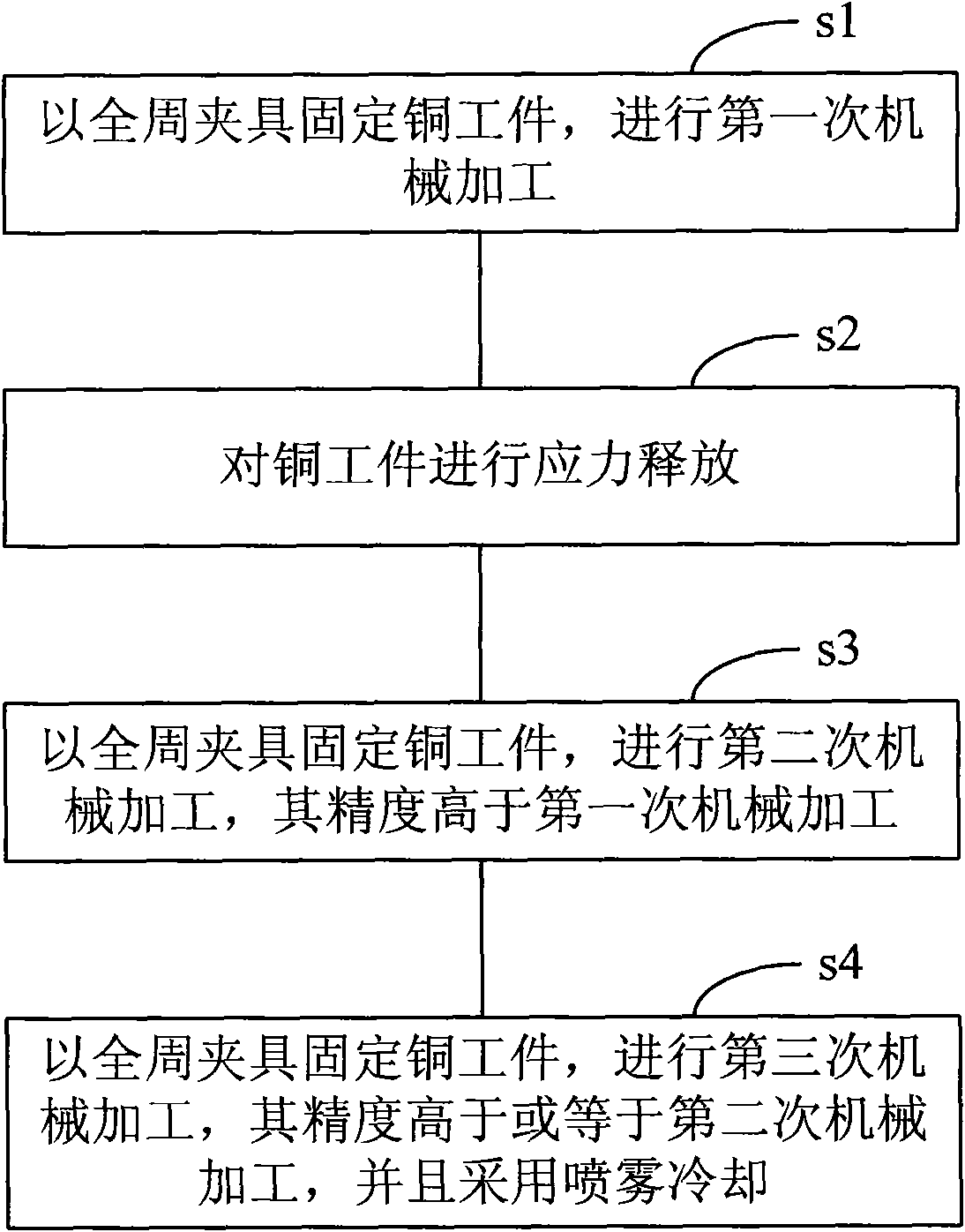

[0025] refer to figure 1 As shown, an embodiment of the processing method of the copper target of the present invention includes:

[0026] Step s1, fixing the copper workpiece with a full-circumference fixture, and performing the first mechanical processing;

[0027] Step s2, performing stress release on the copper workpiece;

[0028] Step s3, fixing the copper workpiece with a full-circumference fixture, and performing the second machining, the precision of which is higher than that of the first machining;

[0029] In step s4, the copper workpiece is fixed with a peripheral fixture, and the third machining is performed, the precision of which is higher than or equal to that of the second machining, and spray cooling is adopted.

[0030] In the above embodiment, the first machining is rough machining, the purpose of which is to remove most of the allowance of the copper workpiece to obtain a more regular semi-finished product, that is, to cut out the approximate shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com