Socket

A socket and pin board technology, used in coupling devices, instruments, discharge lamps, etc., to achieve the effect of expanding the pressing area and reducing scratches and damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The socket according to the invention is preferably realized as a test socket and is described in detail below with reference to the accompanying drawings. It should be noted that the scales given in the drawings are for the convenience of understanding the present invention and do not represent the actual scale of the product.

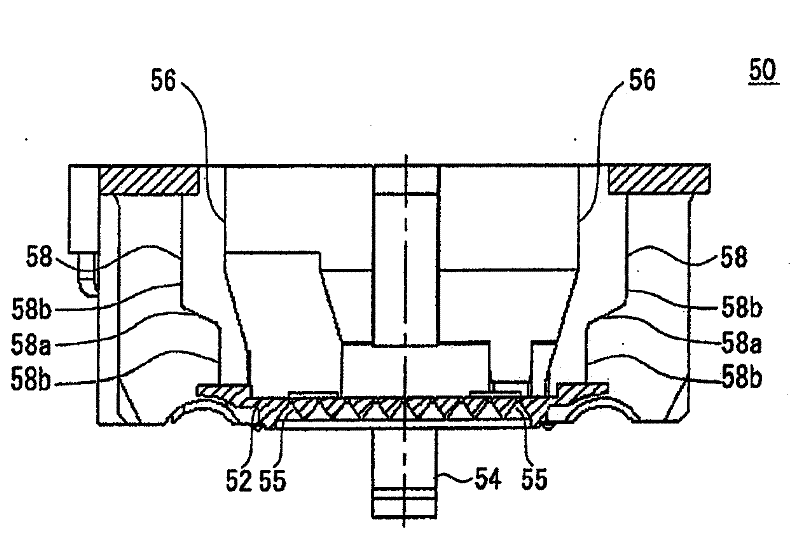

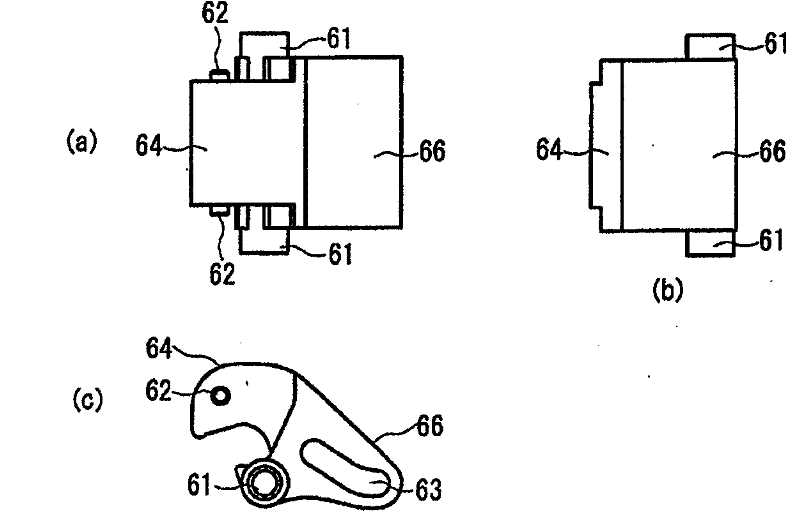

[0042] Figure 8 is a top view of an exemplary socket according to an embodiment of the present invention. The socket 100 according to the embodiment has a Figure 1 to Figure 7 The conventional socket 10 described in is substantially the same structure, but the socket 100 includes a redesigned pin plate 200 . In this embodiment, the latch plate 200 is rotatably connected to the adapter or mounting member 50A for alignment with the latch member 60 as described below. This allows the pin plate 200 to press uniformly over the entire top surface of the semiconductor device (eg, BGA package), which is particularly effective for large and / or thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com