Clamping structure of thin-walled piece, clamping method of thin-walled piece and application of clamping structure of thin-walled piece

A thin-walled parts and clamping technology, which is applied in the field of parts processing, can solve the problems of uneven stress on various parts of the surface of thin-walled parts, easy vibration and deformation, and easy deformation during processing, etc., to achieve high industrial application prospects, The effect of convenient operation and easy clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

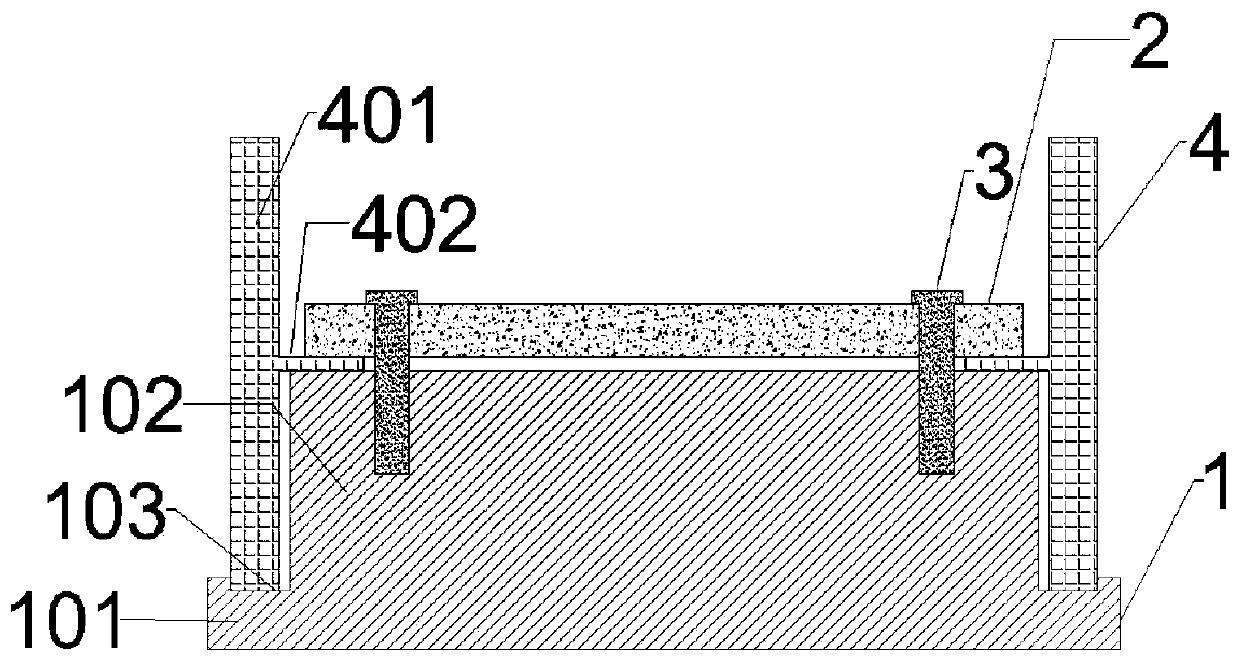

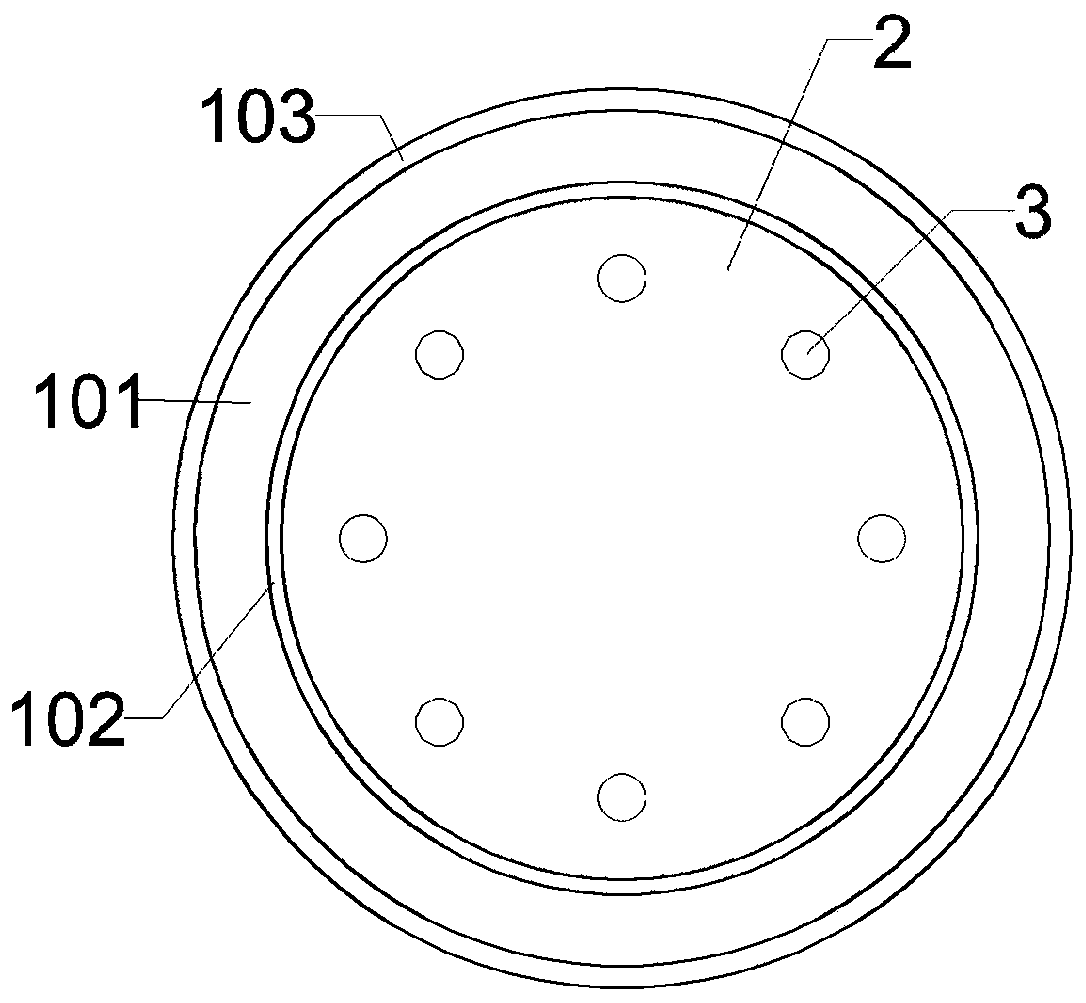

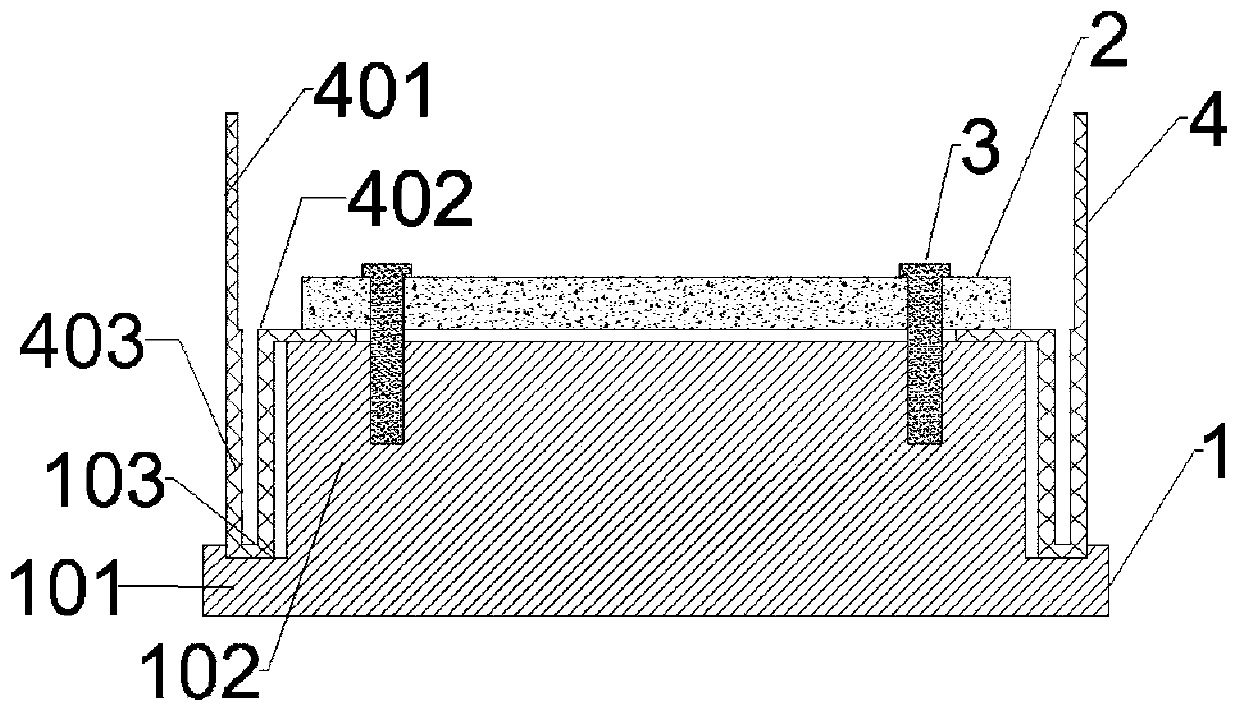

[0076] This embodiment provides a clamping structure for thin-walled parts, such as figure 1 with figure 2 As shown, the clamping structure includes a base 1 and a circular cover plate 2;

[0077] The abutment 1 includes a base 101 and a boss 102 protruding upward from the center of the base. The diameter of the boss 102 is 249.95 mm, the height of the boss 102 is 49.6 mm, the diameter of the base 101 is 260 mm, and the edge is provided with 8.05 mm wide, 0.4 mm deep groove 103, the upper surface of the boss 102 is provided with 8 boss holes (not shown) equiangularly distributed, the radial distance from the center of the boss hole to the circumference of the boss 102 is 16.15mm, so The thickness of the base 101 is 20mm, and the material of the abutment 1 is stainless steel;

[0078] The cover plate 2 is arranged on the boss 102, the thickness of the cover plate 2 is 5 mm, the diameter of the cover plate 2 is 249.8 mm, and the cover plate 2 is provided with 8 cover plates t...

Embodiment 2

[0082] This embodiment provides a clamping structure for thin-walled parts, the clamping structure includes a base and a circular cover plate;

[0083] The abutment includes a base and a boss protruding upward from the center of the base. The diameter of the boss is 49.9 mm, the height of the boss is 39.7 mm, the diameter of the base is 55 mm, and the edge is provided with a groove with a width of 3.1 mm and a depth of 0.3 mm. The upper surface of the boss is provided with three boss holes equiangularly distributed, the radial distance from the center of the boss hole to the circumference of the boss is 14.9 mm, the thickness of the base is 10 mm, and the material of the base is aluminum alloy 6061;

[0084] Described cover plate is arranged on the boss, and the thickness of cover plate is 15mm, and the diameter of cover plate is 49mm, and cover plate is provided with 3 cover plate holes that run through cover plate and is equiangular distribution, the circle center of cover p...

Embodiment 3

[0088] This embodiment provides a clamping structure for thin-walled parts. The clamping structure is the same as that of Embodiment 1 except that the circular cover plate is replaced by a circular cover plate.

[0089] The clamping structure specifically includes: an abutment and an annular cover plate;

[0090] The abutment includes a base and a boss protruding upward from the center of the base. The diameter of the boss is 249.95 mm, the height of the boss is 49.6 mm, the diameter of the base is 260 mm, and the edge is provided with a groove of 8.05 mm wide and 0.4 mm deep. The upper surface of the boss is provided with 8 boss holes (not shown) equiangularly distributed, the radial distance from the center of the boss hole to the circumference of the boss is 16.15mm, the thickness of the base is 20mm, the The abutment is made of stainless steel;

[0091] The cover plate is arranged on the boss, the thickness of the cover plate is 5mm, the outer diameter of the cover plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com