Clamp for machining annular casing of aero-engine with large length-diameter ratio

An aero-engine, large aspect ratio technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, to achieve the effect of high product qualification rate, small vibration of workpiece, not easy to vibrate and process deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

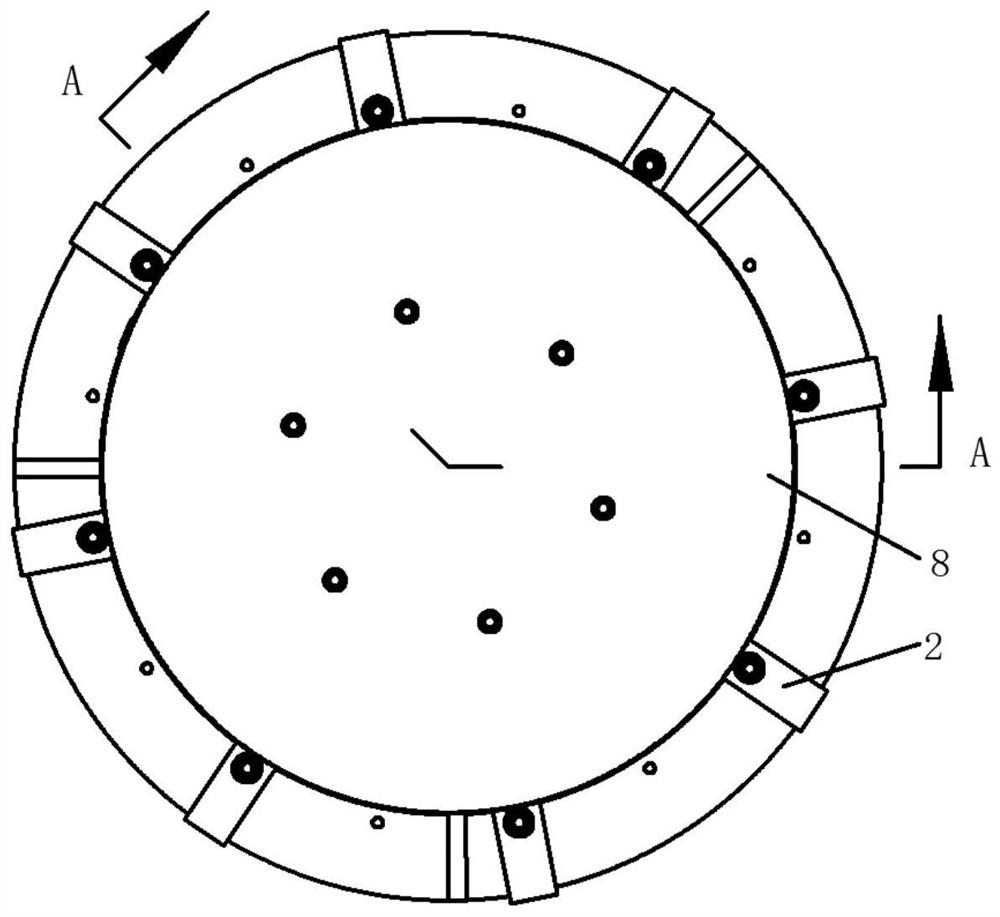

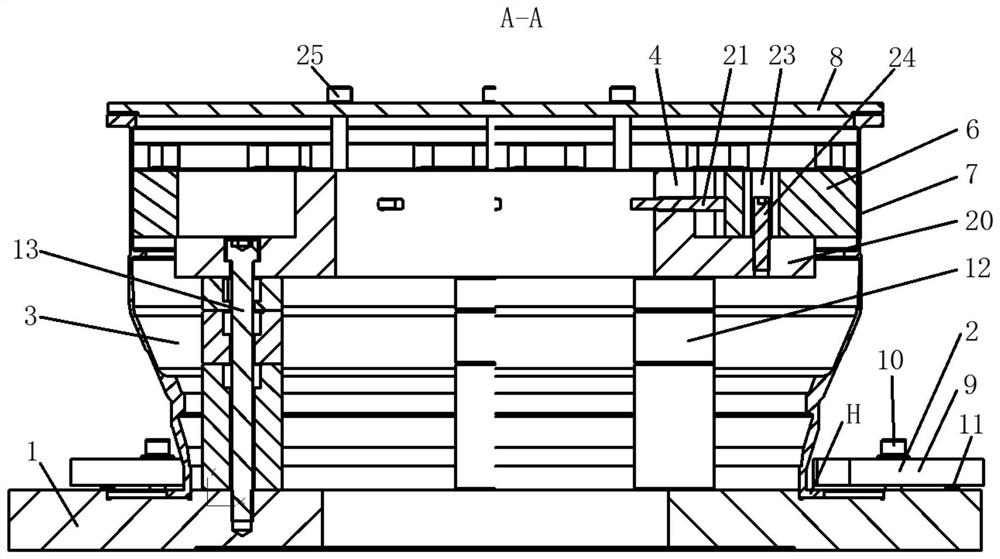

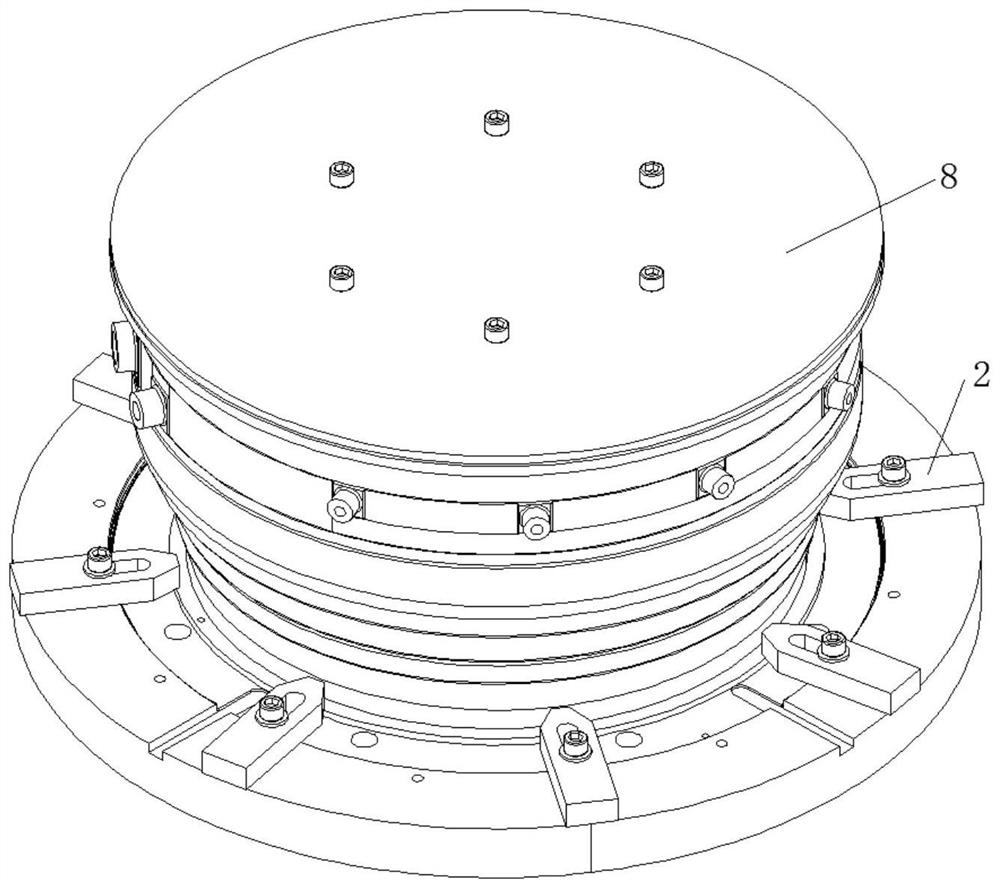

[0020] Such as Figure 1-5 , a fixture for processing an aero-engine annular casing provided by the present invention includes a chassis 1, a pressing device 2 is provided on the top of the chassis 1, and the pressing device 2 can press the annular plate H at the bottom end of the annular casing 3 Tightly fixed on the top of the chassis 1, the top of the chassis 1 is detachably fixedly connected with an inner support assembly 4, and the inner support assembly 4 includes four circumferentially arranged support blocks 6, and the outer surface 7 of the support block 6 It can be pressed and fitted on the inner wall of the top of the annular casing 3, and the top of the inner support assembly 4 is detachably fixedly connected with a cover plate 8, and the bottom surface of the cover plate 8 can be pressed and fitted on the annular casing 3 on the top surface.

[0021] Preferably, the pressing device 2 is eight groups of circumferentially arranged pressing plate assemblies, the pre...

Embodiment 2

[0029] According to the clamp for the aero-engine annular casing of processing large aspect ratio described in embodiment 1, the method for processing the inner and outer profiles of the annular casing of large aspect ratio comprises the following steps:

[0030] Step 1, fixing the chassis 1 on the chuck of the five-axis linkage turning and milling compound machining center, pressing and fixing the annular plate H on the chassis 1 with the pressing device 2, and processing the inner surface of the annular casing 3;

[0031] Step 2, install the hollow pillar 12 and the inner support assembly 4, loosen the screw 22 and turn the adjustment screw 21, the adjustment screw 21 can push the support block 6, so that the outer surface 7 of the support block 6 is compressed and fitted On the inner wall of the ring casing 3 top, tighten the screw 22;

[0032] Step 3, install the cover plate 8 so that the bottom surface of the cover plate 8 is pressed and fitted on the top surface of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com