Scraper device for welded joint of welded tube

A technology of scraper device and welded pipe, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unsatisfactory scraping effect, short service life, strong tool vibration, etc., and achieve good removal effect, small wear, Guaranteed removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

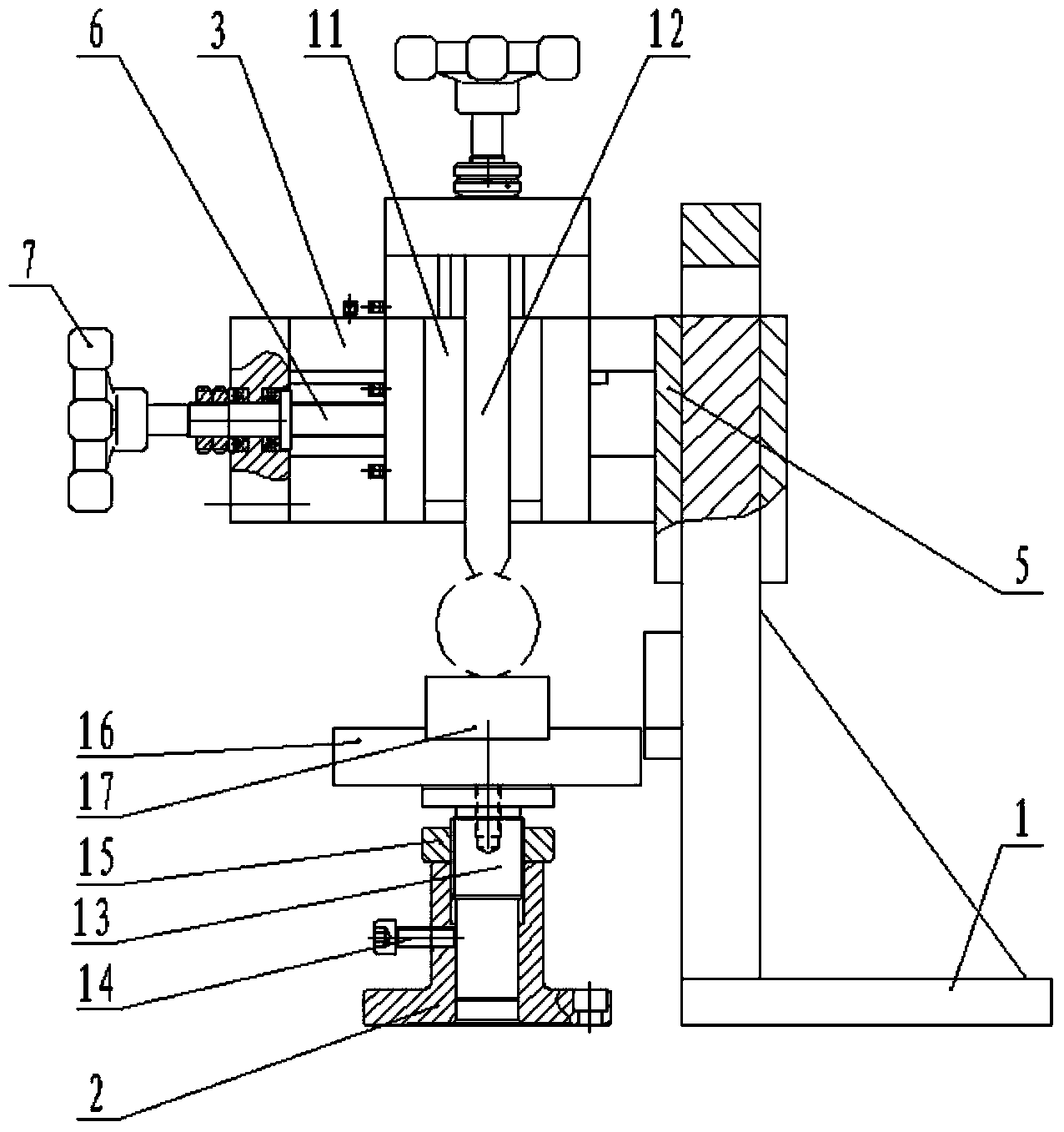

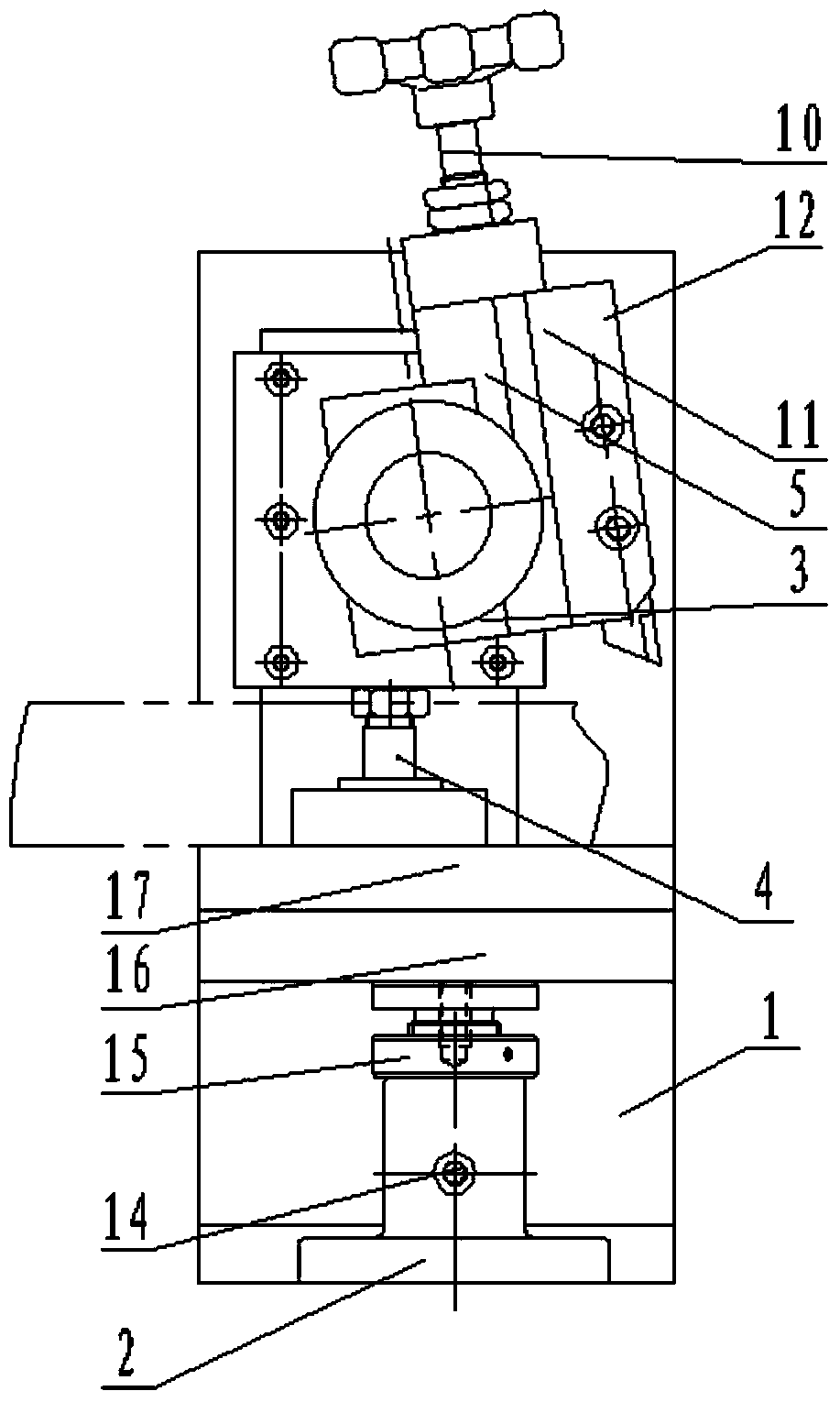

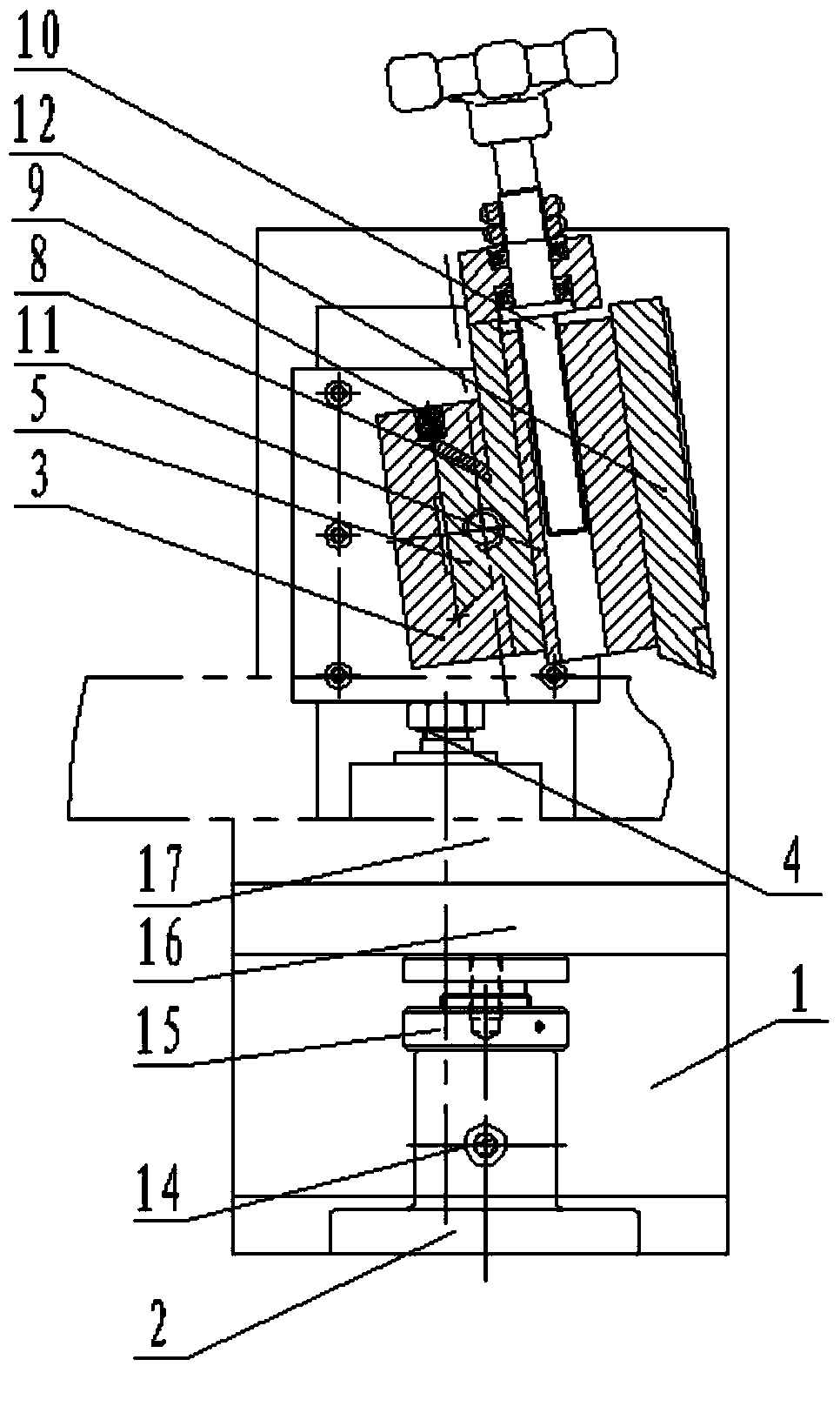

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-3 As shown, a welded pipe weld seam scraper device includes a knife holder seat 1 and a support seat 2 . A cross arm 3 that can move up and down and a cylinder 4 that drives the cross arm 3 to move are arranged on the tool rest seat 1 . A horizontal dovetail groove is arranged on the cross arm 3, and a sliding seat 5 is movable in the dovetail groove, and the sliding seat 5 is clamped in the dovetail groove by a block provided thereon. Rotate in the cross arm 3 and be provided with horizontal leading screw 6, horizontal leading screw 6 is connected with slide seat 5 by screw thread, and leading screw end is provided with adjusting hand wheel 7. A clamping member 8 is provided between the top surface of the dovetail groove and the clamping block. The cross arm 3 is provided with an oil cup 9 for filling lubricating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com