Outer discharging type pressure regulating device for circulating water pump

The technology of a pressure regulating device and a circulating water pump is applied to the components, pumps, and pump elements of the pumping device for elastic fluids, which can solve the problem that the water bubble occupies the space of the pipe coil, the dynamic resistance of fluid transportation, and the high compressibility of the gas. and other problems, to achieve the effect of good gas-water separation effect, small conveying resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

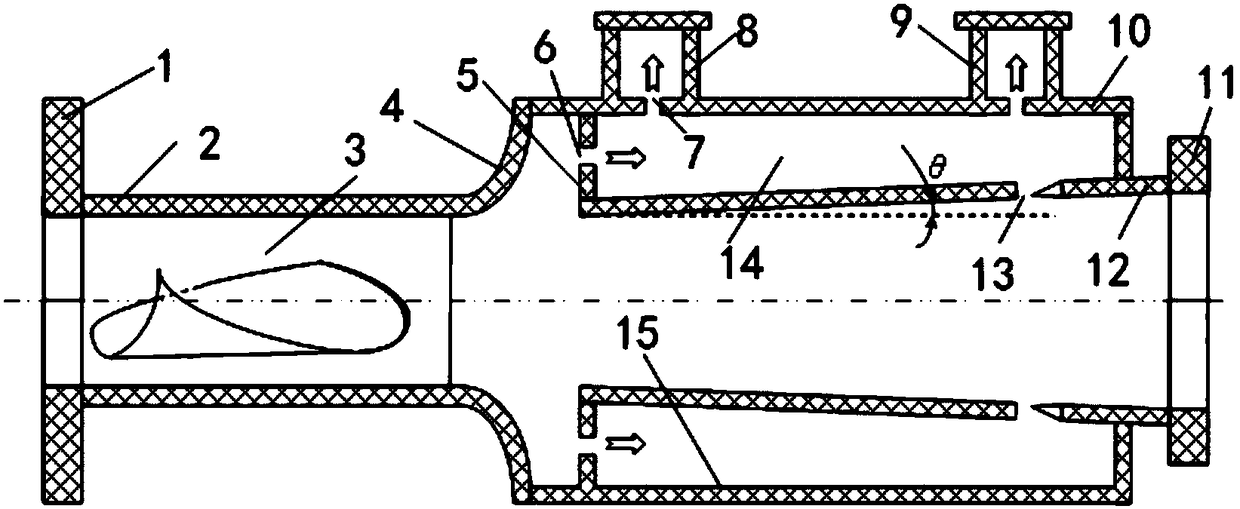

[0034] This embodiment provides a leaking type circulating water pump pressure regulating device, which can quickly separate the water and gas in the pipeline.

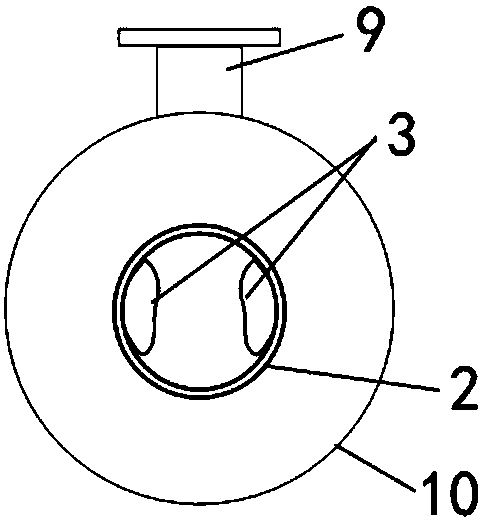

[0035] see figure 1 and figure 2 As shown, in this embodiment, the leakage type circulating water pump pressure regulating device is a hollow cylindrical cylinder, which includes a swirl tube 2 and a pressure regulating tube 15 connected to the swirl tube 2 .

[0036] The inner diameter of the swirl tube 2 is smaller than the inner diameter of the pressure regulating tube 15 , and a separation component 3 for separating gas and water is fixedly arranged in the swirl tube 2 .

[0037] Specifically, the separation component 3 is a spiral guide vane, and the spiral guide vane is fixedly connected to the inner wall of the swirl tube 2 .

[0038] When the water pump works, the water in the pipeline flows from the swirl pipe 2 to the pressure regulating pipe 15 and is output from the pressure regulating pipe 15 . At thi...

Embodiment 2

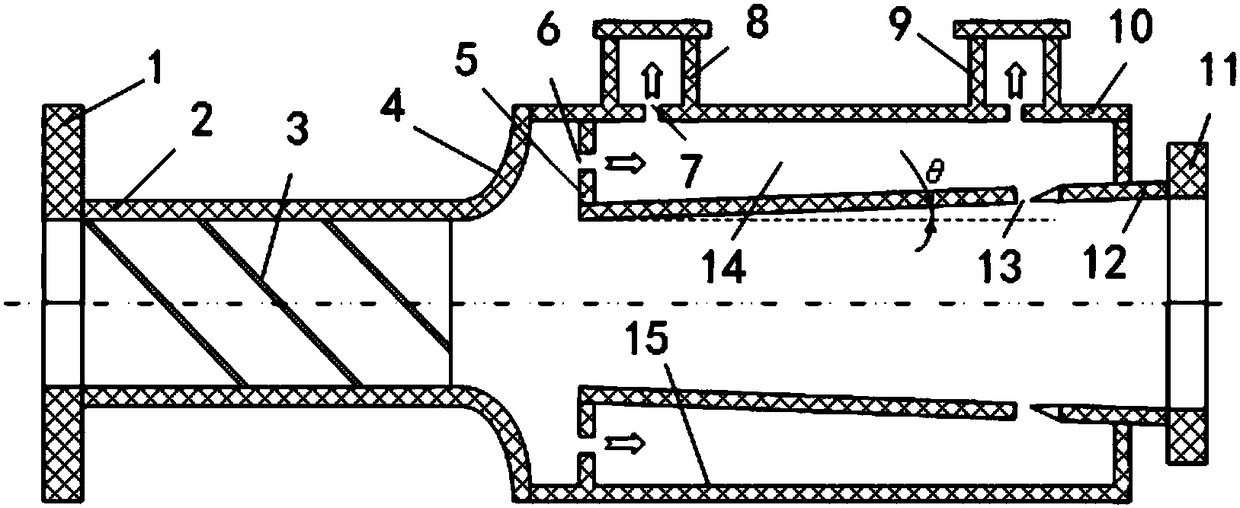

[0050] see image 3 , the separating component 3 is the thread on the inner wall of the swirl tube 2 .

[0051] The inner wall thread is a triangular or rectangular right-handed thread, and the inclination angle of the inner wall thread is 50° to 60°, which can avoid excessive flow resistance and make the gas and water separation effect better.

Embodiment 3

[0053] see Figure 4 and Figure 5 ,, the shape of the sealing plate 5 is arc-shaped, preferably arc-shaped. The suction hole 6 is opened in the arc-shaped sealing plate 5, which can further enhance the ability to separate gas and water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com