Special milling NC (numerical control) fixture machine tool of ledge

A special fixture and groove technology, applied in milling machine equipment, milling machine equipment details, clamping and other directions, can solve the problems of difficult machining of large workpieces with grooves, high rejection rate, low work efficiency, etc., to save manpower, process convenience, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

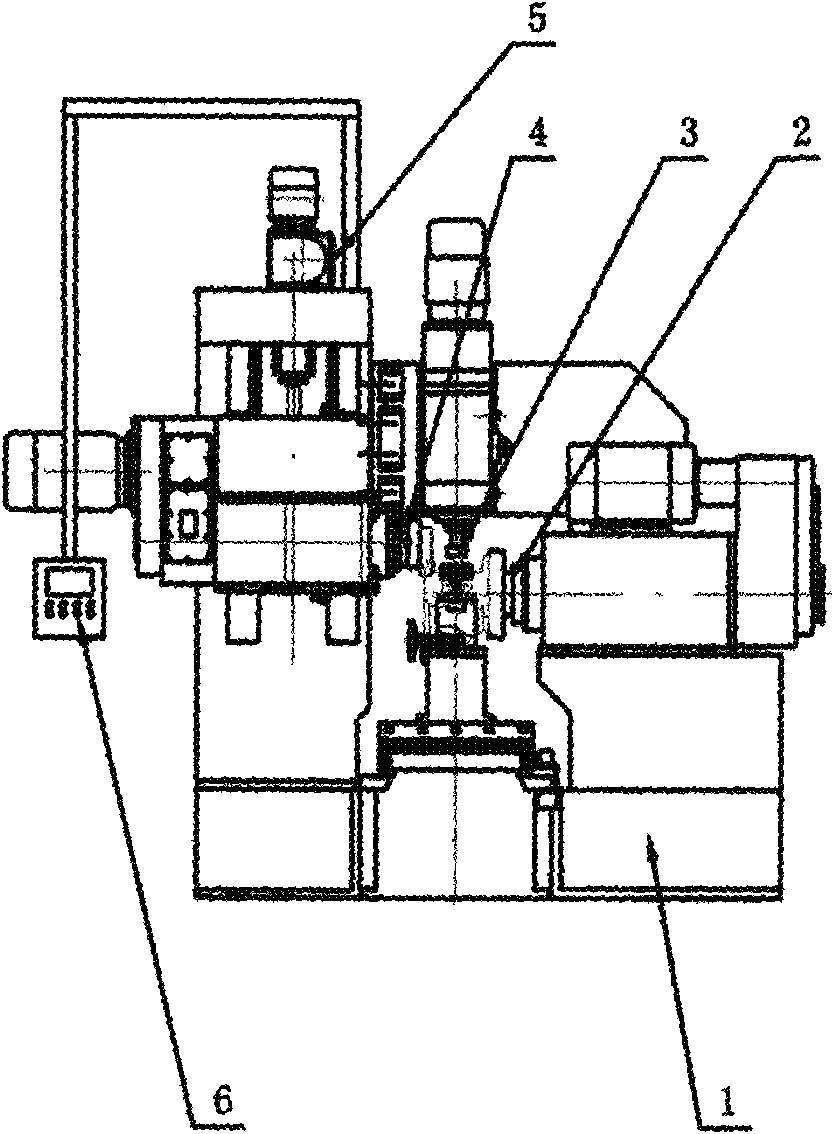

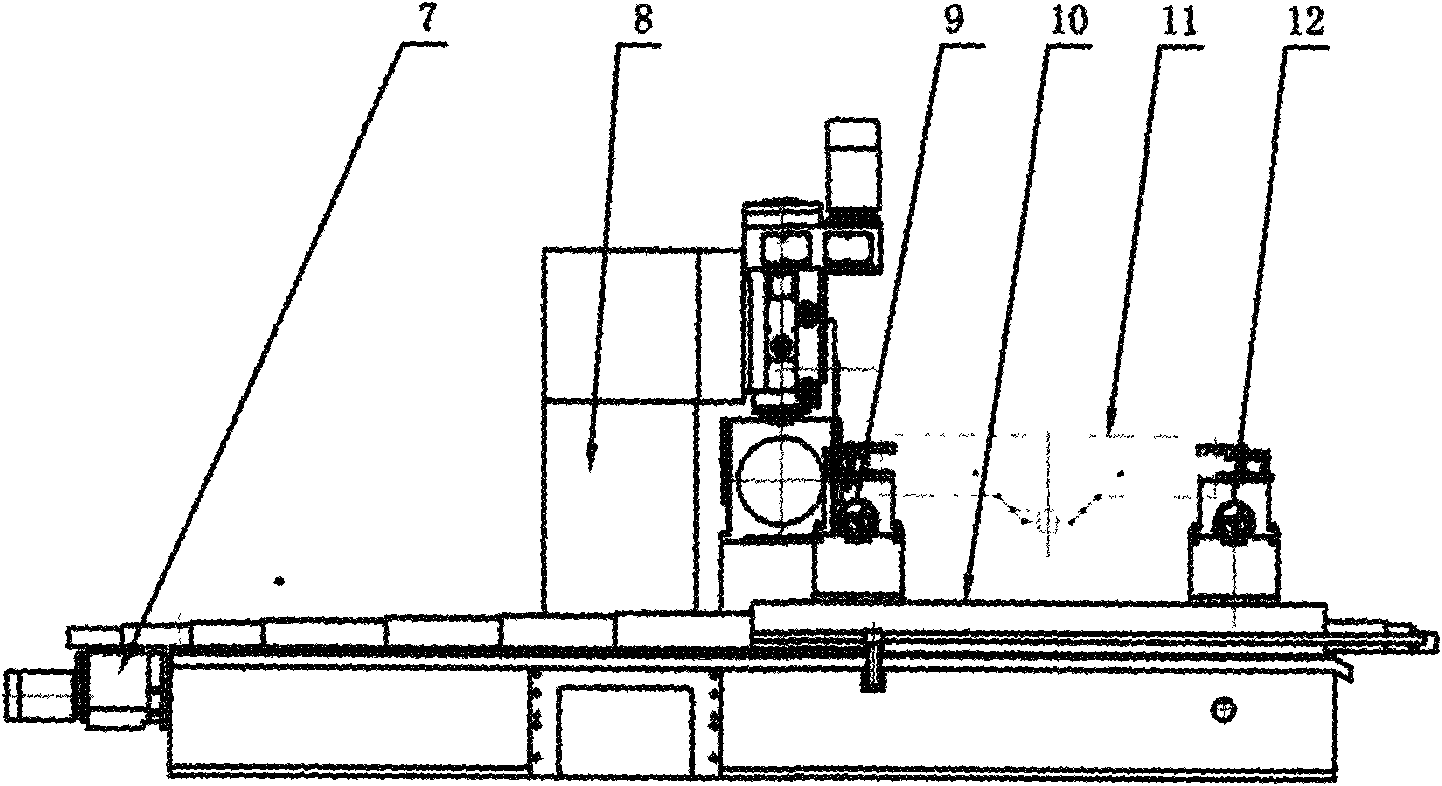

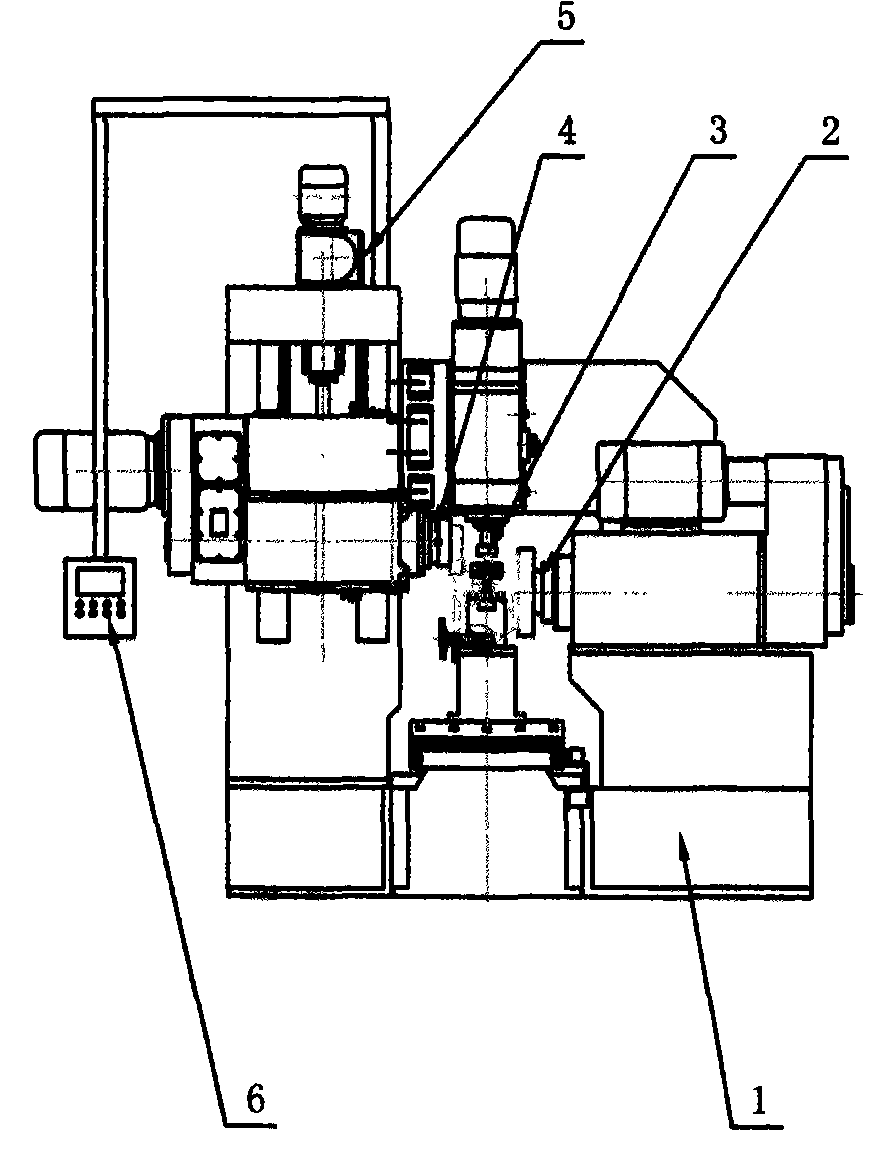

[0011] exist figure 1 , figure 2 Middle: The bed 1 is a rectangular shape, the bed 1 is provided with a support seat 8, and the support seat 8 is provided with a vertical slide table. The top milling head 3 is provided on the vertical slide table. There is a numerical control feed box 5, and a right longitudinal milling head 2 and a left longitudinal milling head 4 are arranged on both sides of the bed 1, and the upper end of the left longitudinal milling head 4 is always provided with a numerical control feed box 5 the same as the top milling head 3, A hydraulic left fixture 9 and a hydraulic right fixture 12 are arranged on the workbench 10 of the bed 1, and the groove side workpiece 11 is clamped between the two fixtures. A guide rail control box 7 is provided on the top of the bed 1, and the numerical control operation Case 6 is connected with the electric circuit of numerical control feeding box 5, right longitudinal milling head 2, left longitudinal milling head 4, top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com