Machining method for omega-shaped ring sealing washer

A processing method and ring sealing technology, applied in the field of heat exchanger sealing internal parts processing, can solve the problems of difficult processing, low carbon content, poor plasticity, etc., and achieve the effects of shortening production cycle, improving productivity, and not easy to vibrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

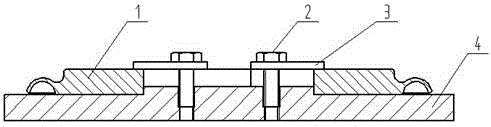

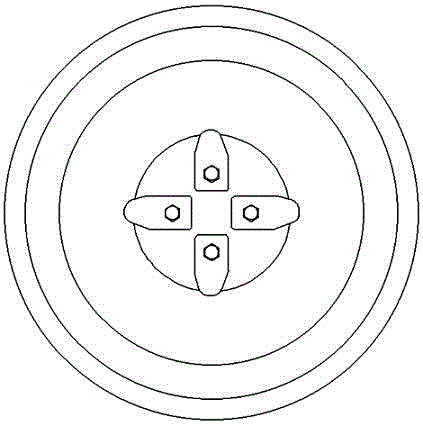

[0023] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing now:

[0024] A processing method of an omega ring sealing gasket according to the present invention comprises the following steps:

[0025] ⑴ Tooling and cutting tools, adopt the special process mold invented by our company for processing Ω-ring sealing gaskets; select turning tools: the front angle of the turning tool is 20°~40°, the rear angle is 8°~20°, and the cutting tool should be kept sharp

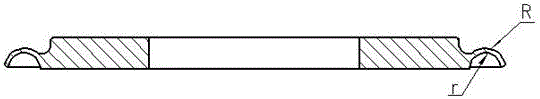

[0026] (2) Rough turning, first rough machining the two planes and the inner and outer circles of the Ω ring sealing gasket, such as image 3 shown;

[0027] ⑶ semi-finishing car

[0028] Such as figure 1 , image 3 As shown, insert the omega ring sealing gasket 1 into the special process mold 4, fix it with the compression bolt 2 and the pressure plate 3, and process the outer circular plane and R part by semi-finishing; turn the workpiece over, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com