Forward and reverse tooth grinding device and full-automatic numerical control screw tooth grinding machine using same

A positive and negative tooth and grinding technology, applied in the field of automatic CNC screw tooth grinding machine, can solve the problems of difficult to grasp the precision, low mechanical utilization rate, increase the internal stress of the screw, etc., to ensure the processing accuracy and processing quality, solve the problem of heat generation problems, and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

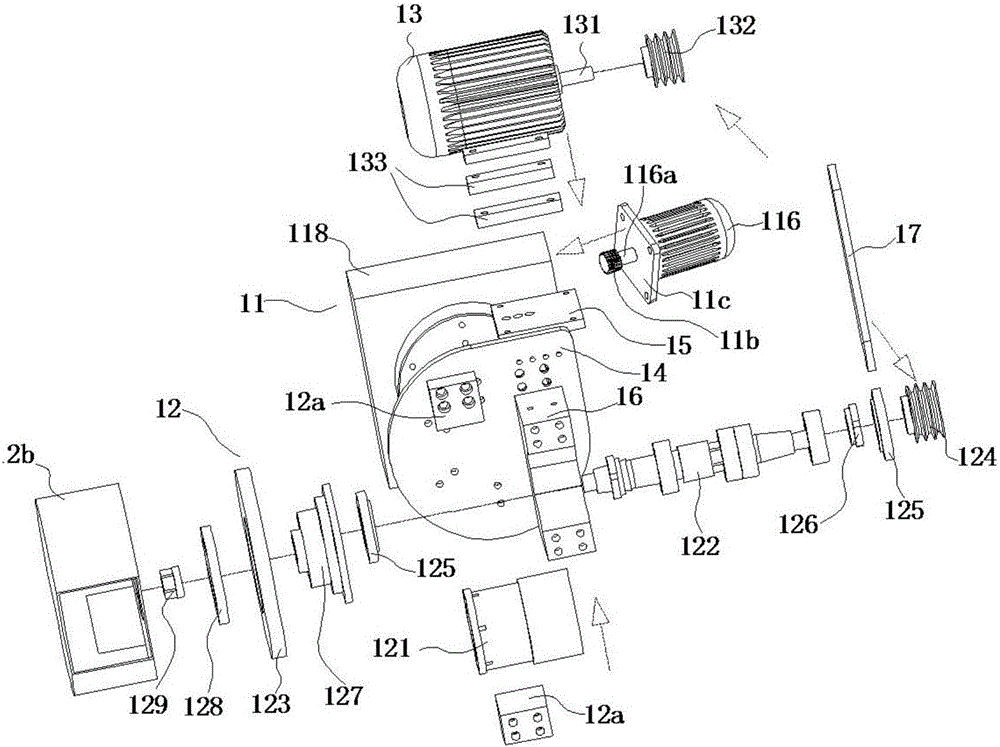

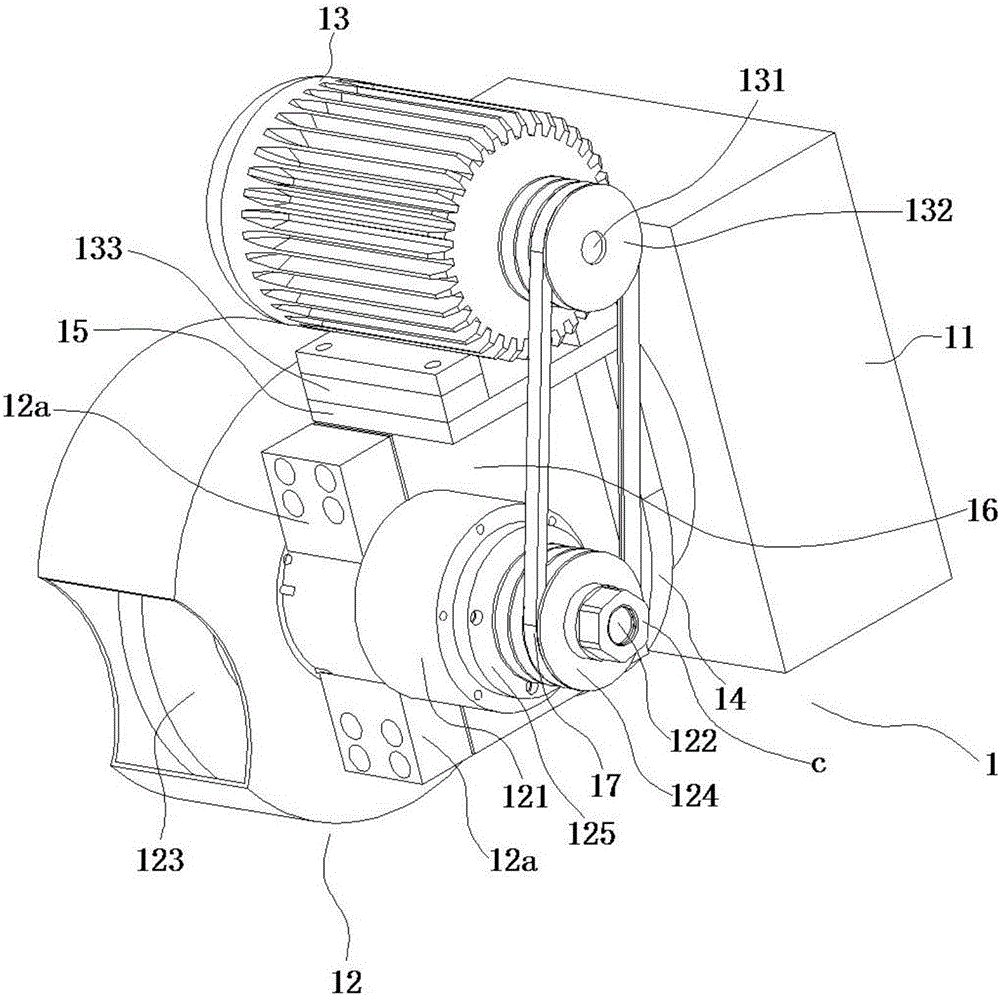

[0044] Such as Figure 1-6 Shown, the present invention relates to a kind of pros and cons teeth molar device, and it comprises: the grinding mechanism 12 of grinding workpiece g, the numerical control indexing head 11 of adjusting grinding mechanism 12 grinding angles and the grinding mechanism that drives grinding mechanism 12 work. Cutting motor 13, numerical control indexing head 11 is connected with grinding mechanism 12 by a transfer fixed disk 14, and grinding motor 13 is installed on the transfer fixed disk 14 by a motor fixed plate 15, and this grinding motor 13 and grinding Cutting mechanism 12 transmission connections.

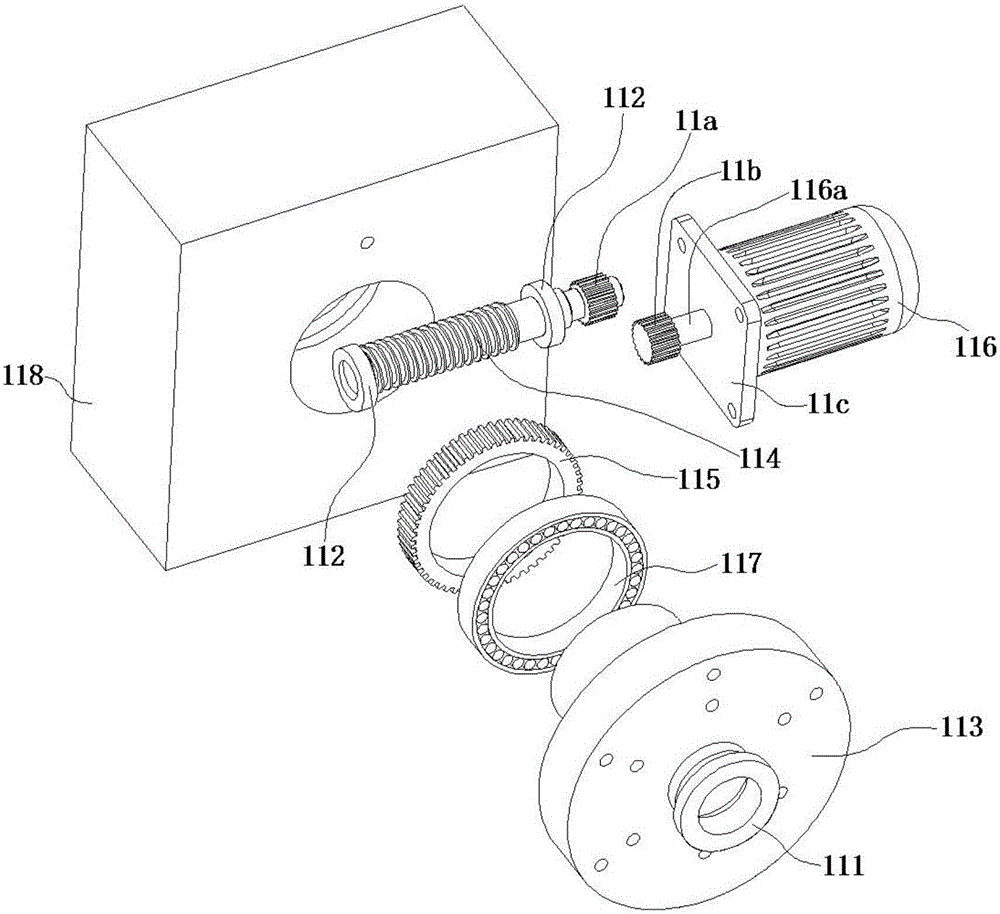

[0045] Such as image 3 As shown, the numerical control indexing head 11 is connected on the transfer fixed disk 14 through a positioning shaft 111, and one end of the positioning shaft 111 is provided with an indexing plate 113, and the other end of the positioning shaft 111 is provided with a worm gear 115 meshed with the worm screw 114. One end...

specific Embodiment 2

[0053] Such as Figure 1-6 As shown, a fully automatic numerically controlled screw tooth grinding machine disclosed by the present invention includes: a bed 2 with a guide rail 22, a tooth grinding device 1 capable of grinding positive and negative teeth, and a chuck 3 for clamping a workpiece g to be processed, The guide rail 22 is provided with a middle tray 21 that prevents cooling liquid from entering. The molar device 1 is the pros and cons teeth molar device described in the specific embodiment 1. The technical characteristics of the molar device 1 are explained by using the technical characteristics of the specific embodiment 1. This will not be repeated here; the tooth grinding device 1 is installed on one end of the middle tray 21 through the support frame 118 to form a fourth axis, so that an angular offset is generated between the grinding wheel 123 and the workpiece g, that is, the grinding wheel axis and the surface normal of the workpiece g are aligned. Angle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com