Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167 results about "Indexing head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly indexed; that is, easily and precisely rotated to preset angles or circular divisions. Indexing heads are usually used on the tables of milling machines, but may be used on many other machine tools including drill presses, grinders, and boring machines. Common jobs for a dividing head include machining the flutes of a milling cutter, cutting the teeth of a gear, milling curved slots, or drilling a bolt hole circle around the circumference of a part.

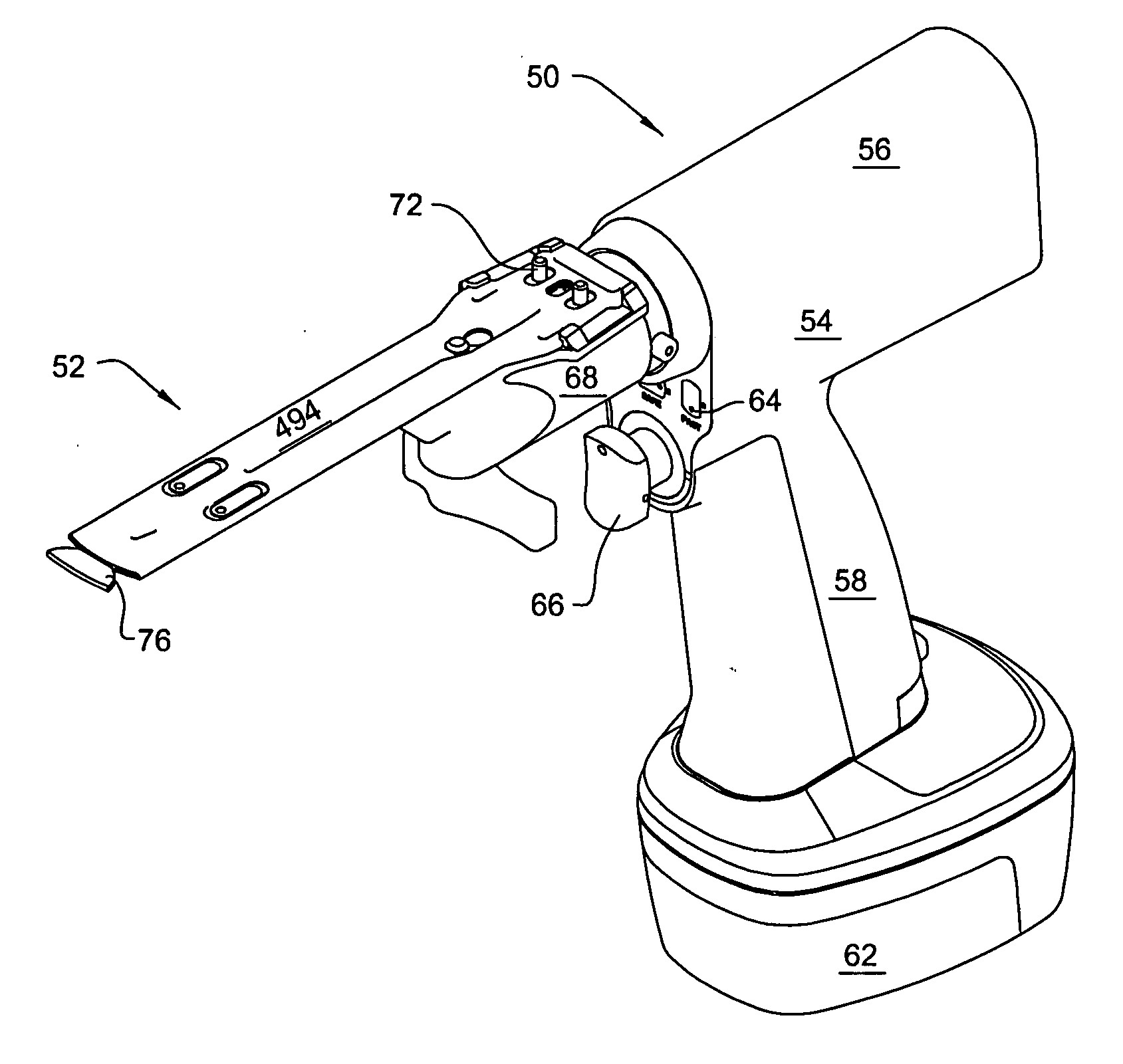

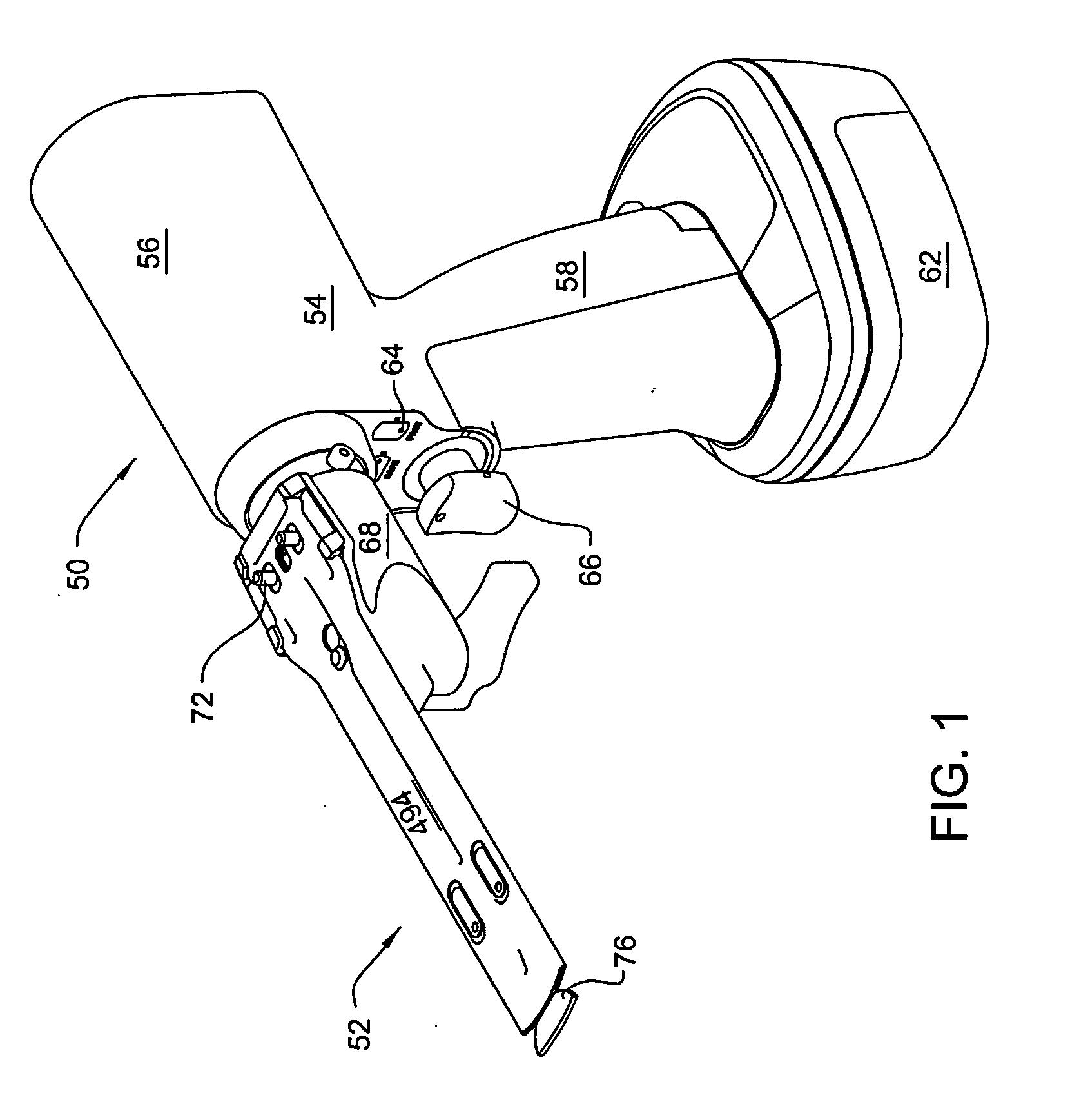

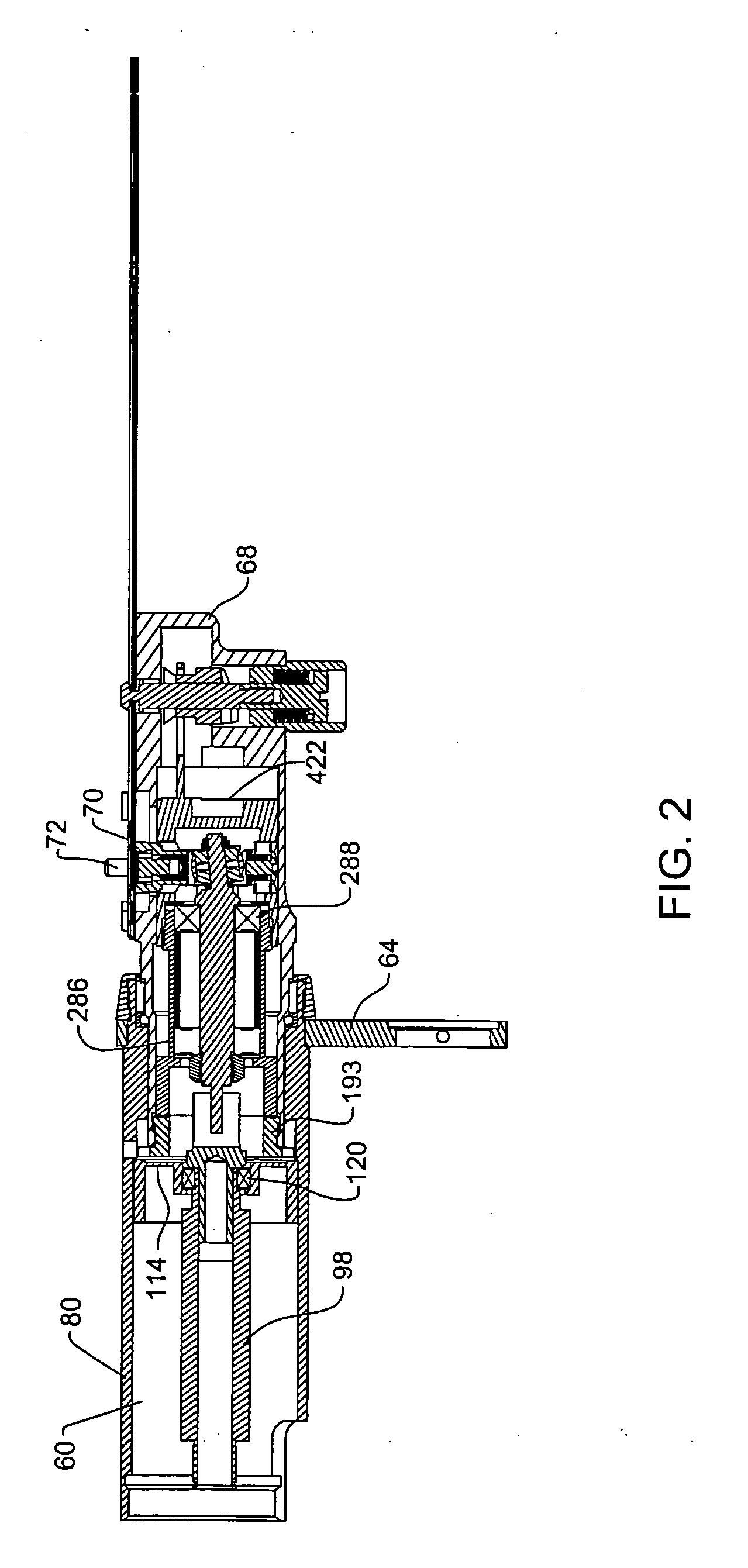

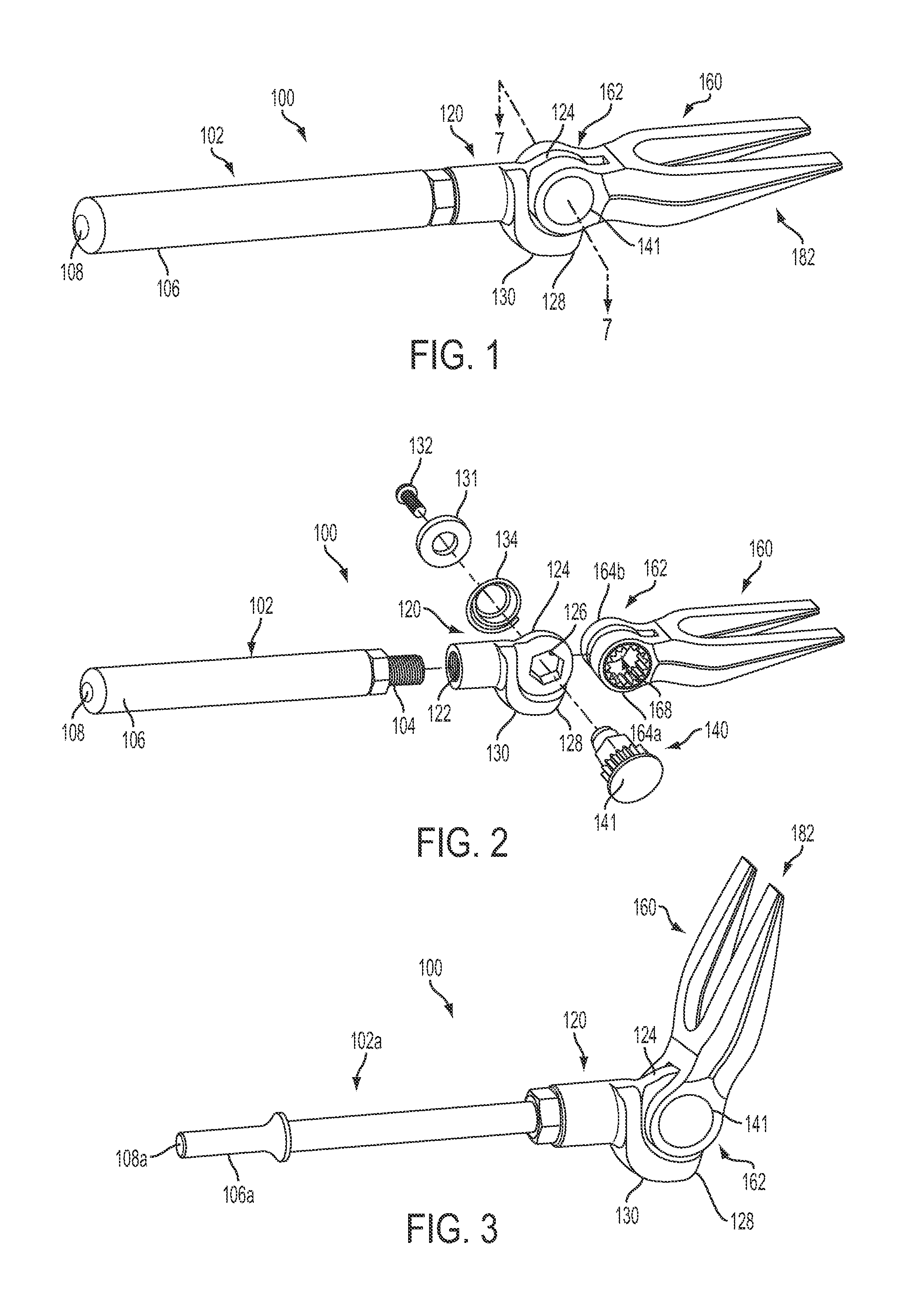

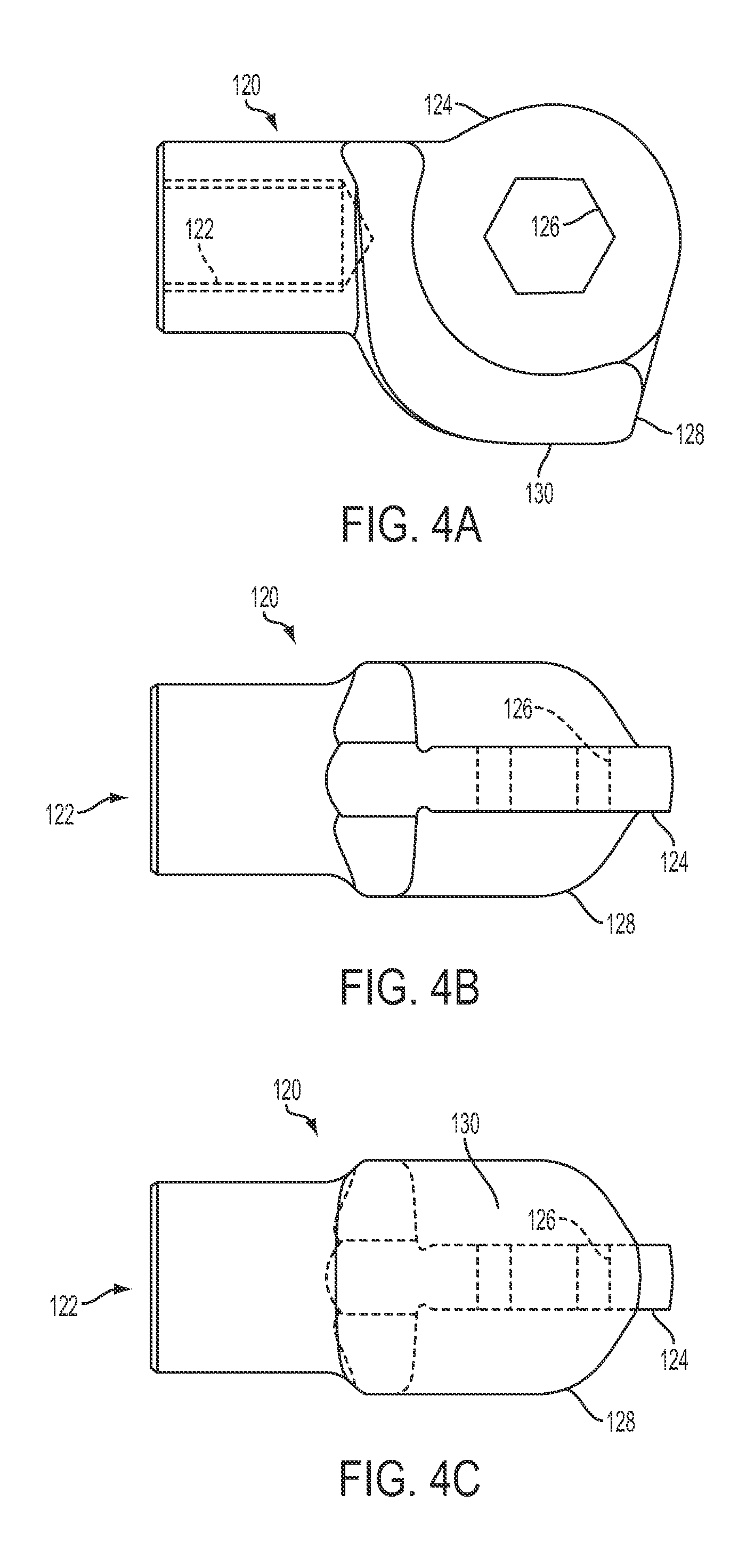

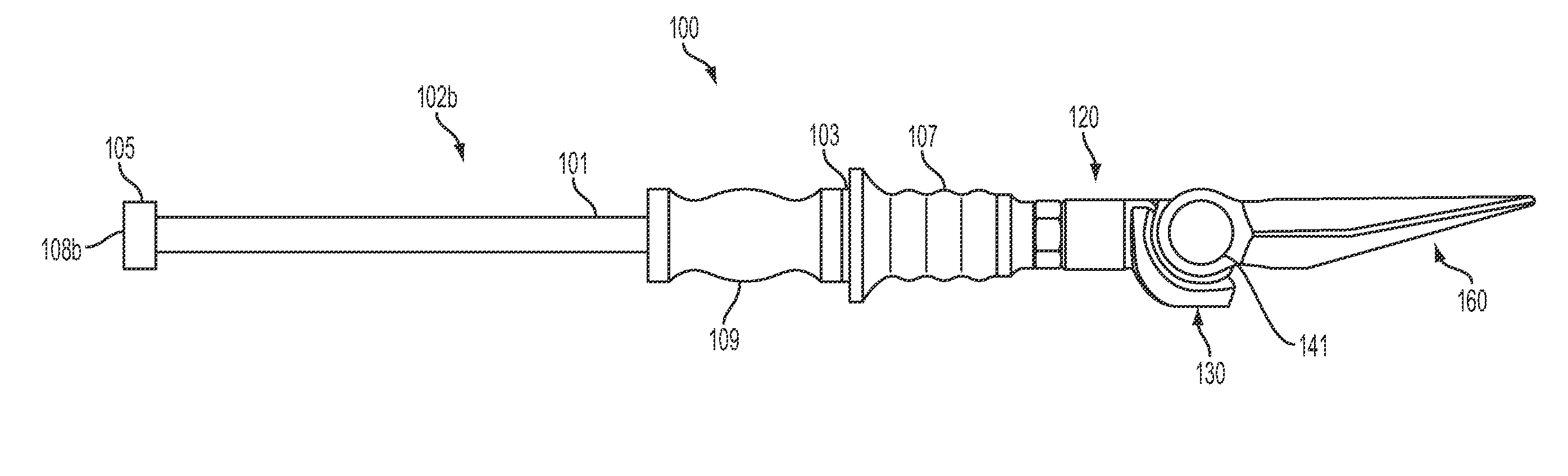

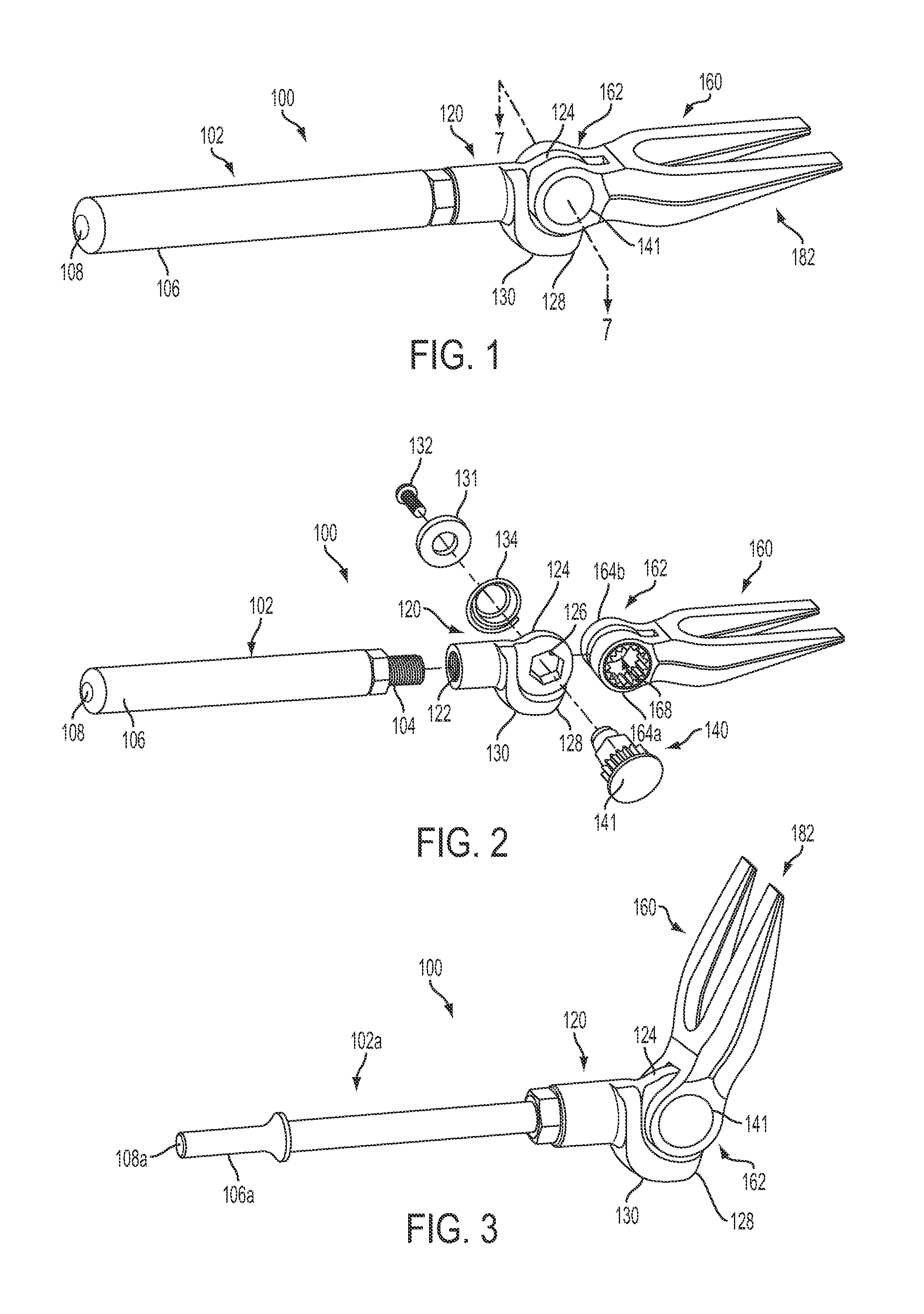

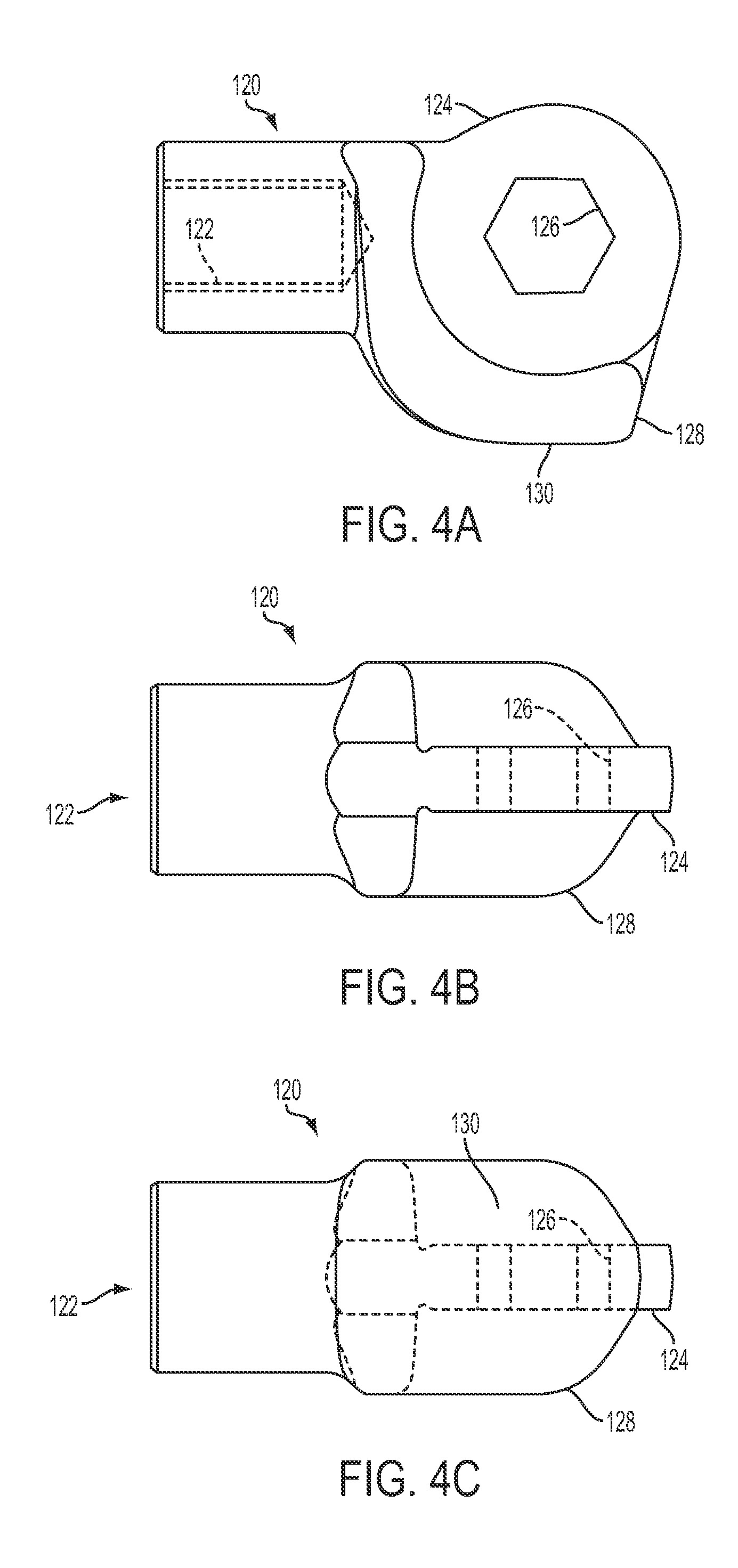

Surgical sagittal saw with indexing head and toolless blade coupling assembly for actuating an oscillating tip saw blade and oscillating tip saw blade with self cleaning head

ActiveUS20070119055A1Facilitated releaseMinimize effortDiagnosticsSurgical navigation systemsCouplingKnife blades

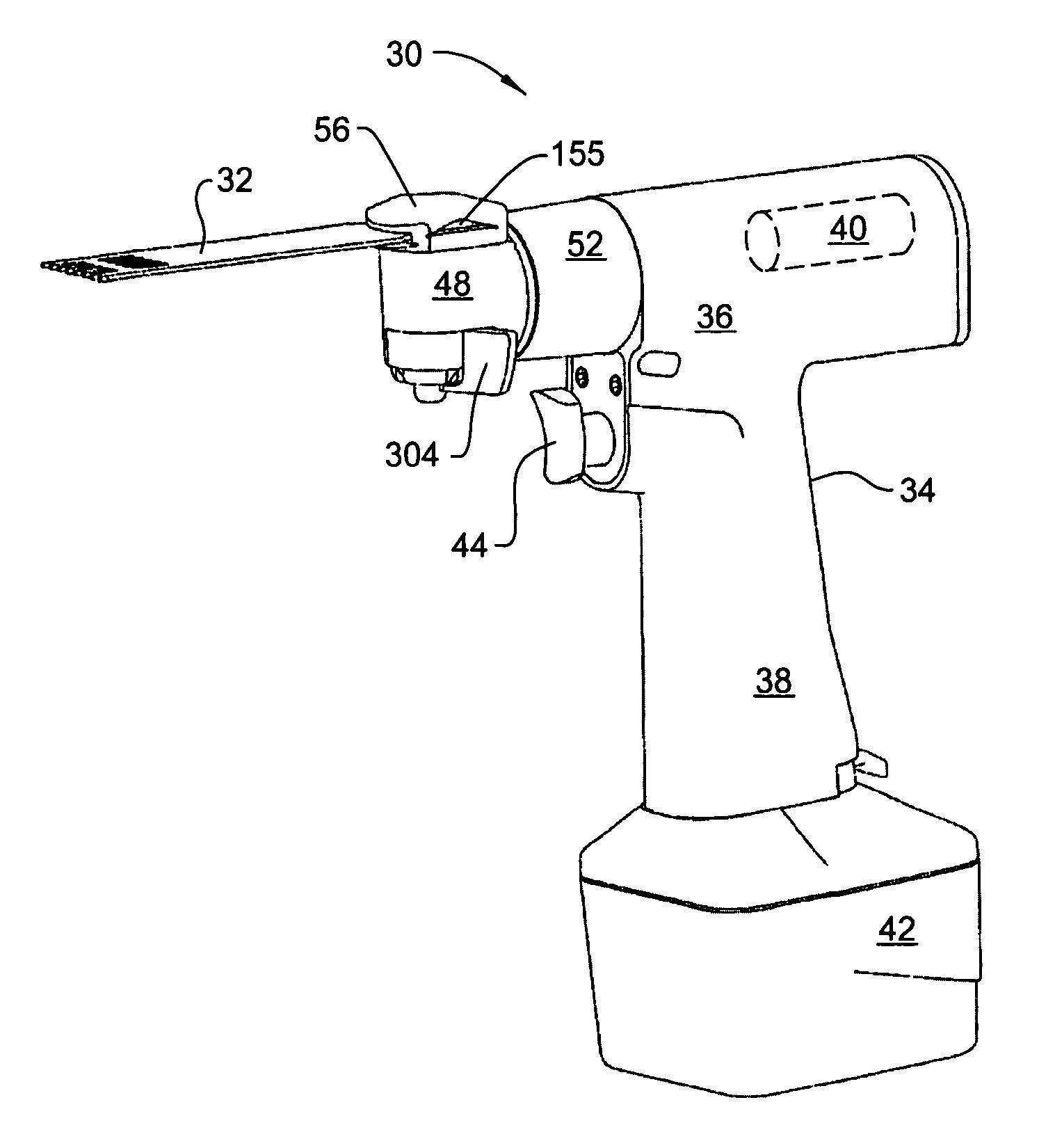

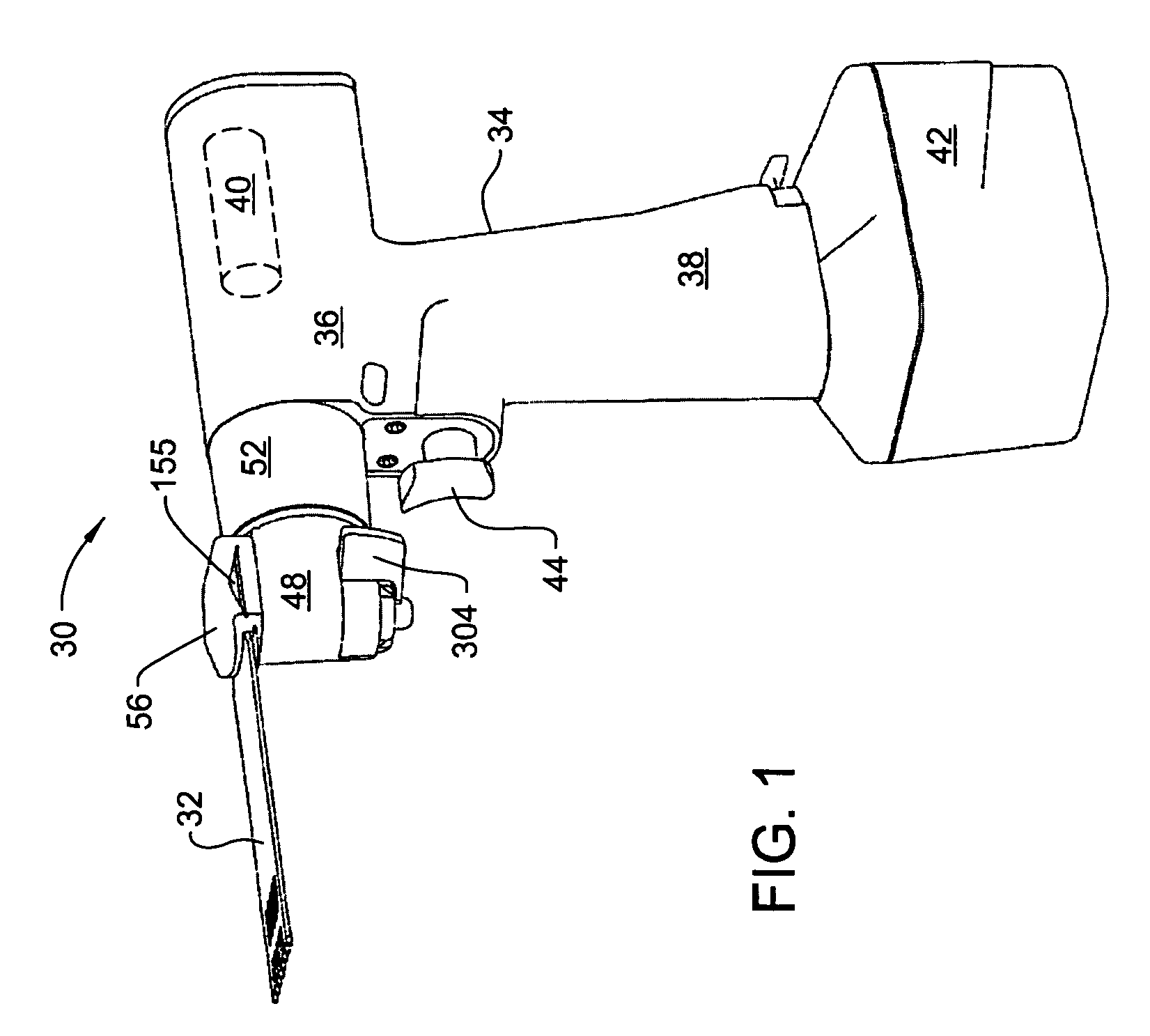

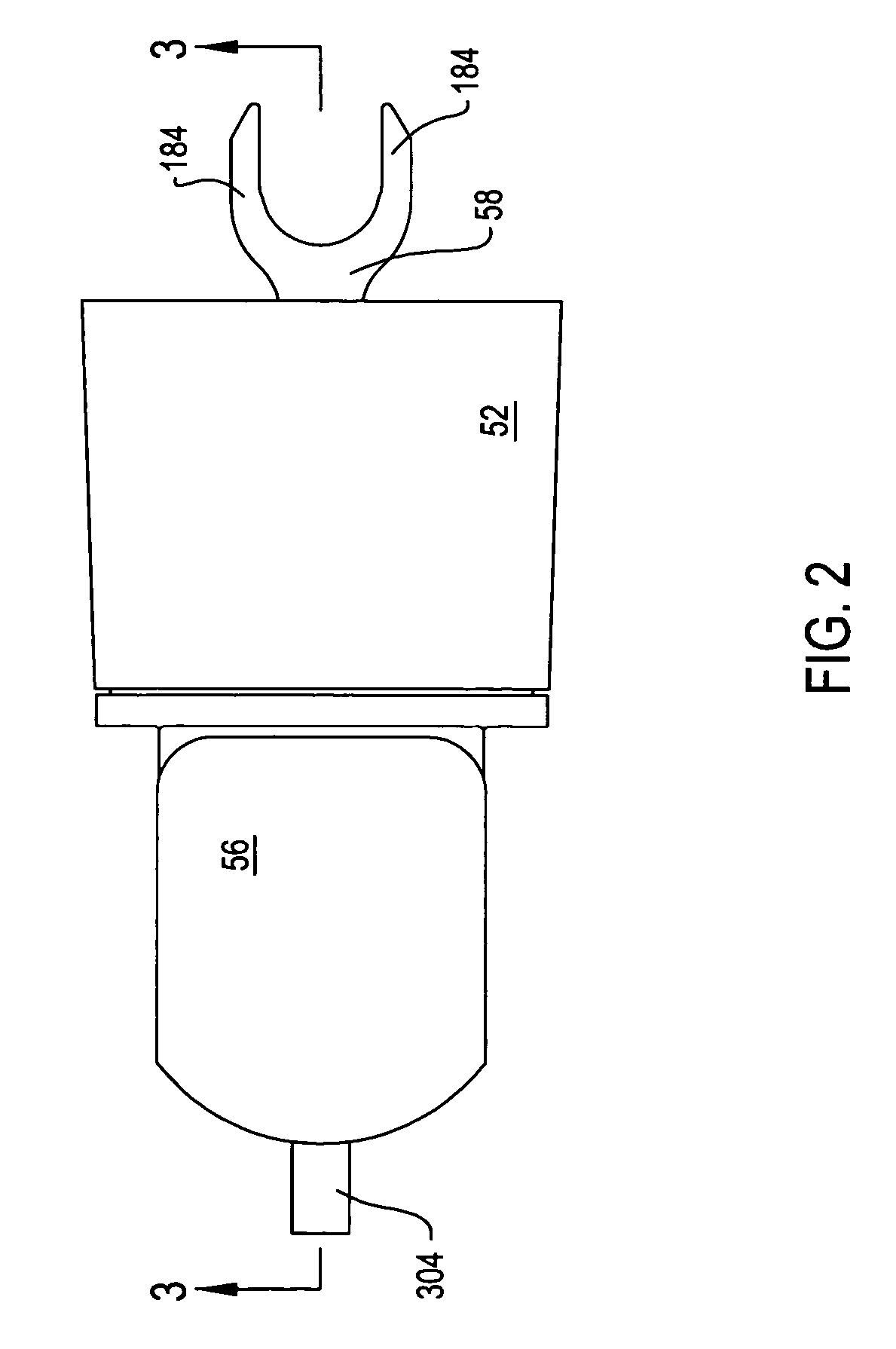

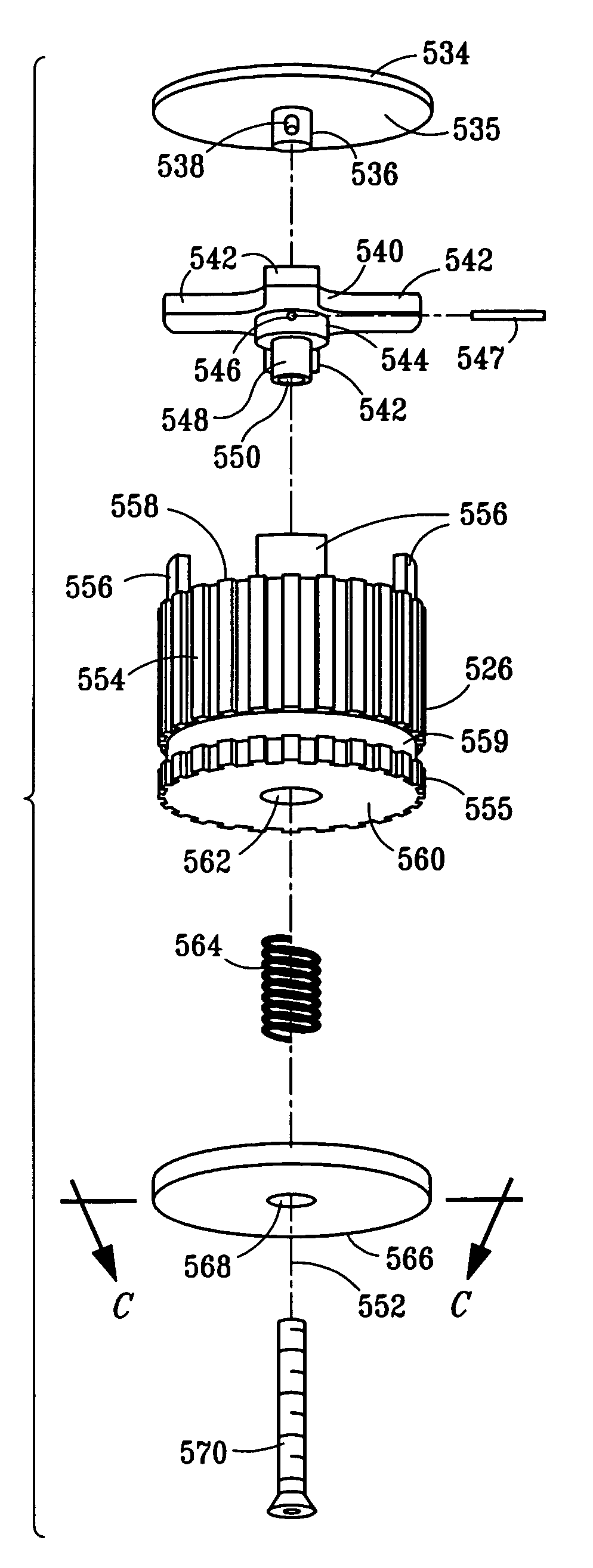

A surgical sagittal saw with an indexing head. The saw actuates a blade assembly that includes a bar from which a blade head extends. An oscillating head extends upwardly from the saw head. The oscillating head, in addition is mounted to the saw head to be able to rotate around its longitudinal axis and so that it can move along the saw head. A biasing spring normally holds the oscillating head in a fixed position. When the oscillating head is in the fixed position, the oscillating head holds the blade assembly against a restraining bracket integral with the saw head. Manual force is used to overcome the biasing spring to allow replacement and removal of the blade assembly.

Owner:STRYKER EURO OPERATIONS HLDG LLC

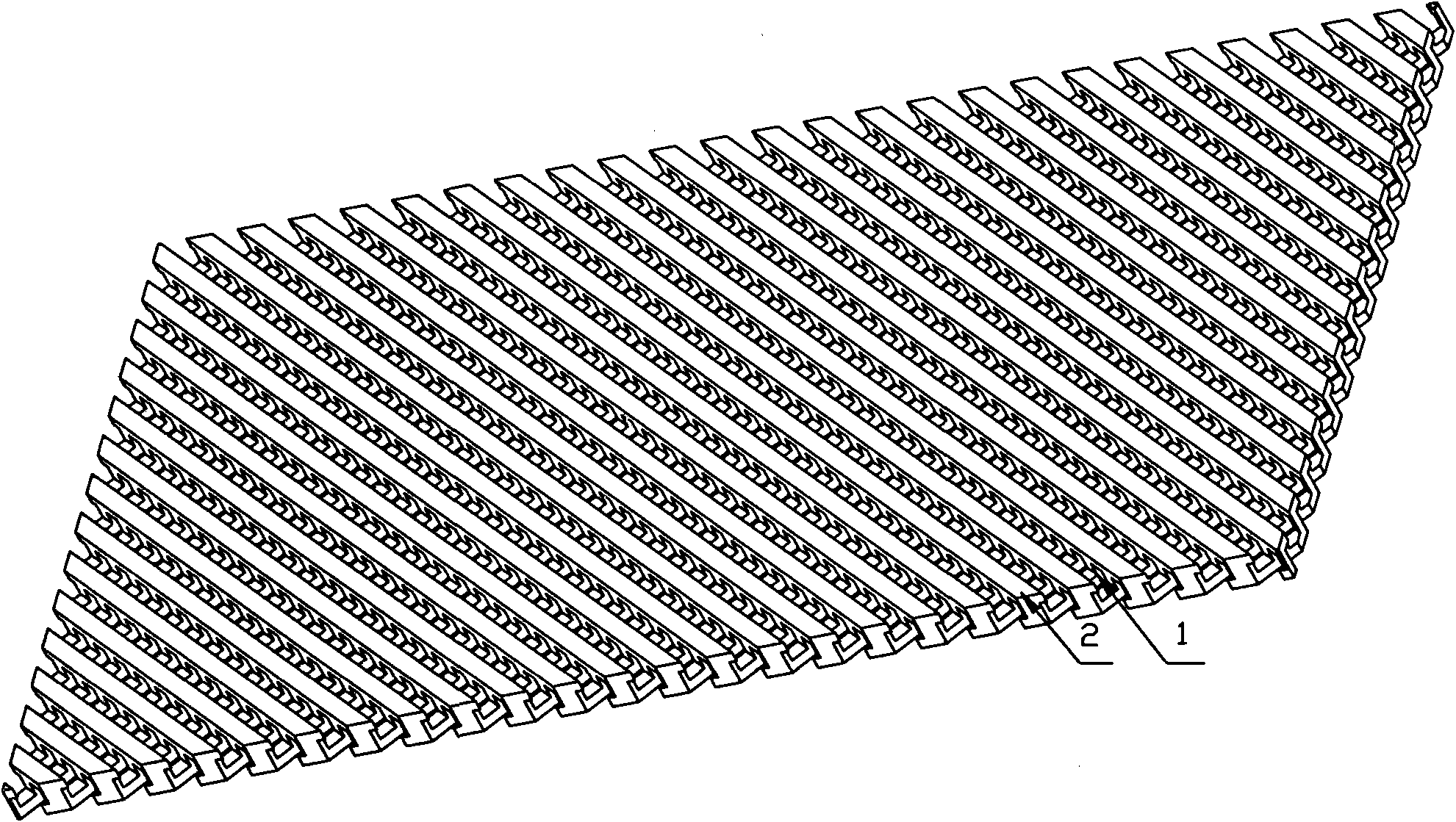

Heat exchange plate with alternate intercommunicating microchannel net structure and manufacturing method thereof

InactiveCN101782346AReduce superheatImprove heat transfer performanceLaminated elementsMilling cutterEngineering

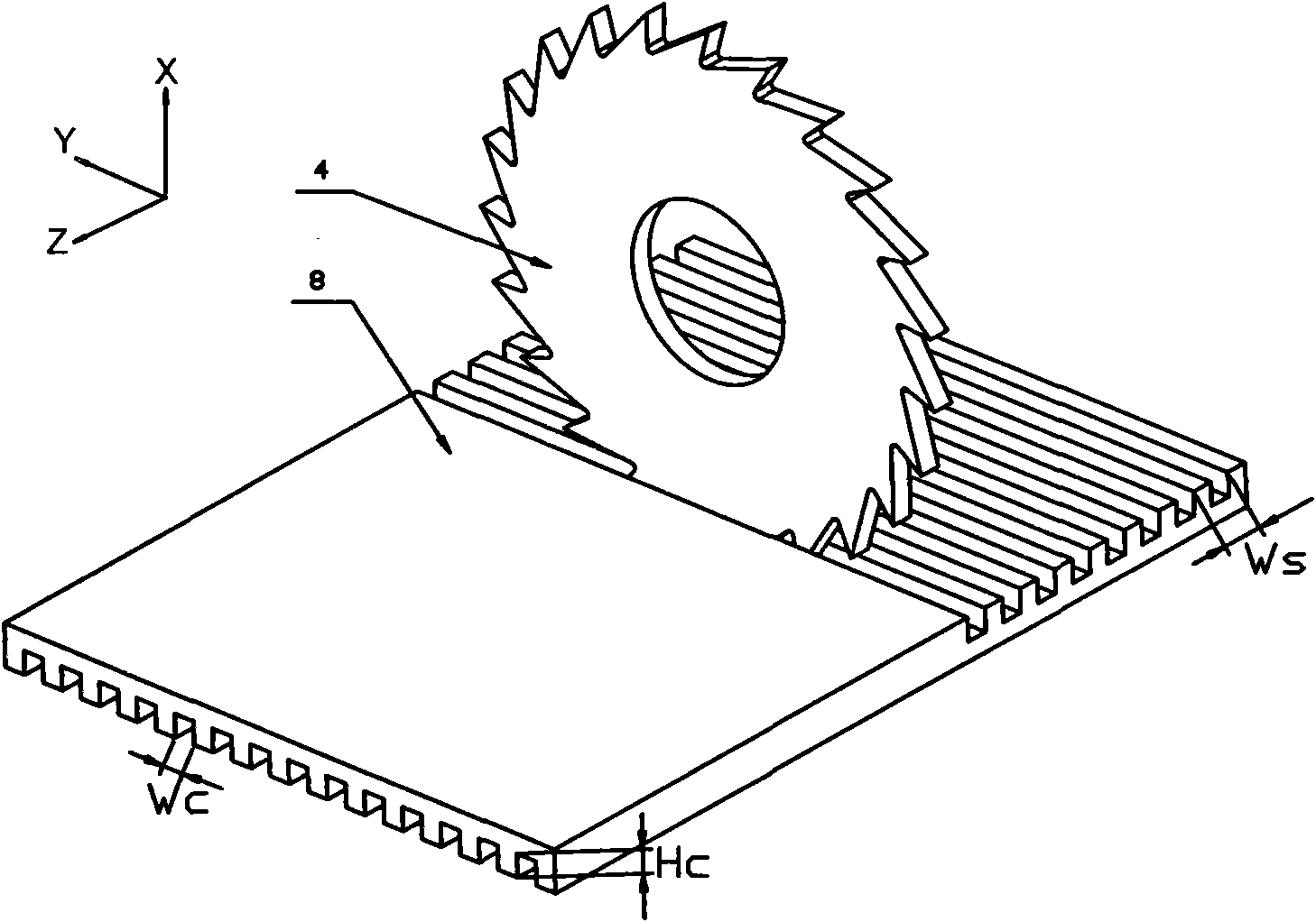

The invention discloses a heat exchange plate with an alternate intercommunicating microchannel net structure and a manufacturing method thereof. Both surfaces of the heat exchange plate are provided with microchannels which are vertical to one another; the depth of the microchannels is 1 / 2 to 2 / 3 of the thickness of a thin plate; the microchannels form the intercommunicating net structure; the width of the microchannels is between 0.1 and 1mm; the width of fins among the microchannels is between 0.4 and 0.8mm; and the thickness of the thin plate is between 1 and 3mm. During processing, the thin plate to be processed is fixed on an indexing head of a milling machine with a clamp; one surface of the thin plate is processed by using a plurality of sheets of superposed milling cutters; through the movement of a main shaft of the milling machine, the depth of the microchannels and the distance among the microchannels are controlled; and then the other surface of the thin plate is processed to ensure that an upper channel is vertical to a lower channel so as to finally form the intercommunicating microchannels. The heat exchange plate of the invention can increase the specific surface area and is beneficial for nucleation. The groove is beneficial for the air bubbles to overflow. The heat exchange plate of the invention has excellent boiling reinforcing performance. The method for manufacturing the heat exchange plate adopts the plurality of sheets of milling cutters to carry out processing, thus, the processing efficiency is greatly improved and the cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Surgical sagittal saw with quick release indexing head and low blade-slap coupling assembly

ActiveUS20070016238A1Smooth rotationMetal sawing devicesNon-rotary toothed toolsCouplingLocking mechanism

A surgical sagittal saw with a head that is able to index, rotate, relative to the longitudinal axis of the saw housing. The head has a neck that extends into an open distal end of the housing. A biasing assembly holds the head and neck sub-assembly in the open distal end of the housing. The biasing assembly is rotatable relative to the housing. A separate lock mechanism selectively holds the head in a fixed orientation around the saw housing longitudinal axis.

Owner:STRYKER CORP

Surgical sagittal saw with quick release indexing head and low blade-slap coupling assembly

ActiveUS8100912B2Smooth rotationMetal sawing devicesNon-rotary toothed toolsLocking mechanismCoupling

Owner:STRYKER CORP

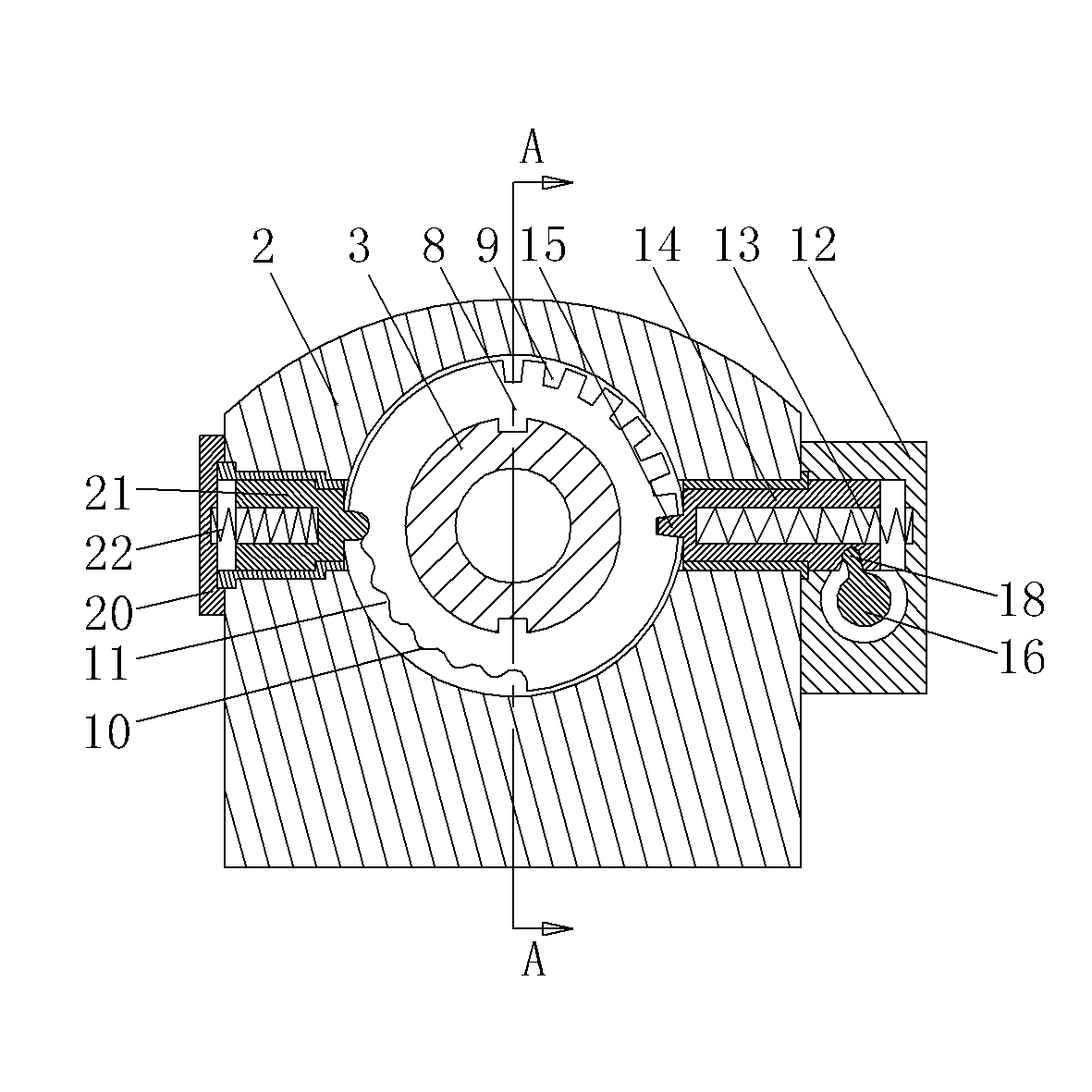

Radial indexing head tool with floating splined pin

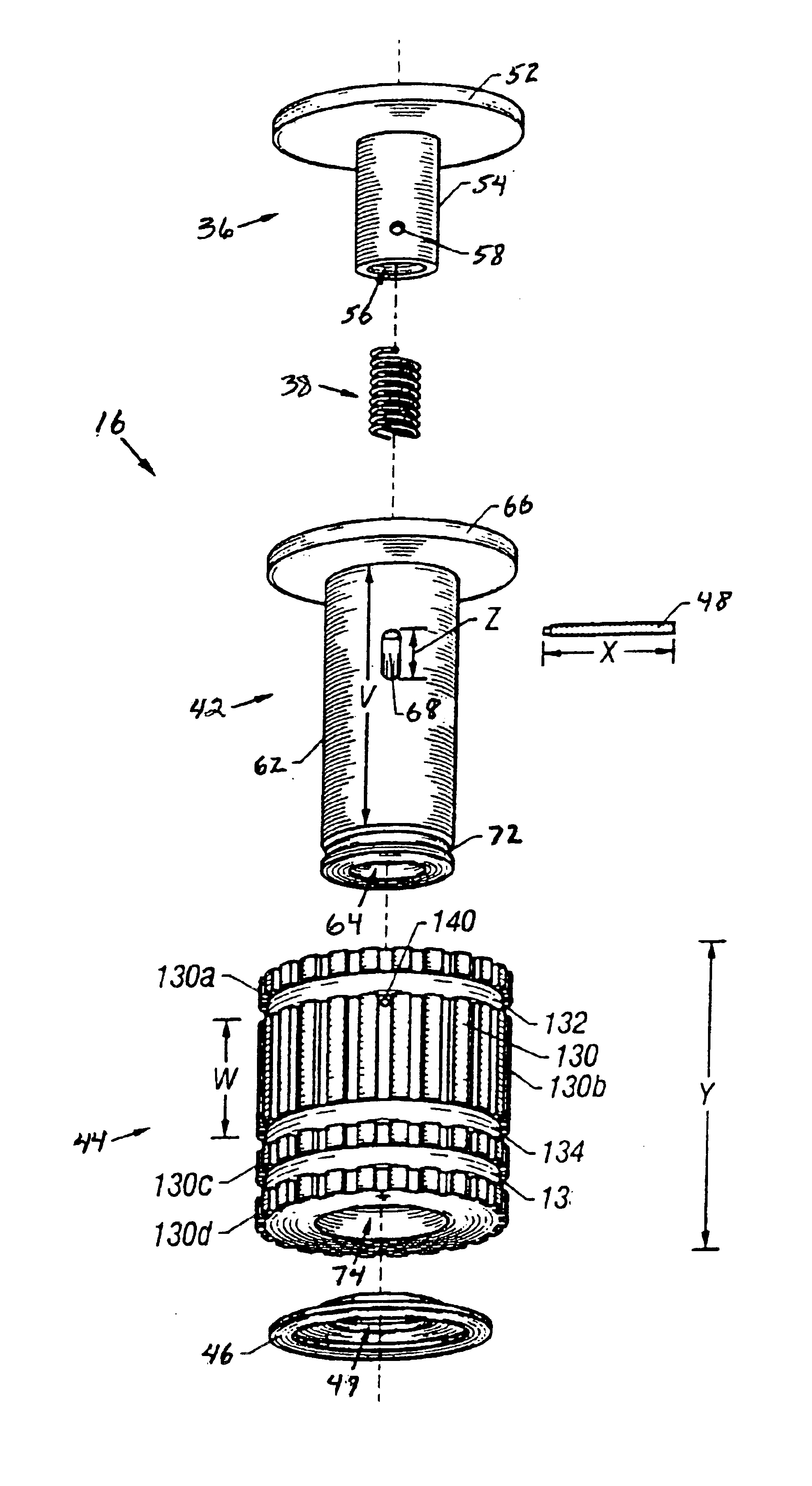

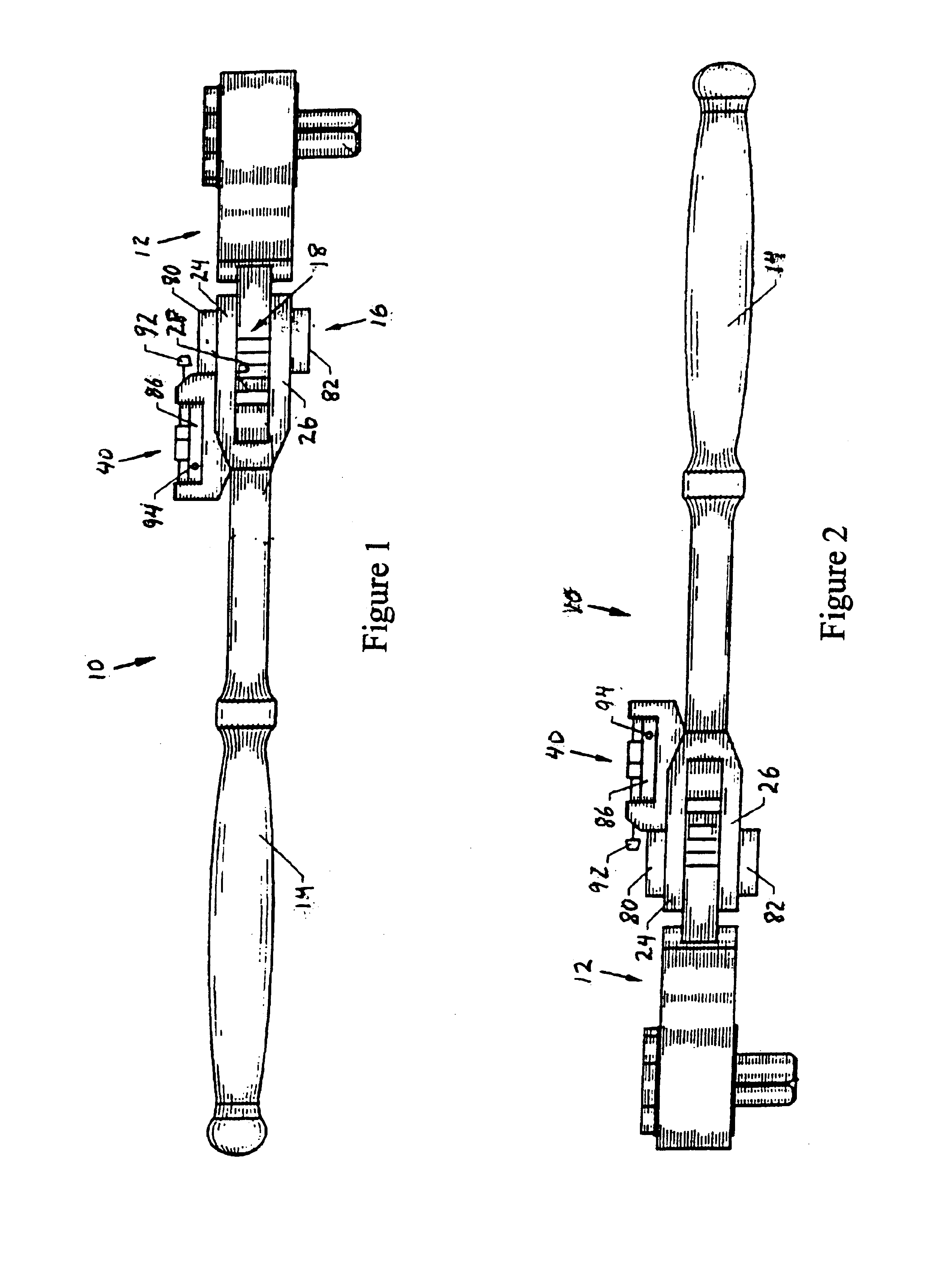

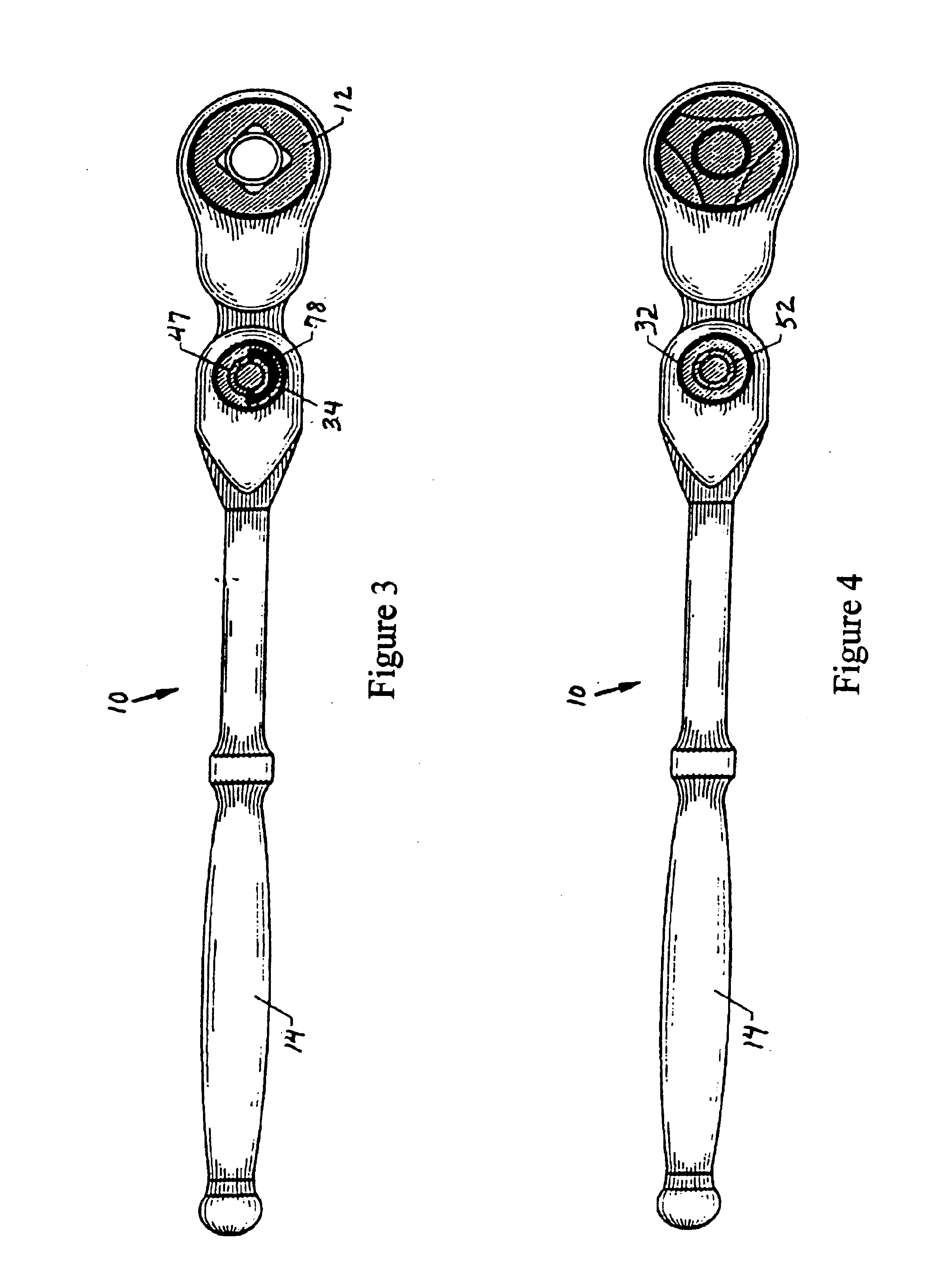

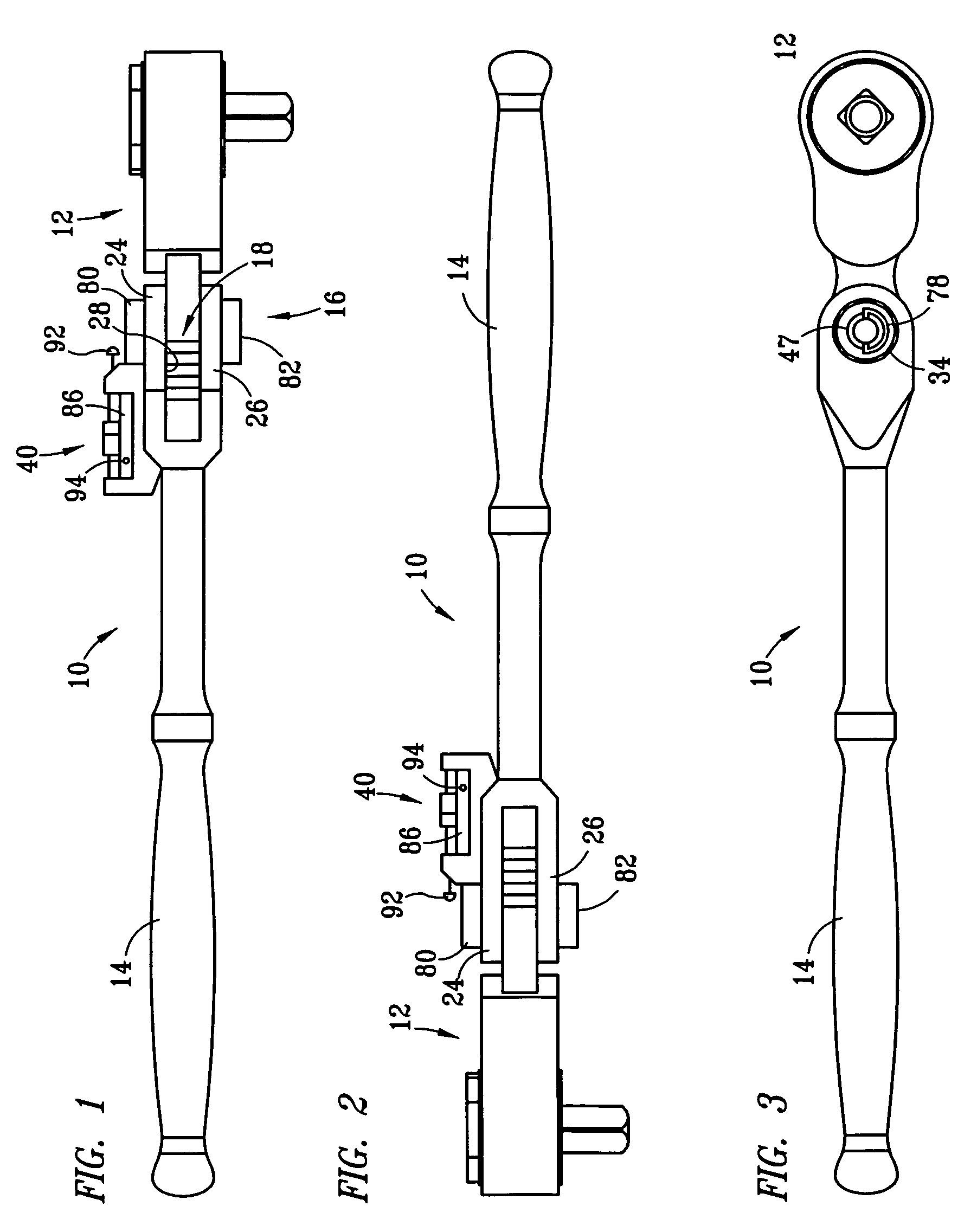

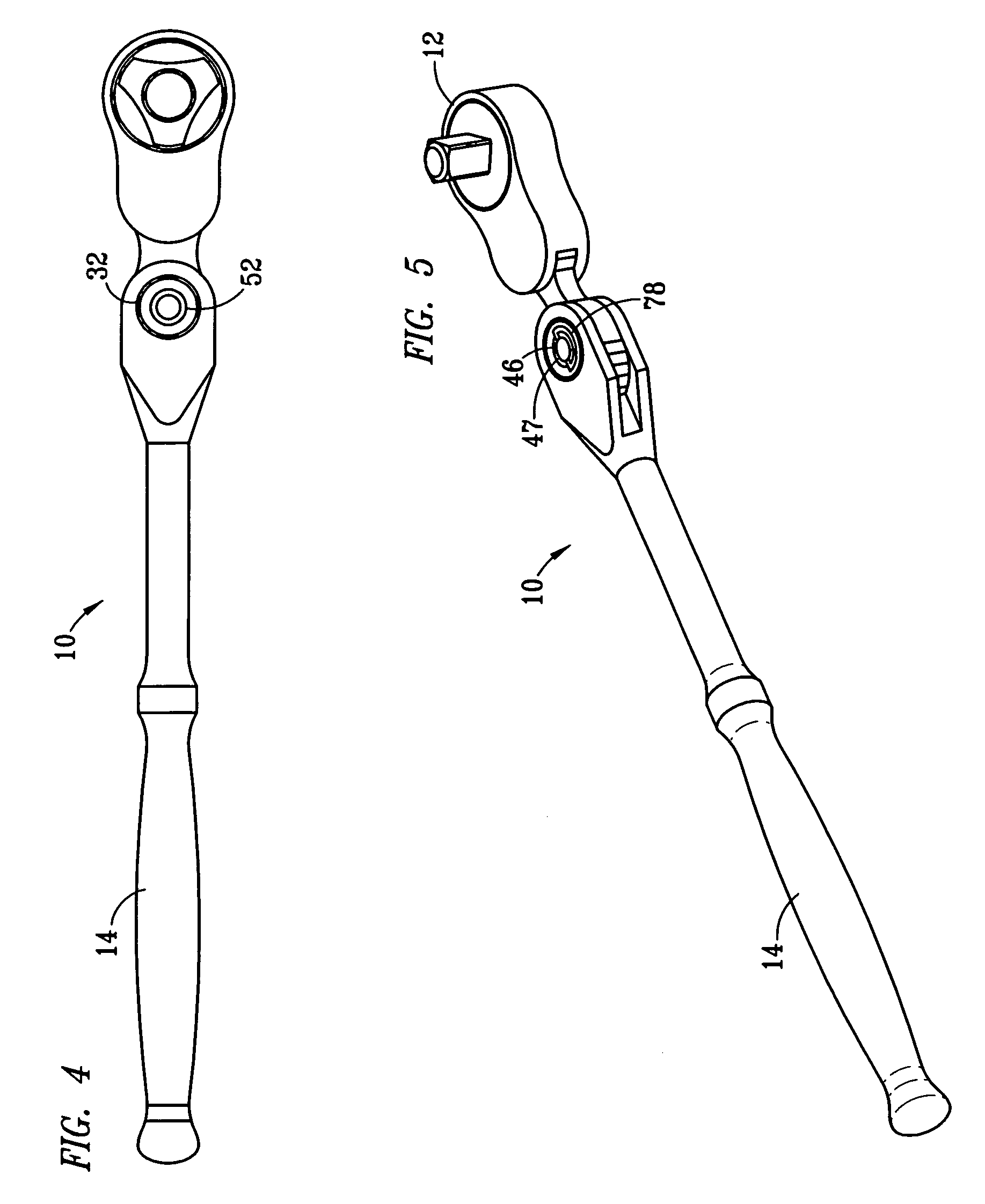

A radial indexing head tool includes a handle and ratchet head, each with a splined orifice, and a floating splined pin disposed in the splined orifices for coupling them together. The floating splined pin includes a cylindrical axial retainer coupled to the handle and extending into the splined orifices, a plunger configured for axial movement within the axial retainer, and a splined cylinder configured for axial movement along the outside of the axial retainer within the splined orifices. The plunger and splined cylinder are coupled to each other through the cylindrical wall of the retainer. Movement of the splined cylinder aligns or misaligns grooves and splined portions formed on the splined cylinder relative to grooves and splined portions formed in the splined orifices to lock or unlock the ratchet head for movement relative to the handle.

Owner:COLE BRIAN T +1

Radial indexing head tool with floating splined pin

The present invention relates to an indexing mechanism which provides a releasing function to permit the rotation of tool and handle members relative to each other. The indexing mechanism is positioned through two extensions positioned on either the tool or the handle and a third member positioned between the two extensions. Each of the two extensions and the central member includes a splined orifice. A splined pin is positioned in the splined orifices and is moveable to permit release or engagement of the handle and the tool so that the handle and the tool can be released for rotation relative to each other and re-engaged to form a rigid connection between the tool and the handle. The indexing mechanism of the present invention minimizes sticking of the splined pin during release and re-engagement.

Owner:CINCOLE

Separator tool with indexing head

Owner:APEX BRANDS

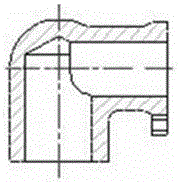

Fixed equational indexing head

InactiveCN102152169AHigh positioning accuracyEasy to operatePrecision positioning equipmentVertical planeLocking mechanism

Owner:平顶山市东方惠普工贸有限公司

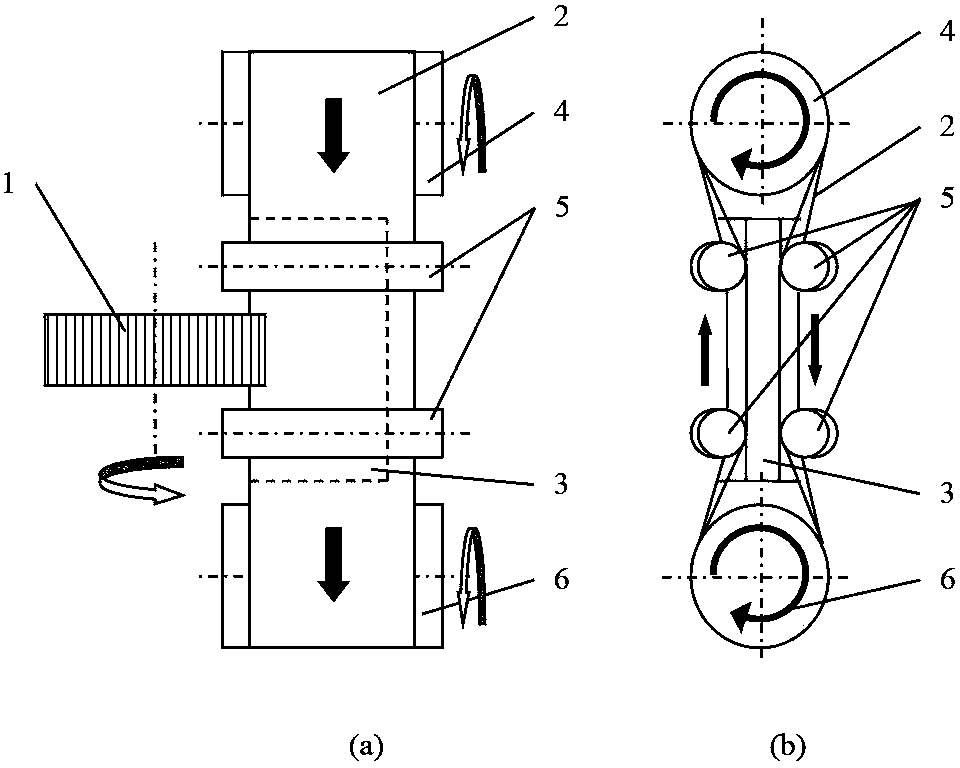

Gear grinding machining method and device

InactiveCN103737119AImprove grinding efficiencyAvoid easy cloggingGear-cutting machinesGear teethGear grindingGear wheel

The invention provides a gear grinding machining method and device. The method adopts an abrasive belt which is high in grinding efficiency, the abrasive belt is in high-speed motion along the tooth width direction of a gear to conduct grinding, and the abrasive belt is in generating motion relative to a gear blank to grind each tooth socket tooth surface sequentially and swings slightly relative to the generatrix of the tooth surface to achieve crowned tooth surface shape correction. The device for achieving the grinding machining method is provided and comprises a bed body, a lifting table, a gear blank rotation dividing head, a gear blank flat moving work table, a gear blank dip angle table, an abrasive belt feeding work table and an abrasive belt deflection rotary disc. A numerical control system controls all the portions to be in linkage and conducts complementation of abrasive belt abrasion loss, machining of various gears can be achieved by using suitable press grinding plates and belt guiding wheels or guiders, disc-shaped or worm-shaped grinding wheels are not required, and the method and device has high machining efficiency and machining quality.

Owner:湖北光辉节能科技有限公司

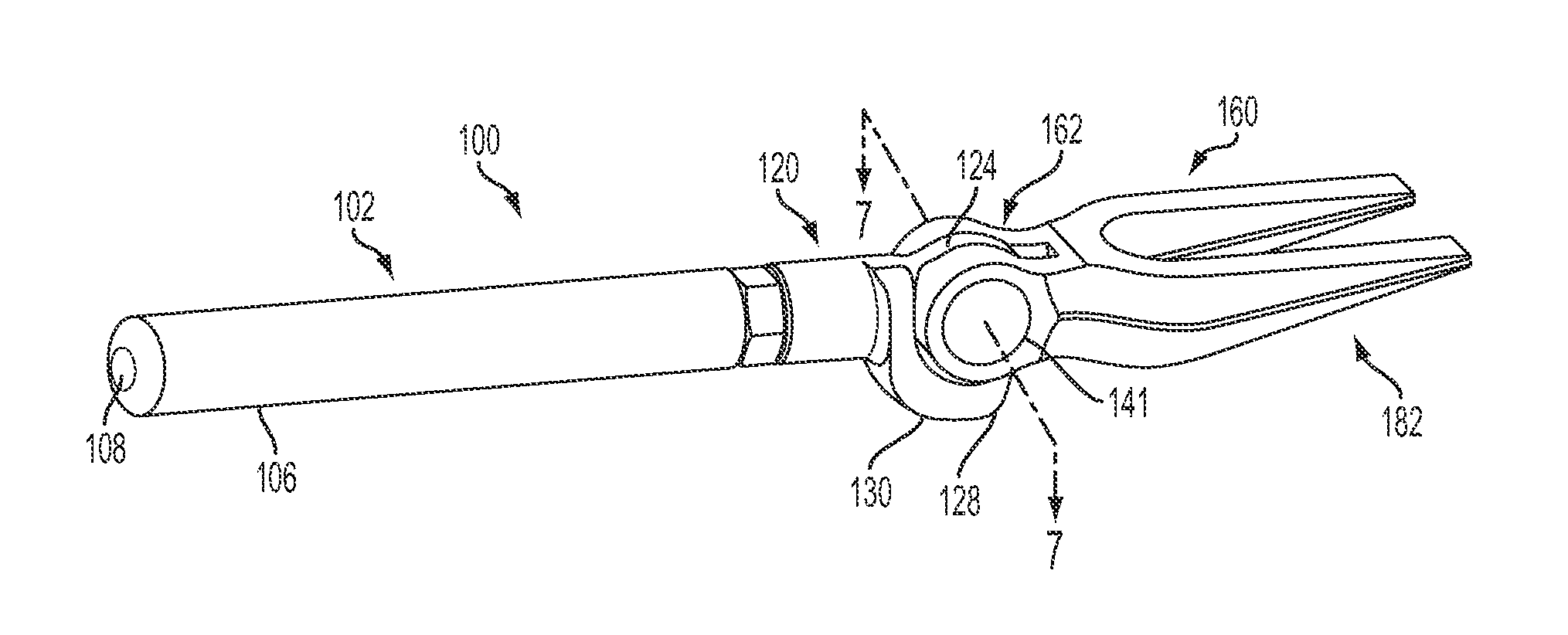

Separator tool with indexing head

A separator tool including a handle formed a hub at a first end, the hub defining a through bore that is transverse to a longitudinal center axis of the handle, a tool head formed with an integral yoke including opposed first and second legs, the tool head being pivotably coupled to the first end of the handle, an indexing stud slidably disposed within the through bores of the hub and first and second legs of the yoke, and the indexing stud being slidable within the through bores between a first position in which the tool head is secured in a fixed position relative to the handle, and a second position in which the tool head is pivotable relative to the handle.

Owner:APEX BRANDS

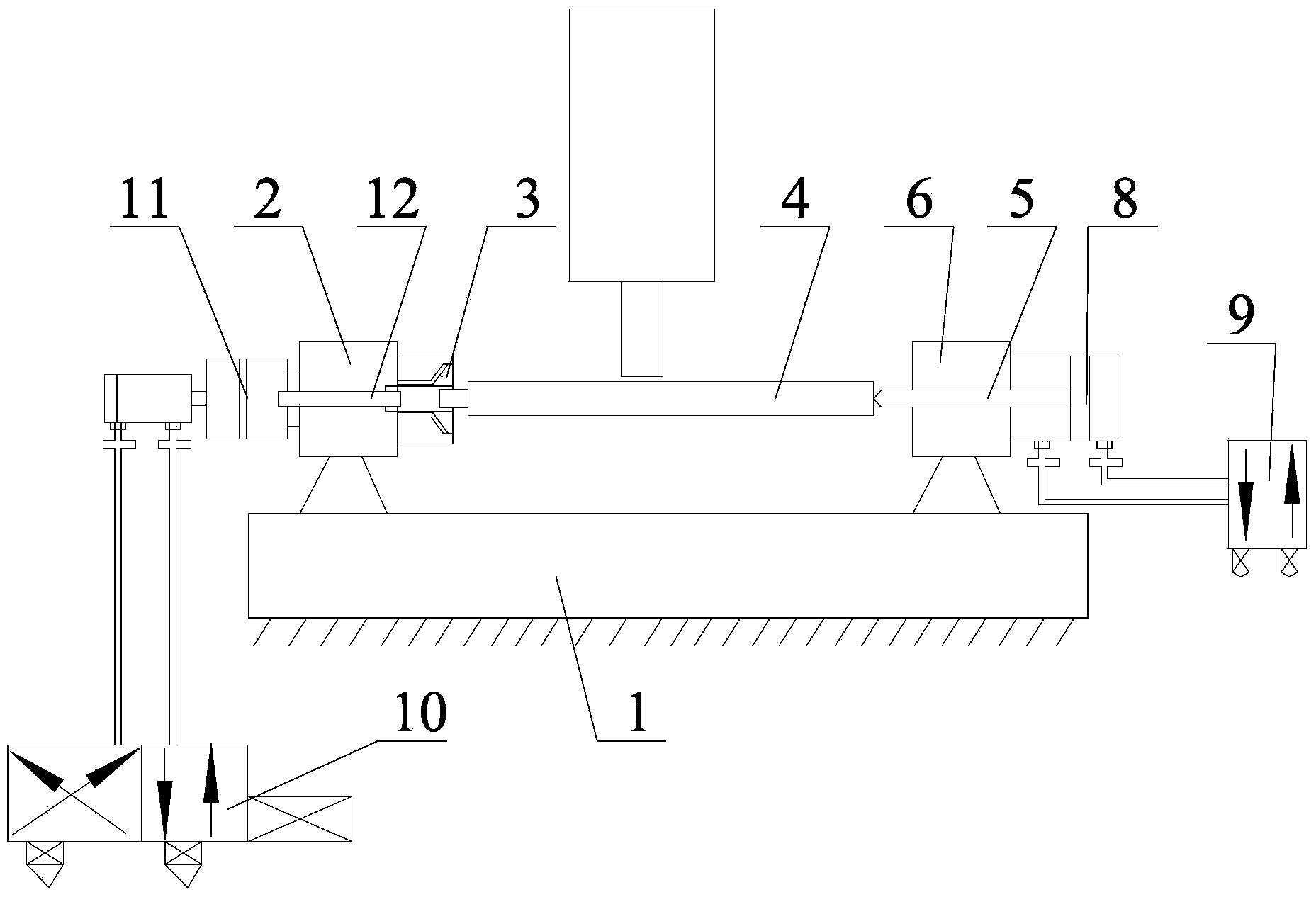

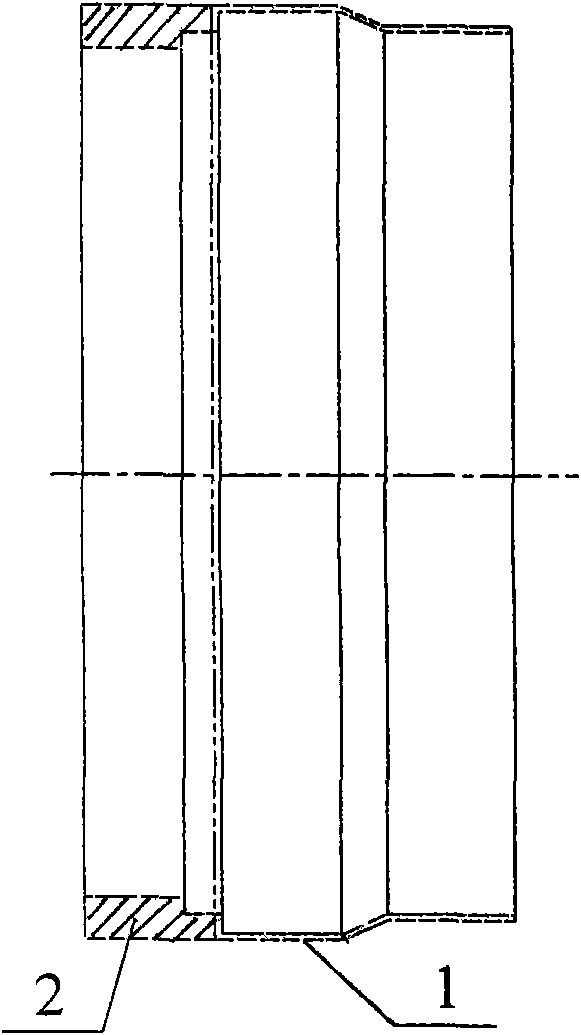

Horizontal type machine tool automatic clamping device and horizontal type machine tool

InactiveCN103862312ALow costImprove efficiencyTailstocks/centresWork clamping meansEngineeringMachine tool

The invention discloses a horizontal type machine tool automatic clamping device. A chuck is a spring chuck, a first through hole is formed in an indexing head, an opening of the end, facing a tail base, of the first through hole is gradually expanded from inside to outside, the opening is matched with the outer side wall of the chuck, a first piston cylinder is arranged on the side, deviating from the tail base, of the indexing head, a pull rod is connected to a first piston rod of the first piston cylinder, the pull rod penetrates through the first through hole and is connected with the chuck, a second through hole coaxial with the first through hole is formed in the tail base, a second piston cylinder is arranged on the side, deviating from the indexing head, of the tail base, a tip is connected with a second piston rod of the second piston cylinder, and the second piston rod is used for driving the tip to stretch out of or retract to the second through hole. A shaft part is clamped through switches of the two piston cylinders, and compared with an existing clamping mode, the speed is high, efficiency is high, the operation is easy, work intensity is lowered, machining time is shortened, then enterprise cost is lowered, and enterprise benefits are improved. The invention further discloses a horizontal type machine tool.

Owner:重庆雁山机械制造(集团)有限公司

Manufacturing method for ultrathin tegular locking plate of nuclear reactor pressure vessel main bolt

The invention provides a manufacturing method for an ultrathin tegular locking plate of a nuclear reactor pressure vessel main bolt, comprising the following steps of: placing a tubular forge piece on a numerically controlled lathe; turning the forge piece and then moving the forge piece to an environment at the temperature of 350-450 DEG C for thermal treatment; then placing the thermally treated forge piece on the numerically controlled lathe with a concave-convex tegular programming; carrying out concave-convex cutting on the circumference of the tubular forge piece with a turning tool the tool nose radius of which is 0.1-0.3mm to ensure that the circumferential wall is cut to be 0.8-2.5mm in thickness to obtain a thin-wall tubular forge piece; then fixing the thin-wall tubular forge piece on the indexing head of a milling machine by using an annular pressing plate and a bolt; milling a waist-shaped hole along the circumferential wall of the thin-wall tubular forge piece by using a centring milling tool and then moving the thin-wall tubular forge piece to the lathe to remove a chunk to manufacture a connected ultrathin tegular locking plate; finally, fixing the connected ultrathin tegular locking plate on linear cutting equipment by using the pressing plate and the bolt, and cutting along a cutting line arranged on the linear cutting equipment to manufacture a single-sheet type ultrathin tegular locking plate. The method has high material use ratio and low cost, and the manufactured ultrathin tegular locking plate is bright and clean and attractive and is accurate in dimension.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

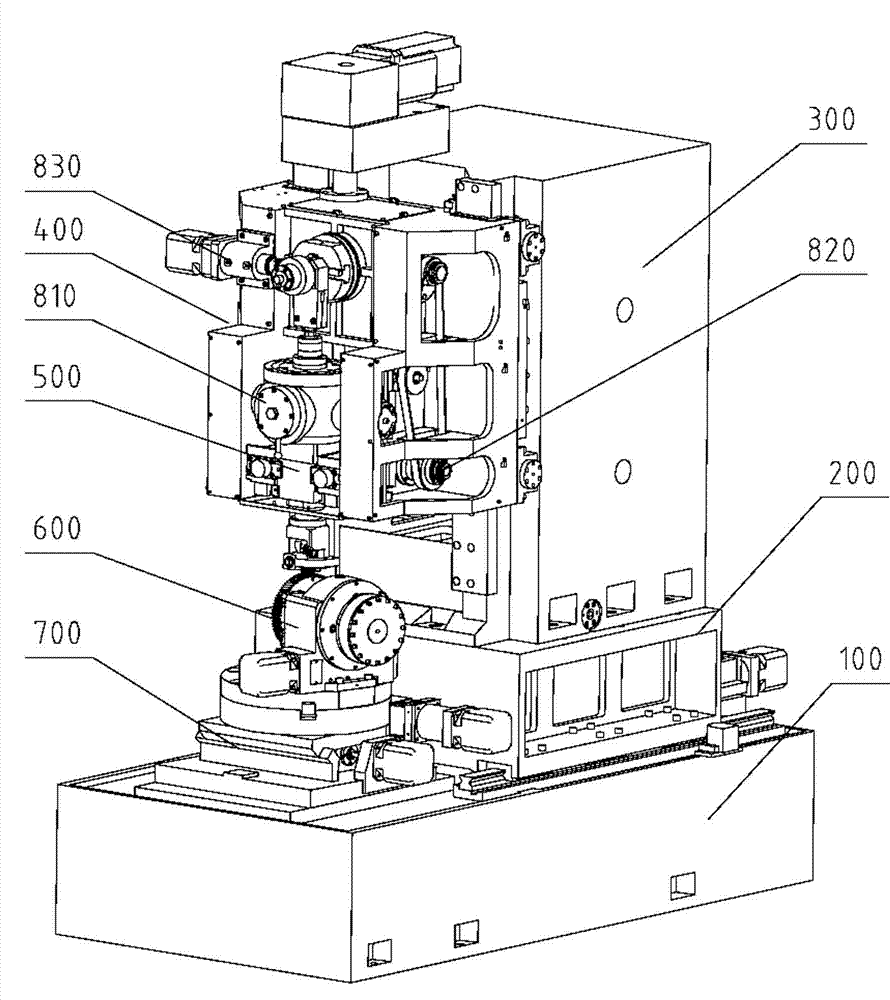

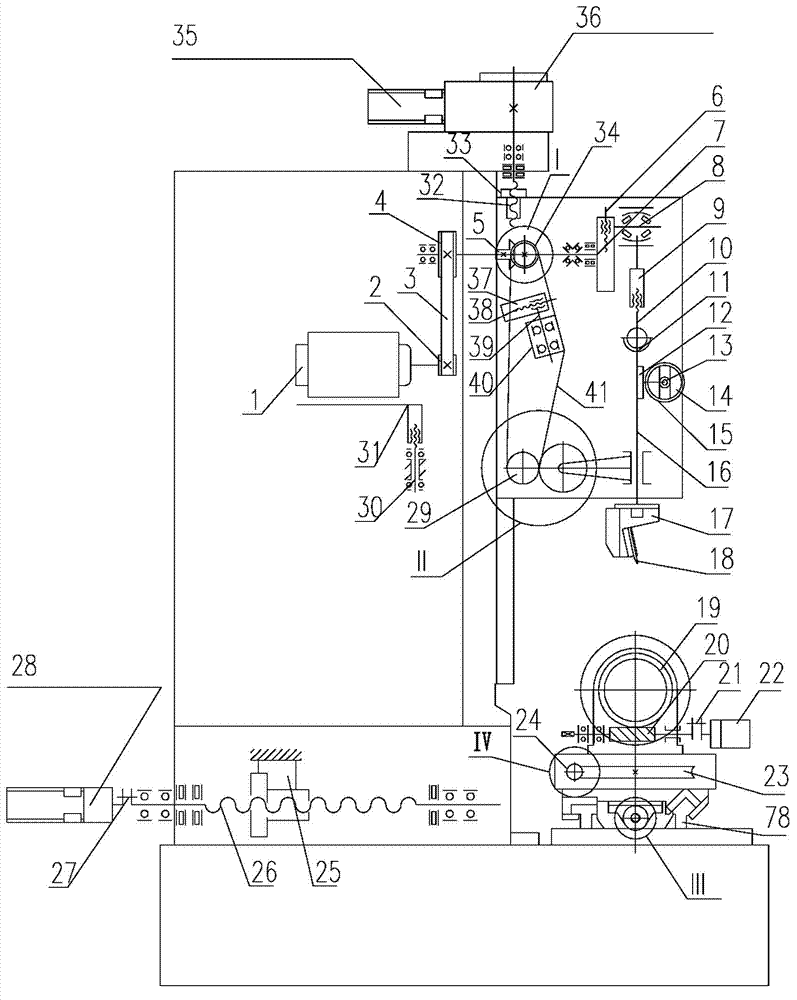

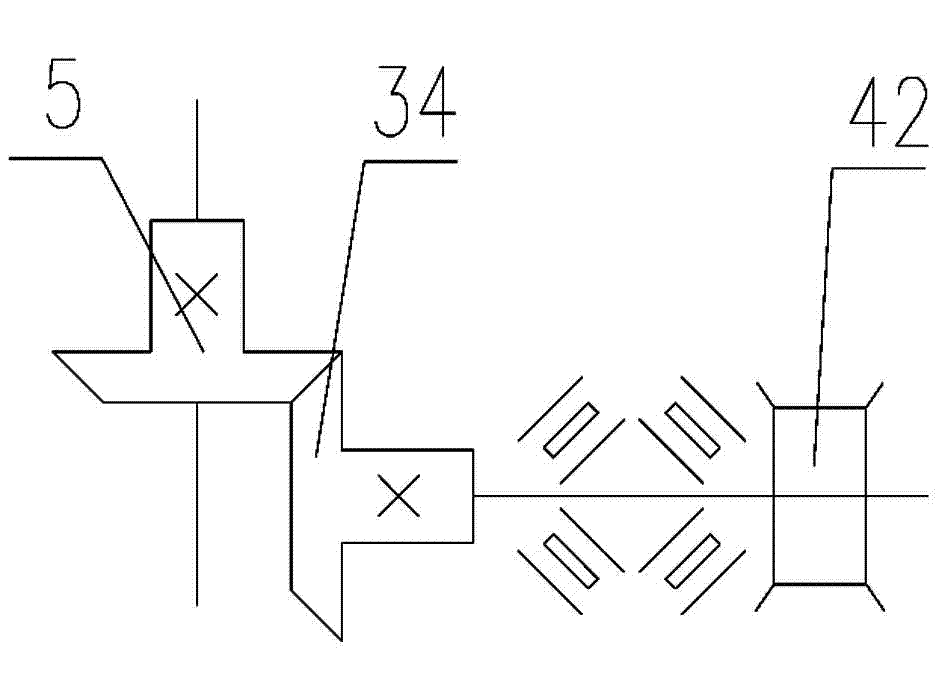

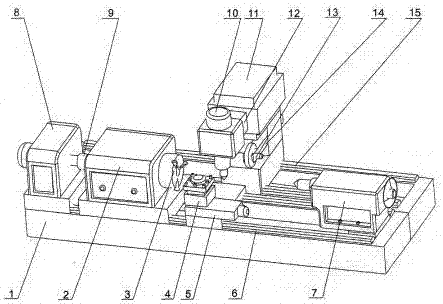

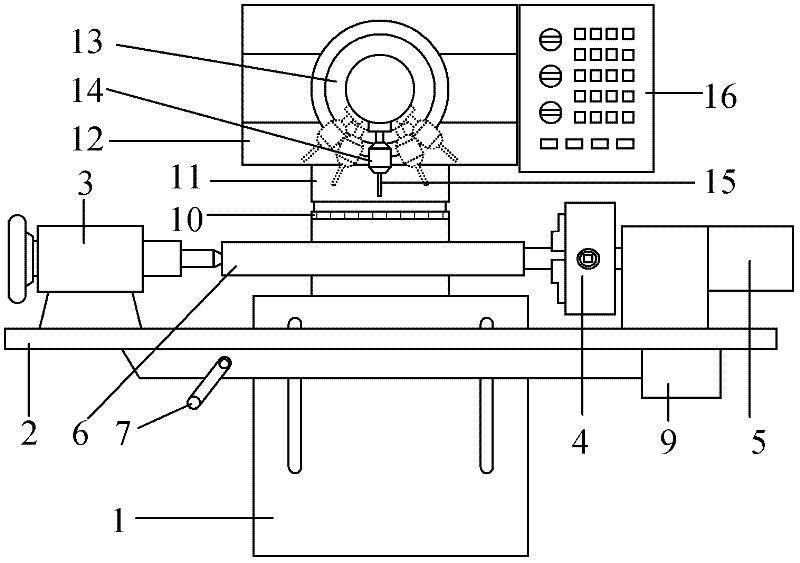

Machine tool used for machining gear shaving cutter chip pocket

ActiveCN103878443ALet the knife come trueEasy to adjustAutomatic control devicesPrecision positioning equipmentEngineeringHelix angle

A machine tool used for machining a gear shaving cutter chip pocket is composed of a tool body, a middle tool body, a stand column, a sliding base, a cutter rest assembly, a dividing head, a transverse sliding platform, a digital control system and a hydraulic system. The machine tool is characterized in that the tool body is fixed to a foundation, the middle tool body and the transverse sliding platform are arranged at the two ends of the upper side of the tool body, a horizontal moving mechanism enabling the middle tool body to move horizontally is arranged between the middle tool body and the tool body, the middle tool body is provided with the stand column, and the side face of the stand column is provided with the sliding base provided with the cutter rest assembly; the transverse sliding platform is provided with the dividing head, and the position of the dividing head corresponds to that of the cutter rest assembly in the vertical direction; the sliding base is provided with a main driving mechanism, an any spiral angle compensation mechanism, a micro cutter relieving mechanism and a stoke length automatic regulating mechanism. The machine tool achieves digital control, can achieve an automatic tool setting function, is convenient to regulate, and lowers labor intensity of workers.

Owner:宜昌长机科技有限责任公司

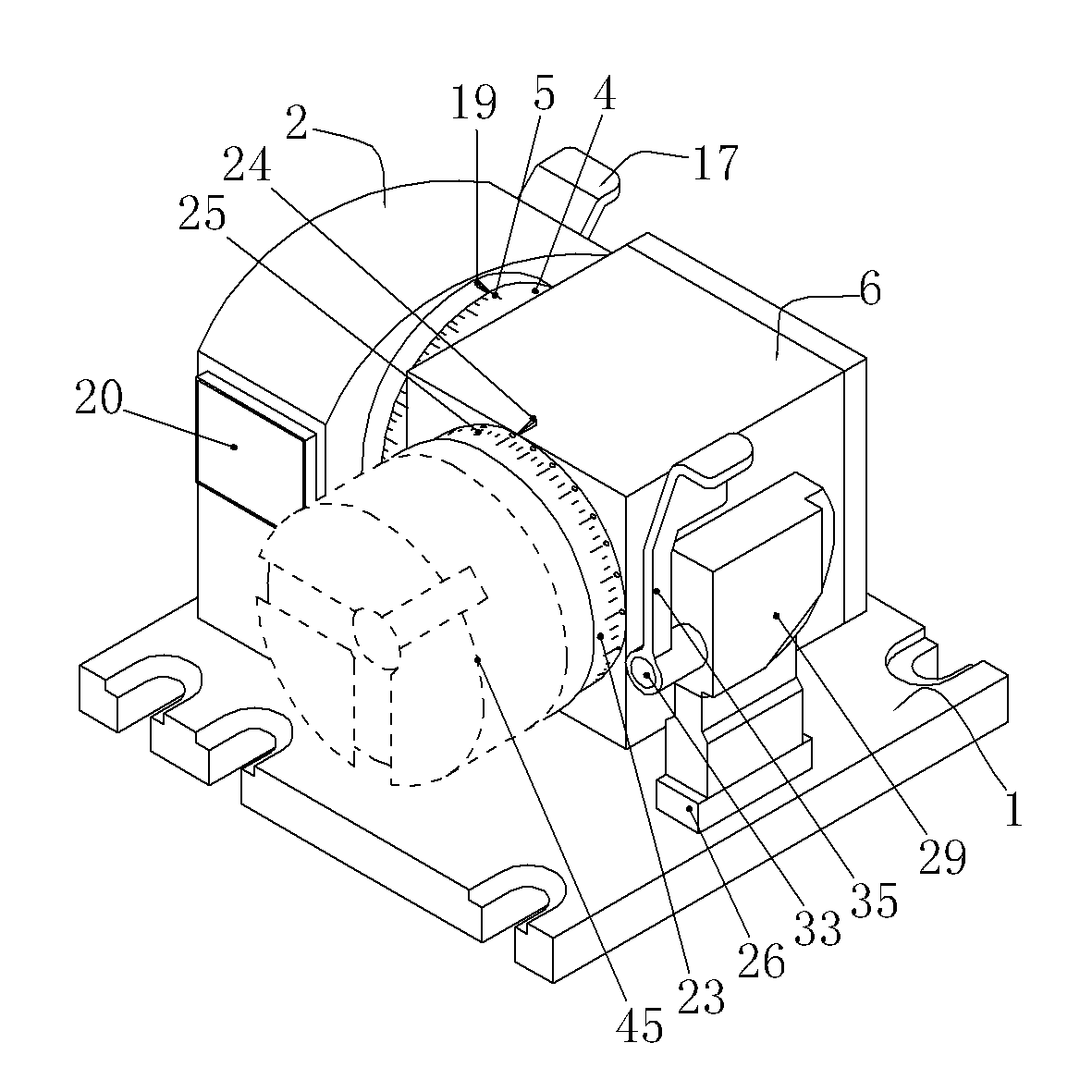

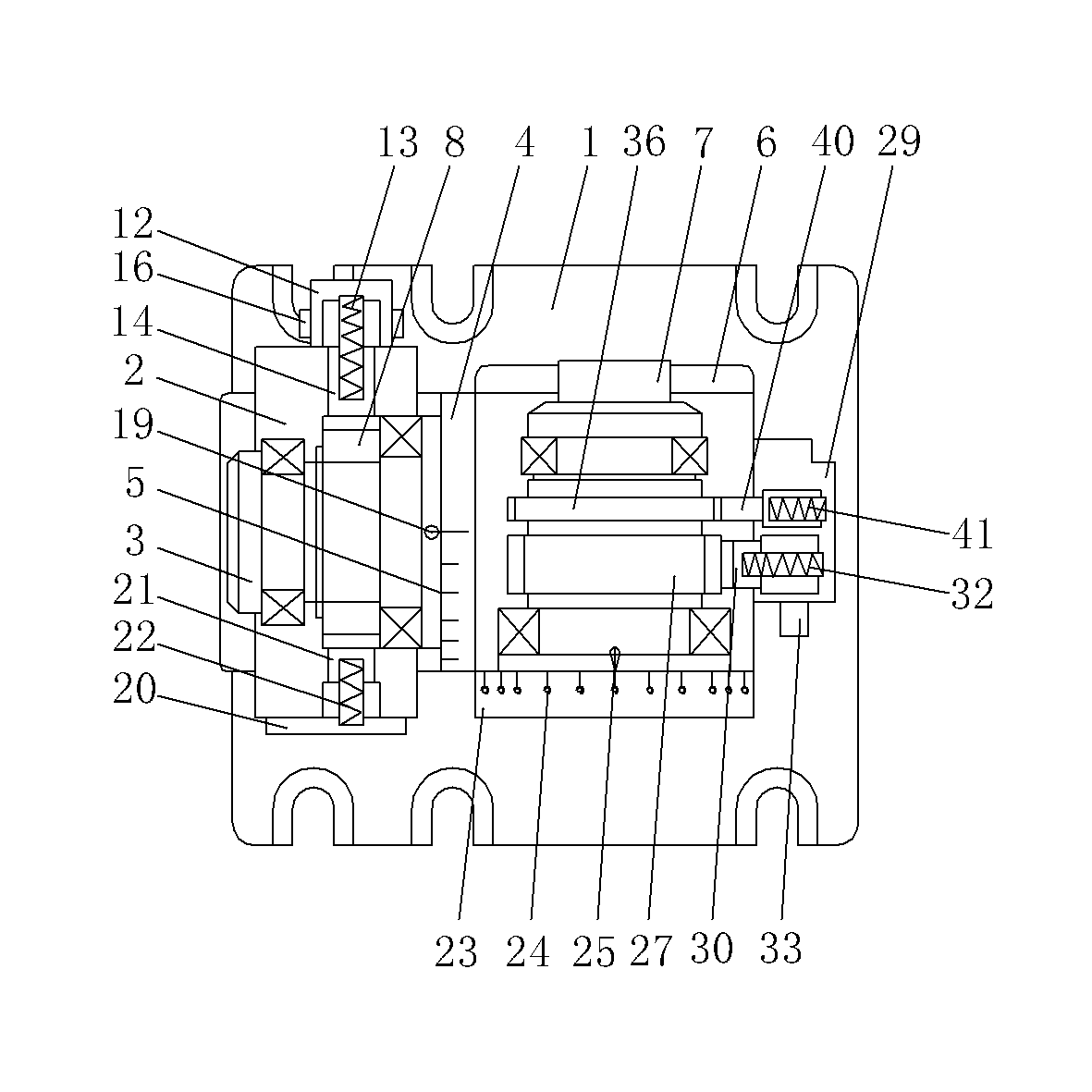

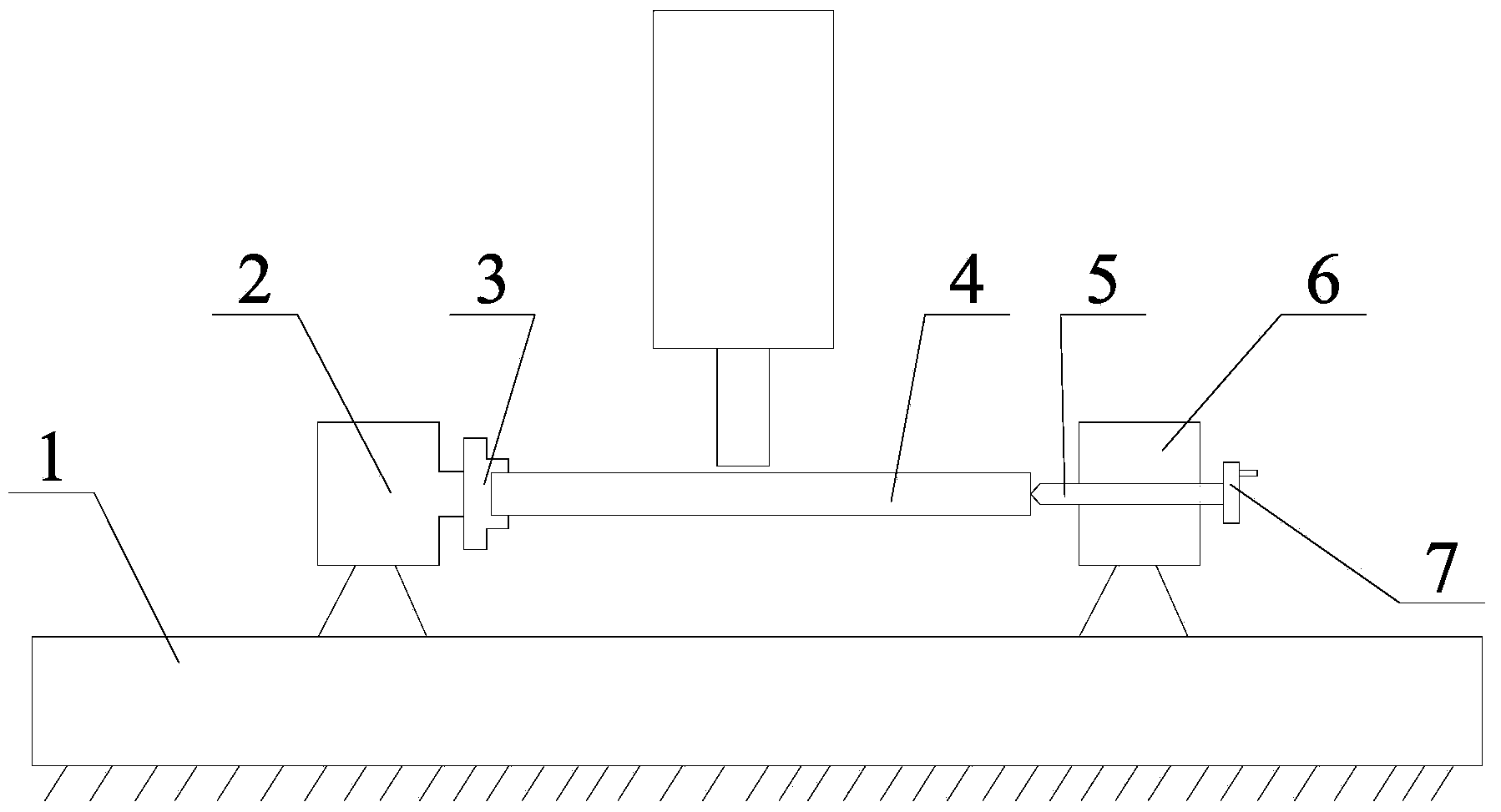

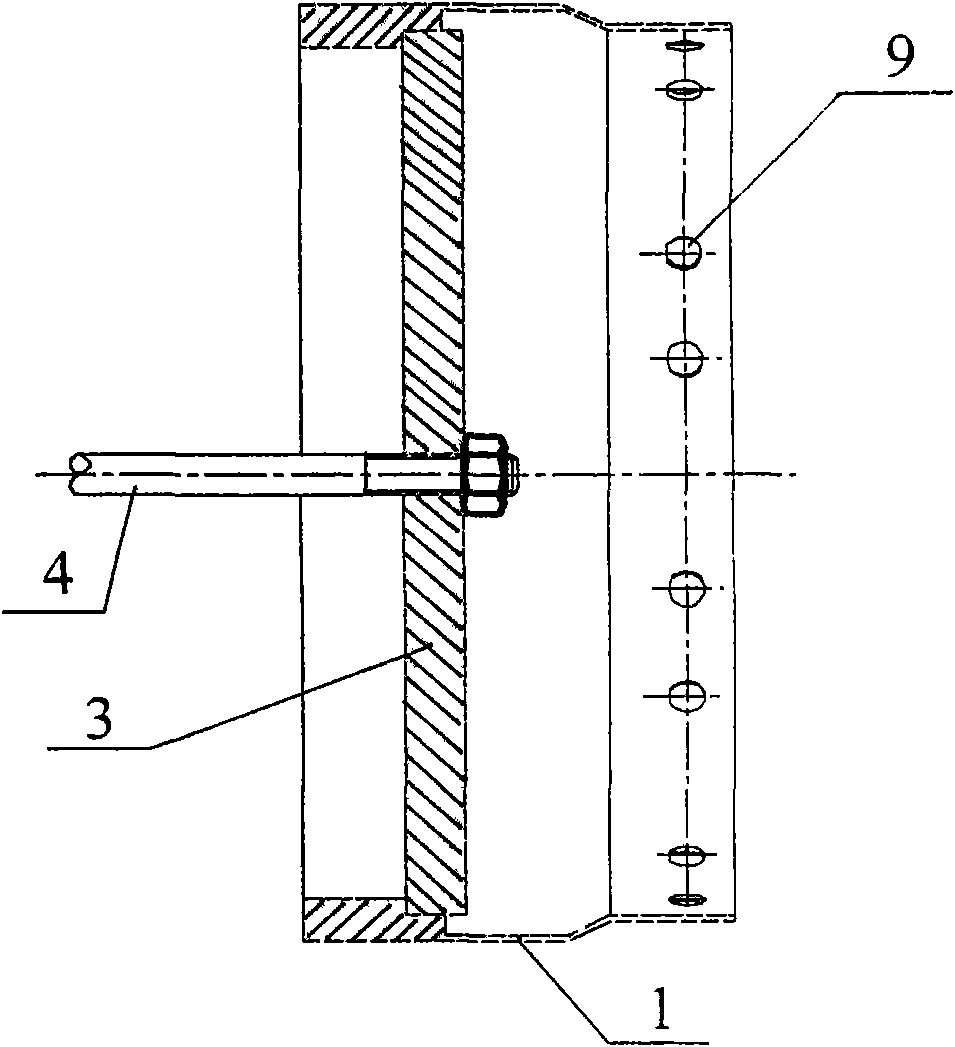

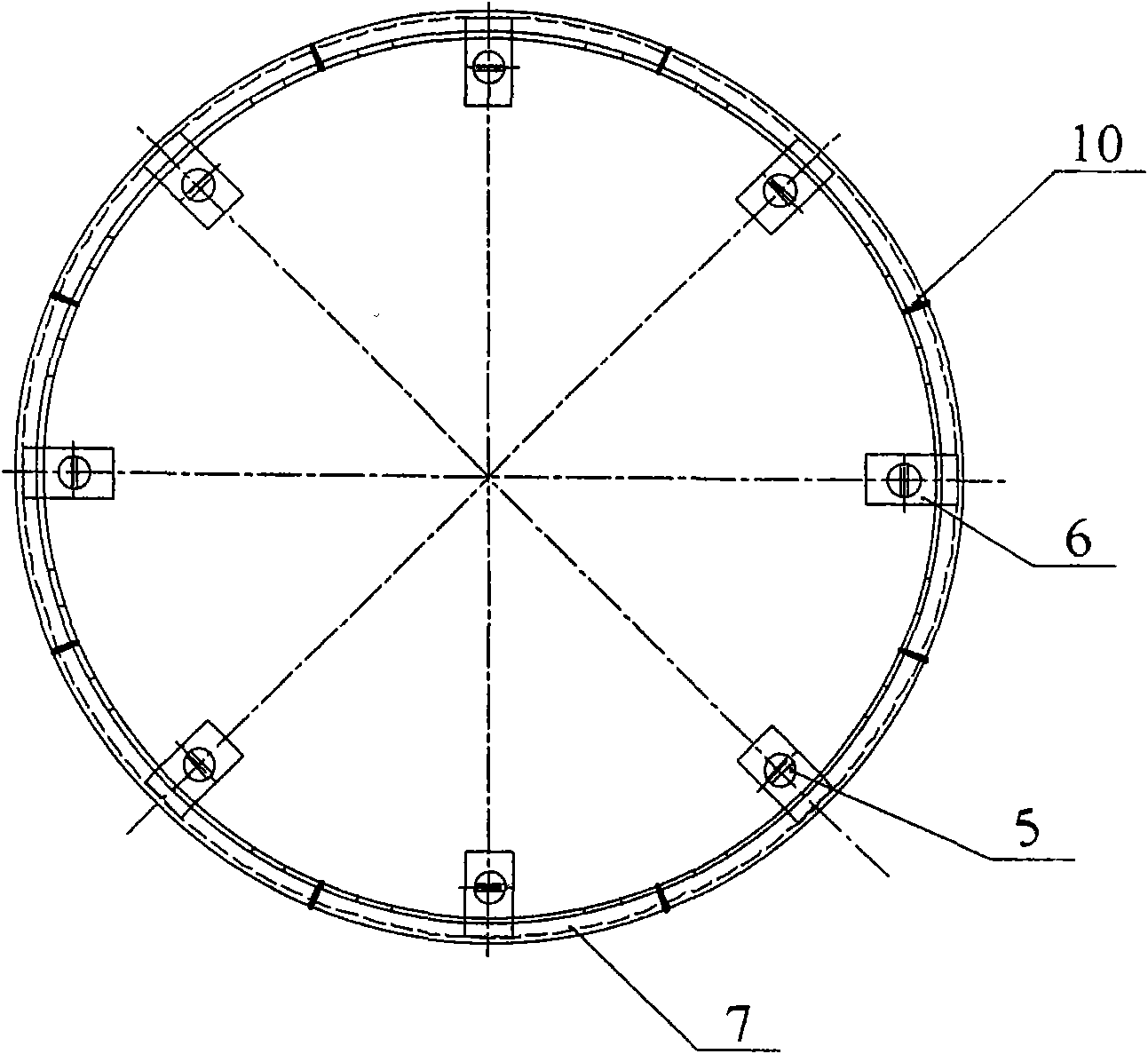

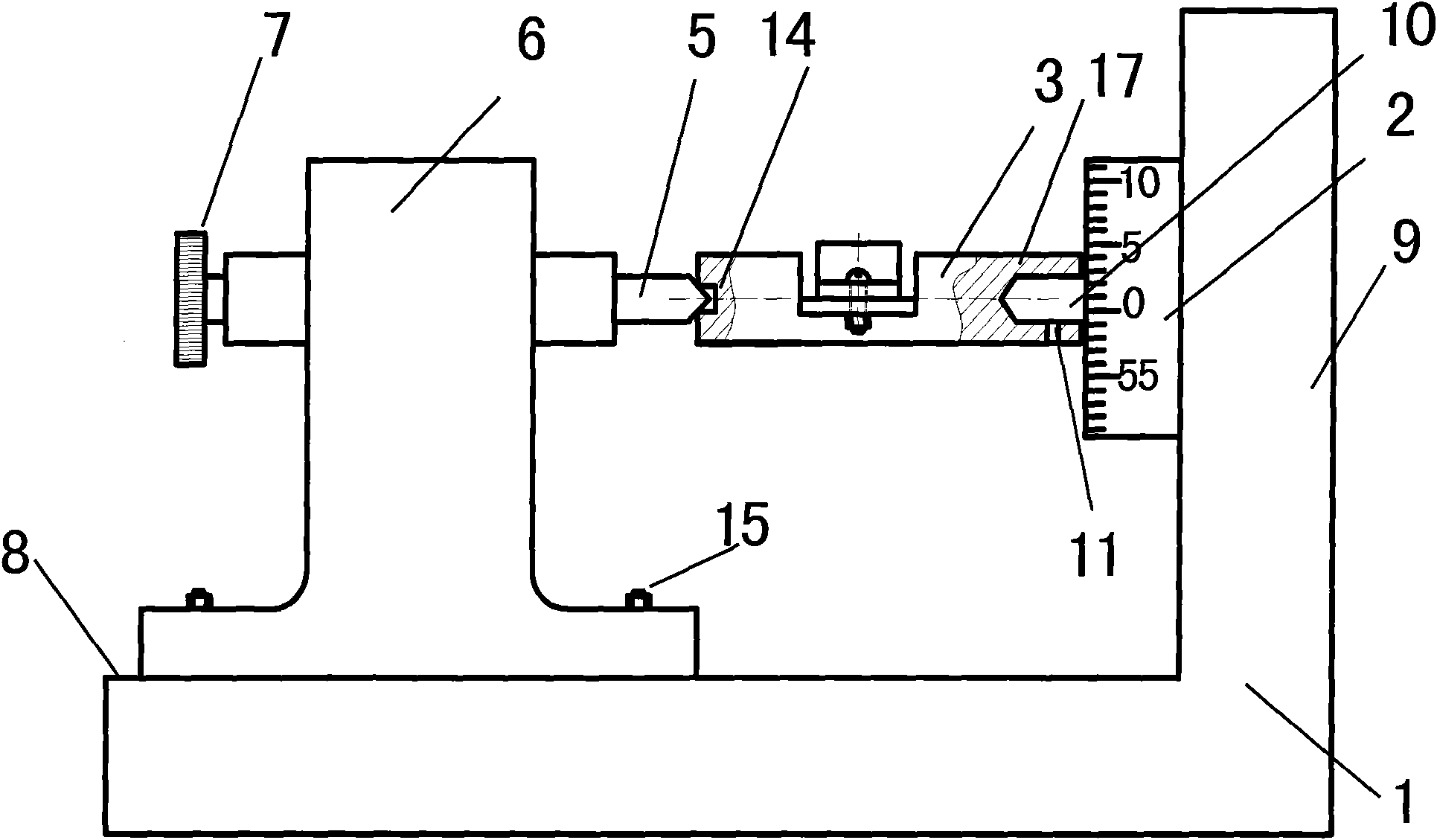

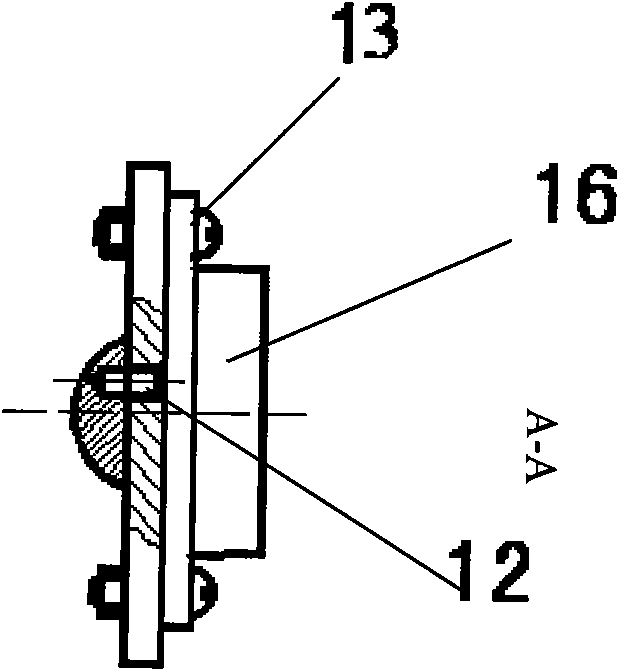

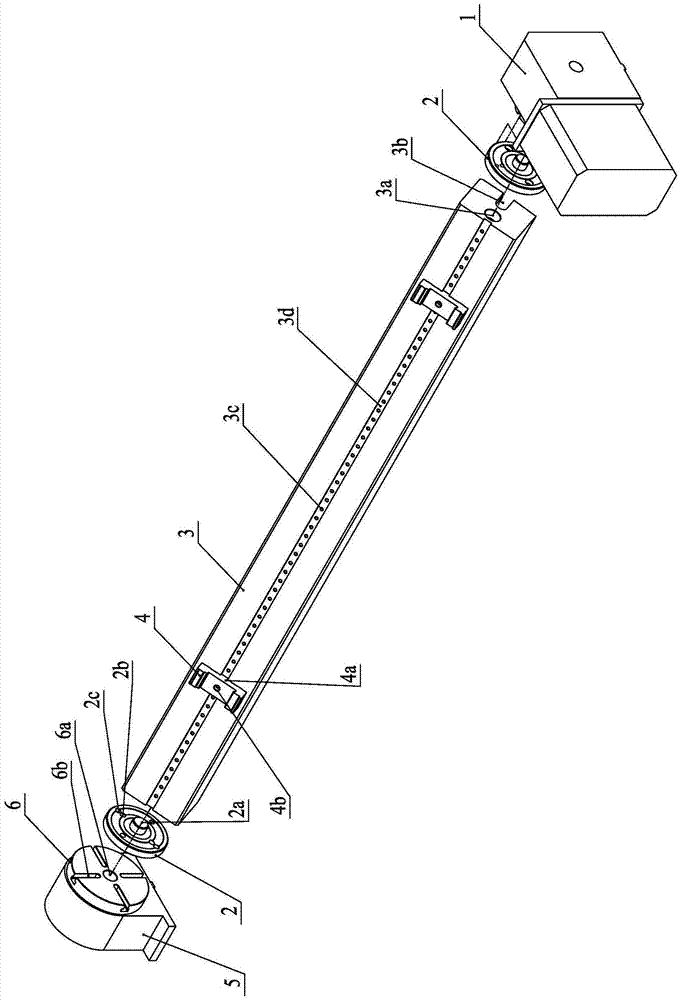

Calibrating device for tilt angle sensor

ActiveCN101915562AEasy CalibrationEasy to replaceUsing optical meansMeasurement precisionIndexing head

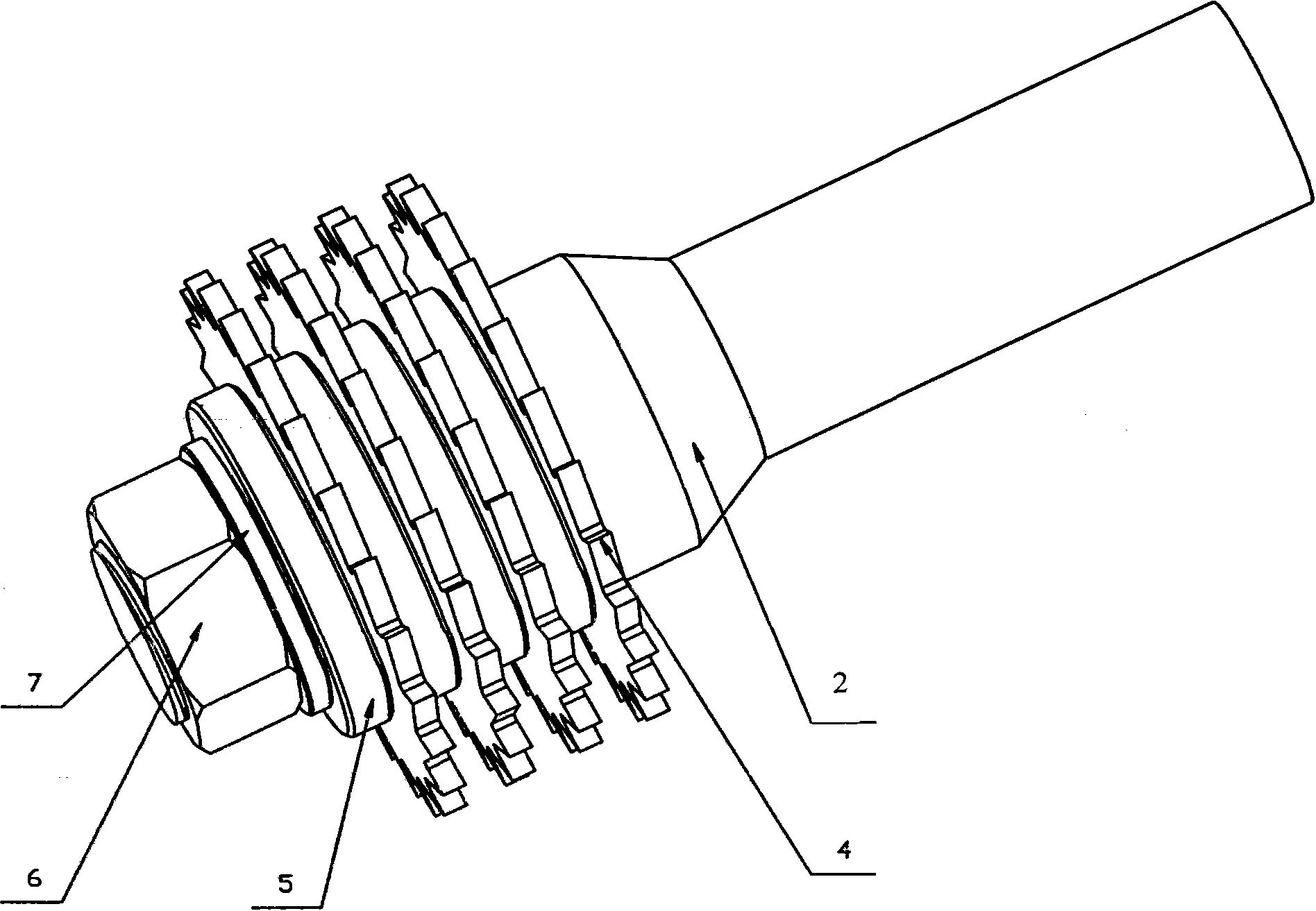

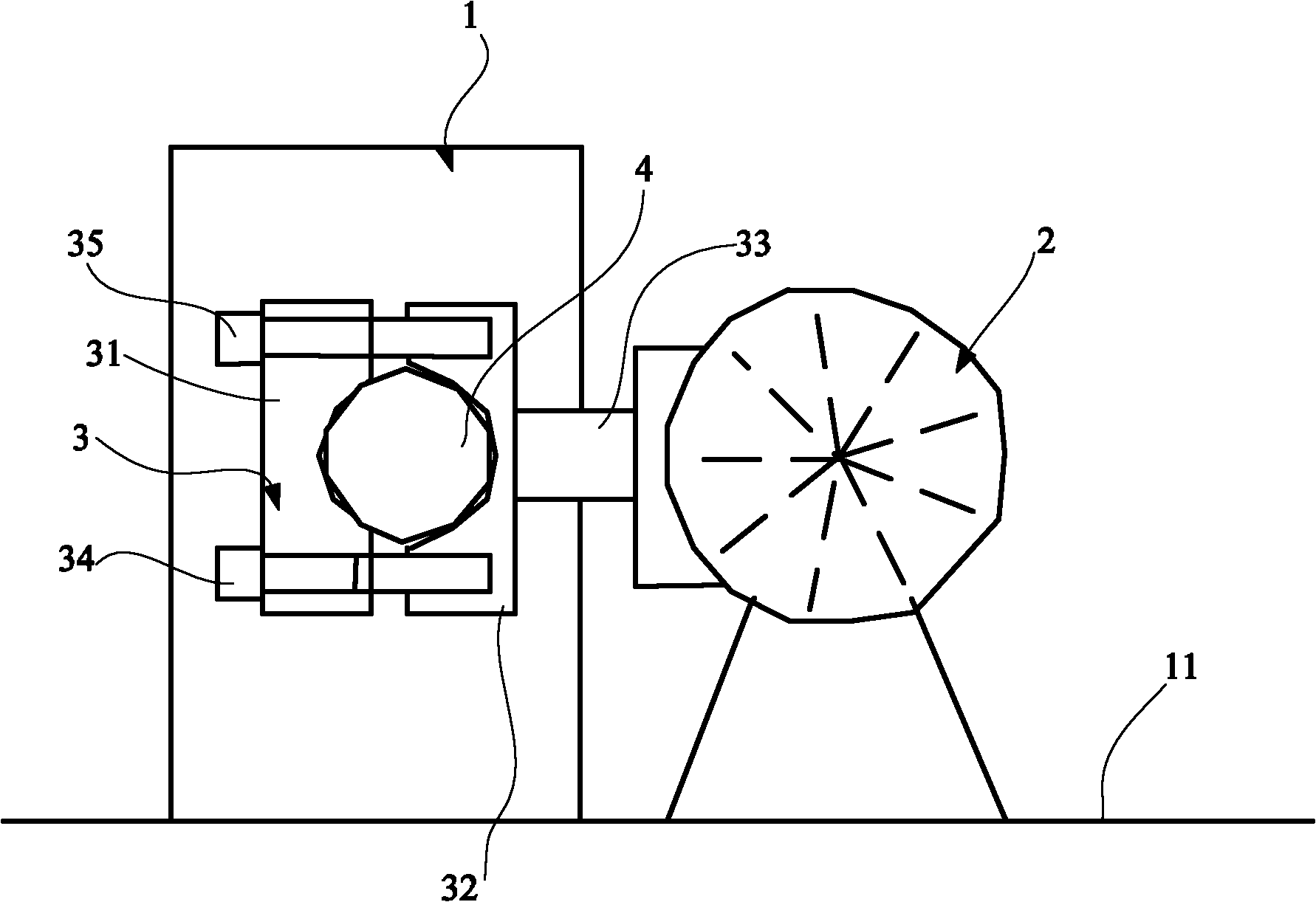

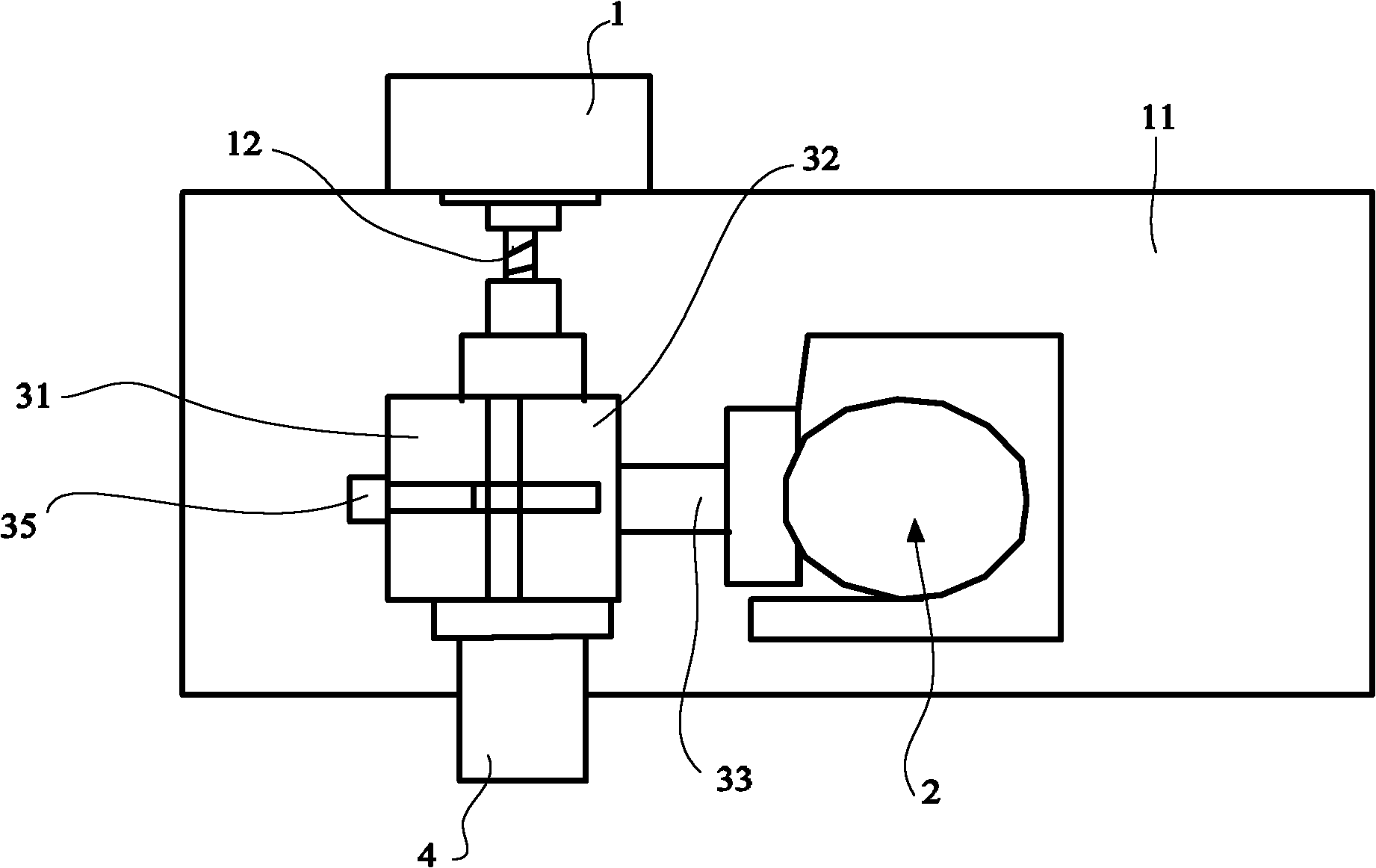

The invention relates to a calibrating device for a tilt angle sensor. The calibrating device comprises a mounting base (1), an optical indexing head (2), a mounting shaft (3), a mounting plate (4), a tip (5), a tip base (6) and a tip handle (7), wherein the mounting base (1) comprises a horizontal base plate (8) and a base station (9); the optical indexing head (2) is arranged on the base station (9); the tip base (6) is arranged on the horizontal base plate (8); the tip (5) is arranged on one side of the tip base (6); and the tip handle (7) is arranged on one side of the tip base (6) deviated from the optical indexing head (2) which passes through a hole with the tip and the shaft (3) for mounting and positioning sequentially to be connected with the tip (5) on the tip base (6). The calibrating device for the tilt angle sensor of the invention has the advantages of simple structure, convenient operation, high working efficiency, high measurement precision and high practicality.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

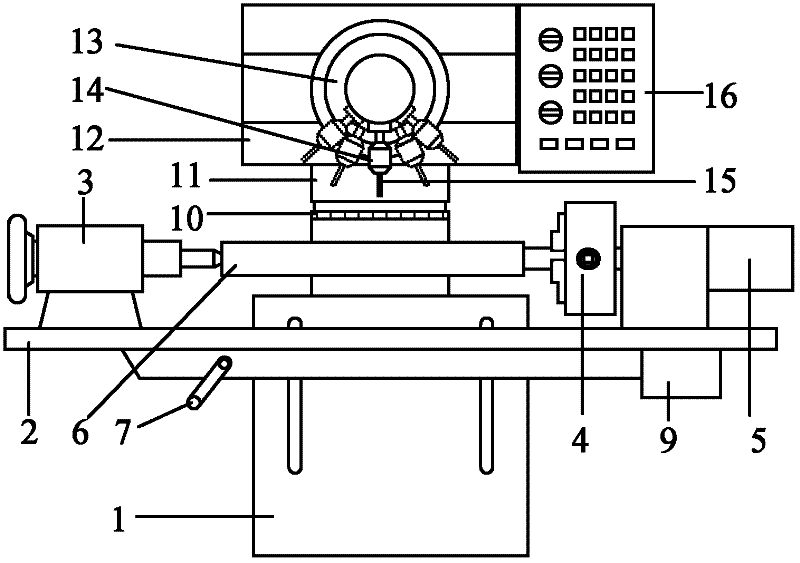

Numerical control turn milling, grinding and carving combination lathe

InactiveCN107283168AInnovative designSimple processOther manufacturing equipments/toolsNumerical controlBall screw

A CNC turning, milling, grinding and engraving universal machine tool, which is composed of a machine bed, a machine tool spindle box, a turning chuck, a turning tool holder, a carriage gearbox in the turning of the machine tool, a tailstock of the machine tool, and a CNC universal indexing Head, hydraulic coupling, engraving milling machine column, cylindrical grinding head, engraving and milling electric spindle, engraving and milling square ram and external grinding square ram. Its characteristics are: on the basis of a pair of guide rails on the ordinary lathe bed, a pair of column guide rails for engraving, milling and grinding machine tools is added, a turning pin spindle box is set on the machine tool bed, a hydraulic coupling is set on the left side, and a CNC universal dividing head is set on the right. There are two square rams on the side of the turning pin tool holder and the tailstock of the machine tool, and the column of the engraving, milling and grinding machine: one is the outer round grinding square ram, the front end of which is equipped with an outer round grinding head and the grinding head motor, and the rear end is equipped with a ball Lead screw and servo motor, the second is engraving and milling square ram, its front end is equipped with up and down walking servo motor, ball screw, electric spindle, and its rear end is equipped with ball screw and servo motor. Realize multiple processing operations such as car sales, indexing, grinding, milling and engraving.

Owner:冯星宇

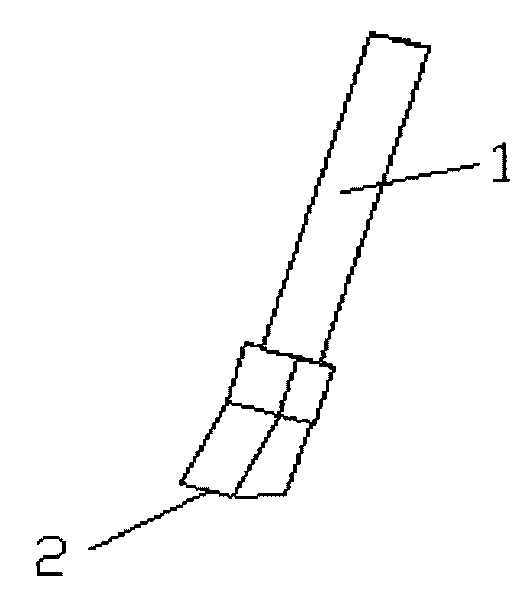

Method for processing nylon internal polygon and special cutter thereof

InactiveCN101745682ANo whiteningNo debris sticking to the knifePlaning/slotting toolsPlaning/slotting machinesMechanical engineeringIndexing head

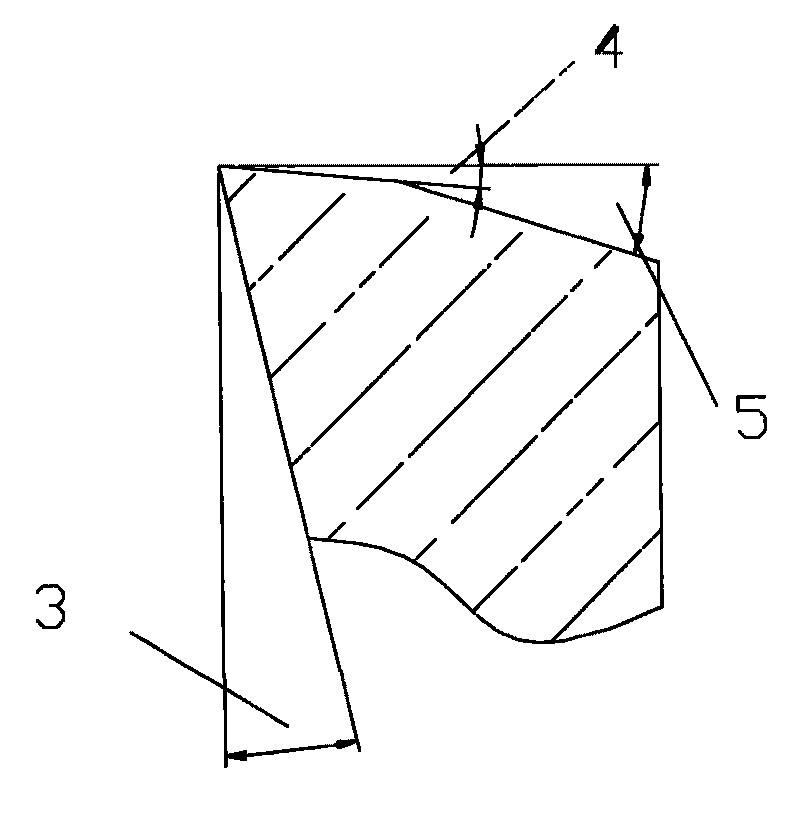

The present invention relates to a method for processing a nylon internal polygon. All surfaces of an internal polygonal hole are orderly cut by common machine processing equipment and a special cutter. The cutting output of a part is from 0.02mm to 0.05mm during the cutting. After one face is cut, an indexing head is rotated for 360 degrees per Newton, the next face of the part is cut, and the other faces of the polygon are processed in the mode. The cutter is a straight handle type or a conic handle type, the width of a cutting edge is equal to the side length of the internal polygon, and a chip removal angle is arranged between the front cutter face and the rear cutter face of the cutter. A front cutter angle (3) is from 8 degrees to 12 degrees. The front angle (4) of a rear cutter angle is from 6 degrees to 10 degrees, and the rear angle (5) is from 9 degrees to 15 degrees. When a part of the internal polygon processed by the method is cut to the internal square root part, the phenomena of whitening part, chip adherence to the cutter, fracture failure, etc due to large cutting quantity and heated materials are avoided. The surfaces of internal square hole are smooth. The present invention has the advantages of high operability, high practicability, low manufacture cost and good product quality.

Owner:XIAN AIRCRAFT IND GROUP

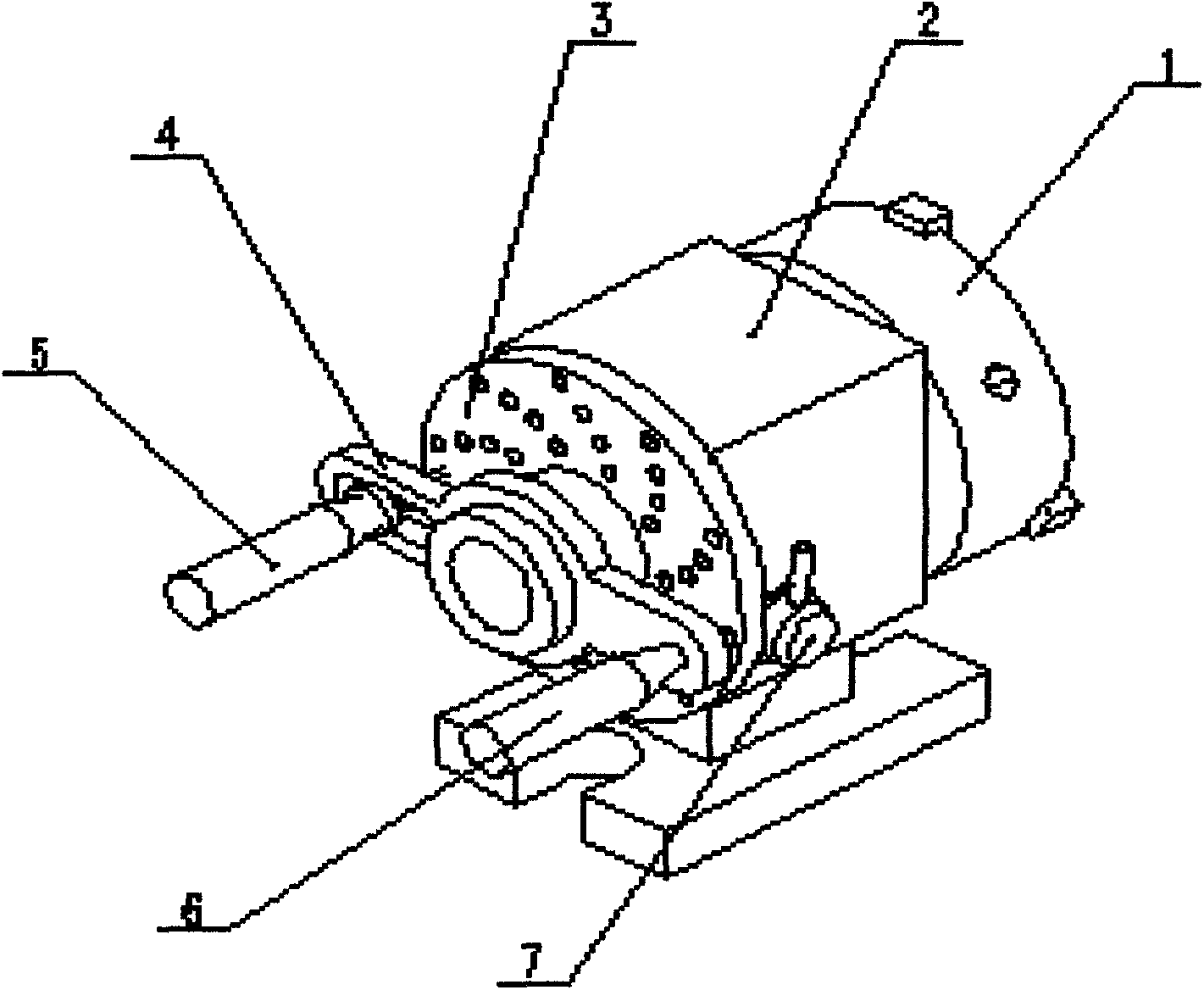

Central hole processing system and processing method of eccentric shaft

InactiveCN102039437ARealize positioning installationSolve the clamping problemPrecision positioning equipmentPositioning apparatusPulp and paper industryMachining system

The embodiment of the invention discloses a central hole processing system of an eccentric shaft, comprising a horizontal type milling machine, an indexing head and an eccentric shaft clamp, wherein a three-jaw chunk of the horizontal type milling machine is provided with a drilling bit; the indexing head is arranged on a working platform of the horizontal type milling machine; and the eccentric shaft clamp is fixedly connected with the indexing head. In the central hole processing system, the indexing head is arranged on the horizontal type milling machine and is fixedly connected with the eccentric shaft clamp for clamping the eccentric shaft, the positioning and the installation of the eccentric shaft on the working platform of the horizontal type milling machine are realized, and the processing of the central holes at the two ends of the eccentric shaft is realized by rotation of the indexing head. By utilizing the processing system provided by the invention, the problems that when the eccentric shaft below 600mm is processed on a boring machine in the prior art, the size of the working platform of the boring machine is larger, the clamping, the positioning and the alignment of a workpiece are difficult.

Owner:LAIWU IRON & STEEL GRP

Double eccentric flange machining method

InactiveCN106312472AGuaranteed quality and accuracyGuaranteed machining accuracyNumerical controlEngineering

The invention relates to the field of machining, in particular to a double eccentric flange machining method which includes the steps: performing numerical control cutting and laying out a 30mm thick steel plate on a numerical control cutting machine; clamping an upper end face and turning a lower end face on a C616 lathe, turning an external circle to reach the diameter of 184mm, turning an inner hole to reach the diameter of 84mm, clamping the lower end face, turning the upper end face and ensuring the thickness of 27mm; symmetrically marking the center line of a flange on the external circle by a vernier height gauge clamped on an indexing head of a vice bench; inversely clamping a three-jaw chuck by a four-jaw chuck on a CK630 numerical control lathe, adjusting eccentricity 3mm to be qualified by a dial indicator, making marker lines, clamping the flange on the three-jaw chuck, aligning the marked lines to the center line, turning the lower end face and then turning a groove and an inner hole with the diameter of 100mm. The external circle diameter of a cut blank is 190mm, and the internal bore diameter of the cut blank is 80mm. The double eccentric flange machining method is simple in operation and convenient in machining, machining quality and machining precision of workpieces can be ensured, production efficiency is improved, and production cost is reduced.

Owner:SHAANXI ALLIANCE LOGISTICS

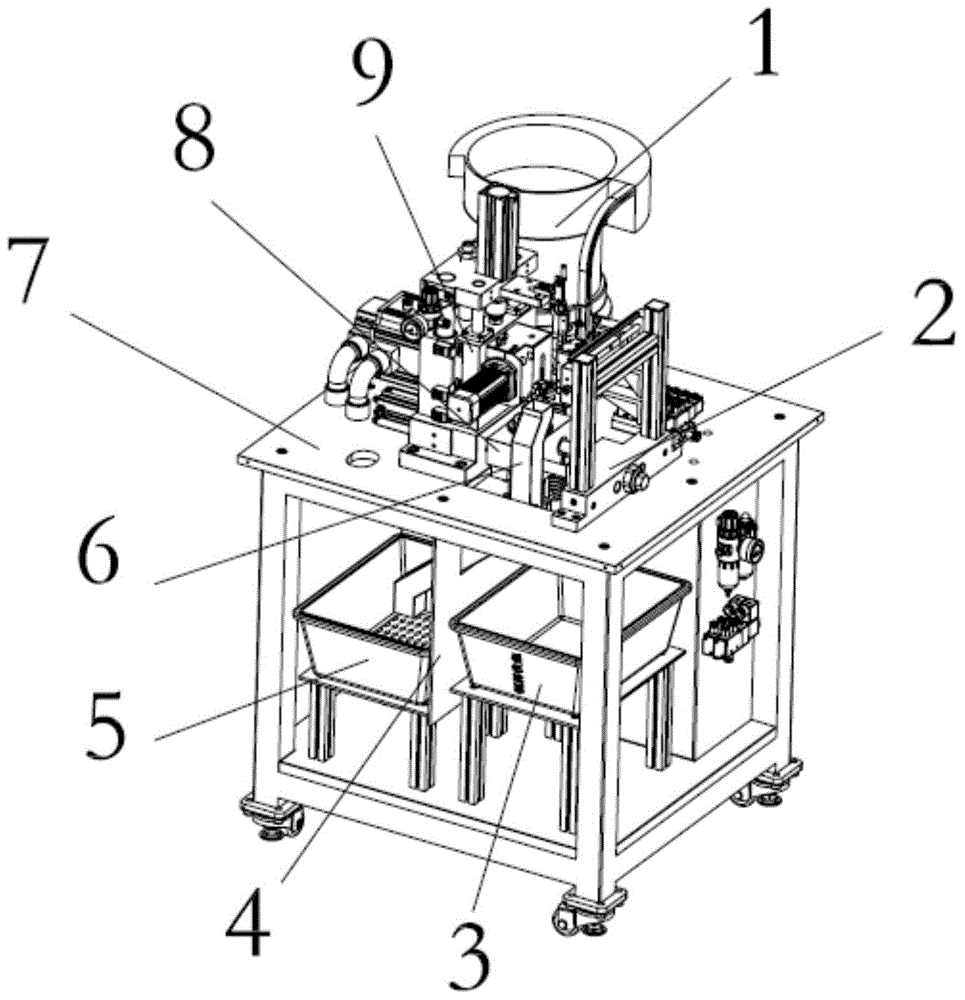

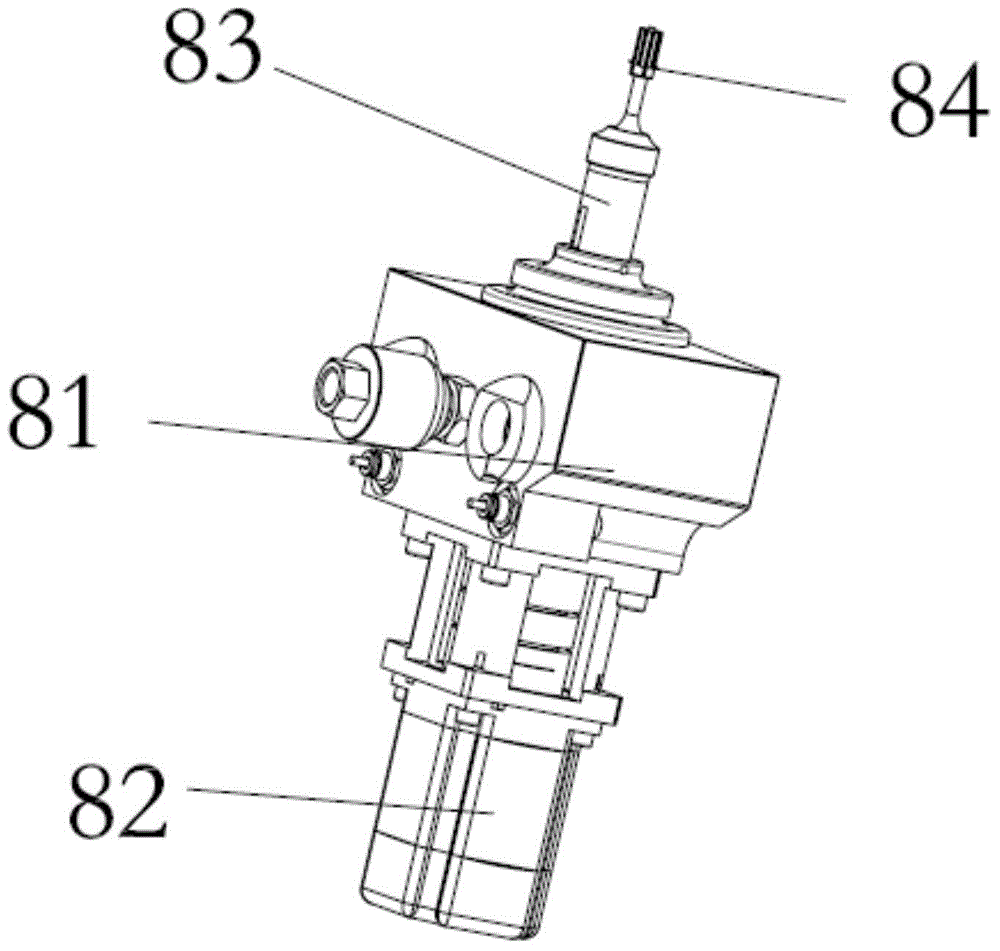

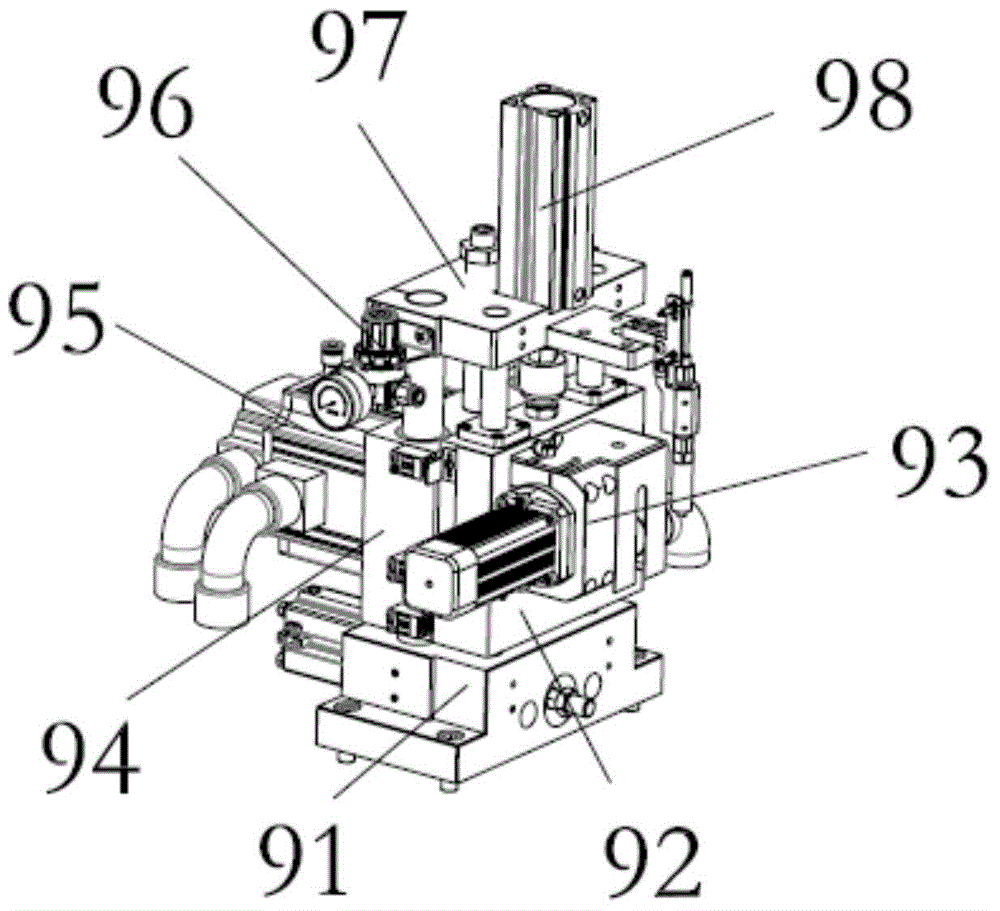

Mini-sized vertical slot milling machine

InactiveCN105522208AIncrease production speedReduce the output rate of non-conforming productsPrecision positioning equipmentFeeding apparatusEngineeringManipulator

The invention relates to a mini-sized vertical slot milling machine. The machine comprises a rack platform, an indexing head assembling mechanism and a milling mechanism, wherein the milling mechanism is mounted at the left part of the surface of the rack platform, and a manipulator charging and discharging mechanism is vertically mounted at the right part of the surface of the rack platform; the indexing head assembling mechanism is vertically mounted at the front part between the milling mechanism and the manipulator charging and discharging mechanism; a vibrating charging tray is mounted on the rear side surface of the milling mechanism; the lower end of a charging slide rail of the vibrating charging tray is fixed on the side surface of the manipulator charging and discharging mechanism; and a blanking tube is mounted at a position, close to the indexing head assembling mechanism, between the milling mechanism and the manipulator charging and discharging mechanism. The machine has the characteristics of being simple in structure and convenient to operate, greatly improving the production speed of a mini-sized reverser, and decreasing the output rate of unqualified reversers.

Owner:NINGBO SHENGKE COMMUTATOR

Processing method for inclined lubricating oil grooves in inner ring

InactiveCN106077780AImprove efficiencyLow costMilling equipment detailsNumerical controlMilling cutter

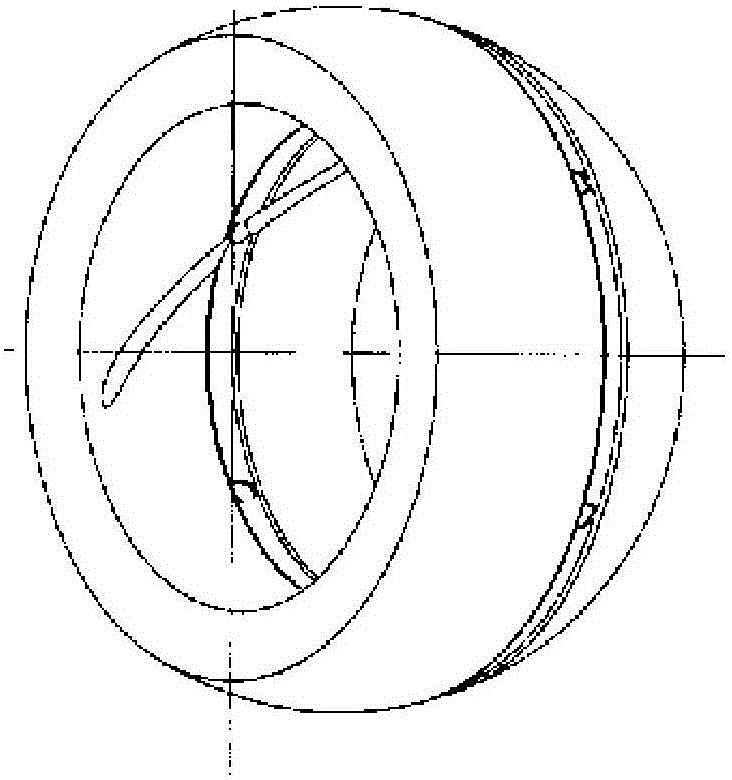

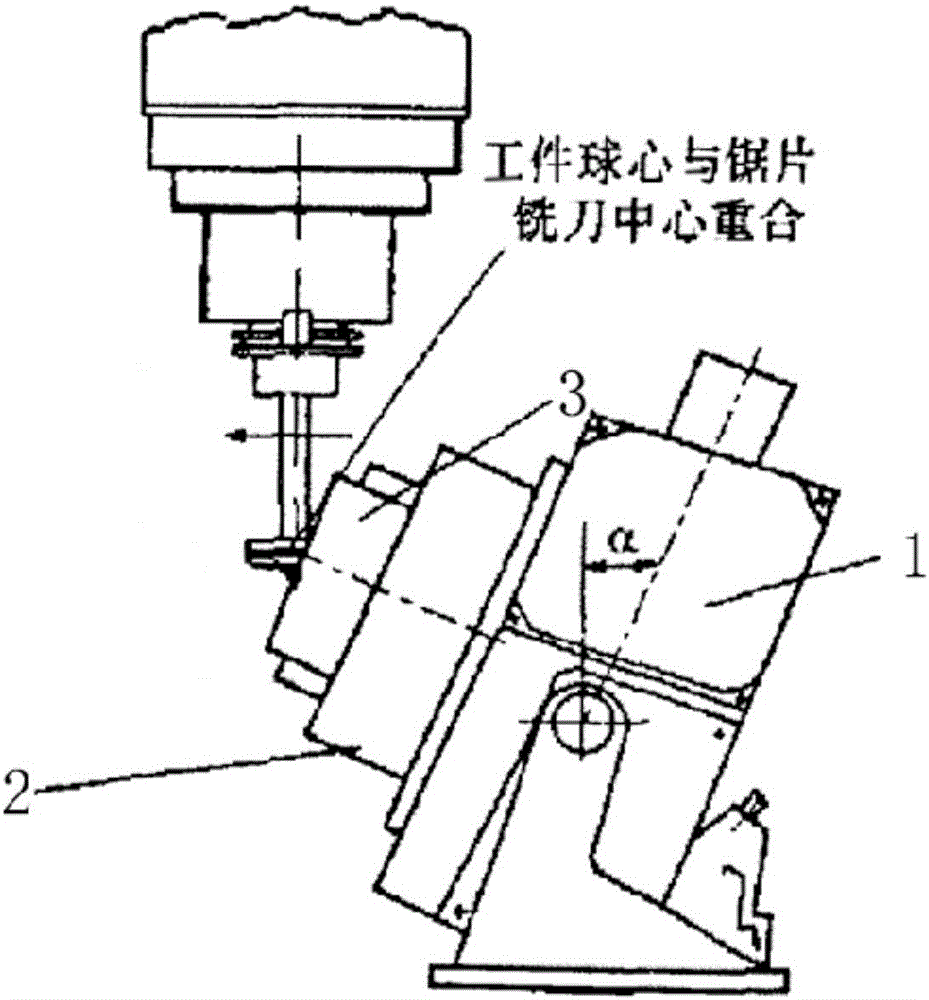

The invention discloses a processing method for inclined lubricating oil grooves in an inner ring, and belongs to the technical field of machining. The processing method comprises the following steps of: 1) selecting a saw blade milling cutter with a diameter D smaller than a spherical diameter of a workpiece by about 2-3 mm, wherein the shape of a cutting edge of the saw blade milling cutter is the same with those of the oil grooves; (2) mounting the saw blade milling cutter on a numerical control milling machine; (3) manually tilting a universal indexing head, tilting a rotating shaft according to an included angle alpha of the lubricating oil grooves, and then, fixing the rotating shaft; (4) correcting and clamping a manual three-jaw chuck with a diameter being 250 mm on an indexing plate; (5) after clamping the workpiece, starting a numerical control processing program, quickly moving a main shaft of the numerical control milling machine in an x-axis direction, a y-axis direction and a z-axis direction till the center of the saw blade milling cutter coincides with the center of sphere of a to-be-processed workpiece; (6) enabling the saw blade milling cutter to enter an inner hole of the workpiece to mill out one lubricating oil groove; and (7) regulating the indexing plate, and performing rotary indexing according to a constant-angle opening of the indexing plate, clamping the workpiece, repeating steps (5) to (7) till all lubricating oil grooves are processed. The processing method realizes numerical control processing of the plurality of discontinuous inclined oil grooves, is high in efficiency and is low in cost. The processing method has very good economical benefits in production without special processing equipment or single-piece small-lot production.

Owner:SHENYANG AIRCRAFT CORP

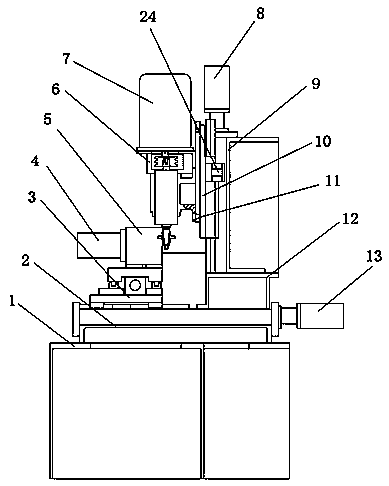

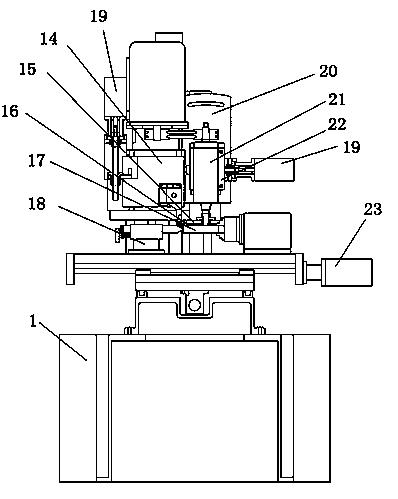

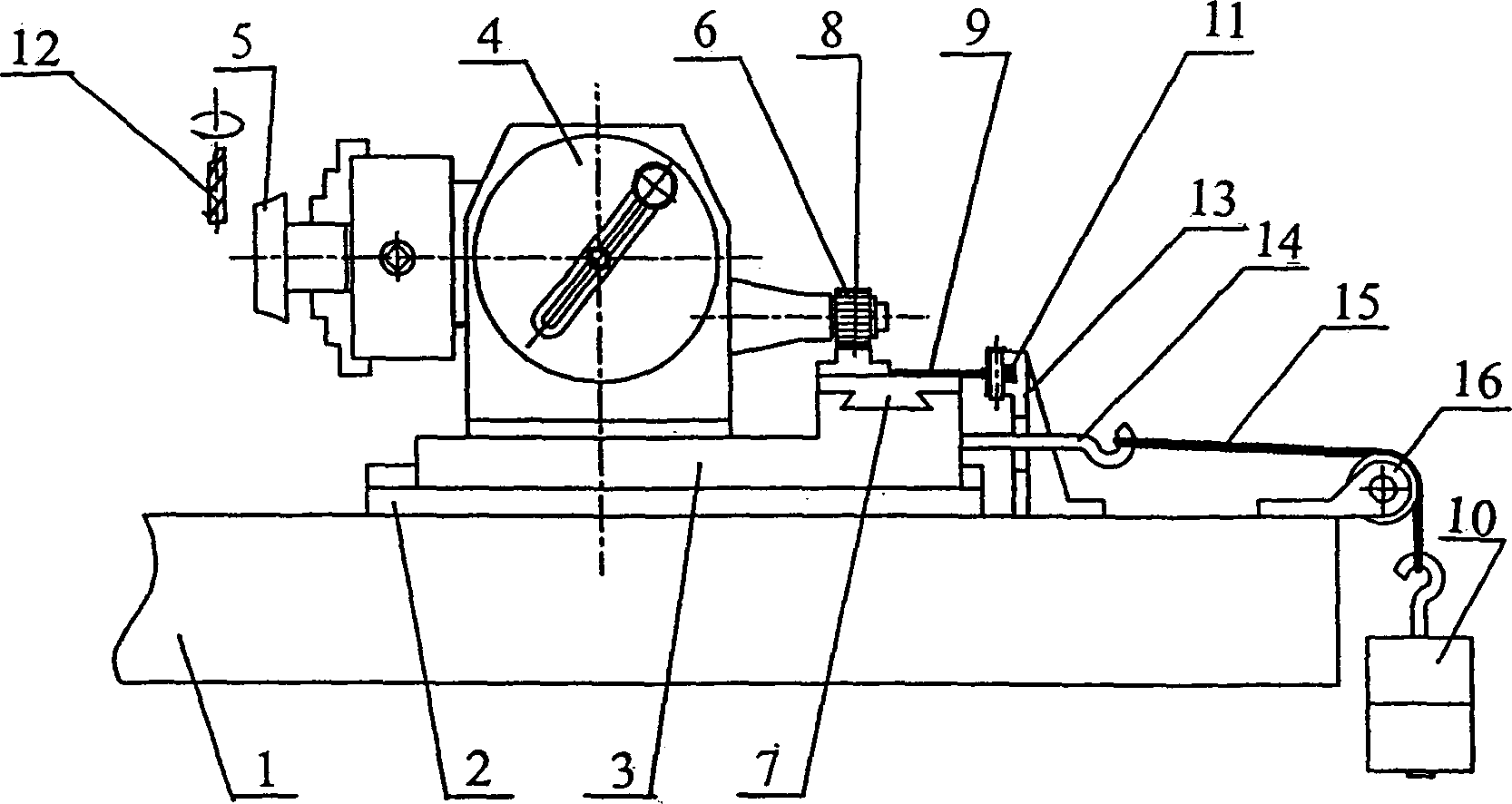

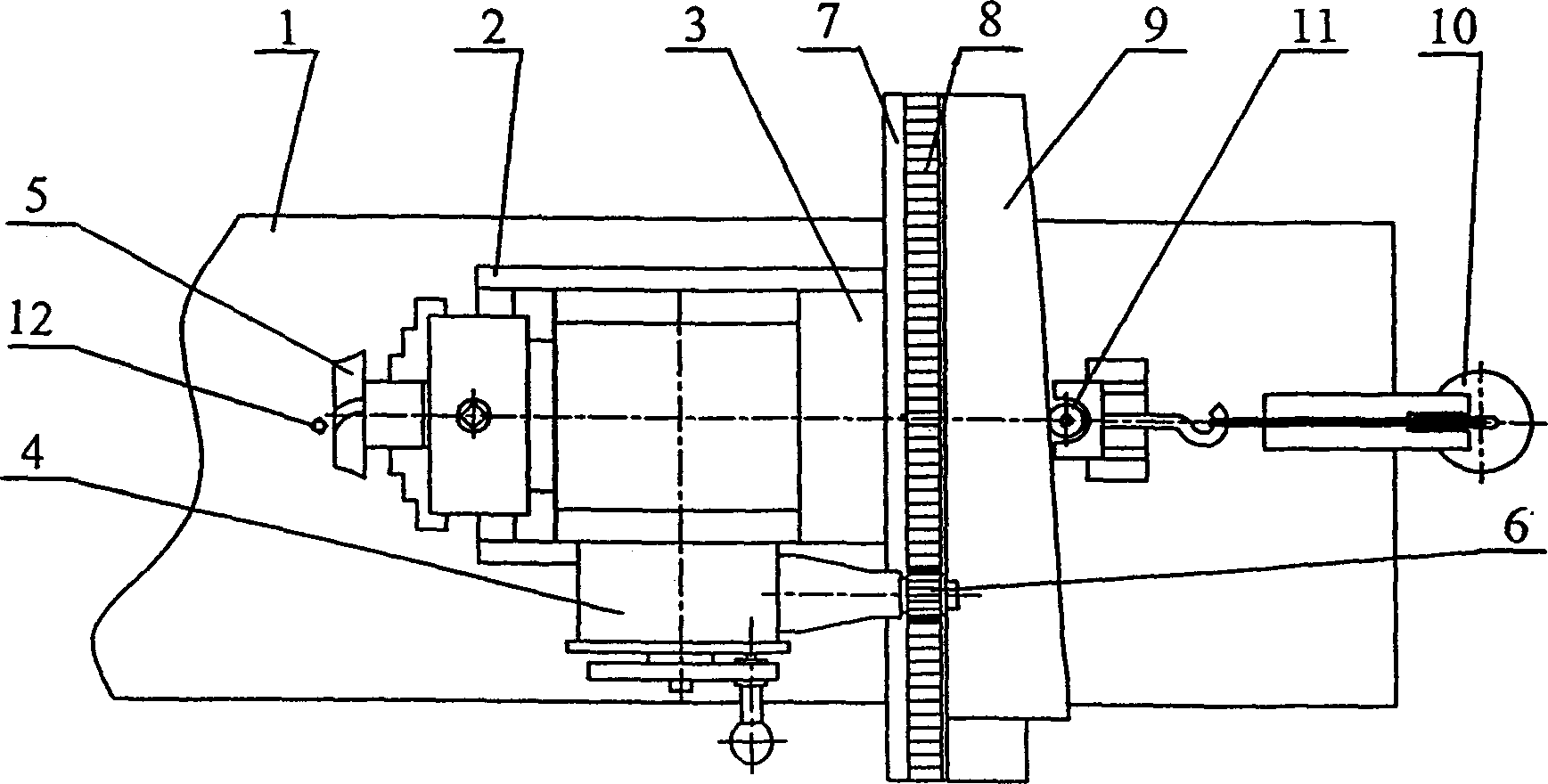

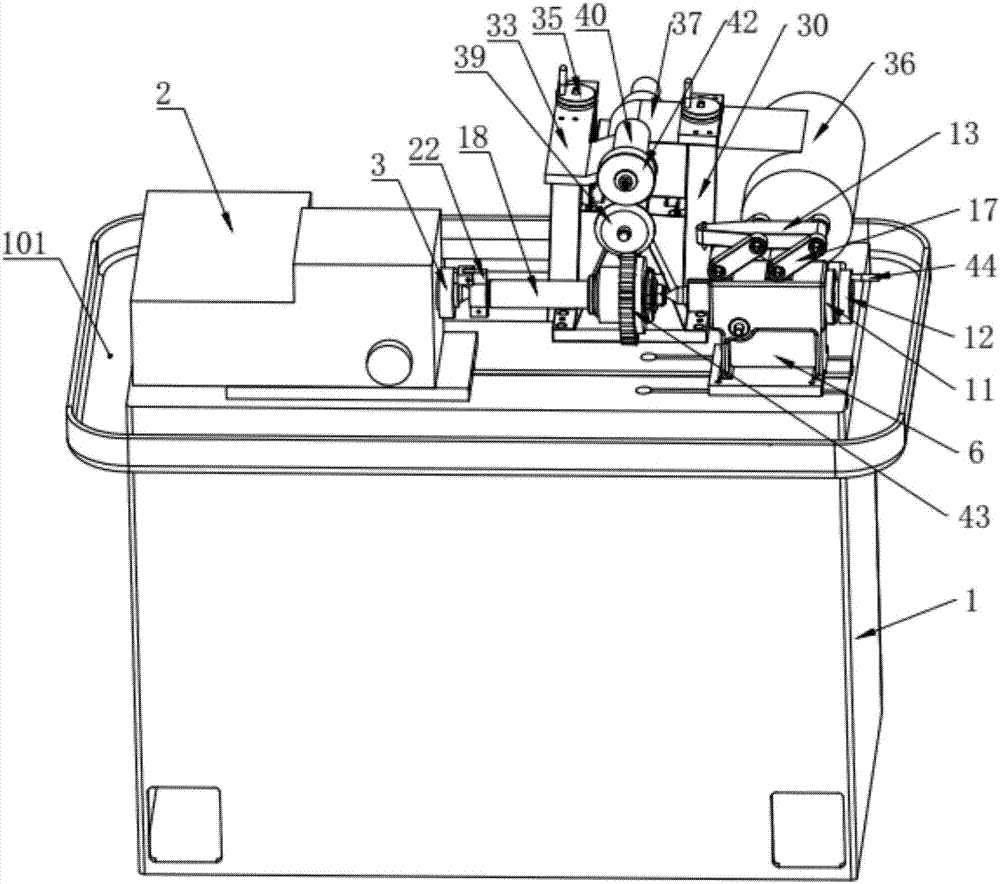

Automatic milling cutter machining grinder

InactiveCN104385067AReduce labor intensityImprove production environmentMilling cuttersOther manufacturing equipments/toolsMilling cutterStructural engineering

The invention relates to an automatic milling cutter machining grinder, which comprises a body and a base arranged on the body, wherein the base is provided with a cross slide for sliding along the base is arranged on the base; a tailstock is fixedly arranged on the cross slide; a dividing head is arranged at the corresponding position of the tailstock; a workpiece is clamped by the dividing head; a grinding head is arranged above the workpiece, and is provided with a grinding wheel for grinding the workpiece. The automatic milling cutter machining grinder has the beneficial effects that 1, the whole production process is automatically controlled, and a worker can finish machining the workpiece only by clamping the workpiece once after tool setting, so that the labor intensity of the worker is reduced; 2, the body is totally sealed by a housing, so that the production environment of an operator is improved; 3, the workpiece forms an Archimedes cambered surface by virtue of a spiral tooth back machining method, so that the strength of tooth backs is strengthened, and the service life of a tool is prolonged; the front and rear angles of peripheral teeth are machined by one step, so that errors caused by repeated clamping are reduced, the quality of a product is completely ensured, and each technical index such as radial runout, roughness and dimensional accuracy is improved.

Owner:ZHENGJIANG DANTU DISTRICT NINGBO RUN TOOLS

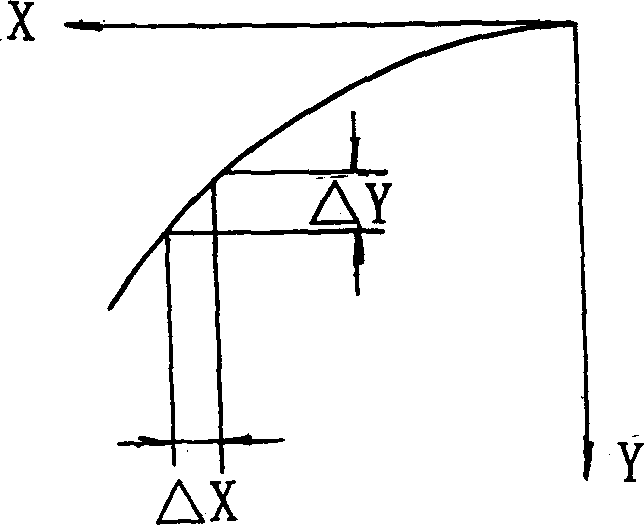

Mechanism for milling impeller inducer of centrifugal compressor with ordinary milling machine

A mechanism for milling the impeller inducer is centrifugal compressor on the ordinary milling machine has a longitudinal slide seat installed to the bench of vertical milling machine, an index head installed to the slide plate moving on the said longitudinal slide seat and the transverse slide plate and gib-headed screw installed on the said slide plate. A copying plate is installed to the said transverse slide plate. A weight is hung from the gib-headed screw via nylon string and pulley, forcing the roller always in contact with the side surface of copying plate. Its advantages are simple structure and high and stable quality of products.

Owner:周国强

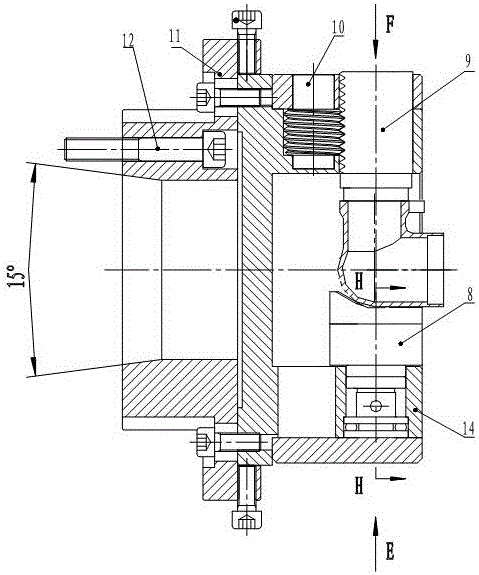

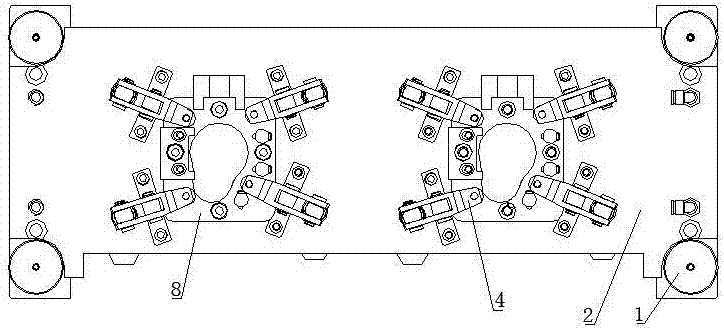

CNC (computer numerical control) rotary clamp of machining center

ActiveCN104493567AEasy to processImprove machining accuracyPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a CNC (computer numerical control) rotary clamp of a machining center. The CNC rotary clamp comprises a main clamp, a CNC index head, a tailstock and a workpiece clamp. The main clamp is elongated; the CNC index head is connected to the head of the main clamp; the tail of the main clamp is rotatably supported on the tailstock. The front surface of the main clamp is provided with a plurality of first mounting holes evenly distributed along the length of the main clamp. The workpiece clamp is provided with a second mounting hole. The workpiece clamp is fixed to the front surface of the main clamp through screws mounted in the first mounting holes and the second mounting hole. The CNC rotary clamp is simple in structure, firm to mount and flexibly adjustable and helps improve machining performance and precision of a four-axis linkage vertical machining center.

Owner:深圳博尚精密制造有限公司

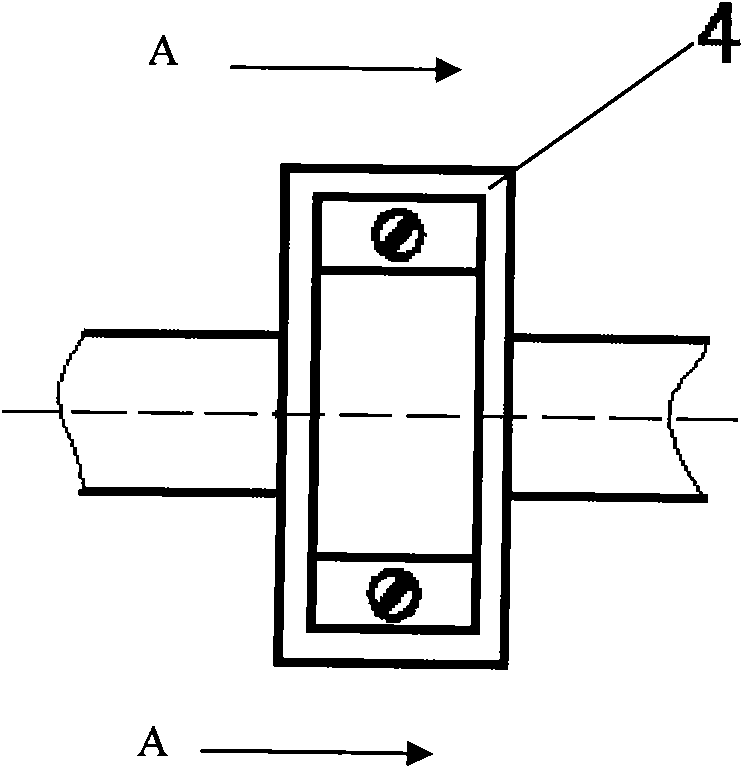

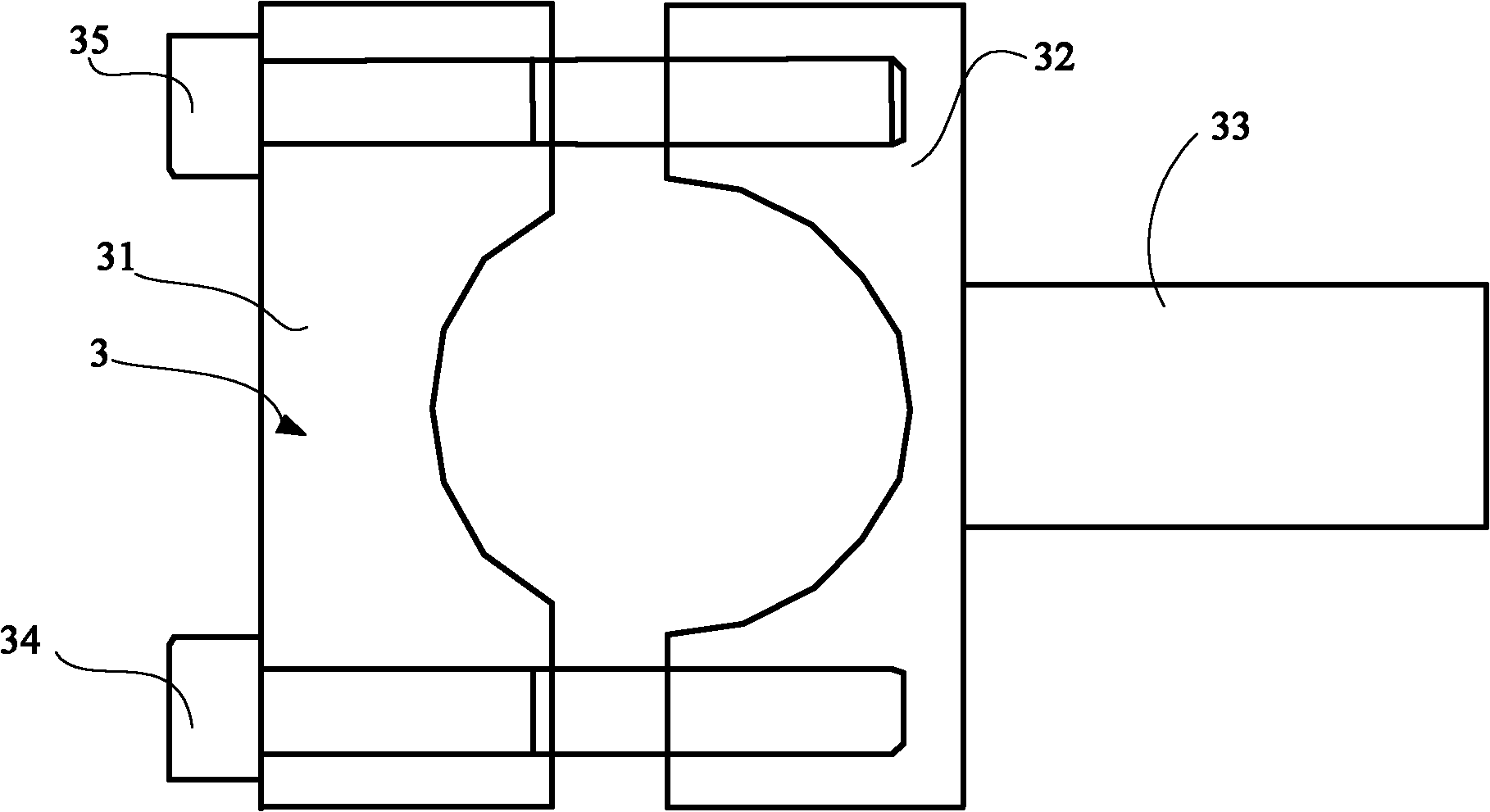

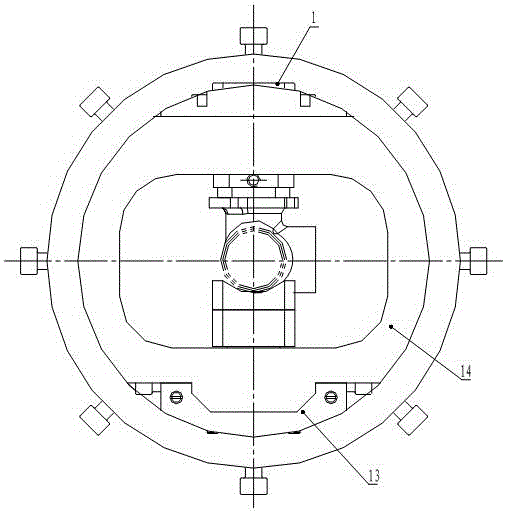

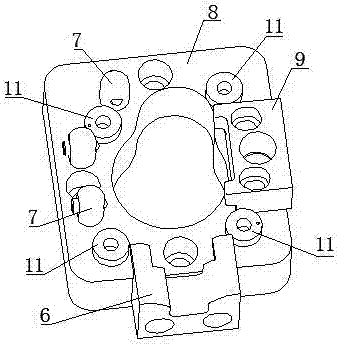

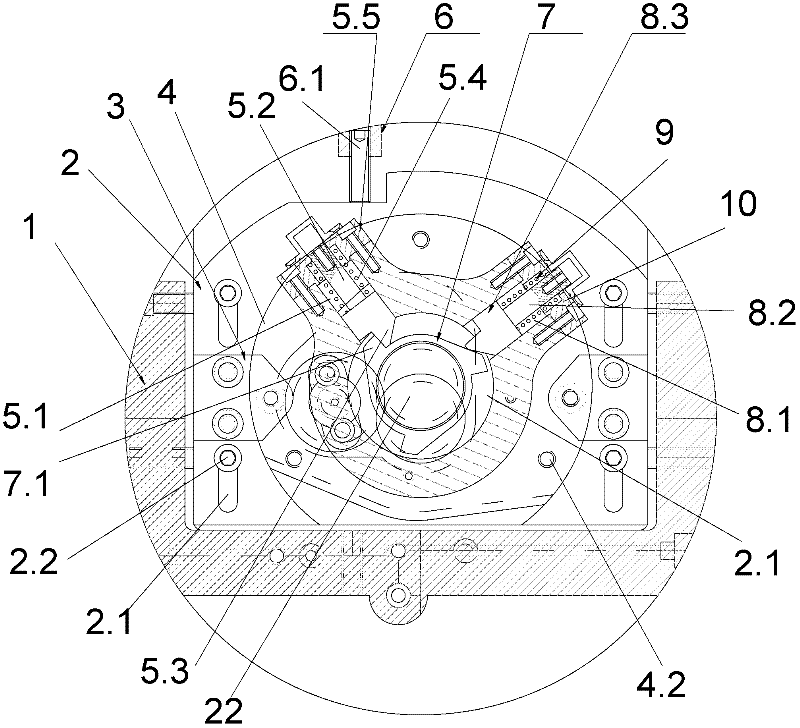

Indexing device for pipe joint

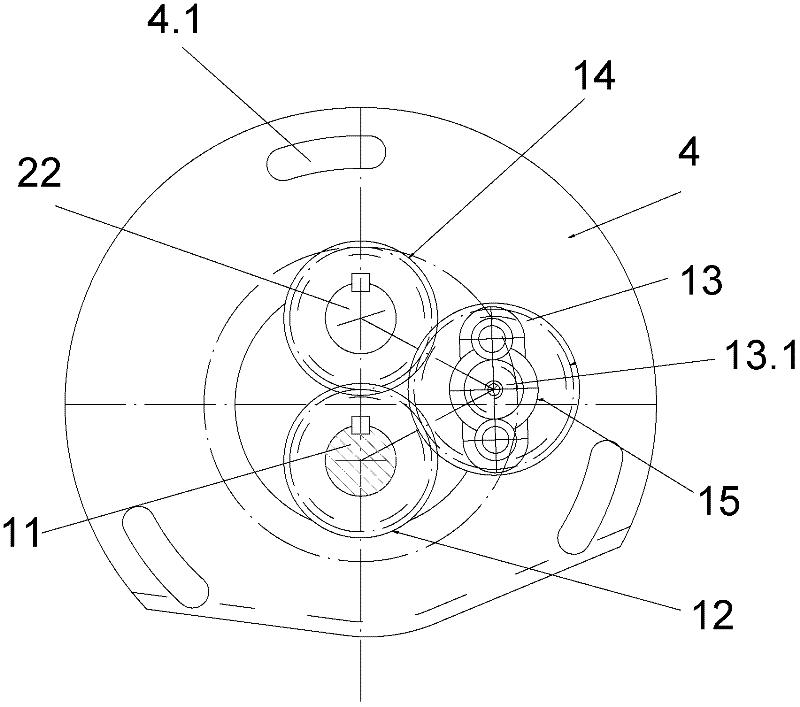

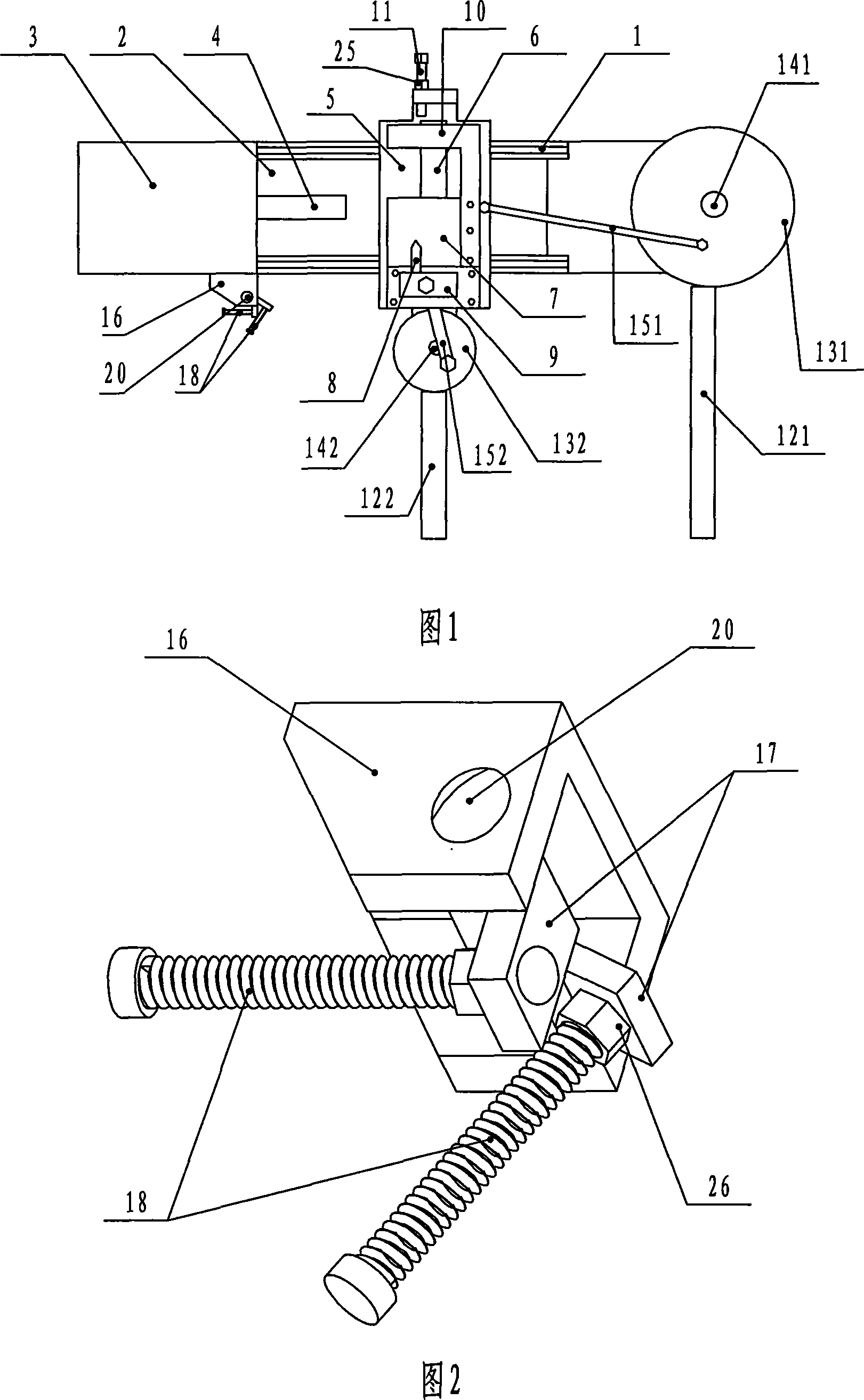

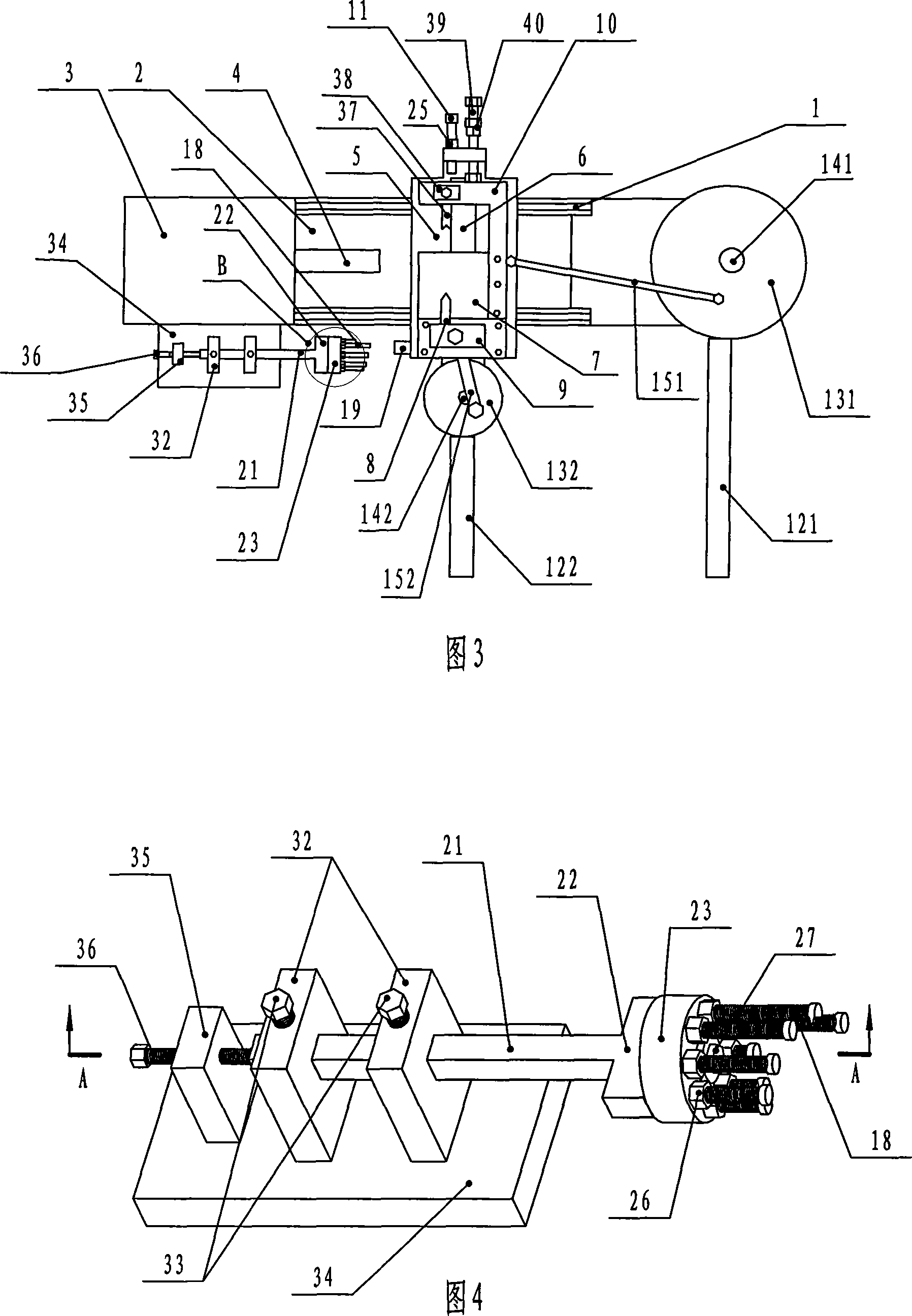

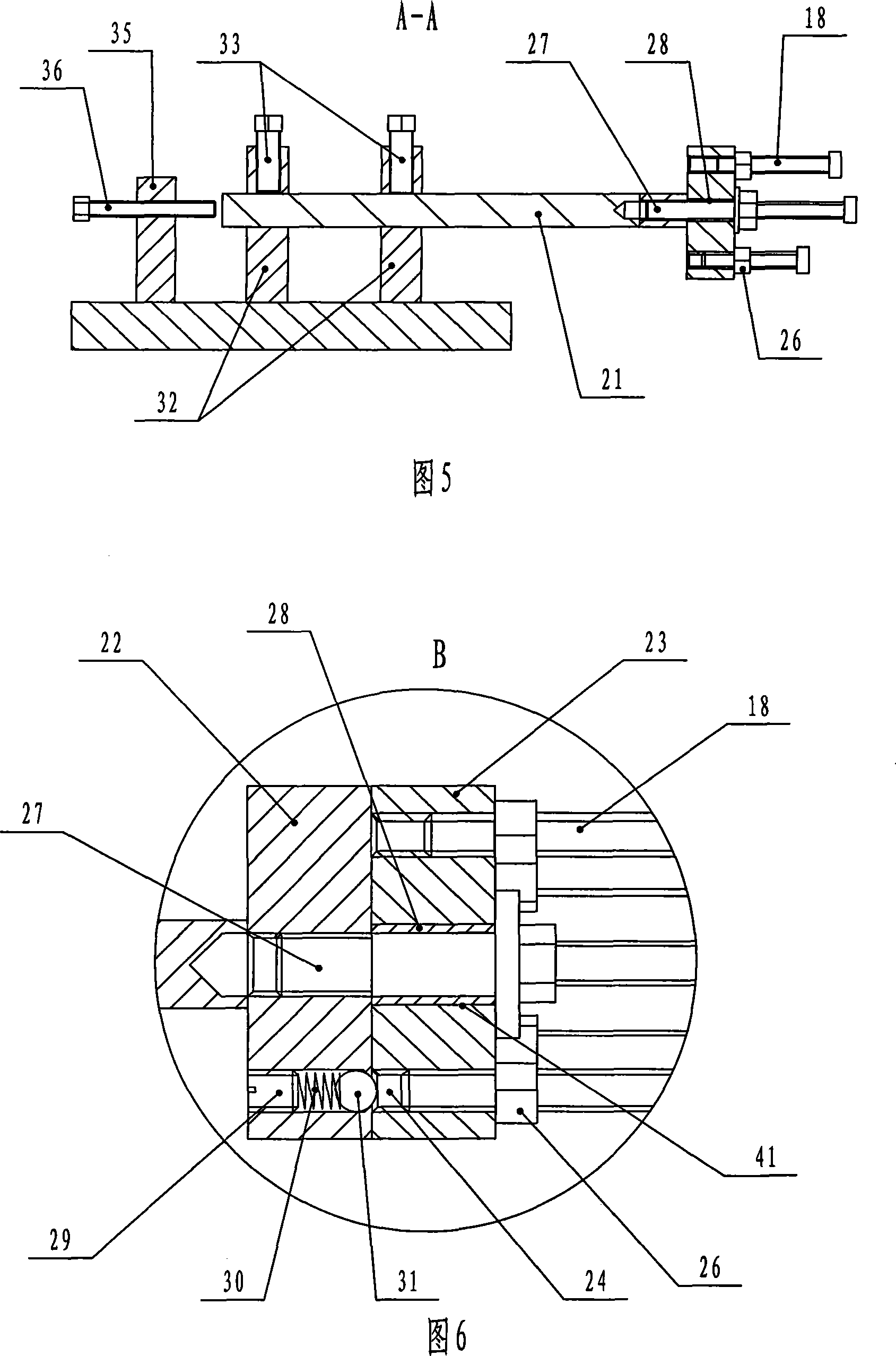

ActiveCN106493596AIncrease productivityImprove shape and position accuracyPositioning apparatusMetal-working holdersEngineeringIndexing head

The invention relates to an indexing device for a pipe joint. The indexing device mainly comprises an upper cover plate, a left locating nut, a right locating nut, a left threaded pin, a right threaded pin, a left locating and pressing assembly, a right locating and pressing assembly, a rotary indexing head assembly, a compression block assembly, a locking screw, a flange plate, a connecting assembly, a lower cover plate and a base; the upper cover plate is located at the upper part of the base and corresponds to the lower cover plate, and both the upper cover plate and the lower cover plate are fixedly arranged on the base through screws; the left locating nut and the right locating nut are fixedly arranged between the left locating and pressing assembly and the lower cover plate and between the right locating and pressing assembly and the lower cover plate through the left threaded pin and the right threaded pin; the rotary indexing head assembly and the compression block assembly are respectively correspondingly arranged at the upper and lower ends of the base; and the locking screw and the compression block assembly are arranged side by side, and the locking screw is used for radially locking the compression block assembly. By using the indexing device disclosed by the invention, not only is the production efficiency of the pipe joint increased, but also the production cost is greatly reduced, and the geometrical precision of a product is improved.

Owner:GUIZHOU HANGFEI PRECISION MFG CO LTD

Gear forming grinding machine tool

ActiveCN107309499AAchieve disassemblyHigh shaping efficiencyAbrasive surface conditioning devicesGear-cutting machinesNumerical controlGear wheel

The invention belongs to the technical field of gear machining equipment and provides a gear forming grinding machine tool comprising a machine tool body; a mounting stand of the machine tool body is provided with a numerical control indexing head, a tooth profile centring device, a gear clamping device, a swing device and a grinding and dressing device; the numerical control indexing head is provided with a tooth space conversion mechanism; the tooth profile centring device comprises a base slidably located on the mounting stand, the base is provided with a position correcting mechanism, and a first centre is slidably arranged in the base and is connected with a first regulating mechanism; the swing device comprises a swing arm mounted in a swing groove of the machine tool body in a limited swing way; the grinding and dressing device comprises supporting plates slidably mounted at two sides of the swing arm, and a second regulating mechanism and a locating mechanism are arranged between the supporting plates and the swing arm, and each of the two supporting plates is provided with a shaping grinding wheel and a dressing wheel. The grinding wheel disclosed by the invention can be used while being repaired, so that the machining precision and efficiency of a drum gear are increased; and the gear forming grinding machine tool can be suitable for flexibly-regulated machining of drum gears with different specifications.

Owner:YIYANG KANGYI MACHINERY DEV

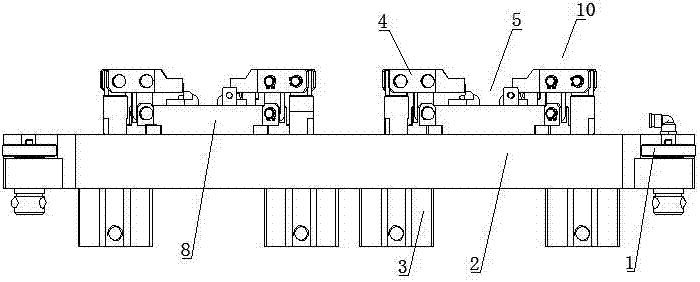

Motorcycle throttle body machining fixture

PendingCN107378581AQuick change operation is simpleSafe and reliable structureWork clamping meansPositioning apparatusSteel ballMachine tool

The invention discloses a motorcycle throttle body machining fixture. The motorcycle throttle body machining fixture comprises bulb locking and positioning mechanisms, a bridge plate, two fixture positioning units and a plurality of pressing units. Two ends of the bridge plate are connected with a tailstock of a machine tool and an L plate of an index head through the bulb locking and positioning mechanisms respectively, and the two fixture positioning units and the multiple pressing units are arranged on the bridge plate. Each fixture positioning unit comprises a fixture base, a positioning block A, a plurality of moving steel ball screw components and a positioning block B, wherein the fixture base is fixed to the bridge plate, the bridge plate and the fixture base are provided with gourd-shaped holes matched with motorcycle throttle bodies, the positioning block A, the positioning block B and positioning bosses are arranged at the edge of the gourd-shaped hole of the fixture base, each positioning boss of the fixture base corresponds to one pressing unit, and the moving steel ball screw components with pre-tightening and false-proof functions are arranged on the fixture base. The motorcycle throttle body machining fixture has advantages of accuracy in positioning, simplicity in operation, high production efficiency and high machining quality.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Five-shaft numerically-controlled drilling and propelling machine

InactiveCN102328119AIncrease the itineraryImprove machining accuracyPrecision positioning equipmentMilling equipment detailsMilling cutterEngineering

The invention provides a five-shaft numerically-controlled drilling and propelling machine which comprises a machine body, a movable table, a clamp head, a rotating head, a rotating motor, a lifting crank, a movable motor, a rotating scale, a rotating disk, a rotating head, an indexing head, an indexing cutter head, a milling cutter and a control disk, wherein the upper part of the machine body is provided with a fixed disk, and the top of the fixed disk is provided with the rotating scale; the movable table is horizontally arranged in the front of the machine body, and the right end of the movable table is provided with the movable motor; the clamp head and the rotating head are installed on the surface of the movable table; the rotating motor is arranged at the right side of the rotating head; the rotating head is fixed on the upper end of the rotating disk, and an index plate is arranged on the front end surface of the rotating disk; and the indexing cutter head is installed on the front end surface of the indexing head, and the lower end of the indexing cutter head is provided with the milling cutter. The five-shaft numerically-controlled drilling and propelling machine provided by the invention can drill in the vertical direction, and the indexing cutter head and the milling cutter can rotate a certain angle through a numerically-controlled device so as to realize the processing of five angles, thus the stroke of equipment is relatively increased, the processing precision is improved, and processing is convenient.

Owner:TIANJIN JINBAO MUSICAL INSTR

Simple indexing head

InactiveCN103447882AReduce carrying volumeEasy to usePrecision positioning equipmentOther workshop equipmentEngineeringMechanical field

The invention belongs to the field of machinery and is used for the indexing and lineation of a part. A simple indexing head is technically characterized in that scale marks are installed on a chuck; the chuck is directly connected with a fixed sleeve on the left side; the fixed sleeve is connected with a rocking bar; a fixing bar is adjusted leftward or rightward according to an adjusted angle; the fixing bar is adjusted into a corresponding indexing hole and is inserted into the corresponding indexing hole. If no corresponding hole is found, the lineation can be implemented via a mode that the chuck is locked by a locking handle. The simple index head is simple and easy to understand for a beginner, small in carrying size and convenient to use.

Owner:蔡利锋

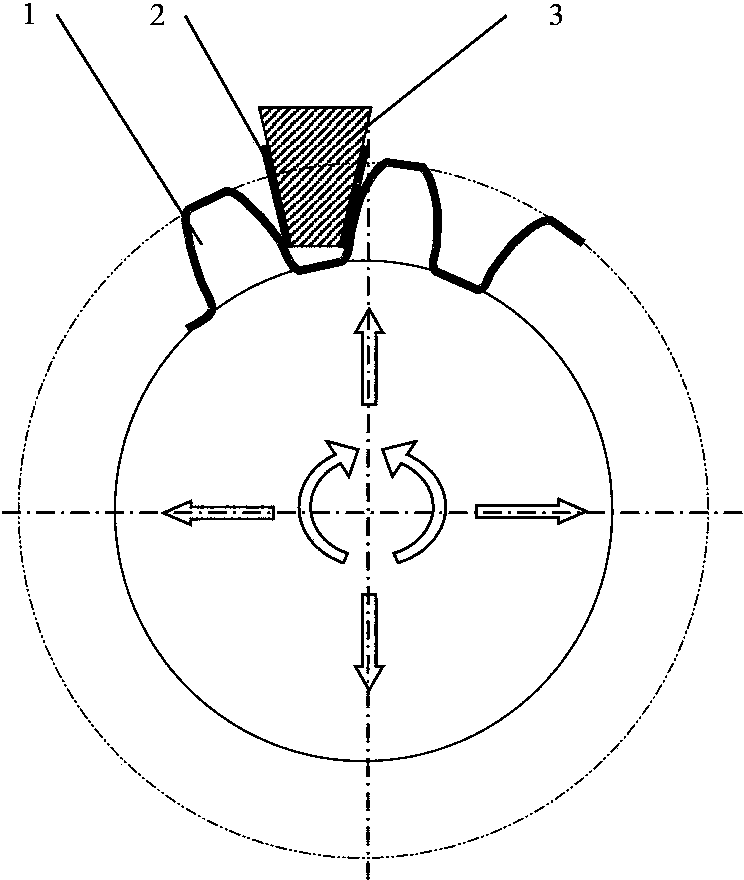

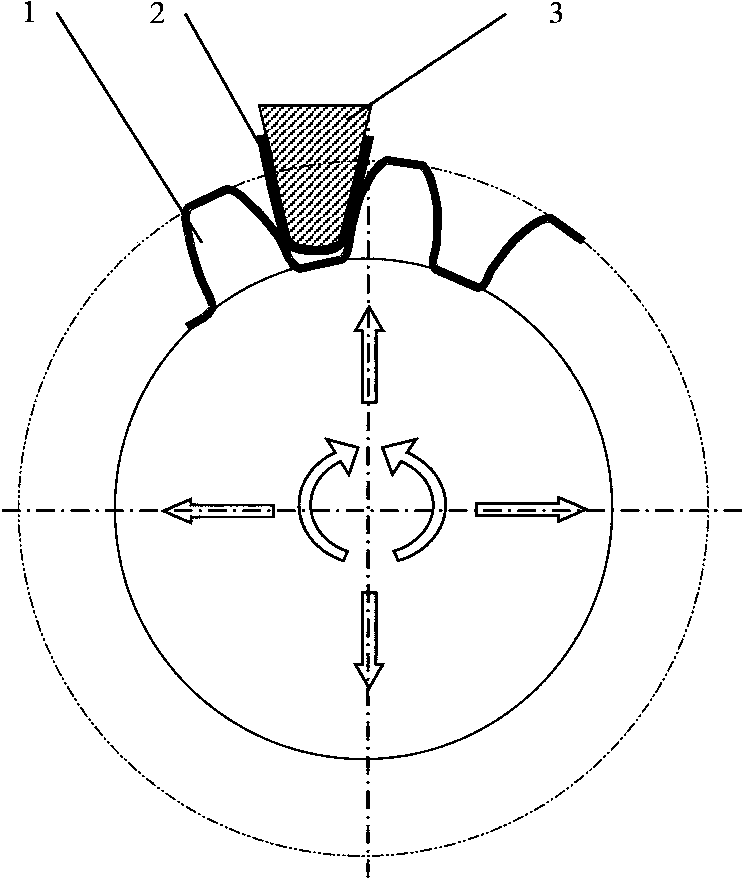

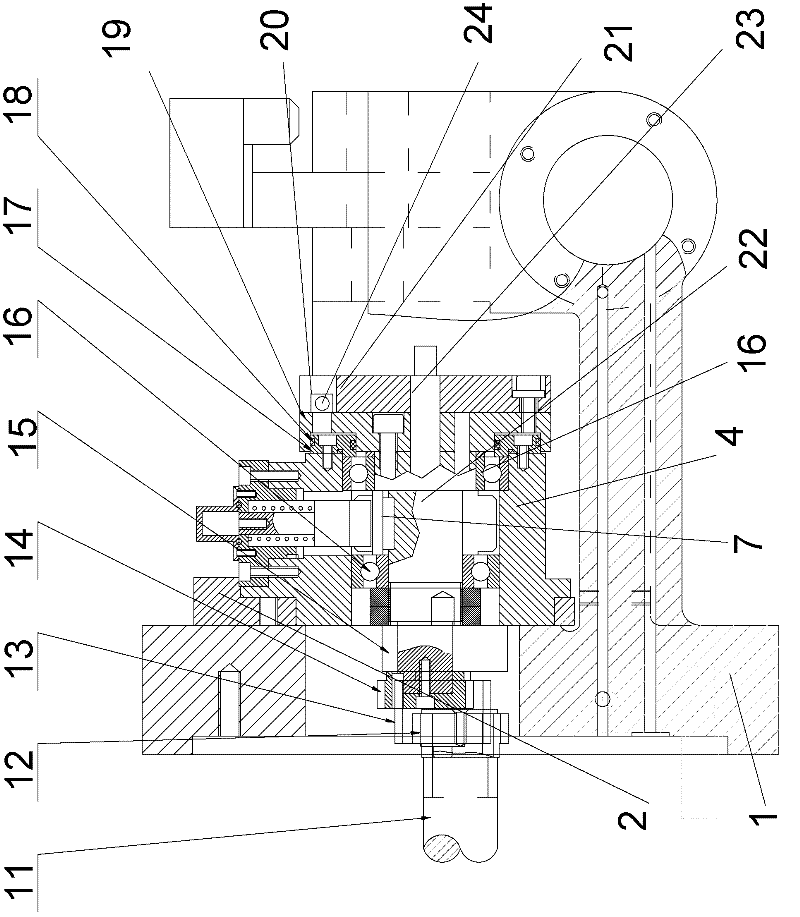

Numerical control servo indexing mechanism for crankshaft connecting rod neck

ActiveCN102259276AImproved Radial Angle AccuracyImprove work efficiencyPrecision positioning equipmentRevolution surface grinding machinesNumerical controlDrive shaft

The invention discloses a numerical control servo indexing mechanism for a crankshaft connecting rod neck. The mechanism comprises a supporting frame connected with an indexing head seat, and is characterized in that: the indexing head seat is connected with an indexing box; a shaft hole is formed in the indexing box; an indexing shaft is supported in the shaft hole through a bearing; a ratchet is arranged on the indexing shaft; ratchet teeth which have the same number as the phase number of the crankshaft connecting rod neck are uniformly arranged on the ratchet along the circumference; an indexing angle is formed by a central angle between two ratchet teeth; a pawl mechanism for positioning the ratchet teeth is arranged in the radial direction of the indexing box; the power input of theindexing shaft and an indexing transmission shaft is realized through a gear transmission device; the indexing shaft is connected with a central output shaft; the end part of the indexing box is connected with an end cover device; and the central output shaft passes through the end cover device. The mechanism has a compact structure and high applicability, is suitable for 120-DEG or 180-DEG indexing, is suitable for crankshaft machining of a main shaft neck and the connecting rod neck within different distances, and has high indexing accuracy.

Owner:湖北伟翔数控机床股份有限公司

Groove cutting machine

ActiveCN101147979ASimple structureEasy to operateAutomatic control devicesPrecision positioning equipmentIndexing headElectric motor

The slot cutting machine includes one slot cutting worktable with tracks, one motor spindle for the workpiece to be installed on, one backing mechanism capable of controlling the cut slot number and one slot milling mechanism. The backing mechanism includes one transverse guide rail connected to the front side of the motor box, one fixing block, one rotatable index head connected to the fixing block, one locating unit, and at least three adjusting screws and nuts on the index head. The present invention has the advantages including capacity of machining at least three slots simultaneously, simple structure, convenient operation and high slot cutting precision.

Owner:NINGBO HAITONG AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com