Numerical control turn milling, grinding and carving combination lathe

A universal machine tool and machine tool technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of limited processing capacity and single processing function, and achieve good practicability and reliability, simple process and novel design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

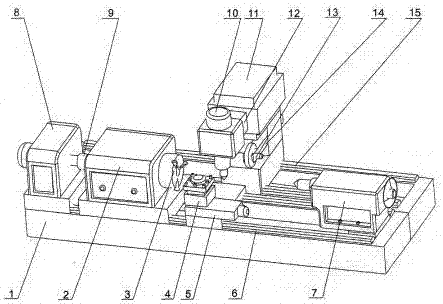

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] As shown in the figure, the machine bed 1 used for CNC turning, milling, grinding and engraving universal machine tools, the machine tool spindle box 2, the turning chuck 3, the turning tool holder 4, the machine tool turning middle carriage gearbox 5, the turning Pin guide rail 6, machine tool tailstock 7, CNC universal indexing head 8, hydraulic coupling 9, engraving and milling electric spindle 10, engraving, milling and grinding machine column 11, engraving and milling square ram 12, outer circular grinding square ram 13, Cylindrical grinding head 14, column guide rail 15 of engraving and milling machine tool.

[0010] The present invention can be realized in the following ways.

[0011] 1. Material selection: The machine bed of the CNC turning, milling, grinding and carving universal machine tool, the column of the carving, milling and grinding machine too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com