Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

410results about How to "Oil evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

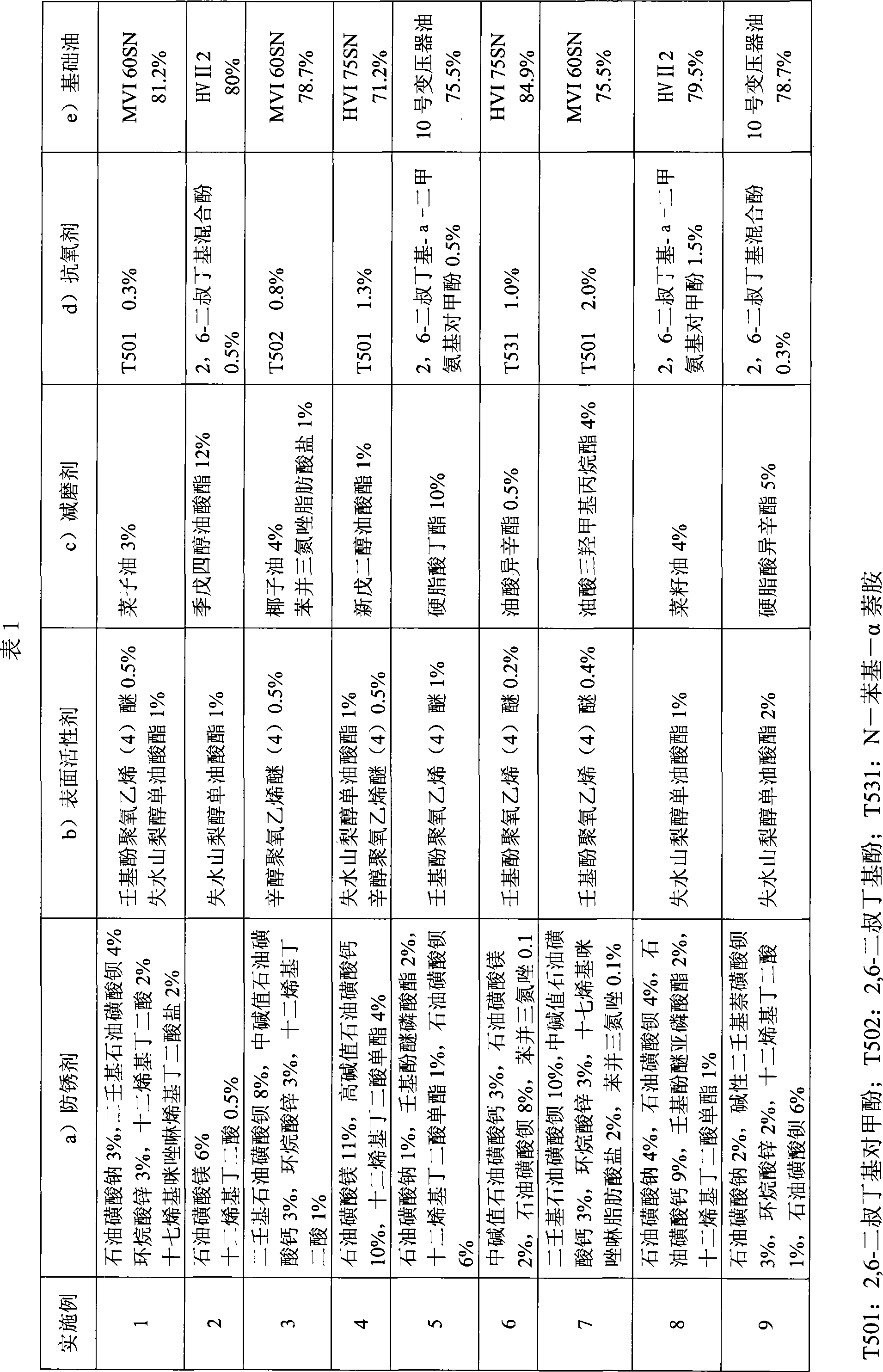

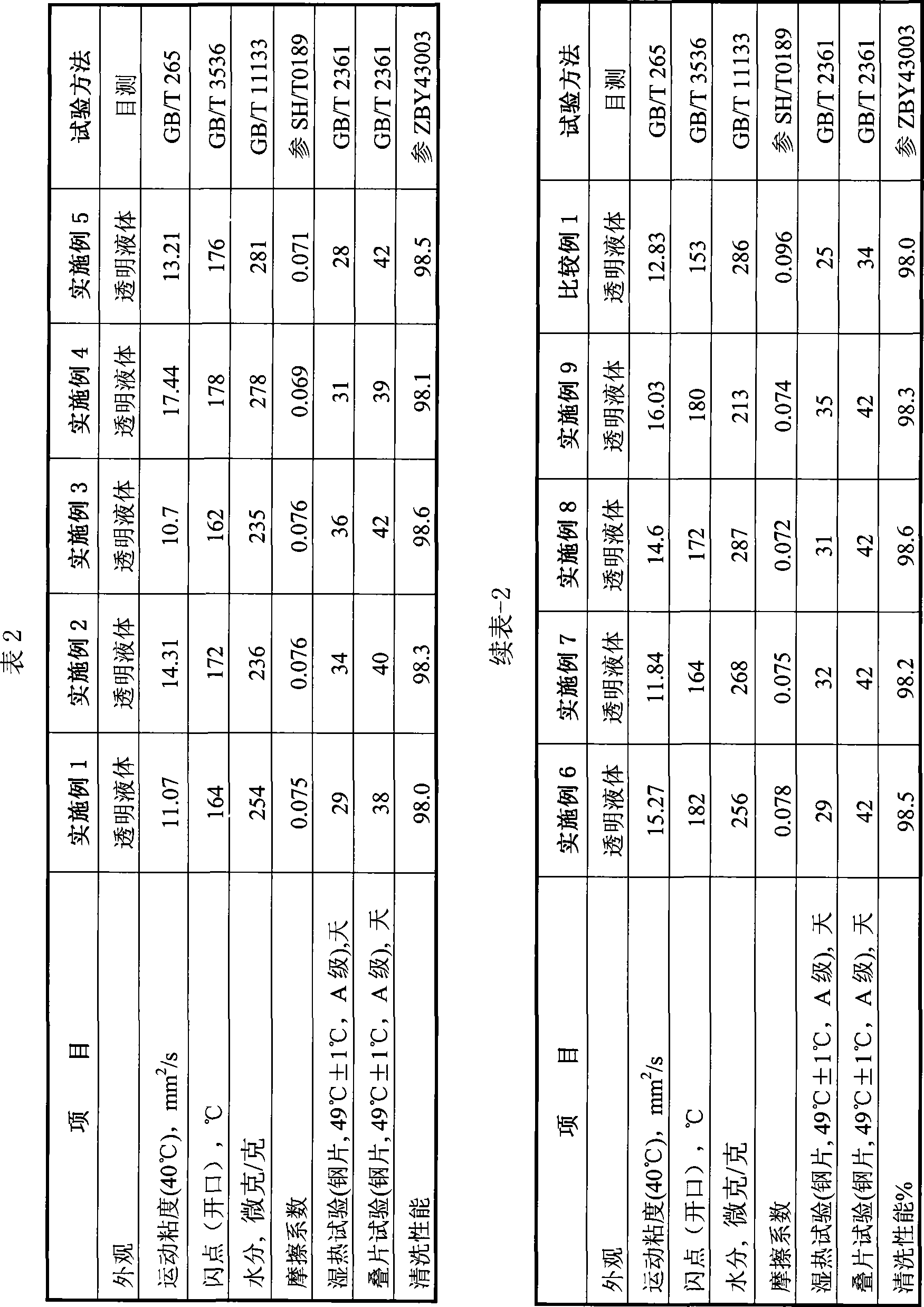

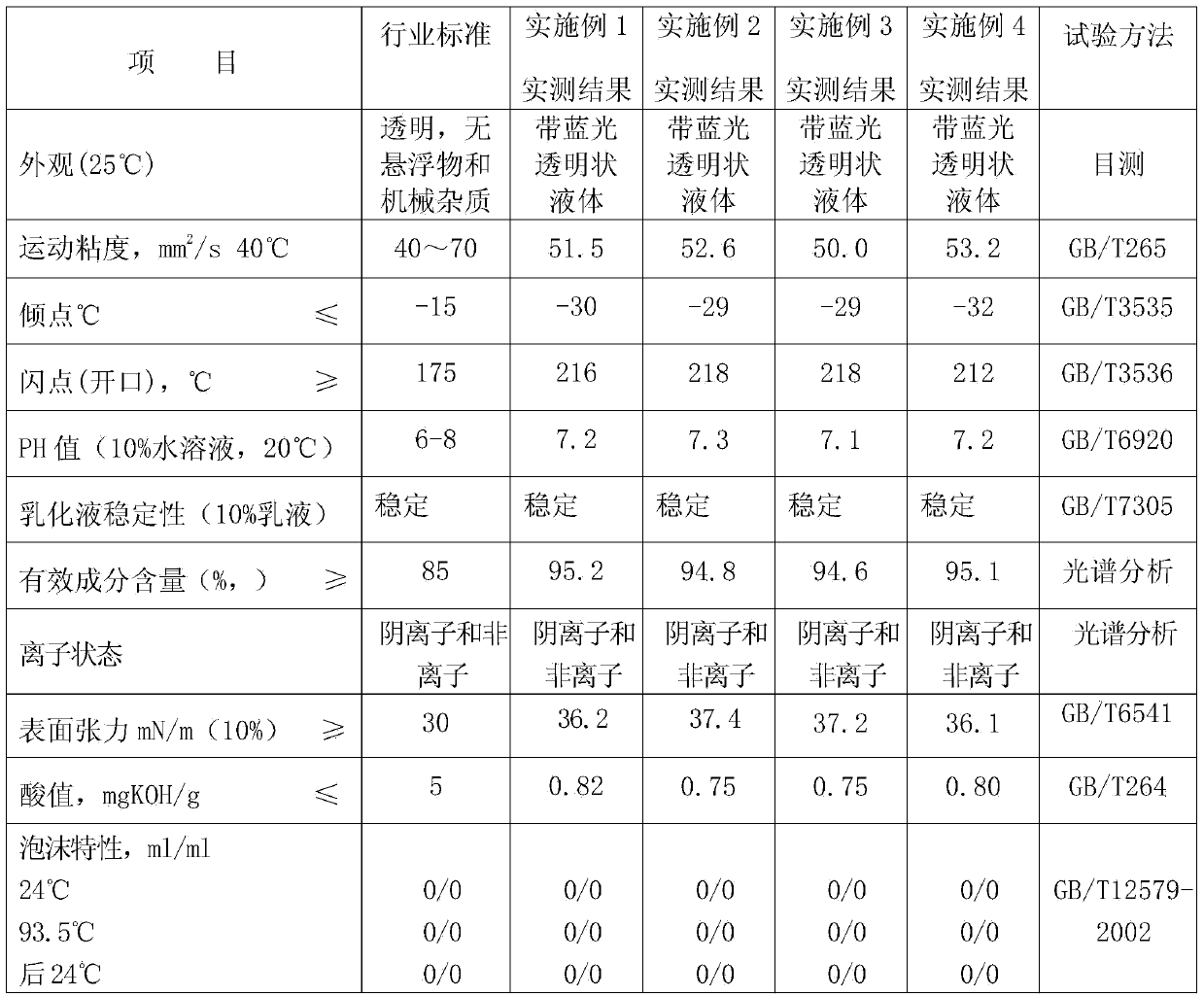

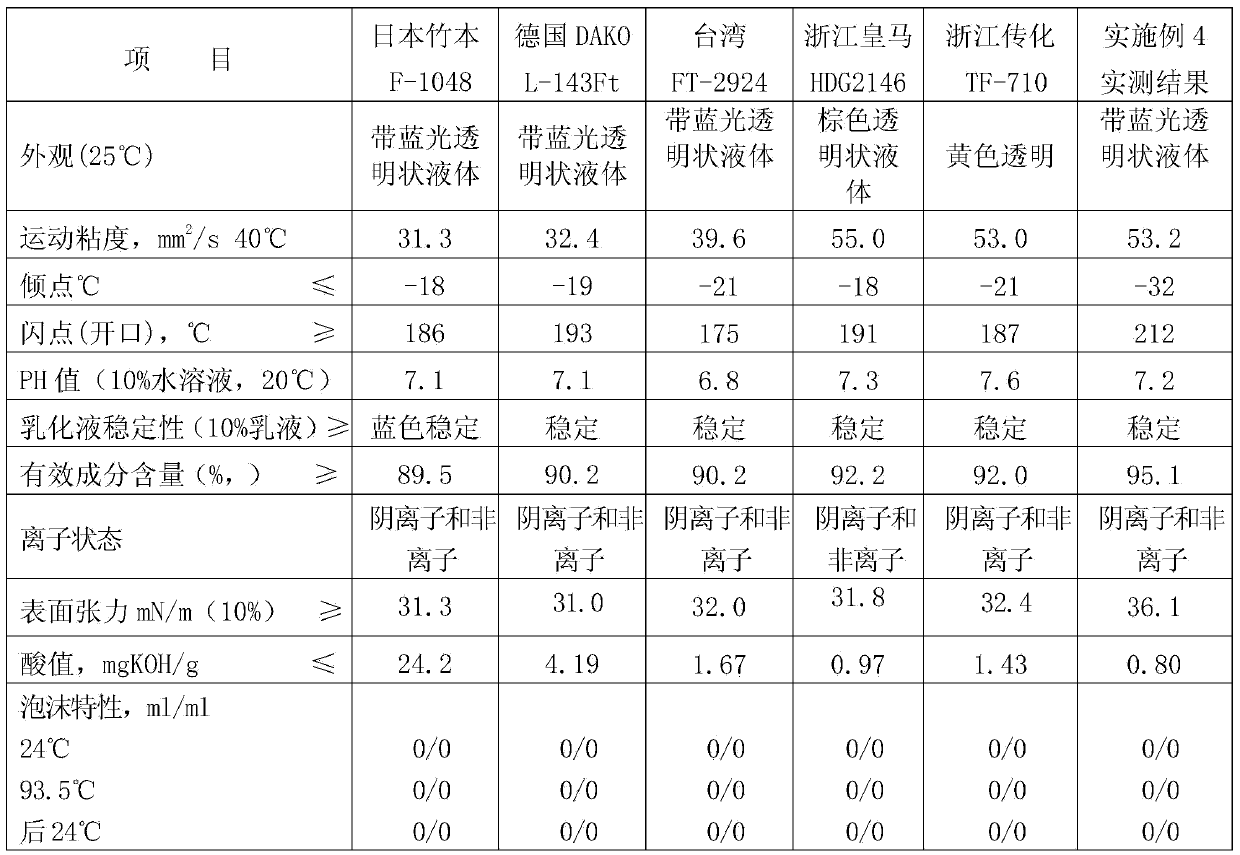

Electrostatic painting anticorrosive oil and production method thereof

ActiveCN101486945ADoes not affect post-processing effectsPost-processing effect is reducedAdditivesAntioxidantBase oil

The invention relates to electrostatic spraying anti-rust oil and a production method thereof, which essentially solves the problems of the prior art that the lubricating property of the anti-rust oil is poor; and interlayer sliding is caused due to larger tension during the reeling process of the steel plate, resulting in steel plate scratch and having impact on the surface quality of the steel plate. The electrostatic spraying anti-rust oil commendably solves the problems by using the technical proposal comprising components of weight percentages as follows: a) 5 to 30 percent of anti-rust agent, b) 0.1 to 5 percent of surface activator, c) 0.1 to 15 percent of anti-friction composition, d) 0.1 to 5.0 percent of antioxidant and e) 50 to 90 percent of base oil, and can be used for the electrostatic spraying rust resistance of the cold-rolled carbon steel plate, galvanized plate and aluminized zinc silicon plate of the steel enterprises.

Owner:CHINA PETROLEUM & CHEM CORP

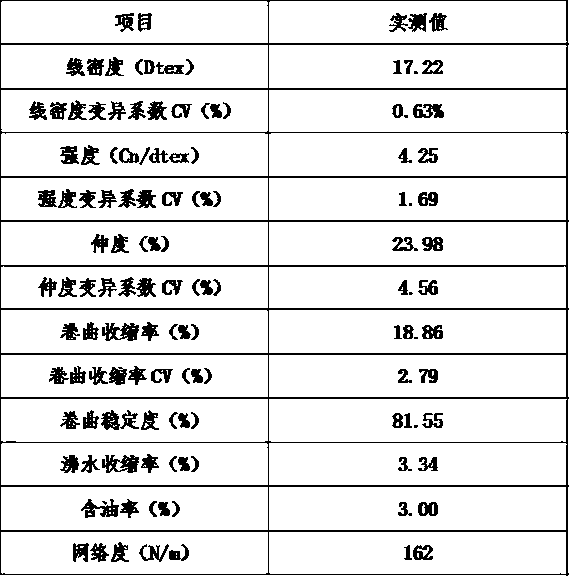

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

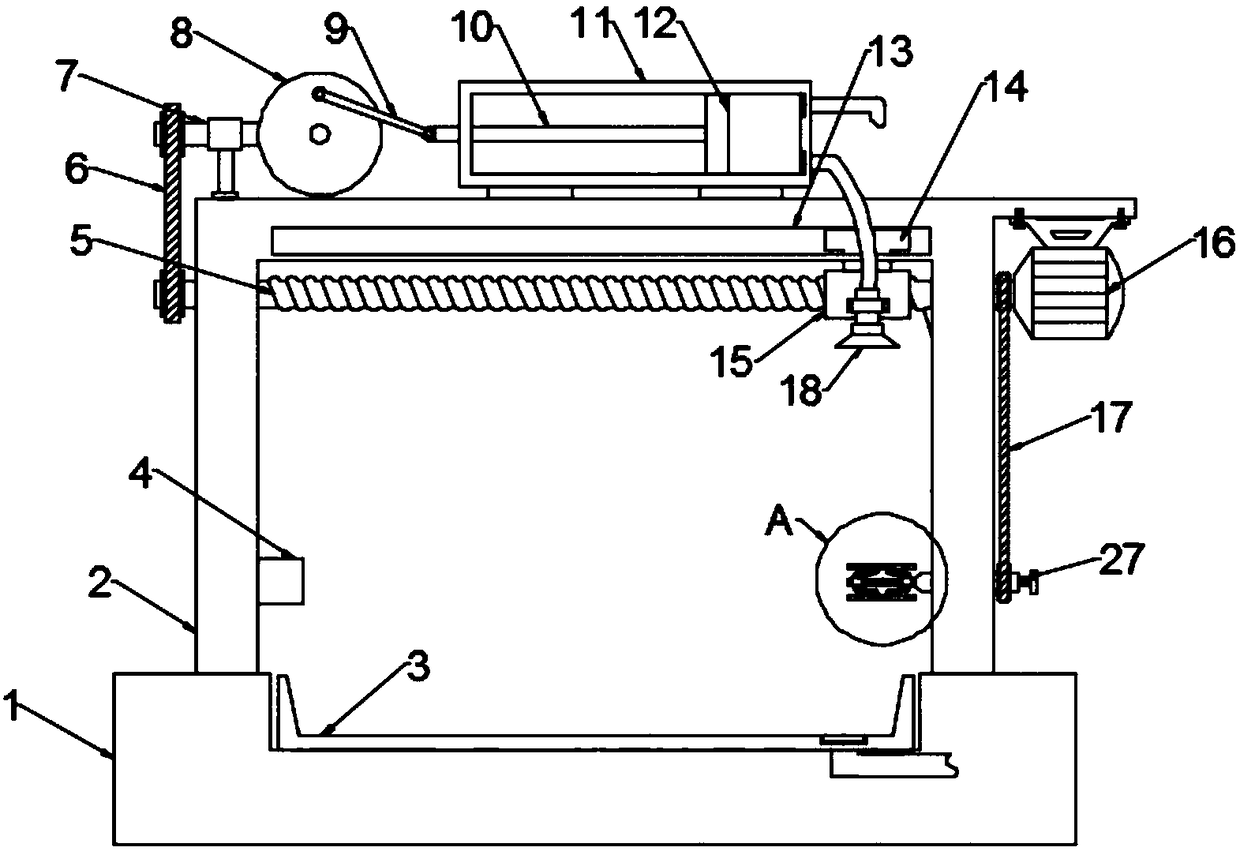

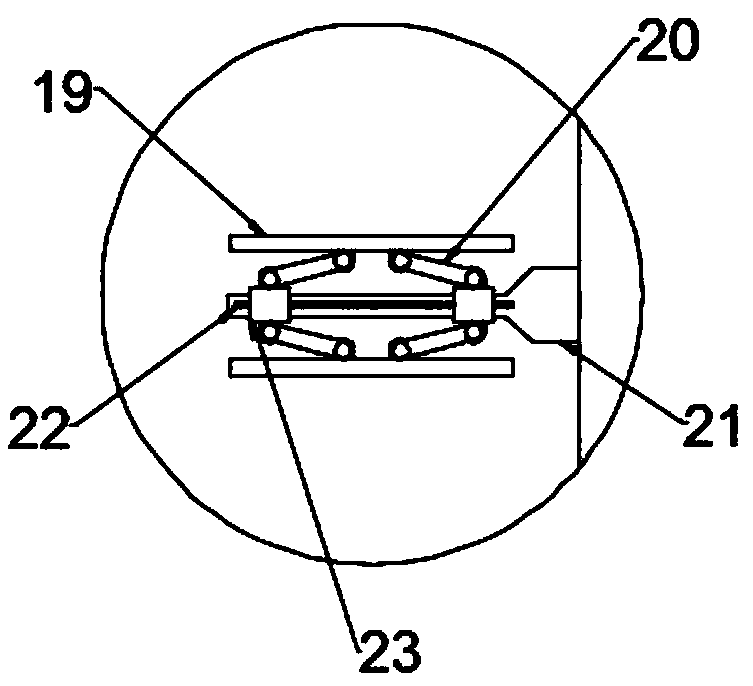

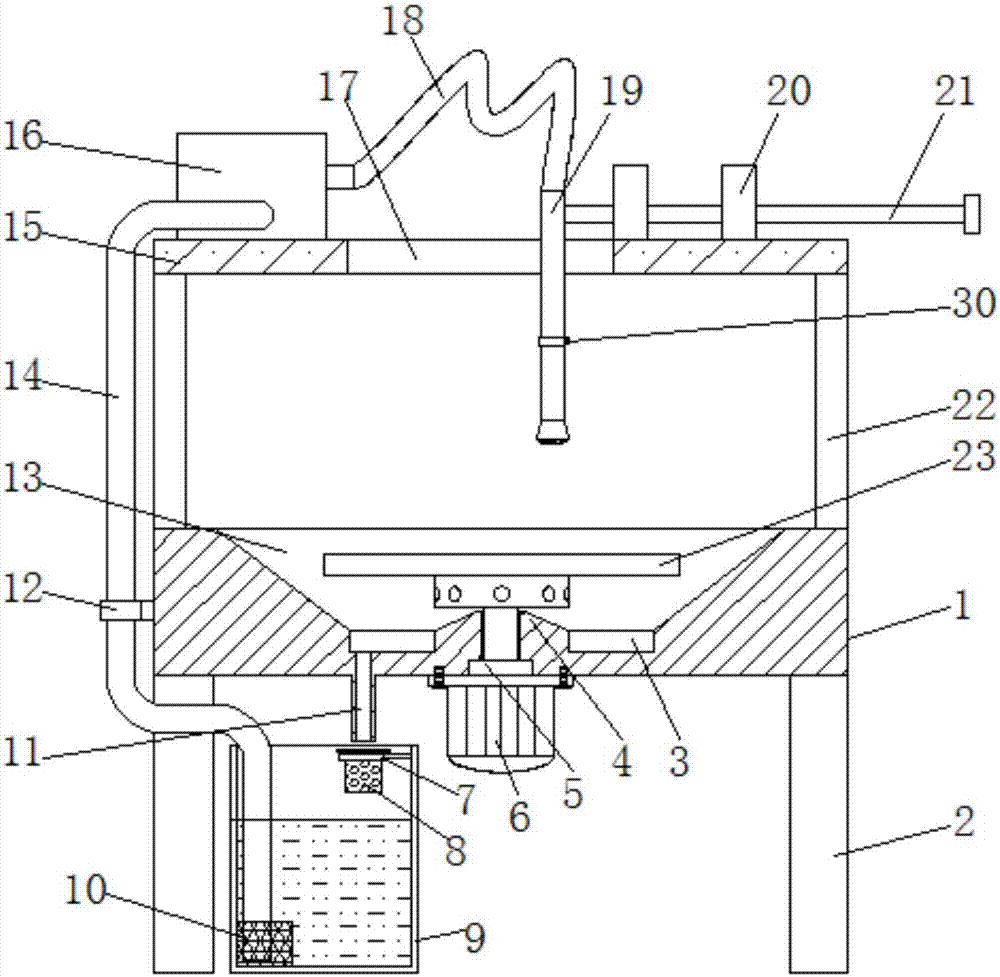

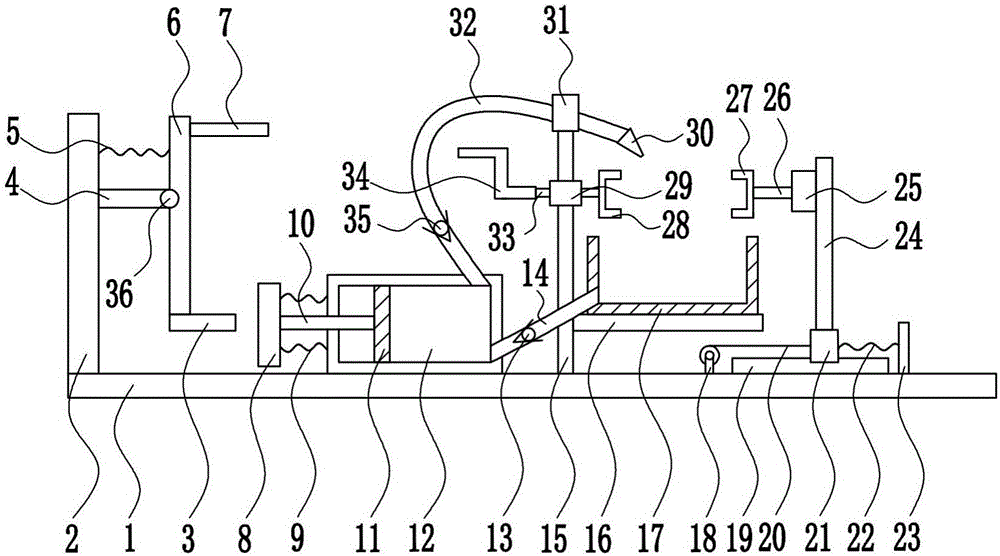

Steel pipe outer wall oiling device

InactiveCN108837980AAchieve fixationOil evenlyLiquid spraying apparatusElectric machineryArchitectural engineering

The invention discloses a steel pipe outer wall oiling device which comprises a base, a shell, a pumping mechanism, a motor and a steel pipe fixing mechanism. The pumping mechanism comprises a rotaryplate, a connecting rod, a pushing rod, a cylinder body and a piston; an arc-shaped placement plate is arranged at the left end of the inner side of the shell; and a steel pipe fixing mechanism is arranged at the right end of the inner side of the shell, and comprises pressing plates, support rods, a sleeve, a rectangular through slot, first sleeve rings, second sleeve rings, a bi-directional threaded rod, a support side plate, a rotary plate and a second threaded sleeve. The steel pipe outer wall oiling device provided by the invention is novel in design; when the first sleeve rings move faceto face or opposite to each other under the action of the bi-directional threaded rod, the support rods drive the multiple pressing plates to spread or contract, so that a steel pipe can be fixed anddisassembled, and the convenience in use is realized; during the oil injection process, the steel pipe is driven to rotate so as to be oiled uniformly; and a collecting groove communicates with the pumping mechanism and is used for collecting and recycling redundant anti-rust oil dripped on the steel pipe and sprayed by a spray head.

Owner:佛山市顺德区唯点工业设计有限公司

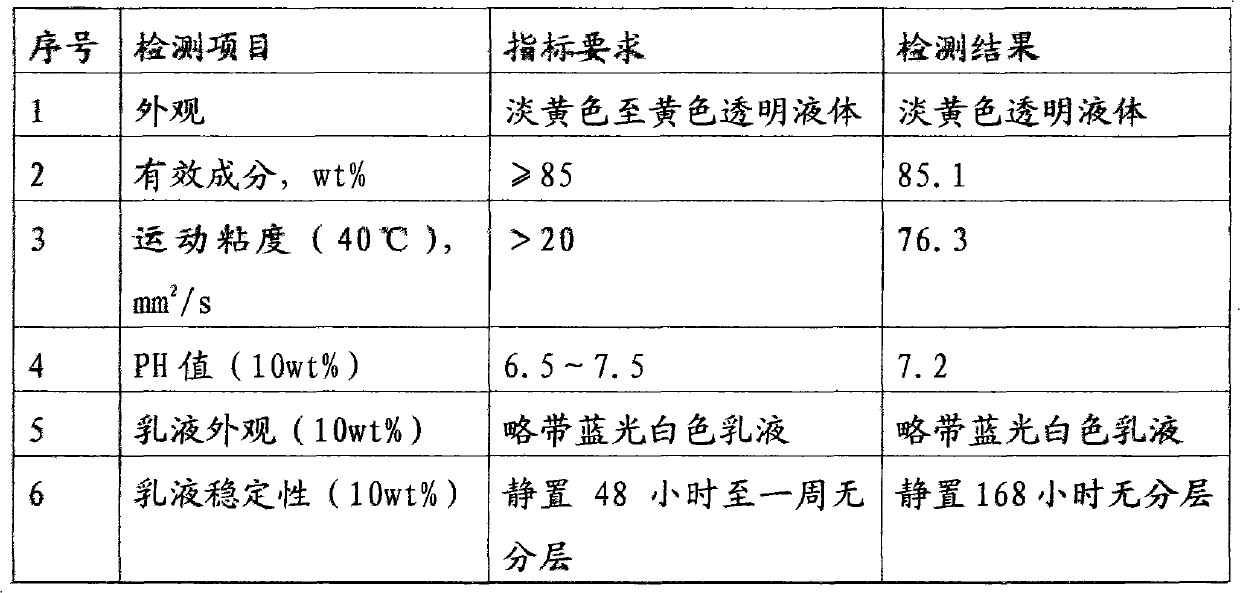

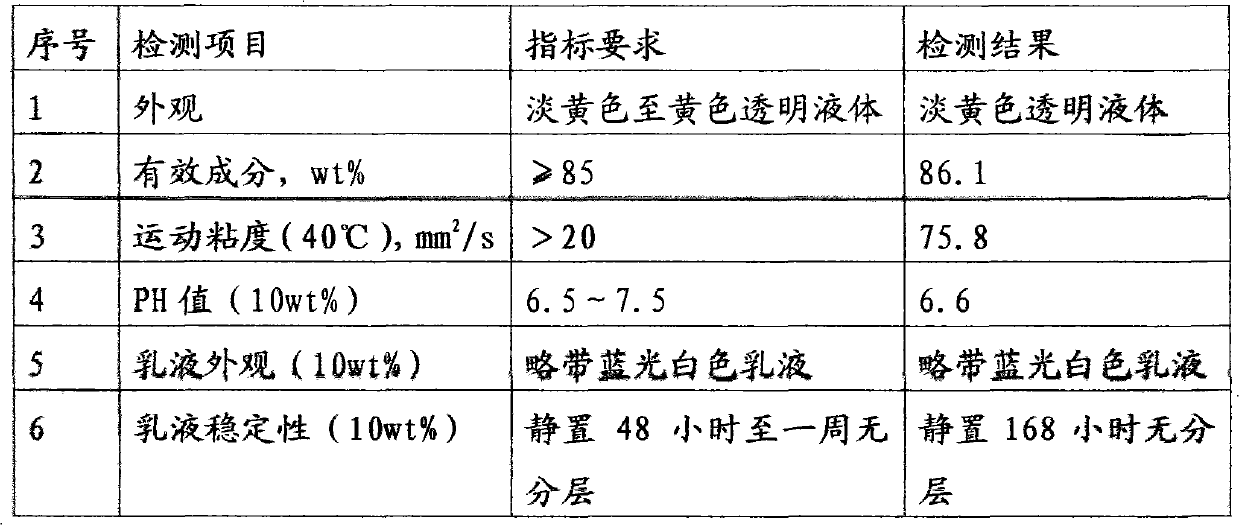

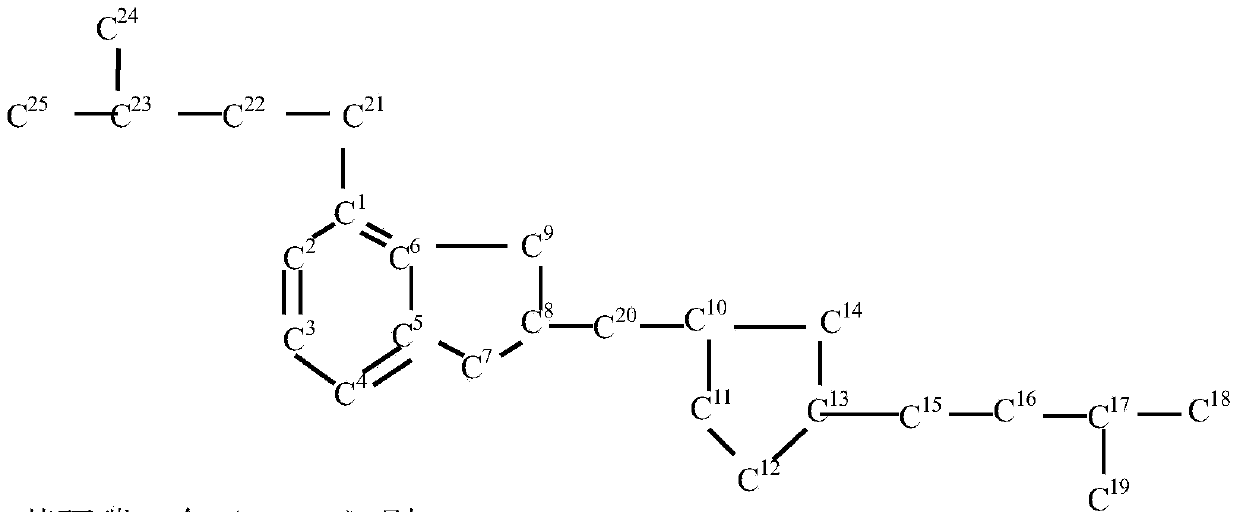

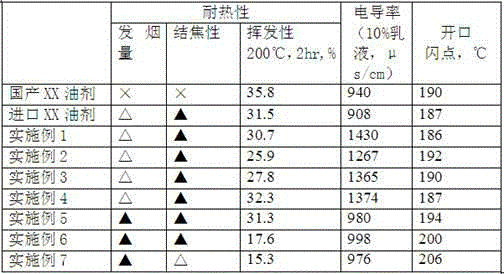

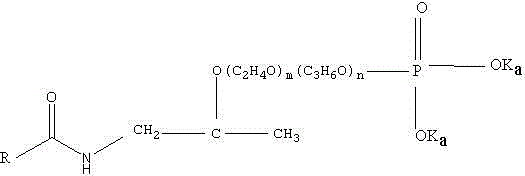

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Fiber fully drawn yarn (FDY) spinning oil and preparation method thereof

The invention relates to a fiber fully drawn yarn (FDY) spinning oil which comprises a high-temperature smoothing agent, a composite antistatic agent, a bundling agent, a phenolic group antioxidant, a phenylamino group antioxidant, an olefine acid antioxidant, a high-temperature dispersant, a softening agent, an environment-friendly emulsifying agent, a defoaming agent, a preservative and an environment-friendly penetrating agent, wherein the high-temperature smoothing agent comprises hydrogenation paraffin-based oil and hydrogenation naphthenic oil. The invention also provides a preparation method of the fiber FDY spinning oil. The fiber FDY spinning oil is stable in emulsion and free from stratification and odor, and is not easily rotted; the fiber is easily not yellowed by dyeing, and the fiber FDY spinning oil is easy to rinse; the production process is stable, and the fiber FDY spinning oil has few broken ends, is good in heat resistance, does not have smoke formation, is not coked on a hot roller, has the excellent anti-static performance under the different humidity conditions, and thus the fiber FDY spinning oil can meet the requirements of high-speed spinning technologies of various specifications of fiber including thick fibers and thin fibers; after the fiber FDY spinning oil is used, the fiber can smoothly pass through the after the spinning of various equipment, so that the yield and the good rate of fiber spinning can be effectively increased.

Owner:上海中孚油品集团有限公司

Nylon 6 short fiber spinning oil agent, preparation method and application thereof

Belonging to the technical field of spinning assistants, the invention relates to a nylon 6 short fiber spinning oil agent, a preparation method and application thereof. The nylon 6 short fiber spinning oil agent is composed of, by mass percentage, 15-60% of a smoothing agent, 10-45% of a balance agent, 10-30% of a bundle collecting agent, 0.5-25% of an antistatic agent, 0.5-20% of a regulation stabilizer, and 0-21.5% of other components. The spinning oil agent can be applied to fore-spinning and after-spinning of nylon 6 short fiber, and has the advantages of uniform oil application, excellent spinnability, good heat resistance, low tarring degree, and good tow properties, etc.

Owner:ZHEJIANG HUANGMA TECH

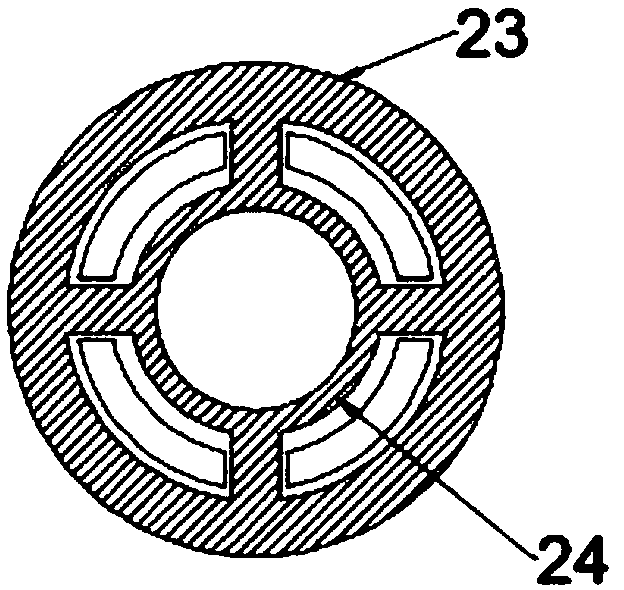

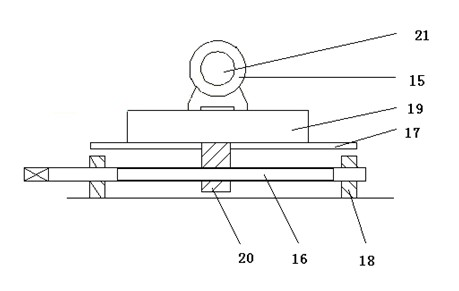

Bearing oil-coating device

ActiveCN105499022AOil evenlyImprove oiling efficiencyLiquid spraying apparatusRotational axisHydraulic cylinder

The invention discloses a bearing oil-coating device. The bearing oil-coating device comprises a platform, a fixing support, a hydraulic cylinder, a fixing cover, an oil injection pump, spray pipes, atomized oil spray heads, a rotation motor, a rotation shaft, a tensioning swivel and fixing blocks, wherein the fixing support is vertically fixed at the top of the side surface of the platform; the hydraulic cylinder is fixed at the top of the fixing support; the fixing cover is connected to the lower part of the hydraulic cylinder; the oil fuel injection pump and the rotation motor are installed in the fixing cover; the spray pipes are connected to the oil fuel injection pump; the atomized oil spray heads are installed at the tail ends of the spray pipes; the rotation shaft is connected to the lower part of the rotation motor; the tensioning swivel is installed at the lower end of the rotation shaft; the fixing blocks are installed at the top of the platform; and a waste oil recovery hole is formed in the top of the platform. According to the invention, bearing oil-coating can be automatically carried out, lubricant oil can be saved, the oil-coating efficiency is high, and the oil-coating is uniform; and the equipment is simple in structure, low in investment cost and capable of coating different types of bearings.

Owner:新昌县林泉轴承有限公司

Novel civil oiling agent composition for FDY polyester filament yarn and preparation method for novel civil oiling agent composition for FDY polyester filament yarn

The invention relates to a novel civil oiling agent composition for a FDY polyester filament yarn and a preparation method for the novel civil oiling agent composition for the FDY polyester filament yarn. The novel civil oiling agent composition is prepared from the following components in percentage by weight: 2-15% of an antistatic agent composition, 2-15% of a tow collecting agent, 30-80% of a lubricating agent, 15-30% of an emulsifier and 1-5% of a regulating stabilizer, wherein the antistatic agent composition consists of a component A and a component B, the component A is fatty acid monoisopropanolamine polyoxyethylene polyoxypropylene ether potassium phosphate which accounts for 3-7% (in percentage by weight) of the oiling agent composition, and the component B is an anionic surfactant or an ampholytic surfactant. The novel civil oiling agent composition disclosed by the invention is good in antistatic performance in a spinning process, uniform in oiling, excellent in spinning property, good in heat resistance, low in tarring degree, less in residues on a stick, and low in oiling rate; moreover, the performances of the spinning tows are good.

Owner:ZHEJIANG HUANGMA TECH

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

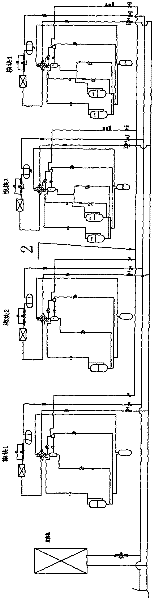

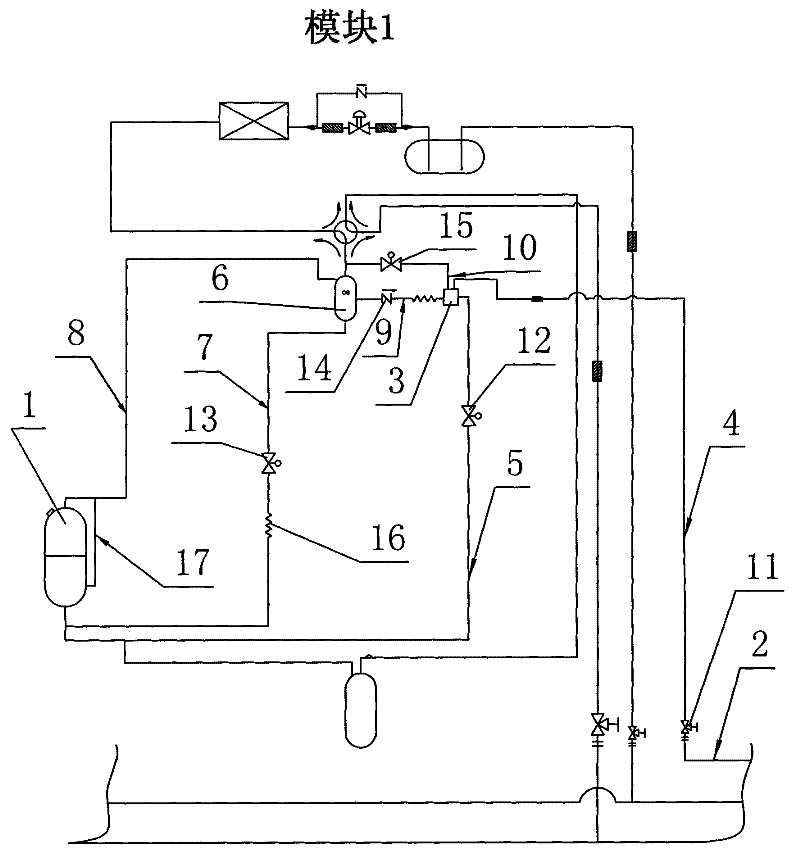

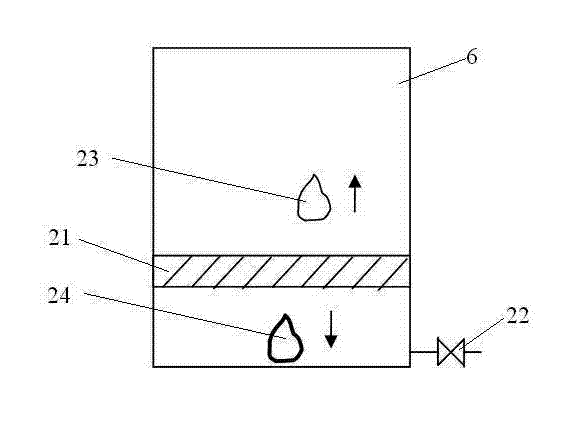

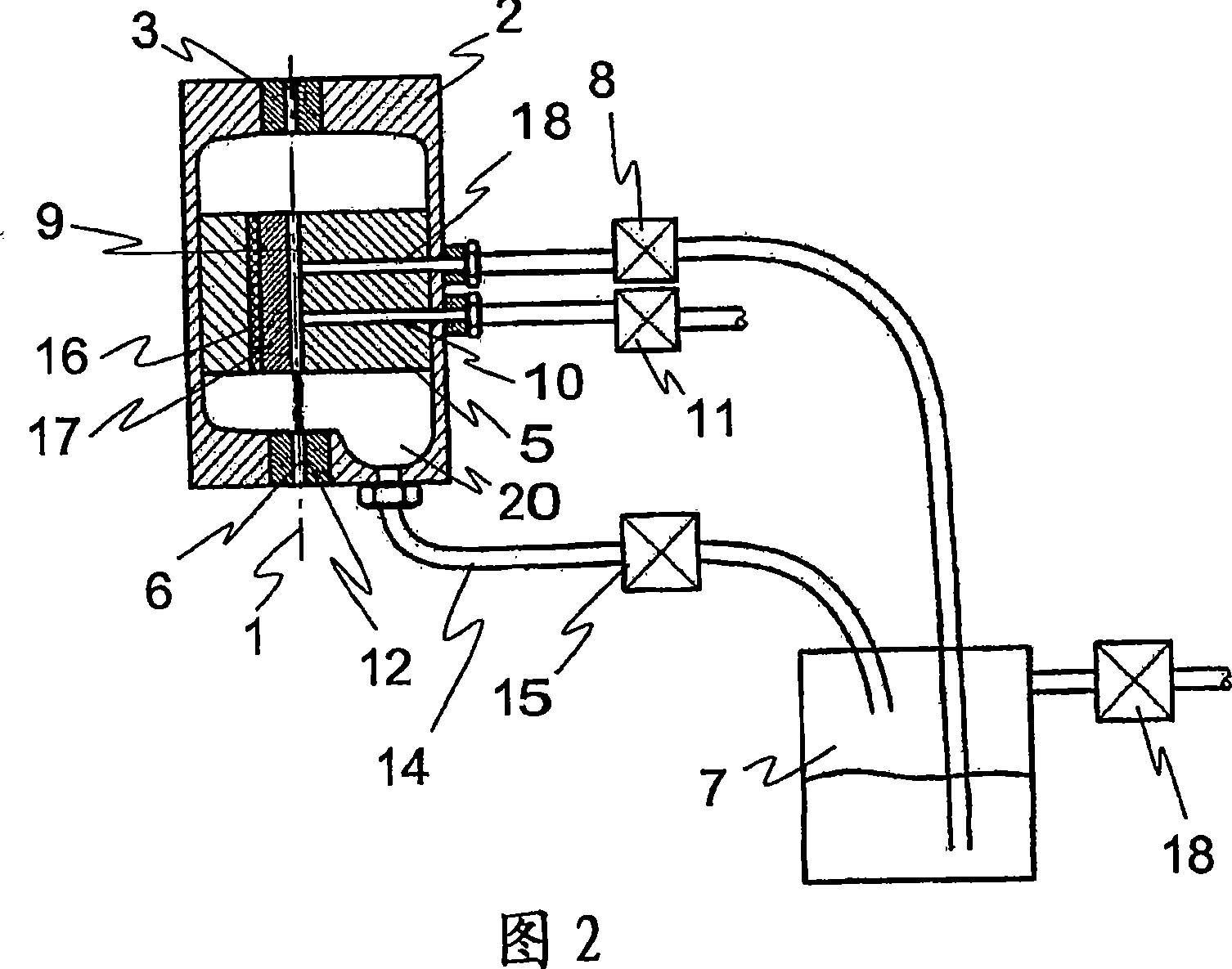

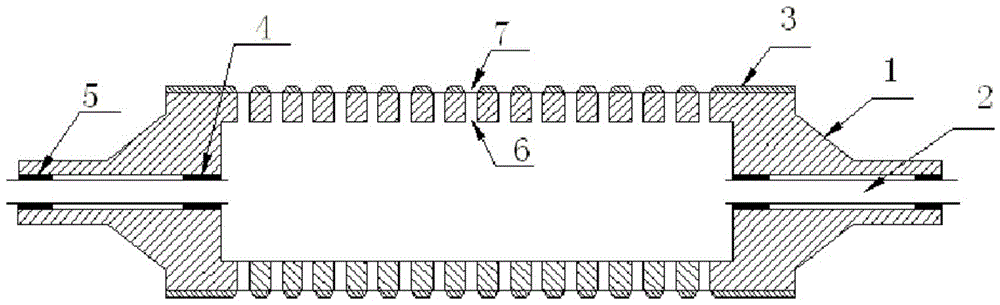

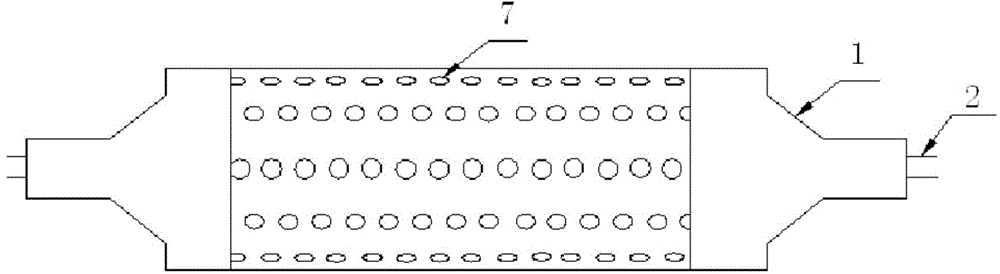

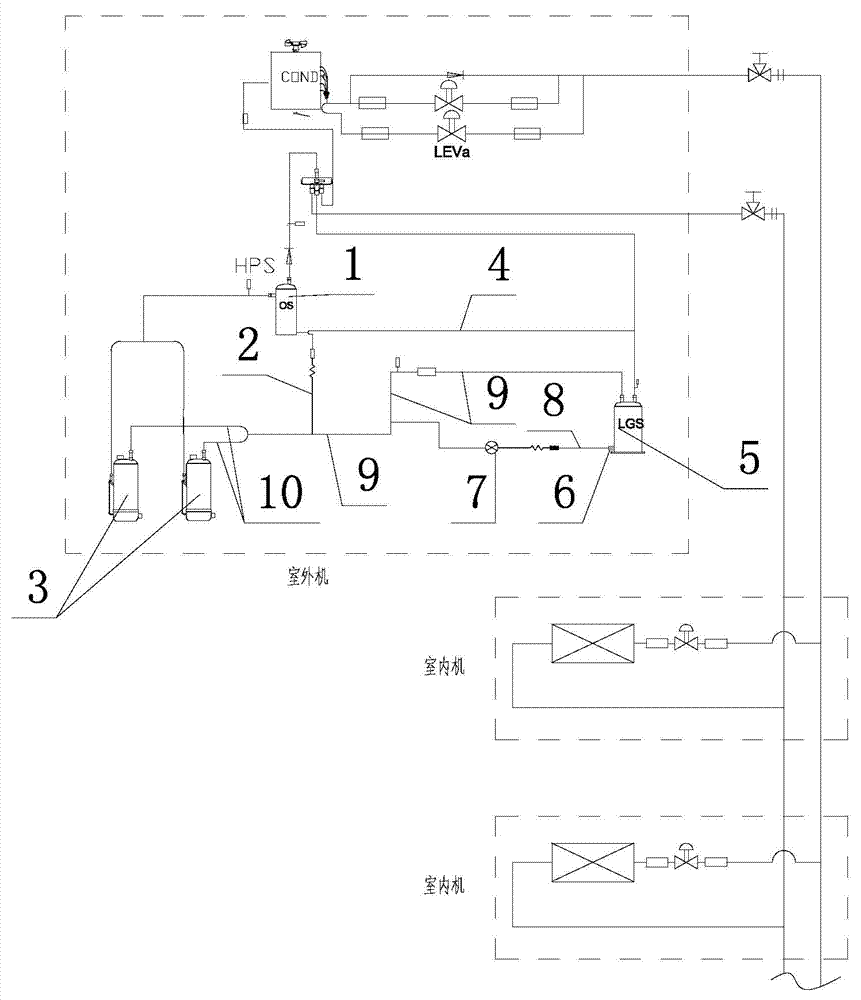

Multi-connected air-conditioning unit

ActiveCN102305439AOil evenlyPut an end to the situation of burningCompressorAir conditioning systemsEqualizationAir conditioning

The invention discloses a multi-connected air-conditioning unit which comprises a plurality of outdoor unit modules and an oil equalization main pipe (2), wherein each outdoor unit module comprises a compressor (1), as well as an oil storage device (3), an oil equalization branch pipe (4) and a first oil return pipe (5); as for each outdoor unit module, the outlet end of the compressor (1) is communicated with the inlet end of the oil storage device (3); the oil equalization opening of the oil storage device (3) is communicated with the oil equalization main pipe (2) through the oil equalization branch pipe (4); an oil equalization valve (11) is arranged on the oil equalization branch pipe (4); a first oil return hole of the oil storage device (3) is communicated with the inlet end of the compressor (1) through the first oil return pipe (5); and a first oil return valve (12) is arranged on the first oil return pipe (5). The reasonable oil equalization of each outdoor unit module can be ensured by the multi-connected air-conditioning unit.

Owner:NINGBO AUX ELECTRIC

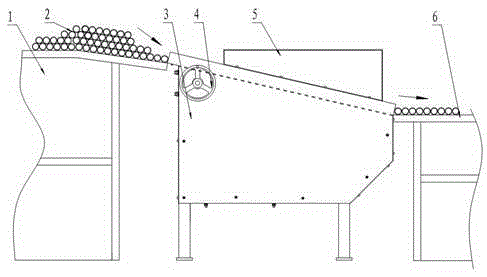

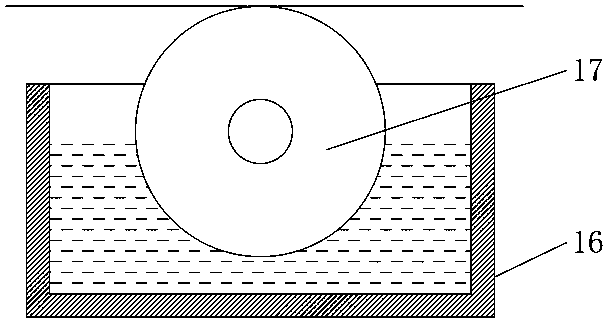

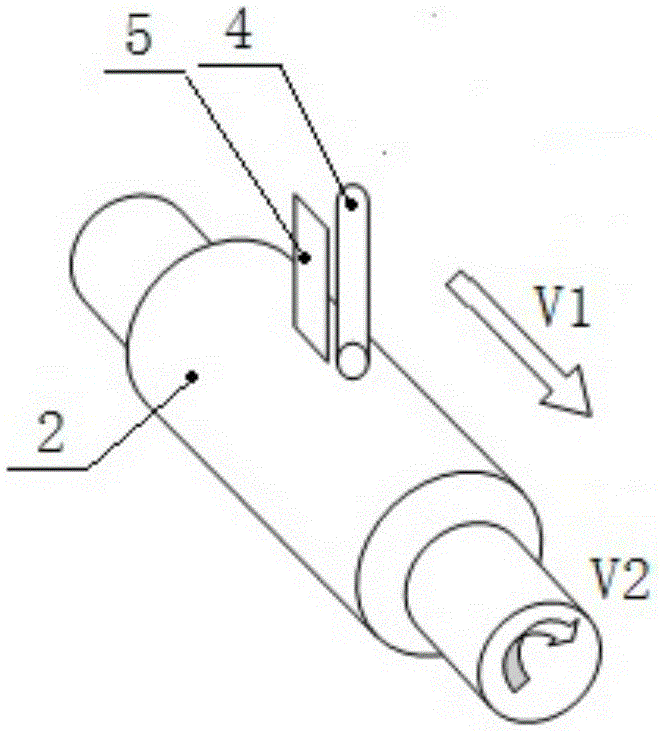

Straight pipe product member oiling device

ActiveCN105396743AReduce labor intensityImprove cleanlinessLiquid surface applicatorsCoatingsDrive wheelDrive shaft

Disclosed is a straight pipe product member oiling device. The straight pipe product member oiling device comprises a feeding table, a receiving table and an oiling machine. The oiling machine is provided with an oiling rack; the upper portion of the oiling rack is inclined; a driving shaft is disposed at the high-position end of the oiling rack and connected with a hand wheel; a driving chain wheel and a driving roller are disposed on the driving shaft; a driven shaft is disposed at the low-position end of the oiling rack; a driven chain wheel and a driven roller are disposed on the driven shaft; the driving chain wheel is in driving joint with the driven wheel through a chain; the oiling rack is provided with an oil pool; a supporting roller is disposed in the oil pool; an annular oiling felt band is arranged on the outer sides of the driving roller, the driven roller and the supporting roller in a sleeving mode; the part, located between the driving roller and the driven roller, of the oiling felt band is an inclined oiling working section which makes contact with a straight pipe product member; the width of the oiling felt band is matched with the length of the machined straight pipe product member. The straight pipe product member oiling device is novel in conception and does not need driving power during usage, and the oiling amount is easy to adjust. By means of the straight pipe product member oiling device, the product member can be uniformly oiled without drips, the labor intensity of manual work can be relieved, and the work efficiency is improved.

Owner:HEBEI LINGYUN ELECTROMECHANICAL

Automatic oil spraying device and method

ActiveCN103657941ARealize automatic separationPrevent rustLiquid surface applicatorsLiquid spraying apparatusControl systemElectromagnetic valve

The invention discloses an automatic oil spraying device which comprises a closed oil spraying room, a fog spraying system, an oil recycling system and a control system. The fog spraying system comprises a main air source, a pressurizing mechanism, an oil drum, an electromagnetic valve and fog spraying valves, wherein the main air source is connected with the pressurizing mechanism, and the oil drum, the pressurizing mechanism and the fog spraying valves are sequentially connected through oil pipes. The electromagnetic valve comprises an air inlet, a first air outlet and a second air outlet, wherein the air inlet is connected with the main air source through a pipe, the first air outlet is connected with the fog spraying valves through a driving air source pipe, and the second air outlet is connected with the fog spraying valves through an atomization air source pipe. The driving air source pipe and the atomization air source pipe are provided with a first pressure adjustment mechanism and a second pressure adjustment mechanism respectively. The electromagnetic valve and the oil recycling system are respectively connected with the control system, and the oil recycling system is connected with the closed oil spraying room. The invention further discloses an automatic oil spraying method achieved through the automatic oil spraying device. By means of the automatic oil spraying device and the automatic oil spraying method, rapid and safe rust prevention processing on a large number of plates can be achieved, operation risks to persons are reduced, and waste oil can be recycled.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

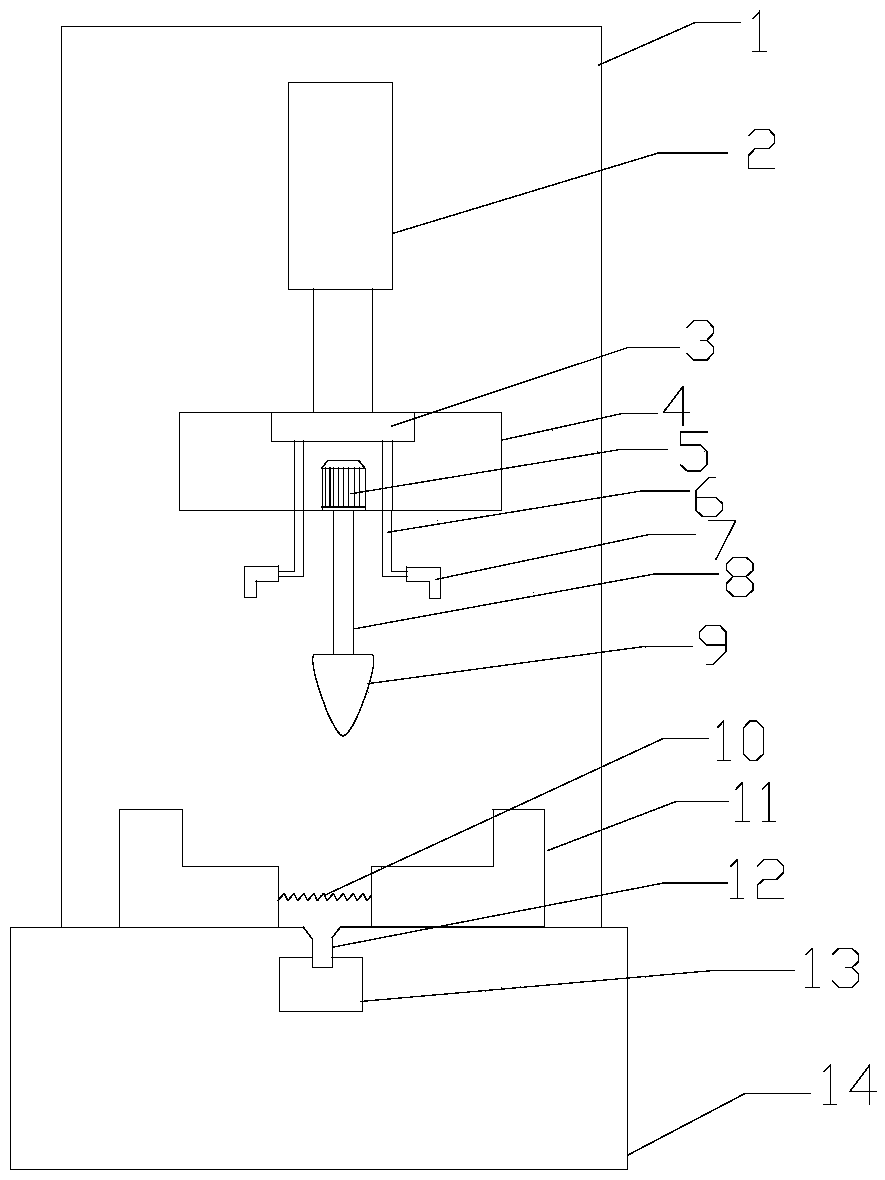

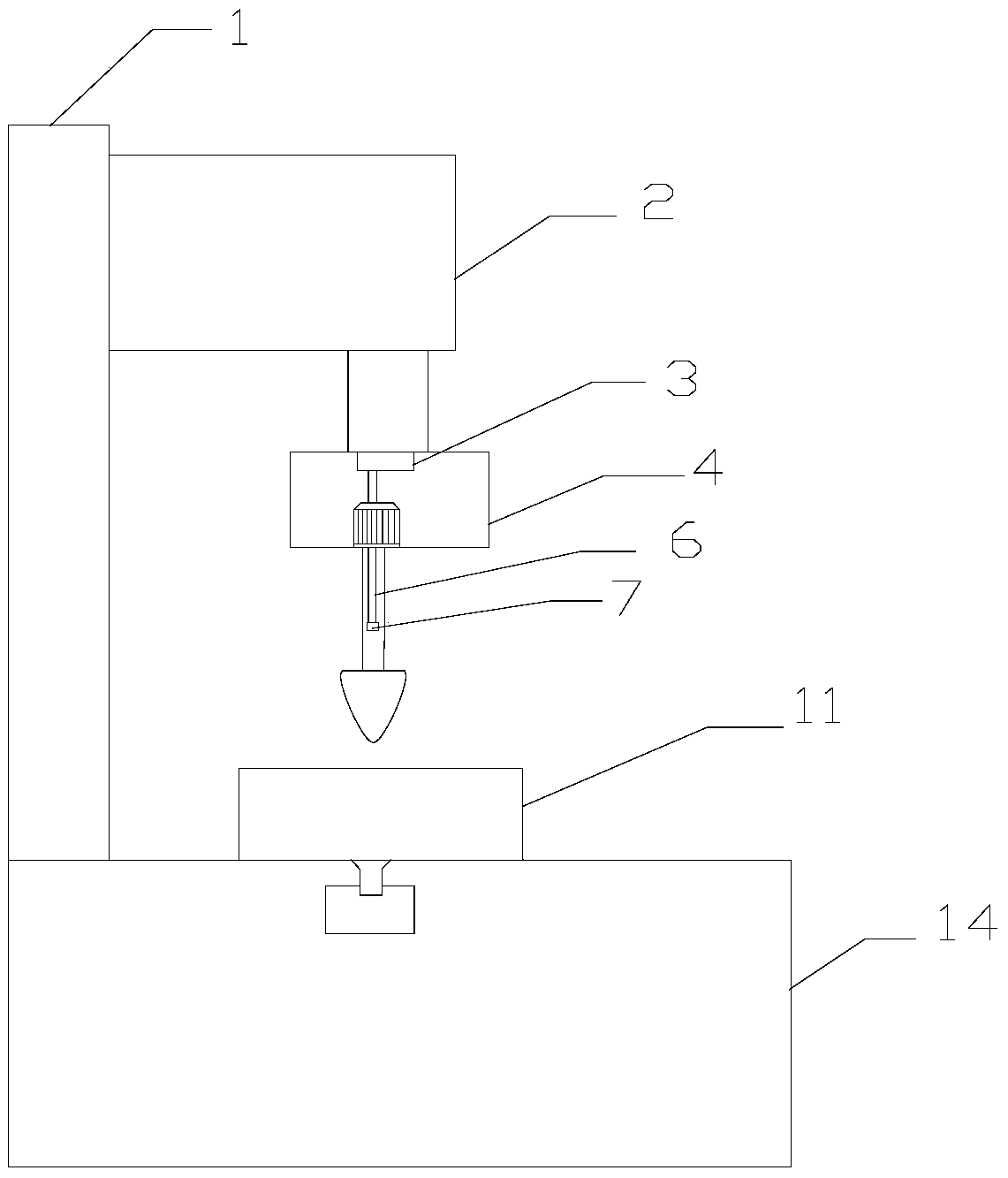

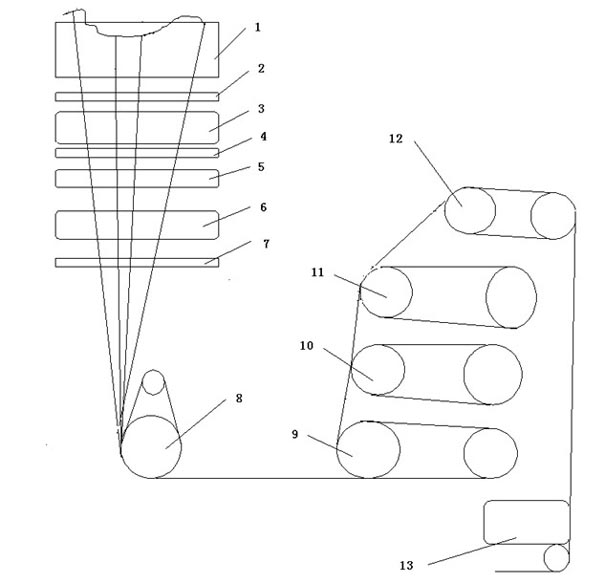

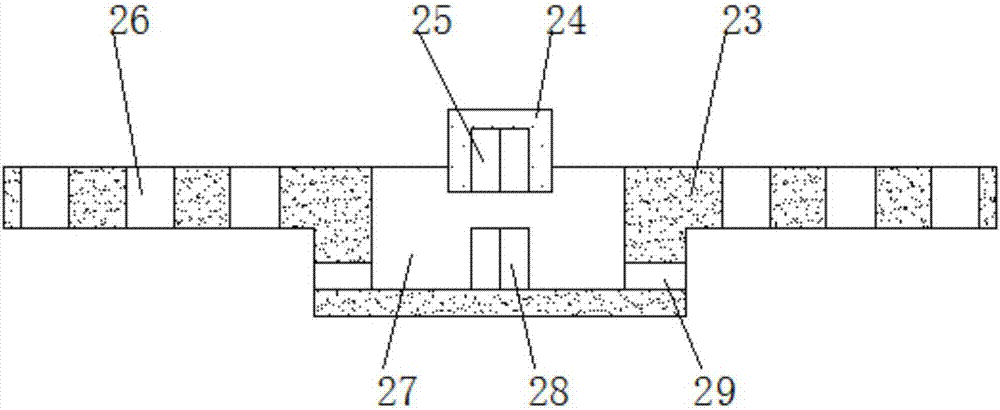

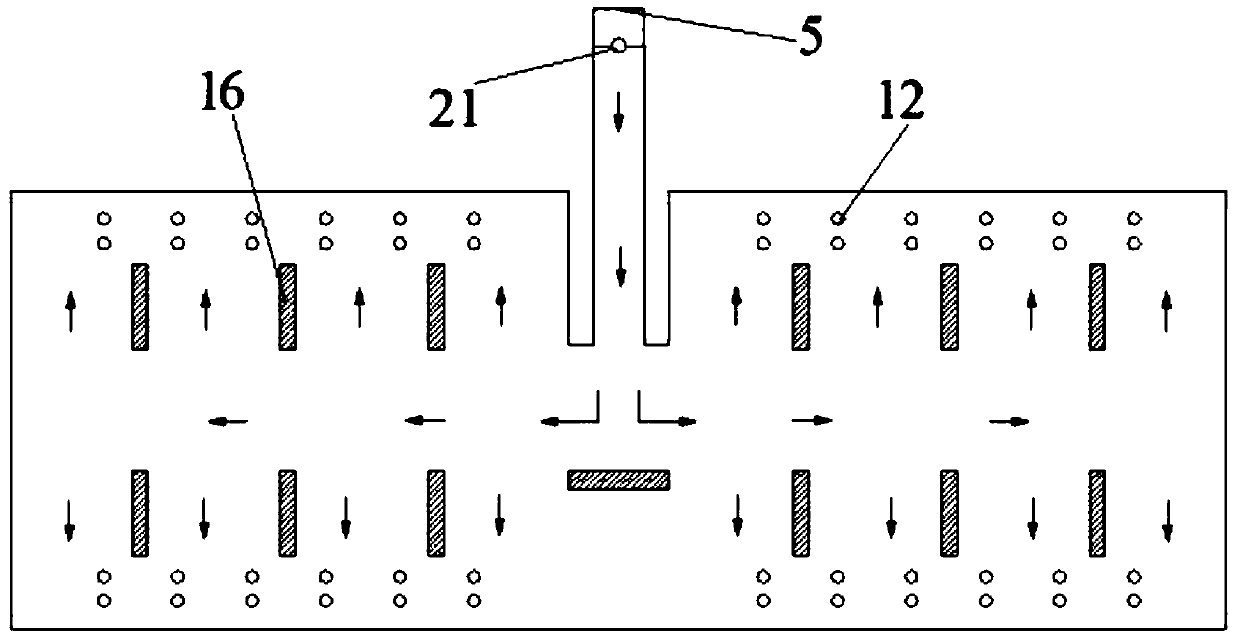

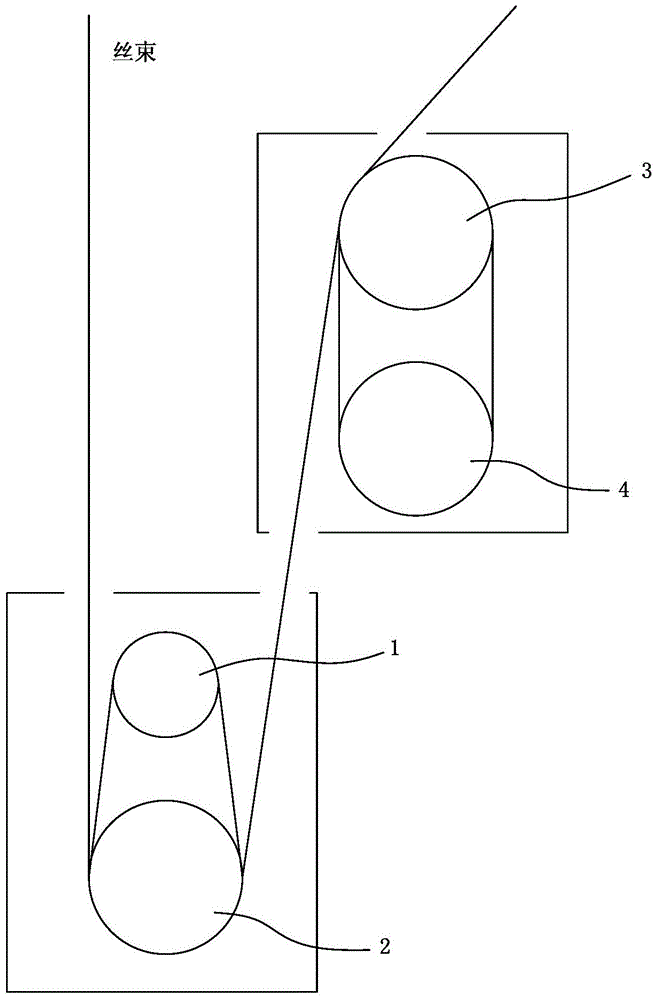

A kind of preparation method and equipment of high-strength polyester mother silk

ActiveCN102277634AOil evenlyOvercoming the phenomenon that the roll cannot be wound normallyArtificial thread manufacturing machinesStretch-spinning methodsPolyesterPolymer science

The invention discloses a method for preparing high-strength terylene mother filaments and equipment thereof. In the invention, a filament bundle sprayed out from a spinning tank component is cooled by laterally blown air, passes through a passage, and is coated with oil for the first time and treated by a tensioning rod (4), then the tension of the filament bundle is regulated by a tension regulator (5) to a first tension which is kept between 40 and 80cN, and the strength of the single-filament product reaches 7.0 to 8.0cN / dtex. In the invention, by using the tension controller, the problemof normal roll winding failure caused by small first tension due to a multi-stage drawing process is solved, the tension of each single filament among the mother filament is controlled, the phenomenon that adverse winding and breaking in later pass due to local filament bundle length inconsistency caused by violent filament bundle vibration is eliminated, and the requirements of the production process and products of high-strength terylene mother filaments are met.

Owner:SUZHOU LONGJIE SPECIAL FIBER

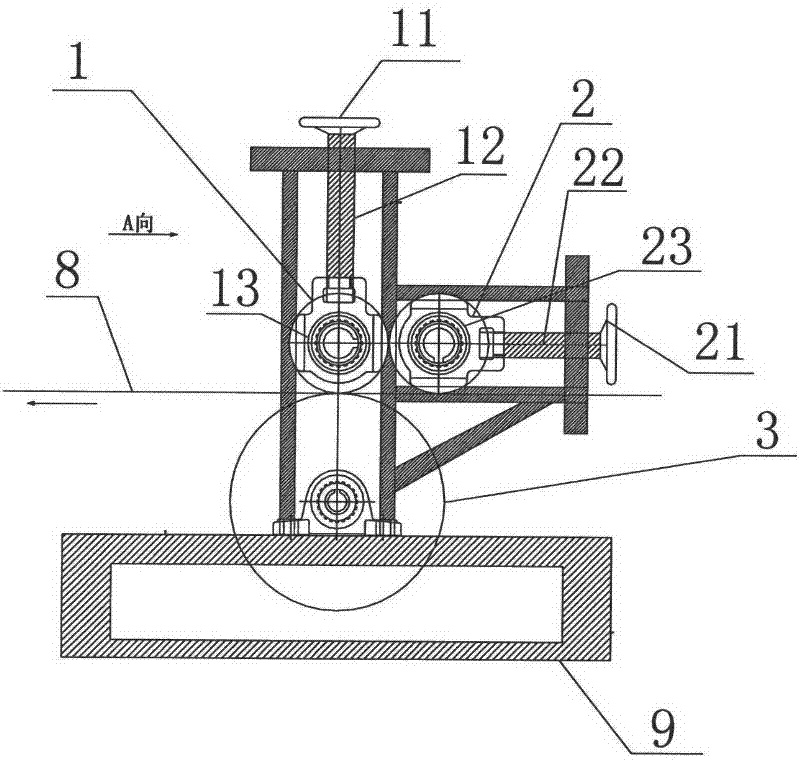

Uniformly-scattered oil-saving type coupler oiling device

The invention discloses a uniformly-scattered oil-saving type coupler oiling device which comprises a workbench; an oil tank is placed below the workbench, the bottom of the inner wall of the oil tank is provided with a filtering mesh hood, four corners of the bottom face of the workbench are all provided with supporting legs in a welded manner, and the four corners of the upper surface of the workbench are provided with supporting pillars in a welded manner. According to the uniformly-scattered oil-saving type coupler oiling device, a drive motor drives a rotary table to rotate and thus drives a coupler to rotate, therefore lubricating oil sprayed on the surface of the coupler by a spray pipe is scattered uniformly under the effects of centrifugal force and gravity, and oiling performed on the coupler is uniform; and meanwhile, oiling efficiency is high, the rotary table is provided with first through holes and second through holes, the lubricating oil of the coupler on the rotary table is discharged into an oil collection slot conveniently, the dropped lubricating oil is collected through the oil collection slot, the lubricating oil is guided into the oil tank through an oil guiding pipe for reuse, utilization of the lubricating oil is thorough, and the oil-saving effect is good.

Owner:徐州海马机械制造有限公司

Method for preparing ultra-fine denier skin-affinity polyester filaments

The invention discloses a method for preparing ultra-fine denier skin-affinity polyester filaments. The method comprises the steps of POY precursors, pre-interlace, first feeding roller, first deformation heat box, cooling plate, false twister, second feeding roller, intermediate interlace, second heat box, third feeding roller, oiling roller, DTY winding shaping and spinning cake inspection, wherein the intermediate interlace procedure can be removed, the temperature of the first deformation heat box is 165 DEG C-175 DEG C, the temperature of the second heat box is 130 DEG C-140 DEG C, the draft ratio is 1.58-1.68, the false twist ratio is 1.66-1.80, and the interlace air pressure is 0.03-0.15 MPA. The method has the advantages of being simple and easy to operate, fabric prepared by polyester filaments prepared by means of the method has the advantages of being more flexible, good in comfort performance and strong in visual and tactile feeling.

Owner:JIANGSU DELI CHEM FIBER CO LTD

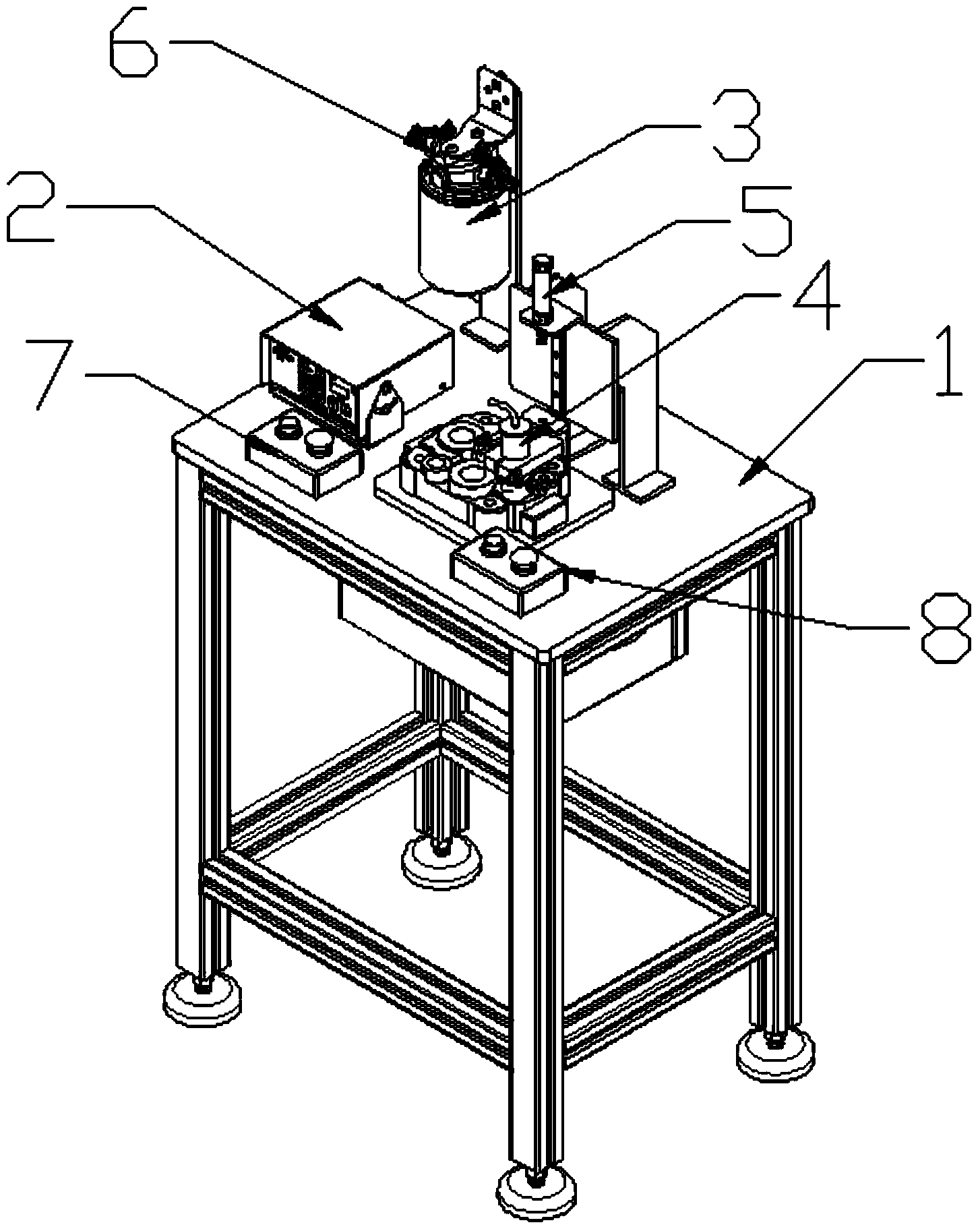

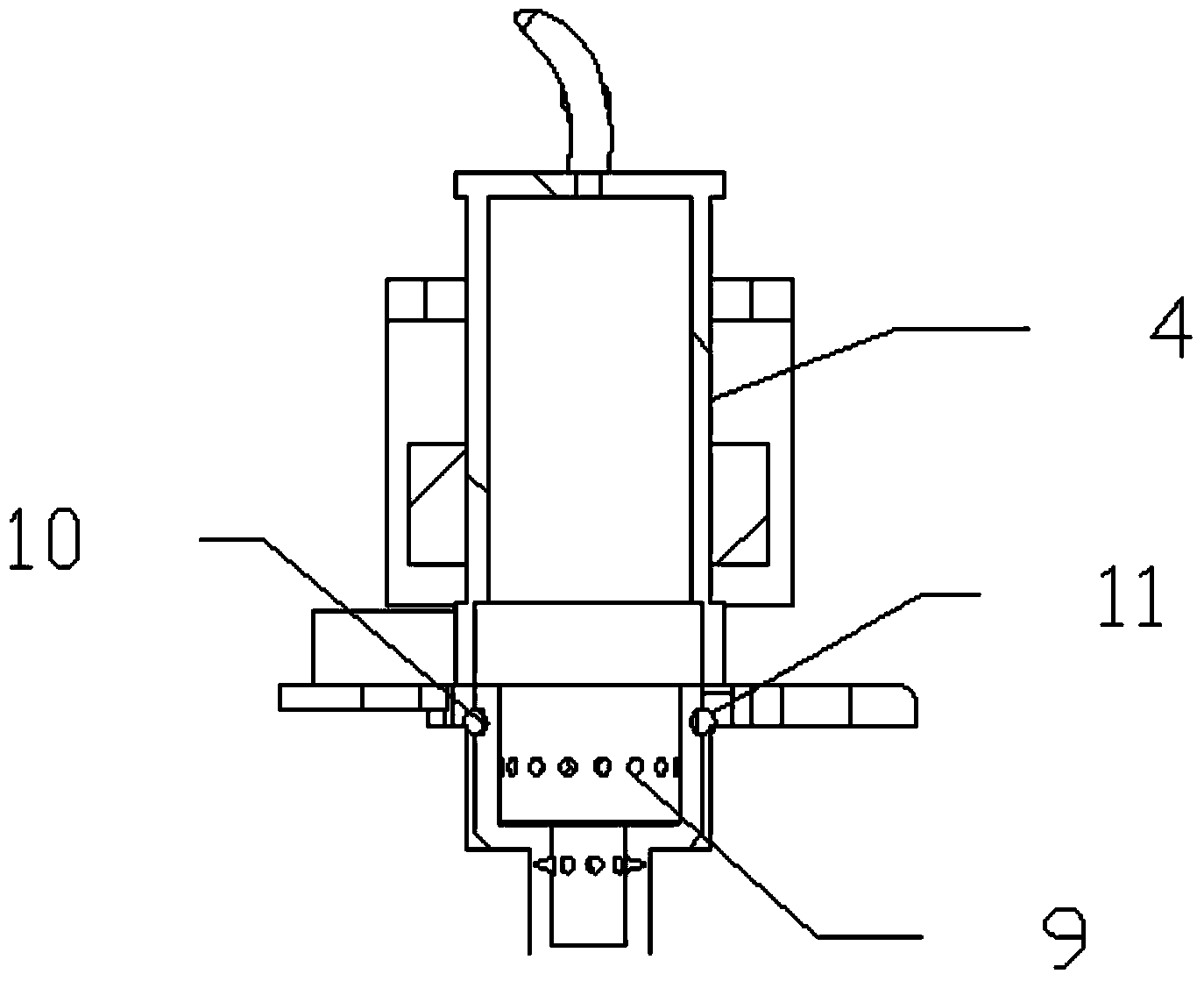

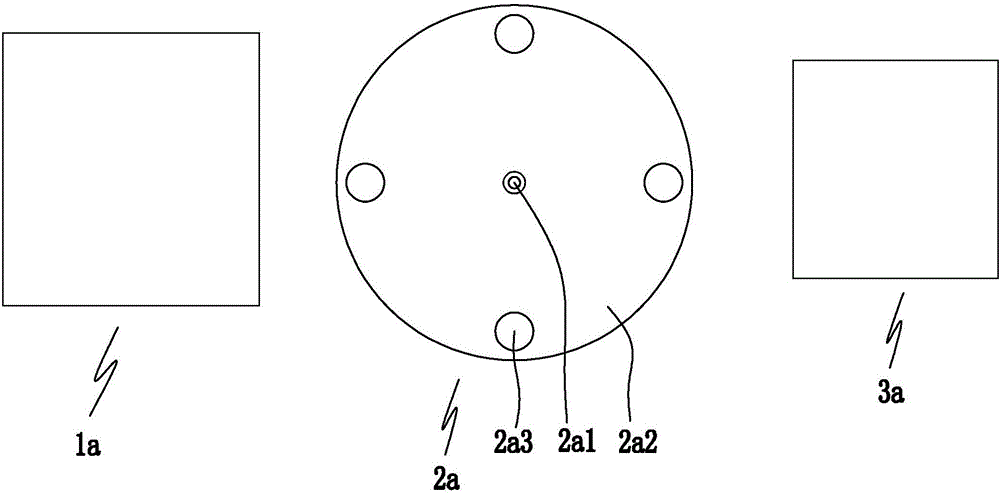

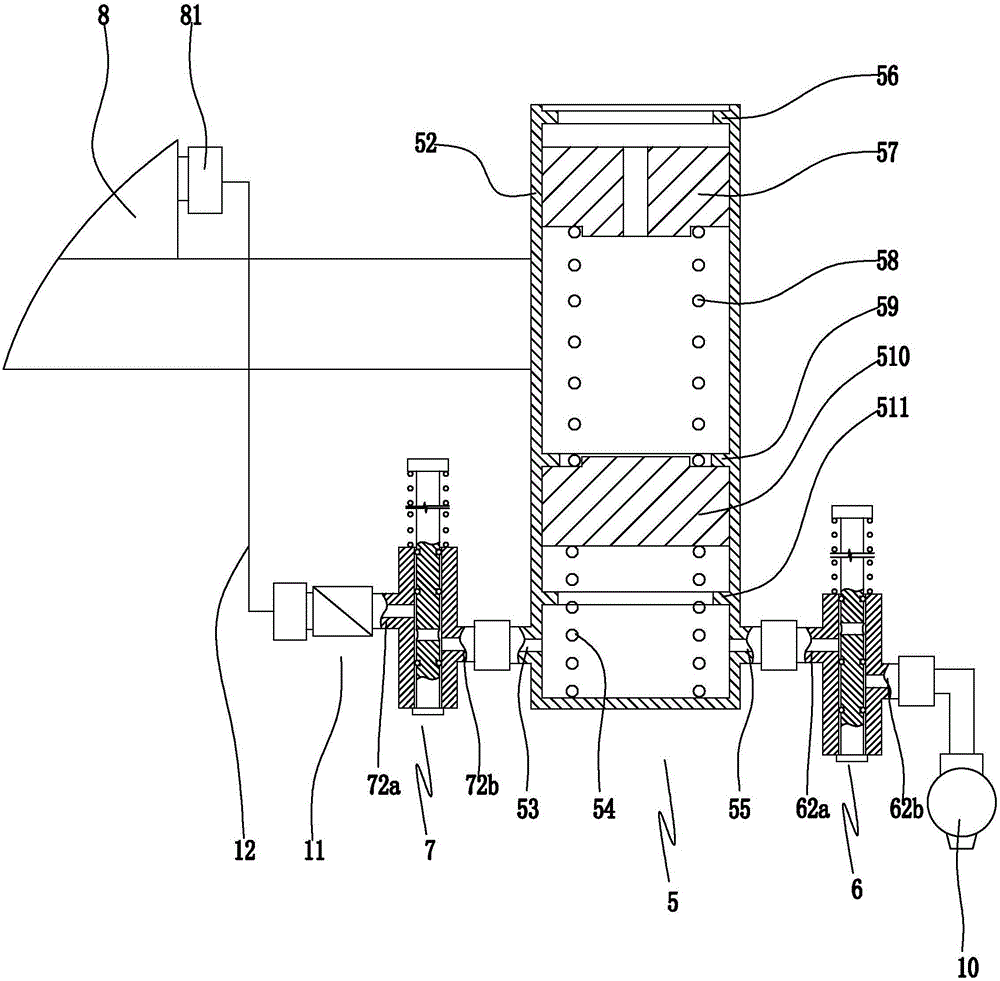

Automatic greasing and riveting device for rotating wheel of vehicle window regulator

The invention provides an automatic greasing and riveting device for a rotating wheel of a vehicle window regulator. According to the device, the rotating wheel is selected through a vibration sieve at the right side; a mechanical arm at the right side is used for feeding the rotating wheel to a designated position; the rotating wheel is driven by a rotating disc to do circling motion and is then greased by a greasing device; a mechanical arm at the left side clamps a rivet to the designated position; and finally, riveting of the rotating wheel and the rivet is performed through a press-connection machine, at the time, work of greasing and riveting the rotating wheel is automatically finished. The problems that greasing for the rotating wheel of the vehicle window regulator is nonuniform, and the efficiency of riveting of the rotating wheel and the rivet is low are solved.

Owner:柳州莫森泰克汽车科技有限公司

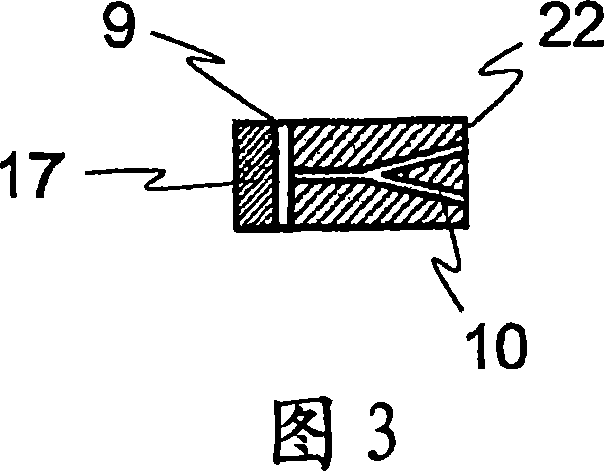

Device and method for applying a preparation to threads

InactiveCN1969069AWill not polluteUniform atomizationTextile treatment containersFilament/thread formingEngineeringBiomedical engineering

Owner:天科部件有限公司

Oil cooling structure of permanent magnet synchronous motor

InactiveCN111181300ASave spaceCooling effectCooling/ventillation arrangementSupports/enclosures/casingsElectric machinePermanent magnet synchronous motor

The invention discloses an oil cooling structure of a permanent magnet synchronous motor, which is characterized in that a rotating shaft provided with a motor rotor is matched in a motor shell through a motor bearing, and the end part of the motor shell is provided with a motor end cover; the motor shell is provided with a shell oil duct; the motor end cover is provided with an end cover oil duct; the rotating shaft is provided with a rotating shaft oil duct; the motor rotor is provided with a rotor oil guide channel; a shell oil duct with an oil inlet function is arranged in the upper shell;a shell oil passage with an oil outlet function is arranged in the lower shell; a shell oil inlet of a shell oil duct with an oil inlet function is formed in the end surface of the upper shell; the lower shell is provided with a motor oil outlet of a shell oil duct with an oil outlet function; the inner wall of the lower shell is provided with a cooling oil recovery port communicating with a shell oil passage with an oil outlet function; the end cover oil duct communicates with the shell oil inlet and the rotating shaft oil duct; the rotating shaft is provided with a rotor oil inlet hole communicating with the rotating shaft oil channel and the rotor oil guide channel. The rotating shaft oil duct leads to the end outlet of the motor rotor; the motor rotor is also provided with a bearing oil injection hole which communicates with the rotating shaft oil channel and faces the motor bearing.

Owner:HEFEI JUYI POWER SYST CO LTD

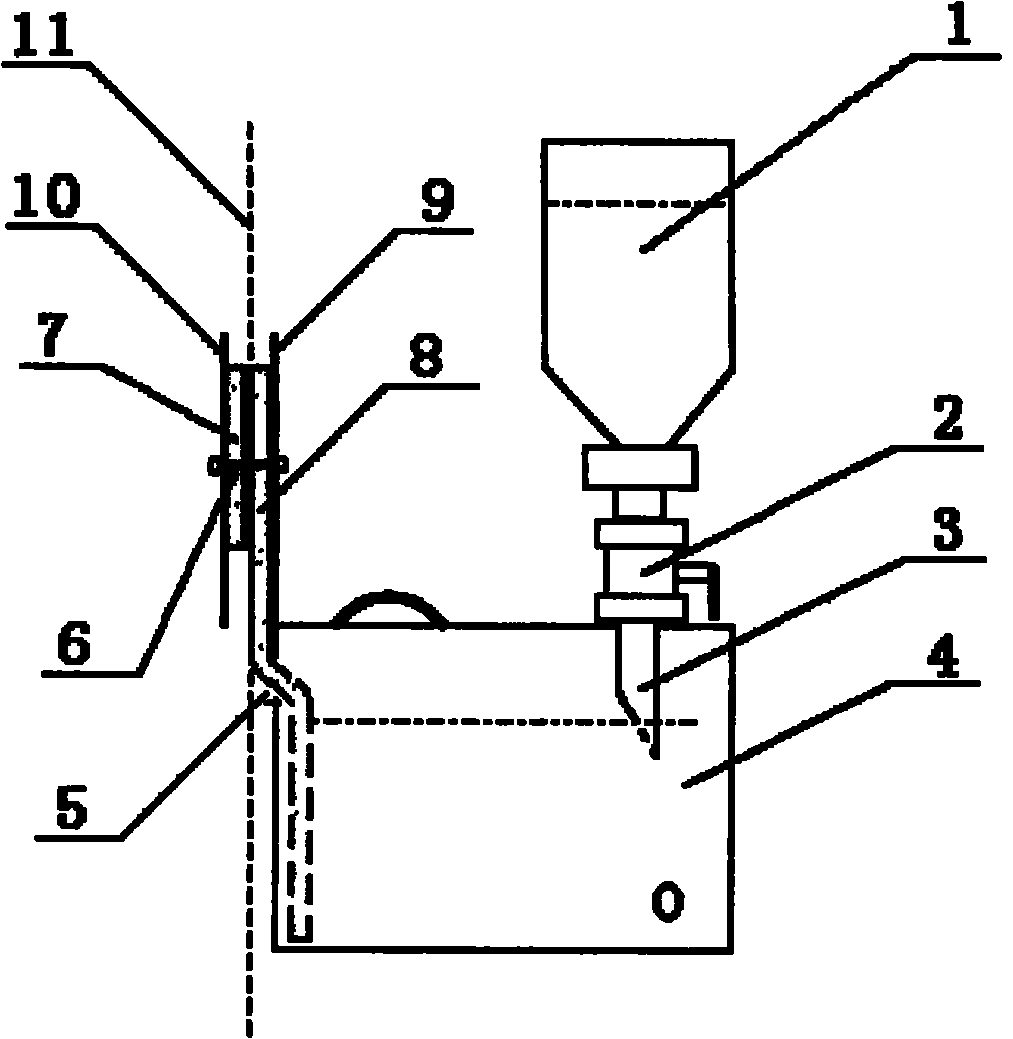

Uniform and high-accuracy oil coating device for inner walls of holes

The invention discloses a uniform and high-accuracy oil coating device for the inner walls of holes. The uniform and high-accuracy oil coating device comprises an equipment bracket, wherein the equipment bracket is provided with an automatic oil supplying machine which is connected with an oil storage barrel; the oil storage barrel is connected with an oil coating nozzle by a hose; the oil coating nozzle is connected to an oil coating nozzle driving cylinder; the oil storage barrel is also provided with an oil returning device; the equipment bracket is provided with a switch I for controlling the automatic oil supplying machine and a switch II for controlling the oil coating nozzle driving cylinder. The uniform and high-accuracy oil coating device disclosed by the invention has the beneficial effects of simple structure, uniform oil coating and high efficiency.

Owner:DALIAN YUN MING AUTOMATION TECH

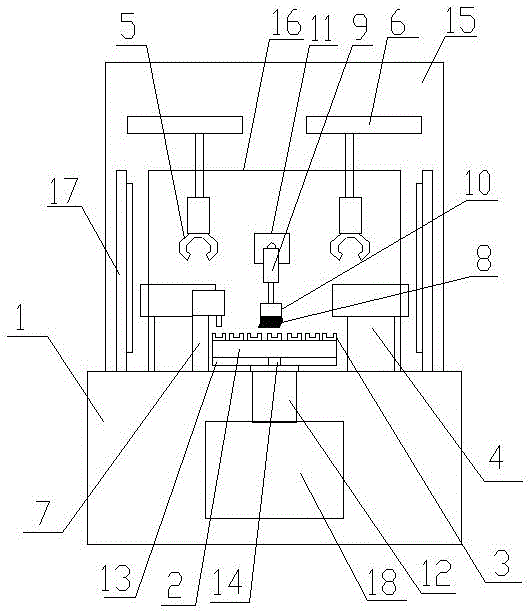

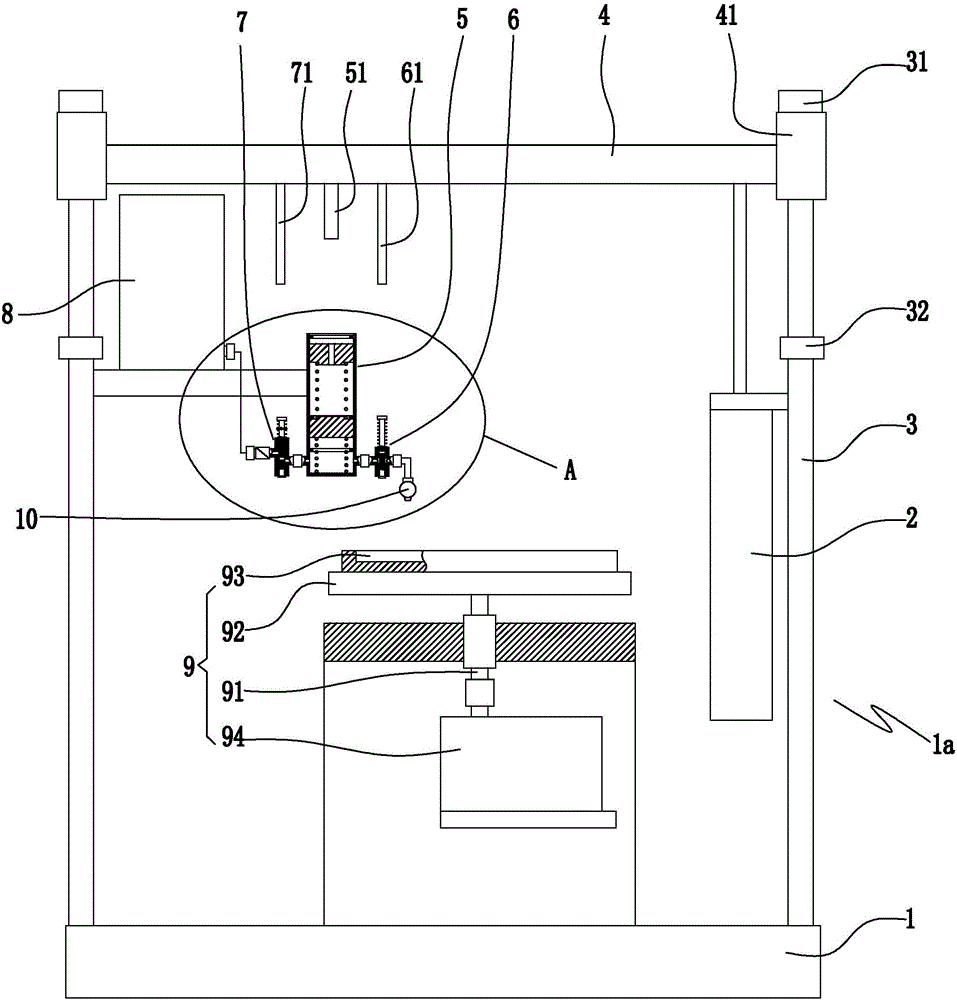

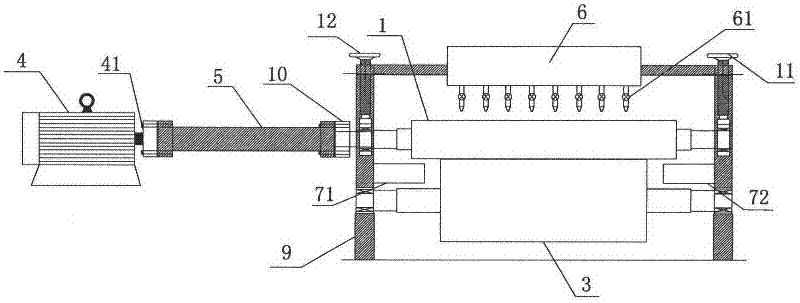

Assembling equipment for motor end cover assembly

ActiveCN106392579AImprove assembly qualityEasy to useLiquid spraying apparatusMetal working apparatusFuel tankEngineering

The invention discloses assembling equipment for a motor end cover assembly, and aims to provide the motor end cover assembly assembling equipment which can automatically and quantitatively coat oil for a motor end cover, guarantees uniform oil coating, and keeps usage amount of oil stable. The assembling equipment comprises a motor end cover automatic oil coating device, a red steel plate assembling table and a motor end cover unloading mechanism. The red steel plate assembling table comprises a supporting frame and a rotary platform which can be rotatably arranged on the supporting frame through a vertical shaft rod. The motor end cover automatic oil coating device comprises an oil tank, a bottom frame, vertical guide posts which are arranged on the bottom frame, an upper frame capable of lifting along the vertical guide posts, a lifting device used for lifting the upper frame, a self-adaptive quantitative oil coating device and an end cover rotating device. The motor end cover unloading mechanism comprises a rack, a horizontal guide rail arranged on the rack, a translation slide table sliding along the horizontal guide rail, a vertical guide rail arranged on the translation slide table, a vertical slide table sliding along the vertical guide rail, and an end cover gripping mechanism arranged on the vertical slide table.

Owner:桐乡市金琪塑料包装有限公司

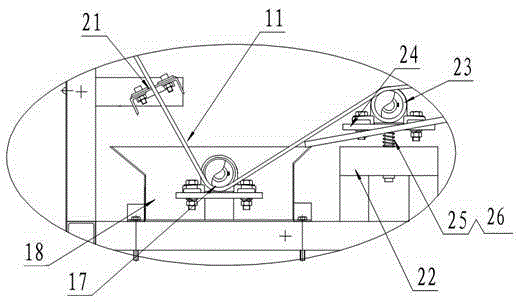

Rotary type oil coater for end cover of motor

ActiveCN106269341AOil evenlyEasy to useManufacturing dynamo-electric machinesLiquid spraying apparatusSelf adaptiveCylinder block

The invention discloses a rotary type oil coater for an end cover of a motor, and aims to provide the rotary type oil coater for the end cover of the motor, and the rotary type oil coater can automatically and quantitatively carry out oil coating on the end cover of the motor, ensures uniform oil coating, and ensures stable usage amount of oil. The rotary type oil coater comprises an oil tank, a bottom frame, a vertical guide post arranged on the bottom frame, an upper frame capable of lifting along the vertical guide post, a lifting device used for lifting the upper frame, a self-adaptive quantitative oil coating device and an end cover rotating device. The end cover rotating device comprises an end cover placing flat plate which can be rotatably arranged on the bottom frame through a vertical rotary shaft; and the self-adaptive quantitative oil coating device comprises an oil spraying mechanism, a vertical cylinder body, a vertical pressure rod arranged on the upper frame, a floating piston arranged in the vertical cylinder body, an oil pressing piston positioned below the floating piston, a first return spring arranged between the floating piston and the oil pressing piston, a second return spring arranged between the oil pressing piston and the lower end of the vertical cylinder body, and a trigger oil spraying mechanism positioned above the upper frame.

Owner:桐乡市金琪塑料包装有限公司

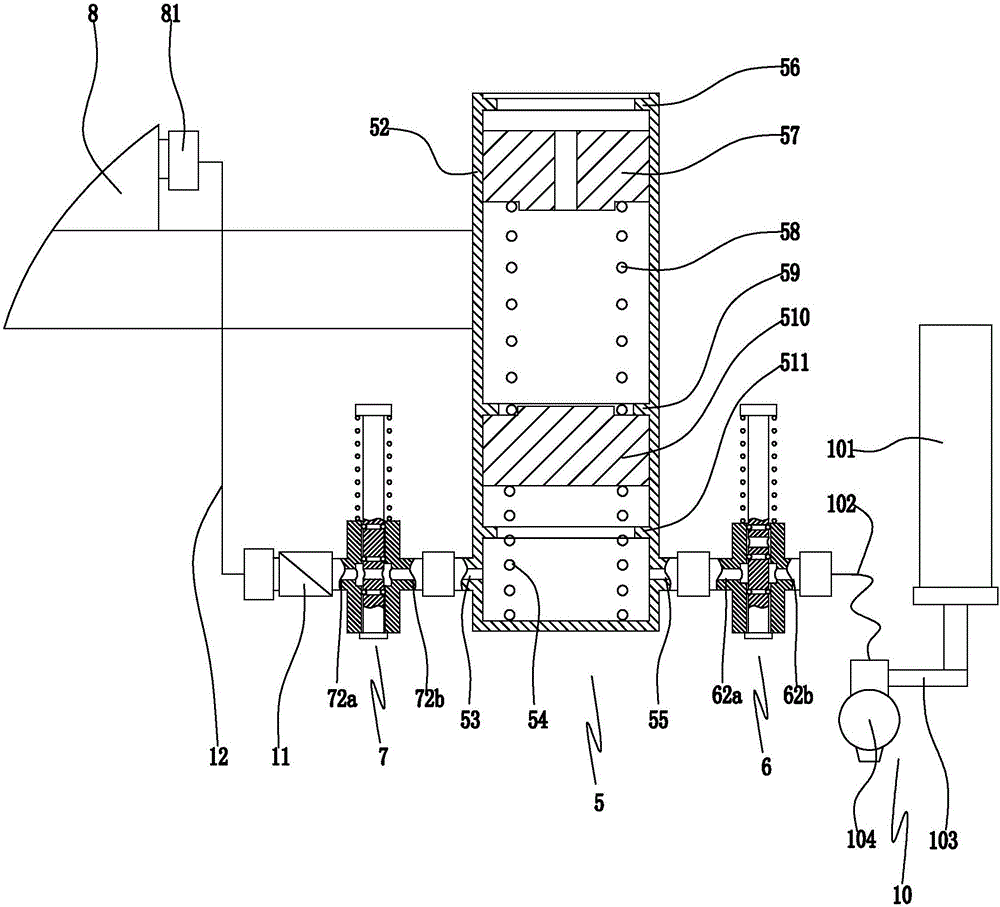

Device for coating oil on steel band in rolling manner

InactiveCN102500689ALow costSmall footprintShaping toolsLiquid surface applicatorsCouplingPulp and paper industry

The invention discloses a device for coating oil on a steel band in a rolling manner. The device comprises an oil coating roller, a compaction roller, a guide roller and a master transmission motor, wherein the master transmission motor is connected with a universal shaft through a coupler; the other side of the universal shaft is connected with the oil coating roller through a coupler; the compaction roller is arranged beside the oil coating roller; the guide roller is arranged on the lower side of the oil coating roller; the roller surface of the oil coating roller is respectively pressed against the roller surfaces of the guide roller and the compaction roller; an oil discharging box is arranged over the oil coating roller; a row of needle valves, of which the flows can be adjusted, are arranged at the bottom of the oil discharging box; distances of adjacent needle valves are equal; and antirust oil in the oil discharging box can flow between the oil coating roller and the compaction roller as long as the needle valves are opened. Preferably, the oil coating roller is a polyurethane oil coating roller; the compaction roller is a chromium-plated compaction roller; the guide roller is a rubber guide roller; and the steel band to be coated with oil is arranged between the polyurethane oil coating roller and the rubber guide roller. The device can be uniformly coated with oil, occupies a small space, and is convenient to use.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD

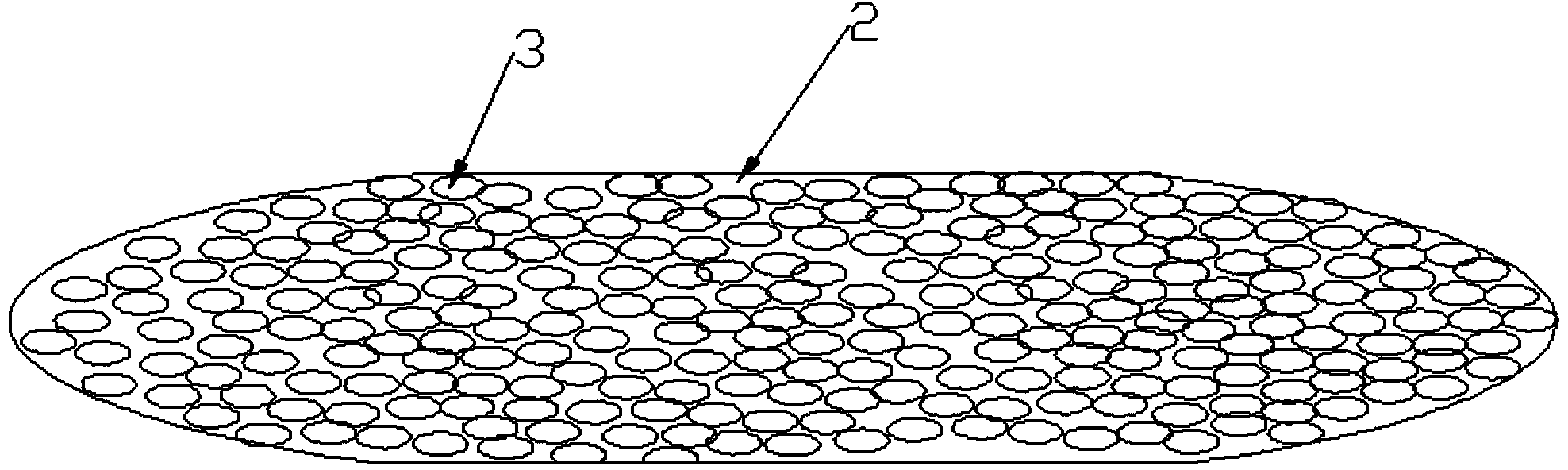

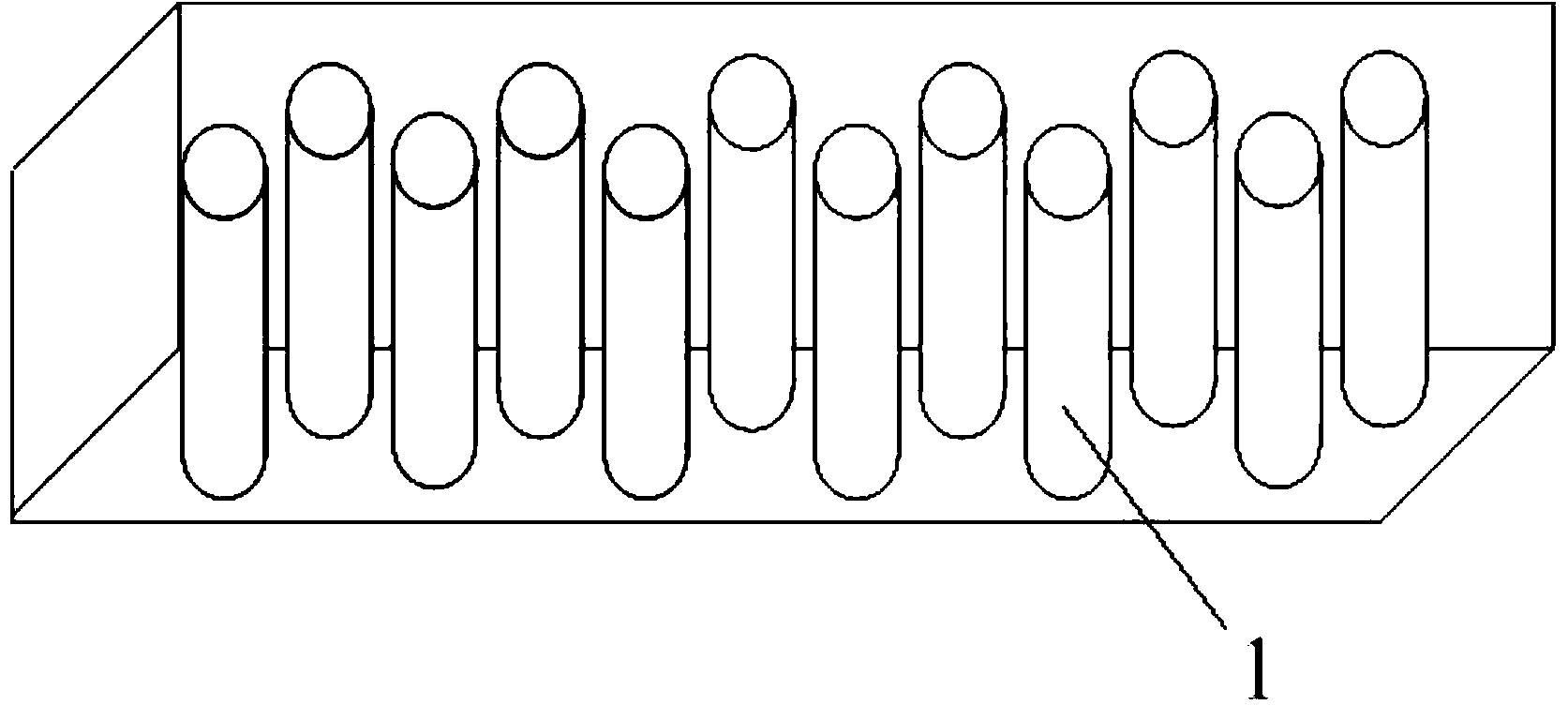

Dacron fine denier multi-hole flat fiber and method for producing same

ActiveCN103510171ABeautiful appearanceImprove inner qualityNew-spun product collectionFilament/thread formingYarnFiber

The invention relates to the technical field of chemical fiber products, in particular to a dacron fine denier multi-hole flat fiber and a method for producing the dacron fine denier multi-hole flat fiber. The dacron fine denier multi-hole flat fiber comprises a fiber body. The fiber body is provided with 192 strips of monofilament, the cross section of each strip of monofilament is in the shape of a waist, the linear density of the fiber body is 207-253dtex, and the monofilament is evenly and irregularly distributed. The produced dacron fine denier multi-hole flat fiber is beautiful in appearance, good in inherent quality, small in inner-layer and outer-layer fluctuation, stable in tension, soft, long and straight in style, fine and smooth in hand feeling, even in dye absorption, bright-colored in dye, large in package density, high in capacity, consistent in whole package width, uniform in hardness, free of overlapped yarn and even in inner-layer and outer-layer quality, and is a high and new-tech product with high quality and high additional value.

Owner:ZHEJIANG HENGYOU CHEM FIBER CO LTD

Oiling roller for wool top

The invention discloses an oiling roller for a wool top. The oiling roller comprises a hollow roller body, wherein a plurality of oil outlets are formed in a cylindrical main body part of the hollow roller body; a cover barrel with holes is arranged on the surface of the cylindrical main body part of the hollow roller body; the holes in the cover barrel correspond to the oil outlets; pipelines communicated with an inner cavity of the hollow roller body are arranged at the two ends of the hollow roller body; an oil inlet pipe is arranged in the pipeline at each end. According to the oiling roller, the surface of the wool top can be directly oiled, so that wool oil waste can be avoided; the oil can be uniformly discharged; the oiling roller is simple in structure, convenient to operate and easy to maintain.

Owner:KUNSHAN CITY SHEN LI MAO FANG CO LTD

Oil coating lubricating equipment for driverless automobile parts

ActiveCN106481957AEasy maintenanceShorten maintenance timeVehicle componentsEngine lubricationMachine maintenanceCheck valve

The invention relates to oil coating lubricating equipment for automobile parts, in particular to oil coating lubricating equipment for driverless automobile parts. A technical problem to be solved by the invention is to provide the oil coating lubricating equipment for the driverless automobile parts, which is even in oil coating, high in oil coating speed and convenient to operate. In order to solve the technical problem, the oil coating lubricating equipment for the driverless automobile parts, provided by the invention, comprises a bottom plate, a left frame, a collision block, a linkage rod, a first spring, a swinging rod, a pushing rod, a first baffle, a second spring, a connecting rod, a piston, a cylinder body and a first check valve, wherein the left frame is welded at the leftmost side of the top of the bottom plate, the linkage rod is welded at the upper part of the right side of the left frame, and the right end of the linkage rod is connected with the swinging rod through a hinge component. The oil coating lubricating equipment realizes the effects of even oil coating, high oil coating speed and convenient operation. The device can reduce machine maintenance time, can save a large quantity of labor, and is great in oil coating effect.

Owner:海汇汽车制造有限公司 +1

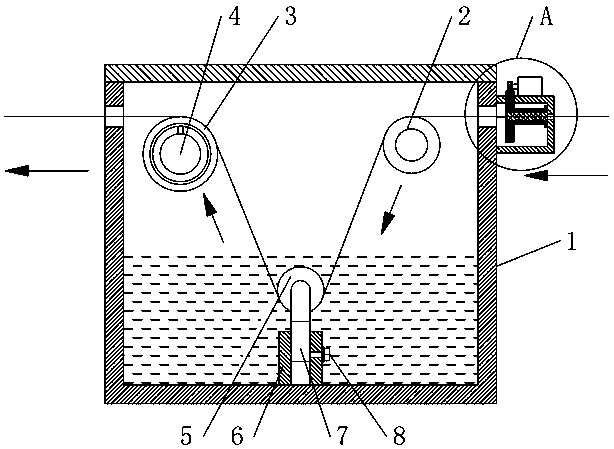

Oiling device of spinning elasticizer

ActiveCN109825969AEvenly distributed oilOil evenlyMechanical cleaningPressure cleaningFuel tankTextile

The invention discloses an oiling device of a spinning elasticizer, and belongs to the technical field of textile machinery. The oiling device comprises an oil tank. Thread passing holes are formed inthe top ends of the two sides of the oil tank respectively. A thread inlet roller, a steering roller and a vibrating roller distributed in a triangular shape are rotationally connected with the innerwall of the oil tank. The thread inlet roller and the vibrating roller correspond to the two thread passing holes respectively. A fixed rod is fixedly connected into the oil tank. The vibrating roller comprises a connecting cylinder, a rotating cylinder and a vibrator. An installation groove is formed in the side wall of the fixed rod. The vibrator is fixedly connected into the installation groove. The connecting cylinder sleeves the fixed rod. A gap is formed between the inner wall of the connecting cylinder and the outer wall of the fixed rod. The inner wall of the connecting cylinder is fixedly connected with the vibration end of the vibrator. The rotating cylinder rotationally sleeves the connecting cylinder. Silk threads can be oiled evenly, and it is avoided that residual oil dropsinto a workshop and contaminates the working environment.

Owner:苏州申久高新纤维有限公司

Production process of nylon-6 coarse-denier high-strength yarns

InactiveCN104695033AReduced drawabilityPromote crystallizationArtificial thread manufacturing machinesFilament manufactureBreaking strengthYarn

A production process of nylon-6 coarse-denier high-strength yarns includes slicing, melting, metering, spinning, cooling, oiling, pre-interlacing, drafting and setting, main interlacing, and winding. In the slicing step, nylon-6 slices 2.8 to 3.2 in viscosity are selected. Melting is performed at the temperature of 270 DEG C to 280 DEG C. In the spinning step, pore diameter of a spinneret plate is 0.36mm, pore length is 1.08 mm, and initial pressure of a component is 135 bars to 142 bars. In the oiling step, oil resistant to high temperature, anti-static and high in cohesion is adopted. The nylon-6 slices of specific viscosity are used, the temperature of the melting step is adjusted, and a melt pipe, a spinning component, an oiling device, pre-interlacing and drafting and setting are modified, and the nylon-6 coarse-denier high-strength yarns up to 6.2Cn / dtex in breaking strength are produced.

Owner:QUANZHOU TIANYU CHEM FIBER WEAVING IND

Oil return control method for fully constant frequency multi-connected air conditioning unit

InactiveCN104236169AOil evenlyPrevent technical problems of oil return failureCompressorMechanical apparatusVapor–liquid separatorConstant frequency

The invention discloses an oil return control method for a fully constant frequency multi-connected air conditioning unit. The method includes the steps that a, an outlet of an oil separator (1) is communicated with inlets of two constant frequency compressors (3) through a first oil return capillary pipe (2), the outlet of the oil separator (1) is communicated with an inlet of a gas-liquid separator (5) through an oil return pipe (4), an oil return opening (6) is formed in the bottom of the gas-liquid separator (5), the oil return opening (6) of the gas-liquid separator (5) is communicated with an inlet of a second oil return capillary pipe (8) with an electromagnetic valve (7), and an outlet of the second oil return capillary pipe (8) is communicated with the inlets of the two constant frequency compressors (3); b, when one constant frequency compressor (3) is started up to operate, the electromagnetic valve (7) on the second oil return capillary pipe (8) is closed, and when the two constant frequency compressors (3) are started up to operate at the same time, the electromagnetic valve (7) on the second oil return capillary pipe (8) is opened. By the adoption of the method, the oil mass of the compressors is balanced, and the excessively high exhaust gas temperature of the compressors can be prevented.

Owner:NINGBO AUX ELECTRIC

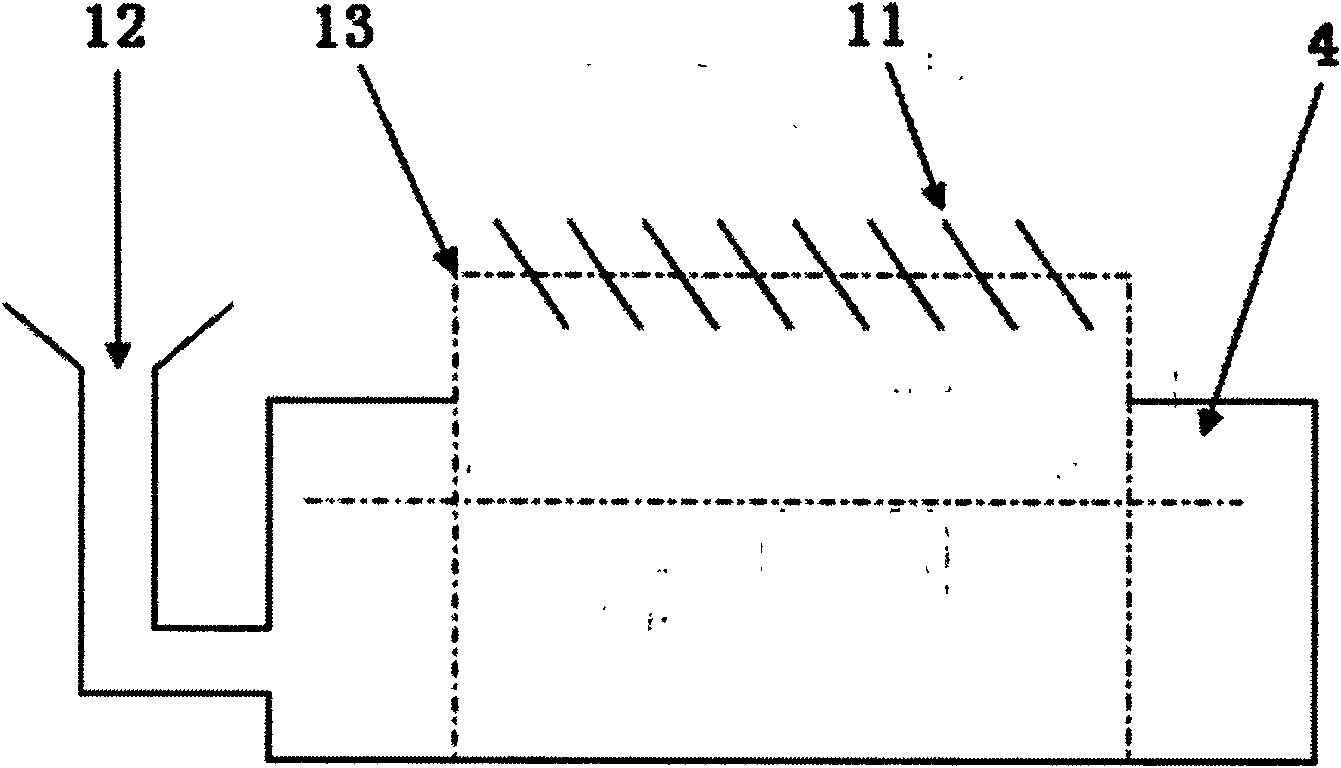

Roll grinding on-line electrostatic oiling device and method

InactiveCN105107652AReduce oiling labor intensityImprove cleaning qualityLiquid spraying plantsElectronic control systemFuel tank

The invention discloses a roll grinding on-line electrostatic oiling device. The roll grinding on-line electrostatic oiling device comprises a grinding machine body, a roll and a grinding wheel head bracket, and the grinding wheel head bracket is provided with a blow-sweep device a high-voltage electrostatic generator, an oiling box, an oil supply and heating device and an electronic control system integrated oiling device. The invention further discloses an oiling method by means of the roll grinding on-line electrostatic oiling device. The method comprises the steps that an electrostatic oiling technology is applied to the roll rust-proofing treatment process, stepping of the oiling device is conducted, the oiling device cooperates with the roll for turning, the quantity for spray is quantified to control the oil consumption, and even oiling is guaranteed; due to the fact that a blow-sweep system is arranged before oiling is conducted, the workpiece cleaning quality is improved, rust-proofing oil is directly absorbed on the surface of the roll, and the cleaning quality of the roll surface is guaranteed. The roll grinding on-line electrostatic oiling device is not limited by the diameter and the length of the roll, the adaptability is strong, traditional roll oiling operation is simplified, and the roll grinding on-line electrostatic oiling device has the advantages of being easy and convenient to operate, high in work efficiency, even in oiling, free of impurities and residues, low in roll oiling labor intensity and the like.

Owner:SHANDONG IRON & STEEL CO LTD

Sealed lubricator of enameling machine

The invention relates to a sealed lubricator of an enameling machine and belongs to the technical field of the structures of lubricators. The sealed lubricator of the enameling machine is characterized in that: a control valve is installed on a cup mouth of an oil cup; an oil output pipe is connected to the other end of the control valve, and is inserted in an oil inlet on an oil box which is refueled through the oil cup at the top part; a felt fixing clamping plate is arranged at the upper end of one side of the oil box; a felt hole is arranged at the side face of the oil box at the lower end of the felt fixing clamping plate; parts of a first felt and a second felt are installed between the felt fixing clamping plate and a pressing plate in an adhering manner; a part of the second felt enters the oil box through the felt hole; lubricating oil permeates to the upper part of the second felt through the part of second felt stretched into the oil box; and an enameled wire penetrates through the two felts, so that the coating of the lubricating oil on the surface of the enameled wire is realized. The sealed lubricator has the advantages of reasonable design, fixed height of the liquid level in the oil box, uniform oil absorption of felts, no volatilization and waste of the lubrication oil and no pollution to the production environment. As the enameled wire penetrates through the two felts, the coating is more uniform.

Owner:山东蓬泰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com