Device for coating oil on steel band in rolling manner

A technology of oiling device and steel strip, which is applied to the surface coating liquid device, coating, metal processing equipment, etc., which can solve the problems of large installation volume, unaffordable for small enterprises, high price, etc., and achieve uniform oiling , low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

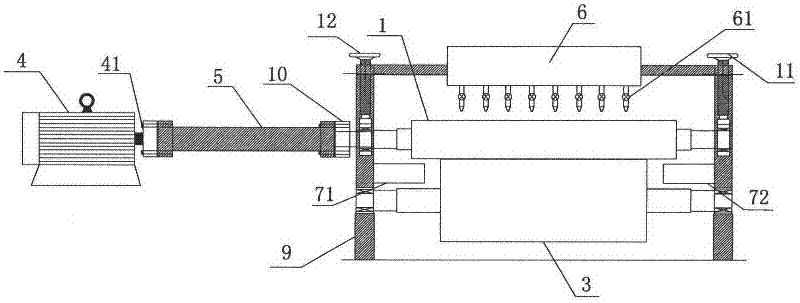

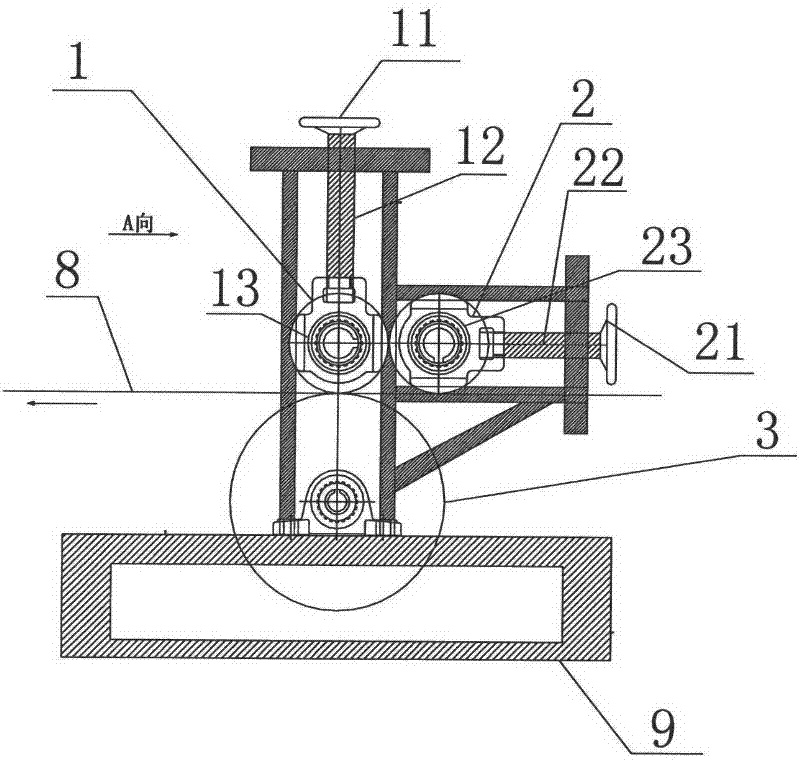

[0031] See figure 1 versus figure 2 , Steel belt rolling oiling device, including polyurethane oiling roller 1, chrome-plated pressing roller 2 beside the polyurethane oiling roller 1, and rubber guide roller 3 under the polyurethane oiling roller 1, which is the same as polyurethane oiling roller 1. The connected hand wheel 11 and the hand wheel 21 connected to the chrome-plated pressure roller 2, the universal shaft 5 connected to the polyurethane oiling roller 1 through the coupling 10, and the universal shaft 5 connected to the universal shaft 5 through the coupling 41 Inverter motor 4, oil drain box 6 located directly above polyurethane oil application roller 1, oil return box 71 and oil return box 72 located below polyurethane oil application roller 1 and on both sides of rubber guide roller 3. The above components are installed together On the base 9.

[0032] The hand wheel 11 is connected to the screw 12, the screw 12 is connected to the polyurethane oiling roller 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com