TCN railway engine network control experiment platform

A technology of network control and test platform, applied in bus network, data exchange network, data exchange through path configuration, etc., can solve the problems of not forming TCN network control test platform in locomotive industry, and relying on import of key equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

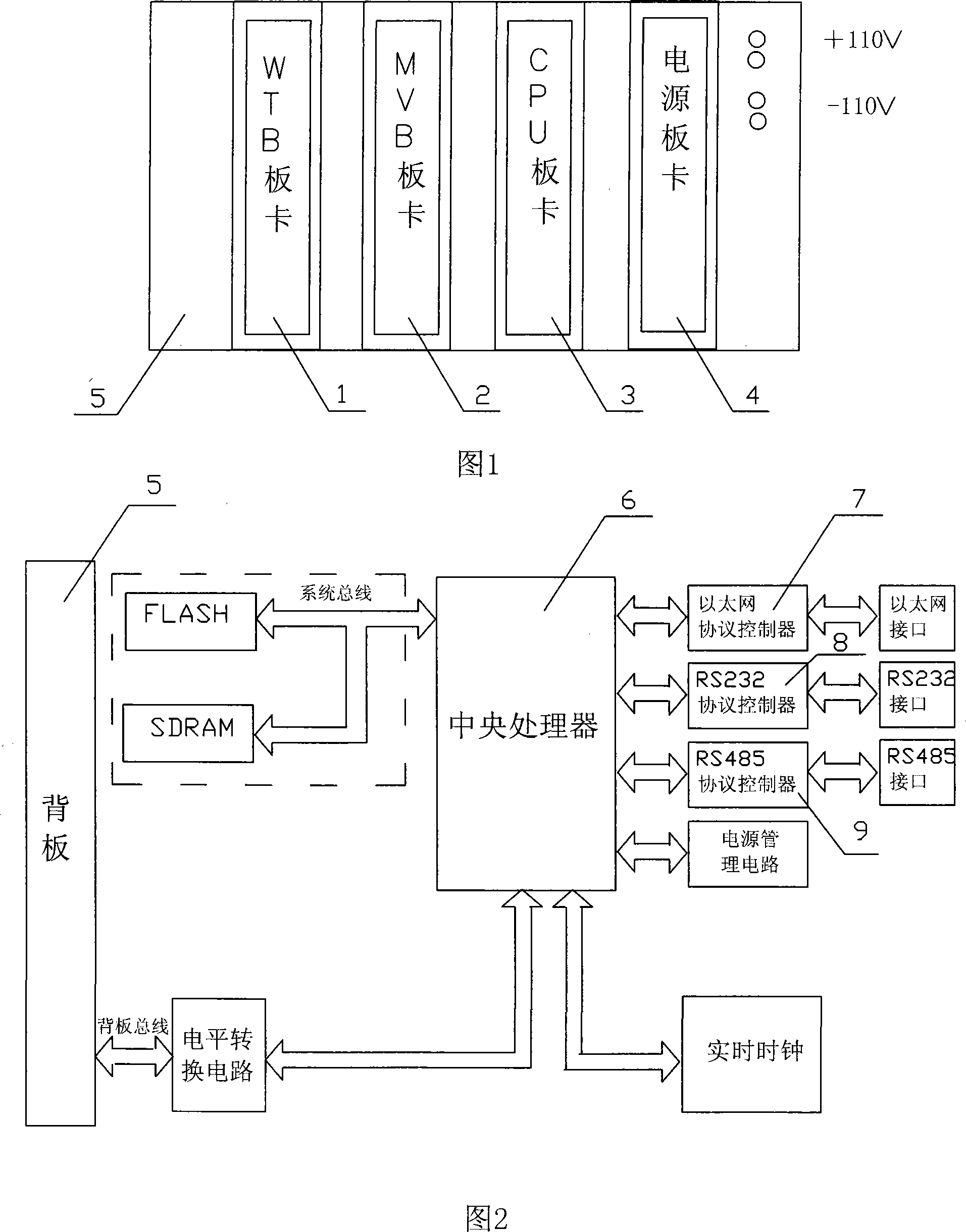

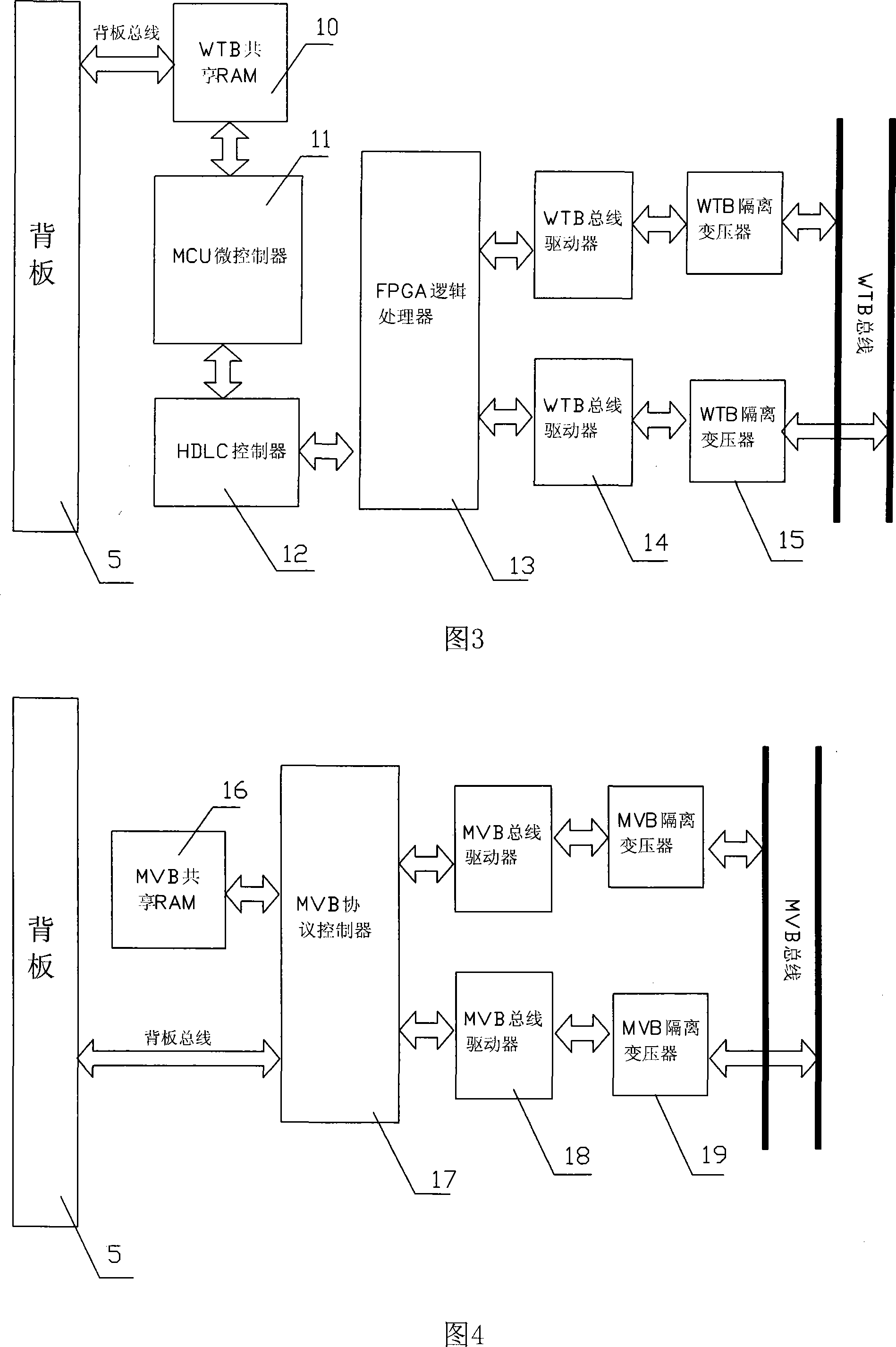

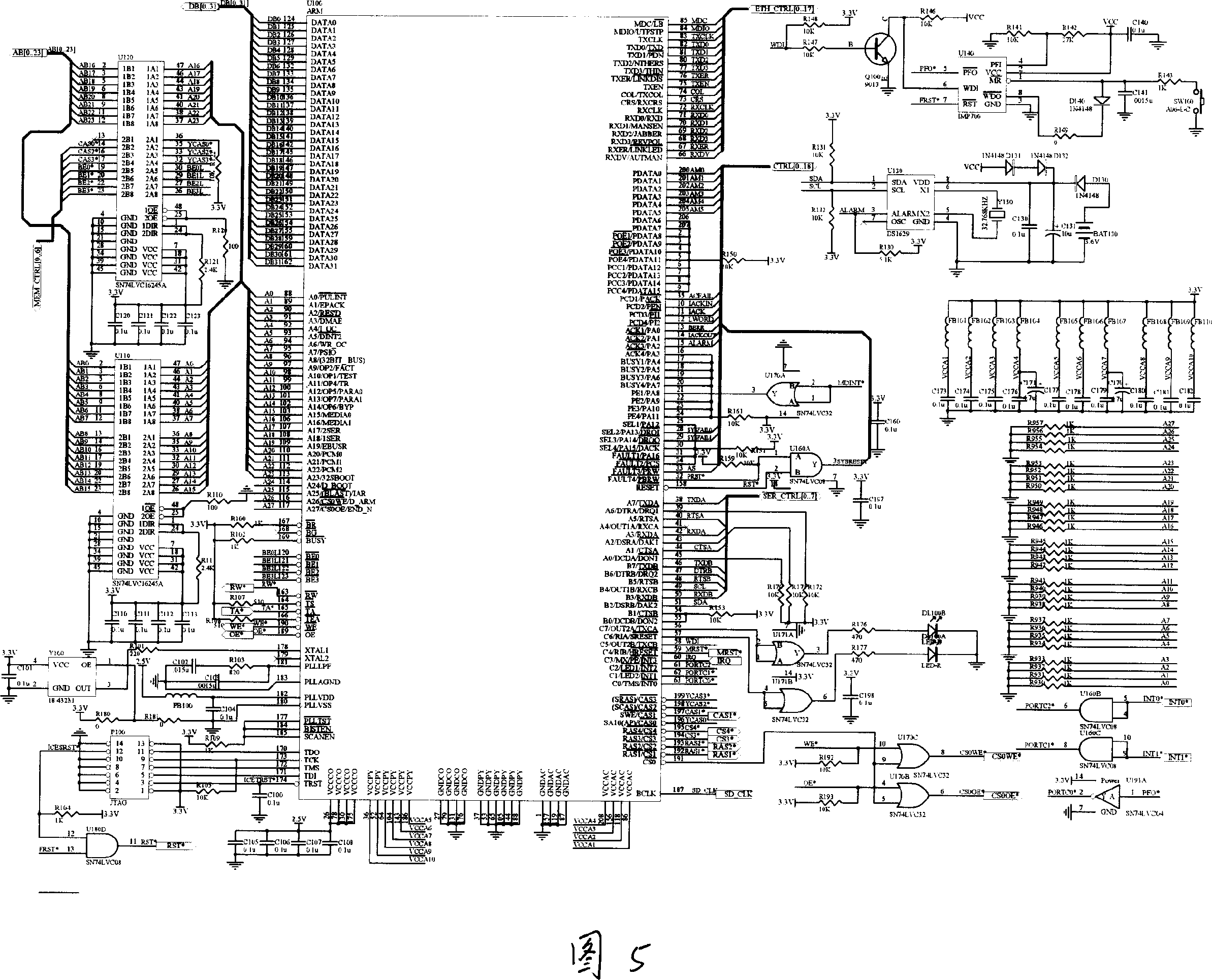

[0032] As shown in Figures 1 to 9, a TCN-based locomotive network control test platform is characterized in that it includes a WTB bus board 1, an MVB bus board 2, a CPU board 3, a power supply board 4 and a backplane 5. Described WTB bus plate card 1, MVB bus plate card 2 and CPU plate card 3 are connected by the backplane bus on the backplane 5; Described power supply plate card 4 is installed on the backplane 5 to WTB bus plate card 1, The MVB bus board 2 and the CPU board 3 carry out unified power supply; the described WTB bus board 1 is responsible for collecting and controlling the data flow of devices on the WTB bus; the described MVB bus board 2 is responsible for collecting and controlling the devices on the MVB bus The data stream; the CPU board 1 is responsible for the central processing of WTB bus and MVB bus device data and generating ETHERNET, RS232 and RS485 monitoring data streams.

[0033] WTB bus board 1 includes WTB shared RAM 10 , MCU microcontroller 11 , H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com